Abstract

Predominant SAPs used for internal curing are anionic gels, such as polyacrylamide, polyacrylic acid, and polyacrylate. They contain or can be hydrolyzed to form carboxylate functional groups. This allows them to retain water up to a few hundred times their dry weight, especially in a high pH environment. SAPs’ swelling behavior is desirable, but other characteristics of SAPs are important for their application as internal curing agents. These anionic SAPs are not only sensitive to the pH environment but also the types of ions. SAPs show less swelling in a calcium-rich solution than in a sodium-rich solution at the same pH. This has direct implications for internal curing because the cement pore solution is rich in various kinds of cations.

In this study, two types of SAPs are developed. One is a neutral SAP in which its swelling ability is independent of its ionic environment, and the other is a semi-anionic SAP, which contains an anionic moiety (polyacrylamide). As expected, the SAPs with anionic moieties show a higher degree of swelling in all environments. The cement pastes dosed with the semi-anionic SAP show a lower calcium concentration in the pore solution. These cement pastes show a lower initial rate of hydration, observed from isothermal calorimetry. The results suggest that the lower calcium content in the pore solution due to calcium absorption into the semi-anionic SAPs may interfere with the initial cement hydration.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Internal curing is considered an effective method in assuring full hydration of cementitious materials, especially in high-performance concrete (HPC) with a low water-to-cement ratio (w/c < 0.4) (de Sensale and Goncalves 2014). HPC is described as concrete that has superior mechanical and durability properties in the hardened state. However, the use of a low water-to-cement ratio can easily cause self-desiccation and autogenous shrinkage at the early stage of cement hydration. To prevent the shrinkage in HPC, supplying additional water materials such as superabsorbent polymers (SAPs) is used to compensate for the water within the cement paste during cement hydration (Jensen and Hansen 2002; Siramanont et al. 2010).

SAPs are networks of cross-linked polymers, which have the ability to absorb many times their own weight of liquid from the environment (Jensen and Hansen 2001). SAPs act as an internal water reservoir for the cement paste matrix. This water is consumed during cement hydration, mitigating self-desiccation (Mignon et al. 2017). Thus the potential use of SAPs is often dominated by their swelling behavior. Previous studies showed that the SAP swelling behavior depends on many factors, including the degree of crosslinking, chemical structure of the polymer, and environmental effects such as temperature, pH, and ionic concentration (Siriwatwechakul et al. 2010).

SAPs can be classified into two groups which are ionic and non-ionic based on the nature of the side chains. The predominant SAPs used for internal curing are anionic, such as polyacrylamide, polyacrylic acid and polyacrylate (Siramanont et al. 2010; Schröfl et al. 2012; Siriwatwechakul et al. 2012; Lee et al. 2018). These SAPs contain amide groups which can interact with water to form carboxylate groups with hydrogen that can be deprotonated, leaving anionic charges along the polymer chains. These charges provide the repulsive force on the polymer chains, rendering SAPs highly swollen in an aqueous environment, especially at high pH (Peppas et al. 2000; Siriwatwechakul et al. 2010).

The ability to swell in aqueous solution is not the only important characteristic for internal curing agents. Previous studies reported that the swelling ratio of polyacrylate SAPs was sensitive to the pH of their environment, and the type of ions in the surrounding solution (Siriwatwechakul et al. 2012; Lee et al. 2018). Siriwatwechakul et al. found that polyacrylate showed less swelling in a calcium-rich solution than in a sodium-rich solution at the same pH (Siriwatwechakul et al. 2012). Lee et al. showed that ion absorption was a dynamic process, in which Ca2+ can replace other monovalent cations, and the bound Ca2+ can also be released when the aqueous environment changed (Lee et al. 2018). These results help in understanding hydration chemistry because the pore solution is rich in various kinds of cations, ranging from monovalent to trivalent cations.

In this study, we synthesized two types of SAPs. One was a neutral SAP made from polyethylene glycol (PEG). It is referred to as a polyethylene glycol dimethacrylate (PEGDMA) hydrogel. The other was a semi-anionic SAP made from PEG copolymerized with polyacrylamide, PEGDMA-co-AM. Their swelling behavior was examined in an ion-rich environment using the teabag method. The ion composition of the solution surrounding SAPs was analyzed by inductively coupled plasma mass (ICP-MS) spectroscopy. Subsequently, two types of SAPs were incorporated into the cement paste with the dosage 0.1% and 0.5% (w/w cement). The pore solutions were collected every 30 min for two hours, to understand the ionic environment in the pore solution at different times. The hydration of cement in the presence of SAPs was also monitored by using an isothermal calorimeter. By understanding the effects of SAPs, the outcome of this work will allow the engineering of SAPs with properties that are suitable for internal curing.

2 Experimental

2.1 Materials

Polyethylene glycol MW4000 (PEG4000) was supplied by Chemipan (Bangkok, Thailand). Methacrylic anhydride (MA), Triethylamine (TEA) and N,N’-methylenebisacrylamide (NMBA) were supplied by Merck (USA). N,N,N’N’-Tetramethylenediamine (TEMED) was purchased from Sigma-Aldrich (St. Luis, MO, USA). Ammonium persulfate (APS), Potassium carbonate (K2CO3), Sodium hydroxide (NaOH), Calcium hydroxide Ca(OH)2 and Dichloromethane (DCM) were obtained from Ajax (NSW, Australia).

2.2 SAP Preparation

Preparation of PEGDMA

Polyethylene glycol dimethacrylate (PEGDMA) was prepared by the esterification of methacrylic anhydride. The reaction was performed by dissolving 50 g of PEG4000 in 150 mL of DCM in a three-neck round-bottom flask equipped with a magnetic stirrer. The solution was purged with N2 gas to remove oxygen which can inhibit the reaction and stirred until all PEG was dissolved. MA (4.1 mL, 2.2 molar equivalent to PEG) and 2 mL of TEA, with a ratio of 1 mL TEA to 75 mL of DCM, were added to the flask. The reaction was performed for 72 h at room temperature under a nitrogen atmosphere.

After 72 h, the reaction mixture was transferred into a separatory funnel. Then, K2CO3 (1.5 M) was added to neutralize the methacrylic acid by-product. The added volume of K2CO3 solution was half of the total volume of the reaction mixture. The mixture was allowed to phase separate by gravity, overnight. The bottom phase contained PEGDMA and was collected for further purification. DCM was evaporated to concentrate the PEGDMA solution, and PEGDMA was precipitated using 300 mL of diethyl ether to obtain solid PEGDMA powder. The solid was dried overnight in a vacuum oven at room temperature. PEGDMA powder was kept for further characterization by FT-IR and NMR.

Preparation of PEGDMA Hydrogels

Two types of SAPs were prepared, based on PEGDMA (see Table 1). The hydrogels were prepared by using N,N’-methylenebisacrylamide (NMBA) as a crosslinker by free radical polymerization with ammonium persulfate (APS) as an initiator. All the monomer concentrations were kept at 8% (w/w), and the crosslinker to PEG monomer ratio was kept at 1:1000 (by weight). The monomers were dissolved in deionized (DI) water and were purged with N2 gas for 30 min. APS and TEMED, used as an accelerator, were added to the solution to initiate polymerization at room temperature. The mixture was allowed to form hydrogels overnight. After 24 h, the hydrogels were collected and washed with DI water to remove the unreacted monomers.

2.3 SAP Characterizations

Fourier-Transform Infrared Spectroscopy (FTIR) and Nuclear Magnetic Resonance Spectroscopy (NMR)

NMR and FTIR were used to ensure that PEGDMA contains the functional groups C=O and C=C from attaching methacrylic anhydride to the PEG chain. The C=O and C=C stretching bands can be observed in the range of 1650–1780 cm−1 and 1600–1680 cm−1, respectively.

Swelling Ratio of PEGDMA and PEGDMA-co-AM Hydrogels in Aqueous Solution

The swelling ability of PEGDMA and PEGDMA-co-AM were measured using the teabag method. Dry hydrogels (1 g) were placed in 50 × 50 mm teabags and soaked into 50 mL of four different aqueous solutions: DI water (pH 7), 0.01 M NaOH (pH 12), 0.01 M Ca(OH)2 (pH 12), and saturated cement solution (pH 13). The saturated cement solution was prepared by stirring 10 g of OPC (type I) in 100 mL DI water for one hour, and subsequently removing the suspended particles by filtration. All of the solutions were kept at room temperature for 24 h, after which each teabag was collected and placed on a tissue paper to absorb the excess water before measuring the weight of the hydrogels. Each measurement was done in 5 replicates, and the swelling ratio (s) was calculated by Eq. (1).

where \( M_{3} \) is the total weight of hydrogel with the wet teabag, \( M_{2} \) is the weight of wet teabag and \( M_{1} \) is the weight of the dry hydrogels. In addition, the ion contents in the aqueous solutions before and after swelling ratio measurement were analyzed by using inductively coupled plasma (ICP).

Isothermal Calorimetry

The hydration of cement in the presence of PEGDMA and PEGDMA-co-AM hydrogels was evaluated by using an isothermal calorimeter. In this study, an 8-channel TAM Air (TA Instruments) was used for the isothermal calorimetry experiments. The samples were prepared according to the design mix in Table 2. In summary, cement pastes were prepared by mixing Ordinary Portland Cement (OPC) with PEGDMA and PEGDMA-co-AM hydrogels (0.1 wt.% and 0.5 wt.%) at a water-to-cement ratio of 0.485 by using a high-speed mixer at 300 rpm for one minute. Mixing was continued at speed of 800 rpm for another two minutes. The samples were then placed in glass ampoules and inserted into the TAM Air to capture the early hydration reaction at 25 ± 0.01 °C for 48 h, using air as a reference.

Ion Concentration in Pore Solution

The samples were prepared by placing 10 g of OPC with hydrogels (dosage according to Table 2) in a mixer. Then, 100 mL of deionized water was added to the mixer, and the paste was stirred at 500 rpm for 2 min before collecting the first sample. Five mL of each sample was collected at 30 min, 1 h, 1.5 h and 2 h. The cement paste was filtrated by using a syringe filter with a pore diameter of 0.2 µm. The ion contents (sodium, calcium, silicon, aluminum, and iron) in the pore solution were measured using ICP.

3 Result and Discussion

3.1 SAP Characterizations

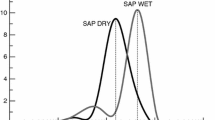

The synthesis of PEGDMA and PEGDMA-co-AM hydrogels was confirmed by NMR and FTIR. The swelling ratio of the hydrogels in four different solutions are shown in Fig. 1. The swelling ratio of semi-anionic PEGDMA-co-AM hydrogels is higher than the neutral hydrogels in all aqueous environments. In an ion rich environment, the swelling ratio is lower than that in the aqueous solution at a similar pH.

The time evolution of the calcium concentration in the pore solution is plotted in Fig. 2. The cement paste dosed with PEGDMA-co-AM SAP (Sample IV and Sample V) show a lower calcium concentration in the pore solution. This result is consistent with previous studies that polyacrylate/polyacrylamide SAPs can effectively bind to calcium ions (Siriwatwechakul et al. 2010); thus, less calcium is dissolved in the pore solution.

Calcium ion concentration in pore solutions. The compositions of the cement paste are detailed in Table 2.

The heat flow curves in Fig. 3 show the impact of the SAP on the hydration of the OPC type I cement. The ascending slope of the first peak is related to the acceleration period, and associated with the precipitation of hydration products mainly C-S-H and CH. The cement paste dosed with PEGDMA-co-AM SAP (Sample IV and Sample V) visibly show a lower initial reaction rate. This suggests that the lower calcium content in the pore solution influences the rate of hydration.

Rate of heat evolved from cement pastes at a W/C ratio of 0.485. The compositions of the cement paste are detailed in Table 2.

4 Conclusion

In this study, we presented two types of SAPs: neutral SAP referred to as polyethylene glycol dimethacrylate (PEGDMA) and semi-anionic SAP made from PEG copolymerized with polyacrylamide (PEGDMA-co-AM). There is a consistent trend for these two sets of SAPs. The semi-anionic SAP shows higher swelling with fewer calcium ions in the pore solution of the cement paste. This leads to a lower initial rate of cement hydration. The results show that as internal curing agents, SAPs may not only act as an internal source of water supply, and also directly interfere with hydration. This could result in a more complex strength development rather than just supplying water for hydration.

References

de Sensale, G.R., Goncalves, A.F.: Effects of fine LWA and SAP as internal water curing agents. Int. J. Concr. Struct. Mater. 8(3), 229–238 (2014)

Jensen, O.M., Hansen, P.F.: Water-entrained cement-based materials: I. Principles and theoretical background. Cem. Concr. Res. 31(4), 647–654 (2001)

Jensen, O.M., Hansen, P.F.: Water-entrained cement-based materials II. Experimental observations. Cem. Concr. Res. 32(6), 973–978 (2002)

Lee, H.X.D., et al.: Effect of alkalinity and calcium concentration of pore solution on the swelling and ionic exchange of superabsorbent polymers in cement paste. Cement Concr. Compos. 88, 150–164 (2018)

Mignon, A., et al.: Development of amine-based pH-responsive superabsorbent polymers for mortar applications. Constr. Build. Mater. 132, 556–564 (2017)

Peppas, N.A., et al.: Hydrogels in pharmaceutical formulations. Eur. J. Pharm. Biopharm. 50(1), 27–46 (2000)

Schröfl, C., et al.: Relation between the molecular structure and the efficiency of superabsorbent polymers (SAP) as concrete admixture to mitigate autogenous shrinkage. Cem. Concr. Res. 42(6), 865–873 (2012)

Siramanont, J., et al.: The impact of SAP structure on the effectiveness of internal curing. In: International RILEM Conference on Use of Superabsorbent Polymers and Other New Additives in Concrete, Lynby, Denmark, RILEM Publications SARL (2010)

Siriwatwechakul, W., et al.: Superabsorbent polymer structures. In: International RILEM Conference on Use of Superabsorbent Polymers and Other New Additives in Concrete, RILEM Publications SARL (2010)

Siriwatwechakul, W., et al.: Behavior of superabsorbent polymers in calcium- and sodium-rich solutions. J. Mater. Civ. Eng. 24(8), 976–980 (2012)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 RILEM

About this paper

Cite this paper

Tangkokiat, P., Thanapornpavornkul, T., Muangkaew, S., Siriwatwechakul, W., Siramanont, J., Snguanyat, C. (2020). Characterization of Neutral Versus Anionic Superabsorbent Polymers (SAPs) in Ion-Rich Solutions for Their Use as Internal Curing Agents. In: Boshoff, W., Combrinck, R., Mechtcherine, V., Wyrzykowski, M. (eds) 3rd International Conference on the Application of Superabsorbent Polymers (SAP) and Other New Admixtures Towards Smart Concrete. SAP 2019. RILEM Bookseries, vol 24. Springer, Cham. https://doi.org/10.1007/978-3-030-33342-3_5

Download citation

DOI: https://doi.org/10.1007/978-3-030-33342-3_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-33341-6

Online ISBN: 978-3-030-33342-3

eBook Packages: EngineeringEngineering (R0)