Abstract

Large plastic deformation through cold-rolling refines microstructure through the accumulation of plastic strains over multiple stages. Machining achieves similar large plastic strains (1–10) in a single stage to produce ultra-fine-grained chips. Effect of cold-rolling and machining on microstructure and mechanical properties of Al6061 was investigated. As-received, solution heat-treated, and peak-aged plates were cold-rolled to 30, 50, and 70% thickness reductions. Ultra-fine-grained chips were produced from low-speed orthogonal-machining under plane-strain condition, using a restricted contact tool to minimize the chip curvature. Grains were equiaxed in as-received, solution heat-treated, and peak-aged bulk samples, while they were elongated in cold-rolled bulk. In chips, grains were elongated in one direction due to severe plastic flow. Hardness and ultimate tensile strength increased with thickness reduction. Chip hardness is 60% more than as-received material due to microstructure refinement. Metal cutting (single-stage process) and thickness reduction greater than 50% by cold-rolling (multi-stage) provide nearly the same enhancement in mechanical properties (40% more than bulk).

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Lightweight, heat treatable alloy Al6061 is widely used in many sectors like submarine, automotive , aerospace, etc., due to its favorable mechanical properties . These mechanical properties can be enhanced by processes like heat-treatment [1], severe plastic deformation , e.g. machining [2,3,4,5,6], rolling [1], which change the microstructure of alloy . The heat-treatment process like solution heat-treatment and artificial peak-ageing can be used to dissolve precipitates and increase uniform distribution of finer precipitates, respectively, to achieve required mechanical properties without changing shape and size of the workpiece with less effort [7]. However, the enhancement in mechanical properties by heat-treatment is limited to some upper limit. Mechanical properties can be further enhanced by flow-based deformation processes like cold-rolling (multi-step process) and machining (single-step process) by altering the grain size of materials. Severe plastic deformation (SPD) processes like machining (metal cutting) impose shear-strains ranging between 1 and 10 in a single-pass [2] and thereby refine the grains size. Orthogonal machining , a two-dimensional SPD process, simplifies metal cutting further by using plane-strain conditions by keeping the depth of cut to within and inclusive of 1/10th of workpiece thickness [8]. Chips produced from orthogonal machining can be minimised in their curvature by using restricted contact length tools [4] which result in nearly straight chips.

In the present effort, mechanical properties of as-received, solution heat-treated, and artificially peak-aged samples were studied after subjecting them to: (1) cold-rolling to 30, 50, and 70% thickness reduction, (2) plane-strain orthogonal machining , and (3) cold-rolling followed by plane-strain orthogonal machining . Further, uniaxial tension tests were performed on all the un-rolled and cold-rolled bulk samples.

Experimental Details

Heat-Treatment

In present effort, chemical composition of as-received Al6061 alloy is (wt%): 0.71 Si, 0.25 Fe, 0.55 Cu, 0.13 Mn, 1.27 Mg, 0.05 Cr, 0.13 Zn, 0.05 Ti, 0.02% other, and 96.8% Al. Solution heat-treatment was performed at 530 °C for dwell time of one hour followed by water quenching without significant delay. Solution heat-treated samples were artificially peak-aged at 185 °C for dwell time of 5 h followed by air cooling. The metallographic study was subsequently performed and compared with as-received sample.

Cold-Rolling

Cold-rolling , a plastic deformation process was performed to refine grains in the bulk plate by reducing thickness at 0.1 mm per pass till the required thickness was achieved. As-received, solution heat-treated, and artificially peak-aged samples were cold-rolled to 30, 50, and 70% thickness reductions to achieve the final thickness of 3 mm. Hardness , microstructure , and strength study were subsequently done on the samples.

Orthogonal Machining

The two- dimensional SPD process of orthogonal machining was performed in a single step on normal direction-rolling direction (ND-RD) plane at low speed to avoid heating and resulting thermal effects on chips by using restricted contact length tool. All un-rolled and cold-rolled samples were machined by using HAAS. CNC milling machine (5.6 kW) to achieve enhance mechanical properties by the refinement of the grains.

Uniaxial Tension Test

Dog-bone shaped samples were prepared from un-rolled and cold-rolled bulk for testing under uniaxial tension. Tension test was performed at displacement rate of 0.5 mm per minute by using Zwick/Roell Z0.5 universal testing machine (UTM), while two-dimensional digital image correlation (DIC) technique was used to measure full-field displacements/strains.

Results and Discussion

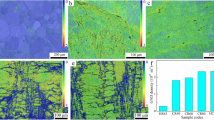

The hardness of as-received samples was decreased by 15% and increased by 65% after solution heat-treatment and peak-ageing, respectively. Hardness increased significantly with increasing thickness reduction for all bulk samples and achieved maximum corresponding to 70% thickness reduction. The hardness of as-received, solution heat-treated, and peak-aged bulk sample after 70% thickness reduction by cold-rolling was increased by 58%, 68%, and 18%, respectively. Study of optical images of cold-rolled samples shows elongated grains in the rolling direction (RD). The hardness of chips produced by plane-strain orthogonal machining from all the un-rolled and cold-rolled bulk samples was significantly higher than the corresponding parent-sample. Chips from as-received bulk show 60% increment in hardness when cut through orthogonal machining and that increment is nearly the same as that resulting from 70% thickness reduction.

Uniaxial tension test results of un-rolled and cold-rolled bulk samples show significantly higher ultimate tensile strength (UTS) and low ductility for cold-rolled samples compared to un-rolled bulk samples. Ultimate tensile strength of solution heat-treated un-rolled bulk sample increased by 50% through thickness reduction of 70% with a accompanying reduction in ductility of 80%.

Conclusions

Effects of heat-treatment , cold-rolling , and machining were studied on the mechanical properties of Al6061 alloy . It was observed that the solution heat-treatment of as-received sample decreased the hardness and strength but increased ductility drastically in contrast to peak-ageing. Higher thickness reduction by cold-rolling and machining give nearly the same hardness enhancement. Cold-rolling of bulk samples result in higher strength but at the cost of ductility. Orthogonal machining of samples results in drastically increased hardness that is achieved in a single-step by producing fine-grained chips.

References

Mishra VD, Rao BC, Murthy H (2018) Enhancement of mechanical properties by cold-rolling of Al6061. Mater Today Proc 5:8263–8270. https://doi.org/10.1016/j.matpr.2017.11.517

Swaminathan S, Shankar MR, Lee S, Hwang J, King AH, Kezara RF, Rao BC, Brown TL, Chandrasekar S, Compton WD, Trumble KP (2005) Large strain deformation and ultrafine grained materials by machining. Mater Sci Eng A 410–411:358–363. https://doi.org/10.1016/j.msea.2005.08.139

Shankar MR, Chandrasekar S, Compton WD, King AH (2005) Characteristics of aluminum 6061-T6 deformed to large plastic strains by machining. Mater Sci Eng A 410–411:364–368. https://doi.org/10.1016/j.msea.2005.08.137

Ghangrekar PS, Banjare R, Rao BC, Murthy H (2014) Tensile testing of Al6061-T6 microspecimens with ultrafine grained structure derived from machining-based SPD process. J Mater Res 29(11):1278–1287. https://doi.org/10.1557/jmr.2014.115

Bai X, Kustas A, Chandrasekar S, Trumble K (2016) Large strain extrusion machining on 6013 aluminum alloy: TMS/light. https://doi.org/10.1002/9781119274780.ch38

Palaniappan K, Murthy H, Rao BC (2017) Production of fine-grained foils by large strain extrusion-machining of textured Ti–6Al–4V. J Mater Res 33:108–120. https://doi.org/10.1557/jmr.2017.445

ASM International (1992) ASM handbook, vol 4. Heat treating. ASM International

Shaw MC (2004) Metal cutting principles. ISBN-13: 978-0195142068

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Mishra, V.D., Palaniappan, K., Rao, B.C., Murthy, H. (2020). Effect of Severe Plastic Deformation on the Mechanical Properties of Al6061 Alloy. In: TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-36296-6_194

Download citation

DOI: https://doi.org/10.1007/978-3-030-36296-6_194

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-36295-9

Online ISBN: 978-3-030-36296-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)