Abstract

The relevance of nanotechnology in the field of energy resources has been growing at a swift pace. The term ‘catalyst’ has a whole new outlook since the foundation of nanomaterials in process industries. Nanocatalysts, in general, play a vital role in the improvement of resource handling and process efficiency. New prospects to achieve sustainable processing have been made possible through the progress in nanotechnology. These developments of nanomaterials in the energy sector have also reached the parts of the oil and gas industry. In downstream processing of oil and gases, the use of nanocatalysts is commonplace. As the focus towards the production of heavy crude oil has seen an uprising, the use of nanomaterials has shown a promising scope in altering heavy oil properties to favour the oil recovery mechanisms. The majority of the reservoirs around the world have volumes of heavy crude oil with only a few effective ways to produce it. With the ever-growing energy demands it is of due importance that the focus has been shifted to implement nanotechnology in heavy oil production. This chapter discusses the role of nanomaterials in the development of heavy oil recovery. Different types of mechanisms that explain the effects of nanoparticles and their interaction with oil and its constituents are highlighted. The effects coupled with the use of various thermal treatment schemes have been explained. The scope of applicability in the field of flow assurance has been discussed. The use of nanoparticles in improving the existing EOR applications and devising new ways to achieve the production of heavy fractions.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Through the advent of nanotechnology at the turn of the century, nanomaterials have invariably become a part of our growing technology. Nanomaterials, especially due to their sizes are preferable over conventional materials for identical applications. The scope for development and the range of wide applicability makes nanotechnology suitable for a vast expanse of operations. Their use as catalysts has been duly appreciated in many areas of expertise. Industrial applications have also recognized the benefits of nanomaterials and have employed them for different purposes. Nanomaterials, for most of their part, have found generous use in the field of energy production. Worldwide energy generation processes (conventional and unconventional) use nanomaterials in some way or the other. This involvement of nanomaterials in the energy sector has been termed as nano-energy which is regarding the role of nanomaterials in harnessing energy from resources (Menéndez-Manjón et al. 2011).

When contemplating energy production it gives us a perspective of how abundantly we are dependent on non-renewable sources of energy. An ample amount of energy around the world is generated through the use of fossil fuels. The needs of power generation and fuel for transportation are only fulfilled through petroleum derivatives which makes the majority of the energy sector dedicated to the oil and gas industry. As such, the scene of economical energy has seen a shift due to the depletion of the worldwide oil and gas reserves. The existence and use of other renewable sources such as hydropower and solar energy to meet the global energy requirements will take a considerable amount of time due to limited accessibility. These situations have put the global energy scenario in a perilous situation. The majority of the oil reservoirs are facing depletion of light crude oil. Crude oil sitting at the bottom of the reservoirs is either void of the driving force or is relatively heavy. Also, the depletion of conventional oil and gas reservoirs has drawn the attention to produce heavy and extra-heavy oil from the unconventional reservoirs. The inherent properties such as viscosity and density of heavy oils make it difficult to extract them for further operations. Several enhanced oil recovery (EOR) processes have been employed to produce the oil deep down in the reservoirs. The emergence of nanotechnology has attracted the necessity to use nanomaterials in the production of heavy crude oil.

Nanomaterials are a broad classification of constituents whose range lies across the nanoscale (1–100 nm). These materials have numerous properties that are favourable for different kinds of applications. Nanomaterials can be used to enhance the attributes of other materials or to imbue them with new ones. Their main merit lies in the fact that the nature of their particle sizes makes them more efficient and effective in facilitating processes that would otherwise need a conventional material of larger dimensions. This chapter gives an overview of the properties of nanomaterials and their applications in the field of heavy oil recovery.

1.1 Need of Nanotechnology

Nanotechnology, in its entirety, focuses on using a minimal amount of resources to process large-scale operations. The reduction of the size of the particles itself is a profound way to utilize any material efficiently. The use of a few micrograms can do the same work that a few grams could do. This is a way to employ the conservation of resources sustainably. Everyday industrial processes generate a lot of unused substances. Nanomaterials, due to their dimensional advantages, minimize their specific amount required for any application which adds an edge to the whole operation regarding resource handling and usage. These properties make the use of nanoparticles an efficient way to achieve a stable groundwork between sustainability and effectiveness.

Nanotechnology and its facets have also shown potential in improving the effluent suppression and gas capture processes. Successful mitigation of greenhouse gases has been achieved in small scale processes involving nanomaterials. Materials such as nanoclay have been identified as a well-known and cheap alternative for CO2 capture and have been an interesting area of research (Roth et al. 2013). In oil recovery, techniques such as CO2 flooding using CO2 foam have also been observed to provide better results with the addition of nanoparticles and improved sequestration of CO2 (Aminzadeh-Goharrizi et al. 2012). Numerous applications can be found where nanomaterials are proven to be better alternatives in tackling these problems. A wide array of properties makes them versatile for some processes requiring high efficacy in energy production. This potential of nanomaterials makes them an attractive candidate in assisting environmental issues with smart solutions.

2 Properties of Heavy and Extra-Heavy Oils

Crude oil is a naturally occurring mixture of different fractions of carbon compounds. These fractions can be classified into groups of Saturates, Aromatics, Resins, and Asphaltenes (SARA) (Fig. 1). These together make the structure of oil and give it its various properties. The viscosity of oil is a vital property that affects its mobility in reservoirs. In the case of heavy and extra-heavy oils, viscosities up to 10,000 cp and higher have been observed. Tar sands being practically solid in nature pose extreme difficulty in extraction. The heavy oil which sits at the bottom of the reservoir creates a challenge as it is very difficult to displace. Owing to the depletion of lighter fractions, the processing of these heavier fractions has become important to sustain the fuel requirements. But what makes this a difficult task is the fact that the heavy and extra-heavy oils are unsusceptible to primary and secondary recovery treatments. Oils are characterized by their API (American Petroleum Institute) gravity. API gravity gives a comparison with respect to water of how heavy or light the oil is. Medium and heavy oils usually range from 25 to 15° API in comparison with light crudes which go above 30° API. Any hydrocarbon which goes below 15° API is considered extra-heavy.

Heavy oils are usually categorized by their inability to flow, highly viscous nature and difficulties posed by being inoperable by conventional techniques. The viscous nature of heavy oil is attributed to the presence of asphaltenes and resins which have a complex molecular structure with high molecular weight. This high viscous nature makes it difficult for further processing of light fractions. It mainly gets utilized in the production of asphalt, and upgrading processes like delayed coking and hydro-cracking. Asphaltene structures are high molecular weight polyaromatic chains containing heteroatoms (compounds containing nitrogen, oxygen, sulphur). They are present in the bulk oil as a suspension which influences the behaviour of the oil. Their deposition in the pipelines is a nuisance to flow assurance operations and require cumbersome treatments. Heavy crude oil treatment is basically how the heavy oil can be made accessible for further handling. The use of thermal treatments to mobilize heavy oil is an old practice. Understanding the interaction between heat and oil forms the basis of upgrading processes.

2.1 Heavy Oil Upgrading and Rheology

Upgrading of heavy oil in basic terms implies reducing the viscosity of heavy oil so it can be processed by downstream operations. Heavy and extra-heavy oils have viscosity several times higher than that of a conventional light crude oil. The reduction of the viscosity of such oils must be carried out through temperature intensive processes. The upgrading process to recover heavy oil from the reservoirs are as follows:

-

1.

Cyclic Steam Stimulation/Steamflooding.

-

2.

Fire flooding/In situ combustion.

-

3.

Steam-assisted gravity drainage (SAGD).

-

4.

Cold heavy oil production by sand (CHOPS).

The methods mentioned above are used, some more than others, and are important for the recovery of heavy and extra-heavy oils. Figure 2 gives the general operation of the steam flooding process. Inside the reservoir, the steam creates a heat front. This heat front comes in contact with the heavy oil, reduces its viscosity and pushes it towards the production well.

Steam-assisted gravity drainage is a relatively new technique that considerably increases recovery through effective steam usage. Two holes, one beneath the other are dug into the reservoir. The hole at the top injects steam into the reservoir. The heat from steam creates a chamber and reduces the viscosity of the oil, and it flows below under the influence of gravity. The bottom hole is then used for the production of oil. Figure 3 gives a representation of the process schematic of SAGD.

Cold heavy oil production with sand (CHOPS) is a non-thermal process that involves the production of sand. During completion stages, sand is calculatingly produced to improve the bottom oil recovery. Though this method allows the production of oil, it is mechanically exhaustive. CHOPS method has been only used in limited fields (namely Canada), thus it is crucial to have a well founded degree of understanding of the flow behaviour of oils. The flow behaviours are dependent on various factors that influence the rheological properties of heavy oils.

Understanding the rheology of heavy oils is of essential interest. The flow of oils in the reservoir is subject to the nature of the oil and its mobility in the reservoir. In comparison with lighter fractions, heavy oil proves to be a big inconvenience because of its characteristic flow properties. Better knowledge about the flow behaviours of these oils is important to figure out the appropriate method to extract them from the reservoirs. Heavy oil at ambient temperatures behaves as an extremely viscous fluid and, in some cases as a semi-solid. At higher temperatures, however, the oil matrix starts to break down and exhibits a Newtonian behaviour (smooth flow). The flow of these oils, at ambient temperatures is that of a Bingham plastic fluid which indicates that the semi-solid structure needs high shear to be broken down which can initiate flow in these oils (Ghaffari et al. 2017). Figure 4 shows the contrasting viscosities of heavy oil and light oils (obtained from various fields in Mexico) at different temperatures (Ramírez-González 2016).

Reprinted with permission from Ramírez-González (2016). Copyright (2016) American Chemical Society

Viscosity versus temperature of crude oils of various API gravities.

It is evident that the properties of heavy crudes differ by a large margin when compared with light crudes. This disparity between the two comes from the fact that the polar components dominate the oil matrix in heavy oils. The high molecular weight structure of asphaltenes and resins associate themselves with the oil which causes them to become viscous and dense in nature. In many instances at cracking temperatures, even heavy oils with lower asphaltene content can display asphaltene deposition whereas high asphaltene content oils exhibit a lower amount of deposition. This might happen due to the temperature affecting the asphaltene structure to a certain extent which allows deposition. Since these heavy oils are complex fluids, an accurate estimate of their behaviour is of questionable nature. These oils exhibit viscoelastic behaviour which is very deterministic of how they behave at high temperatures. Their viscoelastic behaviour can be quantified by observing how they work under a particular frequency of shear. These properties are characterized by loss and storage modulus (Gʺ and Gʹ). These are of importance as they define the characteristics of the viscoelastic material which surfaces during deformations by shear. A more dominant loss modulus (Gʺ) indicates a viscous flow indicating a liquid property of the fluid, whereas a prominent storage modulus (Gʹ) is indicative of elastic nature which implies a solid property behaviour.

Figure 5 shows the dependency of loss (Gʺ) and storage (Gʹ) modulus on the frequency of deformation for oils of different API gravity (ranging from light to heavy) obtained from different oilfields in Russia (Ilyin and Strelets 2018). It is evident that oils of different API gravities behave differently in the presence of different degrees of deformation (Fig. 5). Oil 1 with the lowest API gravity exhibits a narrow band between the loss and storage modulus. This indicates that heavy oils usually have a dominant solid behaviour at ambient temperatures hence the difficulty in mobilizing them. The deformation rates generate small cracks in the semi-solid structure of heavy oil. The oil matrix resists the changes in these deformations by rebounding back to the original structure, which brings forth the elastic nature. This corresponds to the solid behaviour of heavy oil. As the frequency and amplitude of shear changes, these small cracks can propagate into larger ones and initiate the flow of oil which points to the viscous behaviour of oil. These properties are of importance in understanding how the flow of these oils work and what can be done to improve it. This is relevant from transportation to processing of these oils. Their interaction with various chemicals and thermal treatments becomes the basis for understanding the recovery of these oils.

Reprinted with permission from Ilyin and Strelets (2018). Copyright (2018), with permission from American Chemical Society

Dependence of loss (open symbol) and storage (filled symbol) modulus (Gʺ and Gʹ) with respect to deformation frequency of various oils (ranging from 14 to 28° API).

The processes to recover heavy oils are, however, sometimes too energy exhaustive and complex. Heavy oil recovery takes twice if not more time than the extraction of light crudes, which puts in perspective the difficulty of the entire process. The real challenge lies in the optimization of recovery processes. Since most of these methods utilise steam, the steam-to-oil ratio (SOR) determines the economic value of the said process. The SOR ratio shift can cause capital costs and requirements of the process to increase drastically making the process less feasible. Another aspect of using steam apart from providing heat to reduce viscosity is, it brings chemical changes in oil composition. Steam causes bond breakage and hydrolysis in oil structure (Clark and Hyne 1984). Usually, the first bond to break is sulphur–carbon as its dissociation energy is the lowest. The breaking of the sulphur bond helps in achieving low viscosity. This process is termed as aquathermolysis. Aquathermolysis is one of the main mechanisms in the upgrading of heavy oil. Methods to catalyze the aquathermolysis reactions draw attention towards nanoparticles and their abilities as catalysts.

3 Nanomaterials and Their Properties

Nanomaterials are classified as structures at the nanoscale level. They come in various shapes with different arrangements and properties. At such a small scale, their properties become rather profound. Small structural changes drastically affect the nature of the particles. The arrangement of the structures can be of various forms such as nanotubes, crystals, wires, rods and dendrites. They can also be identified based on their dimensional proportion, 1-dimensional, 2-dimensional, etc. A 1-dimensional particle will only have one of its sides in the nanoscale (i.e. a nanorod would only have its radius in nanoscale, and its length could be greater) as such goes for 2- and 3-dimensional particles (Tiwari et al. 2012). Figure 6 shows various structures (nanorod (Cao et al. 2017), nanotubes (Sandoval et al. 2017), nanosheets (Wang et al. 2017)) of nanomaterials that can be fabricated. Specific shapes provide variable surfaces with different dimensional properties.

These specific characteristics define how the particles would behave in certain conditions and how they interact with their surroundings. Following are a few properties of nanomaterials:

-

1.

Surface Area to Volume Ratio: The particles exhibit a very high surface area for a relatively small volume. This expansive area allows for an increase in surface activity. Since most reactions in chemical processes occur at the surface, this makes the surface activity of nanoparticles more suitable to facilitate reactions. This property has been seen to affect the flow behaviours of crude oil in many cases. The increase in surface action makes them excellent for adsorption mechanisms, by adsorbing materials on the active sites.

-

2.

Selectivity: Nanoparticles show a highly selective nature. Specific types show an affinity towards only certain types of molecules. It has been specified in many cases that the active sites of nanoparticles influence the acidity–basic nature of the reactants and selectivity of the product formation when being considered as catalysts (Muraza and Galadima 2015).

This selective nature allows certain catalyst particles to inhibit by-product formation and allow selective yield of product, which is a requirement for most chemical reactions.

-

3.

Structural Stability: The nanomaterials possess superior structures compared to their conventional counterparts. The hardness of the material can be altered by introducing nanomaterials into a host material which imbues them with a more stable structure. An example would be the alteration of the hardness of magnesium done by adding silicon carbide nanoparticles to form composites with improved structural and mechanical properties (Lan et al. 2004). Graphene-based nanoparticles which are, in comparison, smaller than graphene sheets can be used to form composites to give extra mechanical stability and flexibility to other materials.

-

4.

Optical Properties: The optical properties concerning the emission and scattering of light are important for many photochemical processes. The optical properties of nanoparticles are useful in characterization studies of other substances. An example would be the use of optical properties of gold nanoparticles in the field of medicine for photothermal therapy (Huang and El-Sayed 2010).

-

5.

Magnetism: Nanomaterials exhibit magnetism which can be utilized in a number of ways. These can be used for magnetically induced heating in nanofluid applications.

One of the fascinating aspects of nanoparticles and their properties is that they can be crafted to suit particular requirements. There are several methods to attain desirable properties (high surface area, selectivity) and shapes (clusters, nanowires, etc.) in these materials. There are namely two broad classifications of processes involved in nanoparticle production, top-down process and bottom-up process.

The top-down process can be visualized as breaking down of a particular material until nanoscale is reached. Top-down processes usually involve more mechanical input for achieving a reduction in size. Some examples are high energy milling, laser ablation process, nano-lithography, etc.

The bottom-up methodology is the technique which proceeds from individual molecules and atoms to nanoparticle formation. They are widely used because they give high-purity particles and are more preferred for the structural stability of nanoparticles. These processes also allow more control over the size distribution and structure manipulation. Some examples would include the sol-gel process, epitaxial growth processes (atomic, molecular liquid phase), vapor deposition techniques, etc. Figure 7 gives a visual understanding of the processes involved in the fabrication of nanomaterials from the two methods.

4 Role of Nanomaterials in Heavy Oil Recovery and its Operations

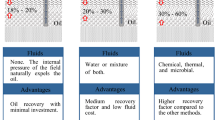

In oilfields, after the primary and secondary oil recovery is done, the reservoir is subjected to external stimulation to retrieve the oil which cannot be produced due to the absence of a driving mechanism. The methods applied at this stage are termed as Enhanced Oil Recovery. These methods can also be applied at the primary stage is the oil is not mobile, as in the case of heavy oil. Processes such as gas injection, polymer injection, steam flood, steam injection, etc., provides the heat to reduce viscosity and also driving force to mobilize the oil at the bottom of the reservoir to increase the production. This is achieved by injecting an external agent (liquids or gases) into the reservoir to push the oil towards the production wells. There are several strategies and methods to execute enhanced oil recovery techniques (thermal, chemical and microbial EOR). Heavy oils being extremely dense and viscous are indispensably subjected to heat treatment to unlock their movement. The interaction between oil and nanomaterials has been an area of interest and its use in oil recovery has seen quite a development. Especially, the treatment of heavy oil and heavy fractions has seen substantial growth in terms of nanotechnology applications.

4.1 Interaction with Nanoparticles and its Effects on Heavy Oil Properties

Involving nanotechnology in the field of heavy oil recovery is a way of exploring efficient ways to implement the same process but with improved results. A clear understanding of how these particles interact with the oil in reservoir conditions is an area of extensive research. Their effects on parameters such as rheology of heavy oil, compositional changes, etc., have been closely studied to obtain insight on how to improve the processing of these oils. Metal and metal oxide particles have shown considerable improvement in altering heavy oil properties. Heavy oil is a complex mixture with a myriad of properties that influence each and every aspect of its flow behavior. Heavy oils are laden with asphaltenes in the bulk which imparts them with their semi-solid structure. Breaking or more technically called ‘cracking’ of the asphaltene structure is the first step in making the oil more accessible to further treatment. Cracking also distributes the long-chain asphaltene into lighter fractions which increases the value of the oil.

4.1.1 Metallic Nanoparticles

Nanoparticles show intriguing behaviour when they are used for thermal treatments of these heavy oils. Their effects in catalyzing the breaking of bonds in heavy oil were first observed by Clark and Hyne in 1984. Further developments in identifying the catalyzing properties of metals were found in the subsequent years. Their effects on heavy oils were observed by Shokrlu and Babadagli (2014) in a series of aquathermolysis reactions. Asphaltenes were found forming clusters on the surface of nanoparticles (Cu, Fe and Ni) of different diameters. This effect has been supported by many literature stating that the surface properties play a key role in causing clustering. Figure 8 shows the microscopic image of the clustering of asphaltenes observed after aquathermolysis of heavy oil (14.7° API) in the presence of nanoparticles.

Reprinted with permission. Shokrlu and Babadagli (2014). Copyright (2014) From Elsevier

Asphaltenes (black patch) forming clusters in the presence of nickel nanoparticles in heavy oil, observed after aquathermolysis (240 °C for 6 days) under a microscope.

Asphaltene particles when present in the bulk oil show a charge distribution across the bulk. Along with resins, they are polar in nature. They exhibit positive charge in most cases but there have been instances in which they exhibit a negative charge across a mixture (Azari et al. 2018). The nature of the asphaltene chains and the presence of heteroatoms influence the charge distribution. Surface charges possessed by nanoparticles influence the adsorption of asphaltenes (Patel et al. 2018). The charge difference in the nanoparticles and asphaltenes causes the adsorption. When asphaltenes come in contact with nanoparticle surfaces, the aggregation process occurs. This aggregation lowers the charge on asphaltene aggregates thereby making them stable (Azari et al. 2018) and less prone to attach back to the bulk of the oil.

Figure 9 illustrates the surface activity and charge of nanoparticles attracting the asphaltenes. Metallic nanoparticles are also excellent heat conductors (Eastman et al. 2001) which when added to heavy oil can increase the heat flow in the oil, effectively reducing the viscosity. Heat conduction due to dispersed nanoparticles can facilitate faster reactions aiding in the reduction of viscosity and catalyzing the aquathermolysis process. Dispersed nanoparticles can be used as nanofluids with high thermal conductivity. The agglomeration removes the asphaltenes from the bulk of the oil which makes the oil less viscous. The cohesive forces between the asphaltene molecules progress the agglomeration. This effect has been observed even in heavier fractions such as bitumen and residual oils. Another approach by means of hydrogen donors has been looked into to upgrade these residual and heavy oils (Del Bianco et al. 1995). Upgrading by using hydrogen donors is an efficient way to improve the Hydrogen/Carbon (H/C) ratio (Hendraningrat et al. 2014; Wang et al. 2012). Hydrogen donors are additional agents which provide hydrogen to improve hydrogen ratio. Hydrogen donors can be solvents, hydrogen gas or hydrogen-producing bacteria which can involve hydrogen into a system. Solvents can be utilized as an effective means of providing hydrogen in heavy oil systems. Nanoparticles can make stable emulsions with solvent mixtures to provide better action with heavy oil (Kumar et al. 2018). Figure 10 shows the viscosity reduction of heavy crude oil (Venezuela fields) in the presence of carbon support nickel nanoparticles (Guo et al. 2017). They have utilized a highly conductive form of carbon black (Ketjenblack) as a support to boost the performance of nickel particles.

Reprinted with permission (Guo et al. 2017). Copyright (2017)

Effects of nickel nanoparticles with ketjenblack carbon support in reducing viscosity of heavy crude oil.

It is apparent from Fig. 10 that the viscosity reduction in the presence of hydrogen gas has the highest impact. Nickel particles having carbon nanostructures as support in the presence of hydrogen gas reduce oil viscosity by a greater margin.

Heavy and extra-heavy oils usually have a poor H/C ratio which makes them more likely to form coke at high temperatures. Coke formation takes place due to the reason that heavy oil undergoes a disproportionation reaction and produces an unusual amount of carbon with little or no hydrogen. When the cleavage of the C–S bond takes place during aquathermolysis, the removal of sulphur makes the molecules undergo polymerization to form a higher molecular weight structure to stabilize. By providing hydrogen, further polymerization remains in control and the formation of intermediate structures becomes stabilized. Desulphurization process is of importance because apart from the reduction of viscosity it reduces the sulphur content thereby upgrading the oil (Guo et al. 2018). Thiophene is an active compound found in the asphaltene structures and requires desulphurization to upgrade the oil. Figure 11 shows the thiophene (heterocyclic aromatic) catalytic conversion under the influence of cobalt and nickel nanoparticle of different sizes. The desulphurization was more successful with nickel nanoparticles of smaller size. Nickel usually exhibits a better catalytic activity due to being more electronegative in nature. The ability of transition metal compounds to alter their oxidation states is of importance in relevance with their catalytic activity. The common trend in the activity of transition elements is a direct correlation to the element’s electronegativity playing a dominant part in their roles as catalysts. As they can donate and accept electrons readily, they serve as excellent catalysts for reactions. The surface and electrostatic properties of nanoparticles are the main contributors to viscosity alteration mechanisms.

Reprinted with permission (Guo et al. 2018). Copyright (2018)

Temperature versus thiophene conversion under the influence of nanoparticles (Co, Ni) of different sizes.

It is apparent from Fig. 11 that the size and concentration of nanoparticles are a deciding factor in C–S bond breakage and the reduction of viscosity. Increase in the size of nanoparticles directly result in an increase of the particle volume. Since the reactions occur on the surface and not inside the bulk, the increased volume causes hindrance and the effectivity is decreased. When the concentration of nanoparticles in a fluid increases, the individual activity of attraction of particles comes into play (Rudyak 2013). The attraction between the particles can be attributed to van der Waals force of attraction. As the concentration of particles increases, the attraction between the nanoparticles become more prominent than the interaction of the particles and oil. As the oil viscosity reduces the entire oil molecule structure starts to slacken up. This causes the movement of nanoparticles to become more erratic and prone to collisions. There is a destabilization due to an increase in surface energy. At higher temperatures, the reduction of oil viscosity can cause metallic nanoparticles to coalesce together to form small aggregates (Hashemi et al. 2012). These aggregates can inversely affect the viscosity of oils by causing a surge in the viscosity of the oil.

Nonetheless, metallic particles can effectively catalyze aquathermolysis to cause a reduction in viscosity of oils. As the oil comes in contact with high-temperature steam, viscosity reduction of oil occurs. This action can be coupled with the viscosity reducing property of metallic nanoparticles in different injection schemes to further improve the process. These particles can be used in reservoirs at the end stages of the steam stimulation process to initiate more recovery of oil (Farooqui et al. 2015). As recovery decreases at the end stages, nanoparticles can be used as a final drive to recover the oil.

4.1.2 Metal Oxides

Other than metal particles, metal oxides are also effective in changing the property of heavy oils. Metal oxides nanoparticles are capable of causing asphaltene deposition on their surfaces. Metal oxides are rather easy to produce and can have better catalytic life. Their catalyst potency lies in their charge distribution. Asphaltene deposition by the use of metallic oxides has been observed in many cases. Table 1 provides an overview of the various nanoparticles used in the studies.

It is evident that transition metals and metal oxides are excellent in improving the adsorption of asphaltene, reducing coke formation and increasing the catalytic efficiency of cracking reaction. Apart from being able to suppress asphaltene precipitation, metal and metal oxide nanoparticles are effectively able to break sulphur linkages. As discussed earlier, the dissociation energy of sulphur–carbon bond is low and hence breaking of the bond can be achieved more rapidly by the addition of nanoparticle catalysts. Metal oxides, due to their ability to change their oxidation states more easily are an interesting candidate for asphaltene adsorption and cracking. Figure 12 shows the conversion of asphaltene during steam cracking reactions and how the presence of different nanoparticles effects the cracking temperatures (Nassar et al. 2011). The asphaltene was extracted from Athabasca bitumen and was subjected to adsorption and subsequent cracking process with nanoparticles.

Reprinted with permission (Nassar et al. 2011). Copyright (2011)

Catalytic conversion of asphaltenes during steam cracking process under the influence of different nanoparticle oxides (nickel, cobalt, ferrous) used as catalysts.

It can be seen from Fig. 12 that the highest conversion effects were observed in the presence of Nickel oxide nanoparticles. In case of asphaltenes adsorbed on nanoparticles, the onset of cracking temperature was found to reduce with the highest reduction observed in cobalt and nickel oxide nanoparticles when compared to iron oxide nanoparticles and pure asphaltene. This is indicative of the fact that metal oxides can readily provide a better reduction in activation energy to initiate asphaltene cracking reactions.

4.2 Effects of Dispersion on the Performance of Nanoparticles

The means by which nanoparticles are introduced into heavy oil systems are also important in determining the reduction of viscosity and upgrading of heavy oil. The dispersion of particles in either the oil phase or water phase is crucial when it comes to the interaction of these particles with the oil matrix. As the particles get dispersed, the stability of the system increases which prevents the degradation of the catalytic activity of the particles. The dispersion of the particles can be achieved in both oil and water depending on the hydrophilic/hydrophobic or lipophilic/lipophobic nature of the particles.

Metals and their compounds such as nickel and even the likes of molybdenum can be dispersed using surfactants in water to be utilized for steam cracking processes (Mironenko et al. 2017). Salts and other composites of transition metals also possess the ability to catalyze upgrading operations. An example would be Keggin-structured (heteropoly acid structure) catalysts which can aid viscosity reduction in aquathermolysis reactions (Chen et al. 2009). The main advantages of these acids are that they are re-usable acid catalysts and can increase the catalyst life. Water-solubility of nanoparticles allows a simple dispersion. These particles can be directly utilized in aqueous applications by forming emulsions and stable mixtures for thermal methods. Water dispersed particles, though effective, can cause a hindrance when their effects are mediated in the presence of oils. In this case, oil-soluble catalysts can allow much better dispersion in the oil phase and be more effective that the water-soluble counterparts. Proper dispersion in the oil phase can improve the viscosity altering effects during in situ processes. Oil-soluble nickel and cobalt are ideal at producing catalyzing effects at low concentrations when used with hydrogen donors for aquathermolysis process.

Certain types of catalyst nanoparticles which can be dispersed in both oil and water called dispersed catalyst nanoparticles have shown remarkable performance in recovery operations. These catalysts can be dispersed with the help of surfactants or organic dispersants and have been found to be more effective than the usual oil-soluble and water-soluble catalysts. These catalysts can be in the form of organometals or suspensions of nanoparticles. Dispersed catalysts of nickel nanoparticles have been used for the upgrading of heavy oil (Alkhaldi and Husein 2014; Li et al. 2007). Effective aquathermolysis can be achieved in the presence of dispersed catalysts because they can be dispersed in both oil and water. Since the dispersion in oil and water is high, the contacting between these two can result in a better aquathermolysis process allowing better cracking. Silica nanoparticles are extremely versatile as far as dispersions are concerned. They can be dispersed quite efficiently in both oil and water (Gavrielatos et al. 2017). They have excellent prospective in development for heavy oil upgrading. They are a cheaper alternative to the metal and metal oxides and are utilized widely.

The dispersions can also be made up of combinations of metals. Multimetallic particles are something which is not common and these can be dispersed in heavy fractions. Multimetallic particles are more focused on incorporating the individual properties of specific metals into a single particle. An example would be a mixture of asphaltene adsorption properties of nickel and better hydrodesulphurization properties of molybdenum and tungsten (Hashemi et al. 2013). Figure 13 shows the recovery plots in a fluid flooding process involving vacuum gas oil (Nexen, Alberta) in the case of ultradispersed (UD) trimetallic (NiWMo) colloidal nanoparticles.

Reprinted with permission (Hashemi et al. 2013). Copyright (2013)

Effects of ultra-dispersed catalyst (NiMoW) on recovery of vacuum gas oil at two temperatures (340 °C and 320 °C) with time from the sand pack experiment.

It is evident from Fig. 13 that multimetallic nanoparticles are effective in colloidal dispersions to recover heavy fractions. As the temperature increases, the effectivity of the particles becomes more prominent in recovering the gas oil. At 340 °C the vacuum gas oil recovery sees a plateau which is in contrast with the increased recovery through the dispersed catalyst at the same temperature.

The effectiveness of dispersed catalysts stems from the fact that apart from being dispersive in both oil and water, they affect the interface and give a dynamic surface for the temperature and water to break down heavy oil structure. The effectiveness of individual nanoparticles can be increased by using them as emulsions and nanofluids. Nanoemulsions (nanoparticles forming colloidal suspensions in fluids) have shown prospective development in oil recovery experiments. They can be developed from many types of nanoparticles which can be used for the formation of suspensions. Other than thermal methods use of miscible injection coupled with thermal methods has also been shown to improve oil recovery. They produce changes in interfacial tension and altering the reservoir rock properties. Heat intensive processes are one of the best ways to obtain high recovery of heavy oil. However, there are other methods that involve the use of injecting miscible gases and uses of solvents to treat heavy oil have also seen a rise in the production of heavy oil.

4.2.1 Nanoparticle Stabilized Miscible Flooding

Miscible flooding operations and their impact are entirely dependent on the changes in interfacial tension of the oil, reservoir rocks and the miscibility of the gas with oil. Miscible gases cause swelling of oil which helps the oil inside pores to flow more easily and allow better recovery. The arrangement of particles at the interface controls the strength of the interfacial tension (IFT). IFT reduction is crucial for processes such as miscible injections. The applicability of metal oxide nanoparticles has pronounced effects on the IFT in the CO2 injection process for heavy oil and CO2 upgrading systems. CO2 injection is an effective mechanism to reduce IFT in heavy oil systems. CO2 dissolution also helps in lowering the viscosity of heavy oils (Hu et al. 2015) and is usually employed in an alternating miscible scheme to recover oil. The only limitation being the precipitation of asphaltenes because of CO2. They reported that the addition of metal oxide nanoparticles in tandem with CO2 injection gave a significant reduction in IFT. Even at higher asphaltene contents, the reduction of IFT was appreciable. Figure 14 depicts the IFT reduction with increasing asphaltene content in the presence of nanoparticles with different oil samples (various API ranging from 16 to 26) obtained from various oil reservoirs in Iran (Kazemzadeh et al. 2018). Figure 14b depicts that nickel oxide particles exhibit a steady decrease in IFT as the asphaltene content increase. The charge distribution of nickel oxide is effective in attracting asphaltenes away from the interface, thereby reducing IFT. The deposition of asphaltenes on the surface of metal particles allows more room for IFT reduction which in turn allows more CO2 to get miscible with the oil hence improving the sweep of oil.

Reprinted with permission (Kazemzadeh et al. 2018)

Effect of nanoparticle dispersion: a Reduction in IFT of different API oils; b Reduction in IFT versus Asphaltene content (%) of the four oil samples.

Another strategy to use CO2 is in the form of foam. The foam helps in increasing the sweep and reduce mobility ratio. Foam also acts as a gas blocking agent which further helps in the recovery of oil. Foam injection coupled with other EOR techniques can give very effective results in mobilising oil. Consequently, to improve the efficiency of CO2 foams, nanoparticles can be used as stabilizers to maintain the foam structure inside the reservoirs. The stability of foams can be improved to achieve better effects in the distance up to which the foams can propagate in the reservoir. The hydrophilic/hydrophobic nature of nanoparticles helps in the stabilization of CO2 foam. Occupancy of nanoparticles at the CO2 interface provide thermal stability to the foam at reservoir temperatures (Espinosa et al. 2010). Nanoparticle-stabilized foams can provide a better sweep at a pore scale-level, which can result in the increased overall recovery of oil (Nguyen et al. 2014). The use of nanofluids in an alternating slug injection pattern coupled with CO2 also results in inhibition of asphaltenes. Lu et al. (2016) observed that asphaltene precipitation can be inhibited by asphaltene adsorption on Al2O3 nanofluids. Using the nanofluids slug in association with CO2 flooding can increase the adsorption at high concentrations of nanofluid.

4.2.2 Applications in Areas of Flow Assurance

Areas of flow assurance also face the disruption of processes caused by heavy oil transportation. Flow assurance deals with the efficient flow of recovered hydrocarbons from the reservoirs to the processing industries. Flow assurance has become an important term in the production process of oil transportation scenario owing to the need for ensuring the smooth working of the processing facilities. Difficulties in flow assurance operations (asphaltene deposition, hydrates, wax deposition, etc.) can cause major problems on a large scale. Problems in flow can cause processing delay which can lead to loss of capital. Heavy oils especially due to their viscous nature and asphaltene deposition cause flow stringencies. They get deposited on the inner surface of pipelines forming large blockages and restricting flow. Different mechanisms exist to counter the problems of asphaltene deposition such as solvent and asphaltene inhibition treatments but these techniques become troublesome at subsea levels.

Few applications have been sought out using nanoparticles and their properties to find a solution to these problems. Nanofluids can be used as asphaltene inhibitors to control the precipitation. Mohammadi et al. (2011) have tested the asphaltene inhibition qualities of silica-, zirconium- and titanium-based nanofluids and found that titanium oxide nanofluids were effective in controlling asphaltene precipitation at acidic conditions. Owing to the hydrogen bonding caused between the nanoparticles and asphaltenes, the precipitation is limited. The use of heating to keep the flow in check has also been explored through the use of paramagnetic nanoparticles for subsea pipelines (Mehta et al. 2014). It has been observed that nanoparticles exhibiting paramagnetic behaviour generate heat when under the influence of a magnetic field. These can be developed to provide temperature control over the flow of hydrocarbons inside the pipe. Such innovative solutions in the field of flow assurance have seen steady growth, allowing further optimal processing.

4.3 Challenges in the Application of Nanotechnology

Nanomaterials certainly have their advantages and potential in the field of heavy oil recovery. Excellent use as catalysts in enhancing the existing EOR techniques is significant merit. However, limitations can be found in the applications which can negatively impact the process economy. Fabrication processes of nanomaterials are quite expensive which makes them a priced commodity. It is evident that EOR operations require the injection of copious volumes of stimulants into the reservoir to extract oil. Injection of nanomaterial-based stimulants can affect the economy of the process. This heavily affects the application of nanomaterials on operational terms.

Introducing nanoparticles in the reservoir is a dicey gamble when it comes to the recovery of these particles. Obtaining these particles back from the reservoir can pose a major challenge as the particles, if once injected, may not be recovered completely. Applications involving the extraction of magnetic particles have been under development which can effectively recover a certain degree of particles. Extracting particles from recovered oil should also be a viable option to improve the recovery of nanoparticles. Another challenge is the aspect of reusability. Reuse of particles should be an option that can guarantee a longer process life. The life of the particles should be high, as the time period for production can vary and the particles should be functional for a long time.

5 Conclusion

Nanotechnology is just beginning to find its applications in oil recovery operations, more so in heavy oil recovery. Tackling different problems of fields related to, production processes and reservoir geology is something which is being constantly improvised to find better solutions. Nevertheless, nanomaterials have shown potential in altering the properties like viscosity and sulphur content of heavy oils. Their extraction processes can certainly be optimized to ensure a better recovery and provide a new outlook at the production of heavy oil. Heavy oil is certainly the next step in catering to the increasing fuel requirements. Field applications of utilizing nanomaterials are on the run. Identifying new and efficient strategies can positively unlock reservoirs of heavy oil to harness and sustain the energy needs.

References

Alkhaldi S, Husein MM (2014) Hydrocracking of heavy oil by means of in situ prepared ultradispersed nickel nanocatalyst. Energy Fuels 28:643–649

Al-Marshed A, Hart A, Leeke G, Greaves M, Wood J (2015) Optimization of heavy oil upgrading using dispersed nanoparticulate iron oxide as a catalyst. Energy Fuels 29:6306–6316

Aminzadeh-Goharrizi B, DiCarlo DA, Chung DH, Kianinejad A, Bryant SL, Huh C (2012) Effect of nanoparticles on flow alteration during CO2 injection. In: SPE annual technical conference and exhibition, San Antonio, Texas, USA, 8–10 October. SPE 160052

Azari V, Abolghasemi E, Hosseini A, Ayatollahi S, Dehghani F (2018) Electrokinetic properties of asphaltene colloidal particles: determining the electric charge using micro electrophoresis technique. Colloids Surf A 541:68–77

Cao T, Zhou Z, Chen Q, Li Z, Xu S, Wang J, Xu M, Bisson T, Xu Z (2017) Magnetically responsive catalytic sorbent for removal of Hg0 and NO. Fuel Proc Technol 160:158–169

Chen Y, Wang Y, Lu J, Wu C (2009) The viscosity reduction of nano-keggin-K3PMo12O40 in catalytic aquathermolysis of heavy oil. Fuel 88:1426–1434

Clark PD, Hyne JB (1984) Steam-oil chemical reactions: mechanisms for the aquathermolysis of heavy oils. Aostra J Res 1:15–20

Del Bianco A, Garuti G, Pirovano C, Russo R (1995) Thermal cracking of petroleum residues: 3. technical and economic aspects of hydrogen donor visbreaking. Fuel 74:756–760

Eastman JA, Choi SUS, Li S, Yu W, Thompson LJ (2001) Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Appl Phys Lett 78:718–720

Espinosa D, Caldelas F, Johnston K, Bryant SL, Huh C (2010) Nanoparticle-stabilized supercritical CO2 foams for potential mobility control applications. In: SPE improved oil recovery symposium, Tulsa, Oklahoma, USA, 24–28 April. SPE 129925

Farooqui J, Babadagli T, Li HA (2015) Improvement of the recovery factor using nano-metal Particles at the late stages of cyclic steam stimulation. In: SPE Canada heavy oil technical conference. Calgary, Alberta, Canada, 9–11 June. SPE-174478-MS

Gavrielatos I, Mohan R, Shoham O (2017) Effect of intermediate wettability nanoparticles on oil-water emulsion stability. J Petrol Sci Eng 152:664–674

Ghaffari A, Sharifi K, Ivakpour J (2017) An experimental study on the effects of temperature and asphaltene content on the rheological behavior of vacuum residues. Pet Sci Technol 35:768–774

Golmohammadi M, Ahmadi SJ, Towfighi J (2016) Catalytic cracking of heavy petroleum residue in supercritical water: study on the effect of different metal oxide nanoparticles. J Supercrit Fluids 113:136–143

Guo K, Zhang Y, Shi Q, Yu Z (2017) The effect of carbon-supported nickel nanoparticles in the reduction of carboxylic acids for in situ upgrading of heavy crude oil. Energy Fuels 31:6045–6055

Guo K, Hansen VF, Li H, Yu Z (2018) Monodispersed nickel and cobalt nanoparticles in desulfurization of thiophene for in-situ upgrading of heavy crude oil. Fuel 211:697–703

Hashemi R, Nassar NN, Pereira-Almao P (2012) Transport behavior of multimetallic ultradispersed nanoparticles in an oil-sands-packed bed column at a high temperature and pressure. Energy Fuels 26:1645–1655

Hashemi R, Nassar NN, Pereira Almao P (2013) Enhanced heavy oil recovery by in situ prepared ultradispersed multimetallic nanoparticles: a study of hot fluid flooding for Athabasca bitumen recovery. Energy Fuels 27:2194–2201

Hendraningrat L, Souraki Y, Torsater O (2014) Experimental investigation of decalin and metal nanoparticles-assisted bitumen upgrading during catalytic aquathermolysis. In: SPE/EAGE European unconventional resources conference and exhibition. Vienna, Austria, 25–27 February. SPE 167807

Huang X, El-Sayed MA (2010) Gold nanoparticles: optical properties and implementations in cancer diagnosis and photothermal therapy. J Adv Res 1:13–28

Hu R, Crawshaw JP, Trusler JPM, Boek ES (2015) Rheology of diluted heavy crude oil saturated with carbon dioxide. Energy Fuels 29:2785–2789

Ilyin SO, Strelets LA (2018) Basic fundamentals of petroleum rheology and their application for the investigation of crude oils of different natures. Energy Fuels 32:268–278

Kazemzadeh Y, Eshraghi SE, Kazemi K, Sourani S, Mehrabi M, Ahmadi Y (2015) Behavior of asphaltene adsorption onto the metal oxide nanoparticle surface and its effect on heavy oil recovery. Ind Eng Chem Res 54:233–239

Kazemzadeh Y, Eshraghi SE, Riazi M, Zendehboudi S (2018) How do metal oxide nanoparticles influence on interfacial tension of asphaltic oil-supercritical CO2 systems? J Supercrit Fluids 135:1–7

Kumar G, Kakati A, Mani E, Sangwai JS (2018) Nanoparticle stabilized solvent-based emulsion for enhanced heavy oil recovery. In: SPE Canada heavy oil technical conference, Calgary, Alberta, Canada, 13–14 March. SPE-189774-MS

Lai YH, Zhou Z, Basheer C, Zare RN (2017) Upgrading asphaltenes by oil droplets striking a charged TiO2-immobilized paper surface. Energy Fuels 31:12685–12690

Lan J, Yang Y, Li X (2004) Microstructure and microhardness of SiC nanoparticles reinforced magnesium composites fabricated by ultrasonic method. Mater Sci Eng A 386:284–290

Li W, Zhu JH, Qi JH (2007) Application of nano-nickel catalyst in the viscosity reduction of Liaohe extra-heavy oil by aqua-thermolysis. J Fuel Chem Technol 35:176–180

Lu T, Li Z, Fan W, Zhang X, Lv Q (2016) Nanoparticles for inhibition of asphaltenes deposition during CO2 flooding. Ind Eng Chem Res 55:6723–6733

Mehta P, Huh C, Bryant SL (2014) Evaluation of superparamagnetic nanoparticle-based heating for flow assurance in subsea flowlines. In: International petroleum technology conference. Kuala Lumpur, Malaysia, 10–12 December. IPTC-18090-MS

Menéndez-Manjón A, Moldenhauer K, Wagener P, Barcikowski S (2011) Nano-energy research trends: bibliometrical analysis of nanotechnology research in the energy sector. J Nanopart Res 13:3911–3922

Mironenko OO, Sosnin GA, Eletskii PM, Gulyaeva YK, Bulavchenko OA, Stonkus OA, Rodina VO, Yakovlev VA (2017) Catalytic steam cracking of heavy crude oil with molybdenum and nickel nanodispersed catalysts. Catal Ind 9:221–229

Mohammadi M, Akbari M, Fakhroueian Z, Bahramian A, Azin R, Arya S (2011) Inhibition of asphaltene precipitation by TiO2, SiO2, and ZrO2 nanofluids. Energy Fuels 25:3150–3156

Muraza O, Galadima A (2015) Aquathermolysis of heavy oil: a review and perspective on catalyst development. Fuel 157:219–231

Nassar NN, Hassan A, Pereira-Almao P (2011) Application of nanotechnology for heavy oil upgrading: catalytic steam gasification/cracking of asphaltenes. Energy Fuels 25:1566–1570

Nassar NN, Hassan A, Carbognani L, Lopez-Linares F, Pereira-Almao P (2012) Iron oxide nanoparticles for rapid adsorption and enhanced catalytic oxidation of thermally cracked asphaltenes. Fuel 95:257–262

Nguyen P, Fadaei H, Sinton D (2014) Pore-scale assessment of nanoparticle-stabilized CO2 foam for enhanced oil recovery. Energy Fuels 28:6221–6227

Patel H, Shah S, Ahmed R, Ucan S (2018) Effects of nanoparticles and temperature on heavy oil viscosity. J Petrol Sci Eng 167:819–828

Ramírez-González PV (2016) Rheological behavior from light to heavy oils: construction of master curves. Energy Fuels 30:7094–7099

Roth EA, Agarwal S, Gupta RK (2013) Nanoclay-based solid sorbents for CO2 capture. Energy Fuels 27:4129–4136

Rudyak V (2013) Viscosity of nanofluids. Why it is not described by the classical theories, Adv Nanopart 2:266–279

Sandoval A, Hernández-Ventura C, Klimova TE (2017) Titanate nanotubes for removal of methylene blue dye by combined adsorption and photocatalysis. Fuel 198:22–30

Shokrlu YH, Babadagli T (2014) Viscosity reduction of heavy oil/bitumen using micro- and nano-metal particles during aqueous and non-aqueous thermal applications. J Petrol Sci Eng 119:210–220

Tiwari JN, Tiwari RN, Kim KS (2012) Zero-dimensional, one-dimensional, two-dimensional and three-dimensional nanostructured materials for advanced electrochemical energy devices. Prog Mater Sci 57:724–803

Wang Q, Guo L, Wang Z, Mu B, Guo A, Liu H (2012) Hydrogen donor visbreaking of Venezuelan vacuum residue. J Fuel Chem Technol 40:1317–1322

Wang F, Zhang L, Xu L, Deng Z, Shi W (2017) Low temperature CO oxidation and CH4 combustion over Co3O4 nanosheets. Fuel 203:419–429

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Jadhav, R.M., Sangwai, J.S. (2020). Interaction of Heavy Crude Oil and Nanoparticles for Heavy Oil Upgrading. In: Ledwani, L., Sangwai, J. (eds) Nanotechnology for Energy and Environmental Engineering. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-030-33774-2_10

Download citation

DOI: https://doi.org/10.1007/978-3-030-33774-2_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-33773-5

Online ISBN: 978-3-030-33774-2

eBook Packages: EnergyEnergy (R0)