Abstract

High voltage equipment and insulation technology is growing rapidly. The insulation quality is of a serious concern as the high voltage equipment and insulation are stressed due to severe service and environmental conditions. It is apparent to investigate the influence of temperature on the dielectric loss of the cable insulation. The knowledge on the relationship between the test voltage characteristic (frequency and magnitude) and tan-delta has advanced, but this cannot be said about the influence of temperature and terminations on the tan-delta of cross-linked polyethylene (XLPE) insulated power cable system. This paper presents a laboratory test performed on both the aged and unaged power cable samples (with termination and without terminations) of 10-meter length each at a very low frequency (VLF) of 0.1 Hz and nominal voltage frequency of 50 Hz at temperature ranges of 20°–70 °C. An investigation is conducted on how the dielectric loss measurement of XLPE insulated power cable responded to the changes in the insulation temperature as well as the influence of terminations. The phenomenon is interpreted in terms of hoping conduction and dynamic mechanical analysis in polymer. The result shows that the temperature of the insulations, terminations and joints influenced the tan-delta values of the XLPE insulations when measured at different frequencies.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The reliability of the high voltage equipment used in an electric power system significantly depends on the material insulation. Cross-linked polyethylene (XLPE) is widely used because of its physical and chemical properties [1, 2].

XLPE cable possesses excellent dielectric strength, low dielectric permittivity, low loss factor, good dimensional stability, solvent resistance and good thermo-mechanical behaviour. Despite the excellent qualities possessed, there are several weaknesses faced by XLPE cables that reduce their performance during service [2, 12].

The properties of the insulation materials change over time, most especially when they are subjected to a long-time loading. The XLPE behaves elastically and rigidly over the working temperature range [3, 4]. The service conditions such as short circuit or over current could thermally affect the insulation and this could lead to early aging of the cable. It is therefore necessary to carried out the dissipation factor measurement of the high voltage cable at different temperature.

The dielectric loss factor is an indicator of power losses caused by the existence of the residual component of the leakage current. In an ideal dielectric only the capacitive current flows, this is offset from the voltage on the insulation by an angle \( \phi \) = 90°. Practically, the angle \( \phi \) is less than 90°. The increase in loss causes an increase in the different \( \delta \) = 90−\( \phi \) and this is shown in Fig. 1.

Tan-delta and temperature analysis of different polymer were discussed in several studies. Wetton et al. investigated PVC, PS and PC at temperature ranges of -100°–200°C and recorded that tan-delta increased with increase in temperature but with a peak at about 50° and 100°C [5]. Dang and his colleague investigated tan-delta value of XLPE material with different densities at different temperatures [6]. In the work of Auriratch et al., tan-delta measurement was carried out at temperature ranges of 20°–100°C in three stages [7]. Tong et al. investigated a cable semiconductor material and observed that dielectric loss increased at higher temperature with a peak at 90°C.

This paper presents an analysis of temperature dependency of dielectric loss measurements of XLPE power cable on the experiments performed in the laboratory on both aged and unaged XLPE power cable samples (with termination and without termination) of 10-meter length each at a very low frequency (VLF) of 0.1 Hz and nominal voltage frequency of 50 Hz at temperature ranges of 20°–70°C in accordance with the IEC 60502-2. It is significant to recognise the importance of a cable system, as a whole, by including terminations and splices; hence, the investigation of how the dielectric loss measurement of XLPE power cable responded to the changes in the insulation temperature as well as the influence of terminations.

2 Conduction in Polymers

In solid insulation as XLPE, ionic mobility is greatly reduced and, consequently, the tan-delta values of insulation are very small [8, 9].

Conduction current is the electric current which exists in a conductor when the electrons flow in the conductor at a uniform rate.

The charge carriers (electron and ion) and the transportation mechanism explained the electrical conduction in polymer. In the absorption current measurement of a low density polyethylene, there are two peaks, one below 80 °C and the other above 80 °C [3, 5]. The peak in the conduction current, as a function of temperature, is attributed to the presence of carbonyl group in the polymer’s oxidised impurities.

The phenomenon is interpreted in terms of hoping conduction and dynamic mechanical analysis (DMA) in polymer. Polymer conduction are expositorier by the term charge carriers and their transportation mechanism. The hoping conduction mechanism in polymer explained current as a function of temperature. At temperature below glass transition (Tg), the conductivity increases as the temperature increases. The thermal expansion of polymer that causes a reduction in the carbonyl group density has made a continuous increase in the temperature.

The dynamic mechanical analysis (DMA) in polymers explains the thermal transition and polymer flow. The relationship between the storage modulus (E′) and the loss modulus (E″) of DMA gives the tan-delta of polymer over a temperature range [4];

The charge transport mechanism is temperature dependent and it is expressed as [10];

Where:

-

\( P \) = Temperature dependent conductivity of polymer

-

\( P_{o} \) = Constant

-

\( E_{o} \) = Activation energy

-

\( K \) = Boltzmann constant

-

\( T \) = Temperature in Kelvin

The dielectric loss in terms of conductivity and dielectric constant of the insulation is expressed as [10];

Where:

-

\( \varepsilon_{o} \) = Permittivity of vacuum

-

\( \varepsilon_{r} \) = Relative permittivity of the dielectric

-

\( \omega \) = Angular frequency

The energy loss in dielectric is proportional to the tan-delta value:

Electric cables with high dissipation factor at high temperature could explode due to thermal runaway [12].

3 Experimental Setup

The tan-delta measurement TDA Compact™ was used to measure the dissipation factor of cable samples with stress-graded terminations and without stress-graded terminations to evaluate the influence of temperature and nature of terminations on tan-delta measurement.

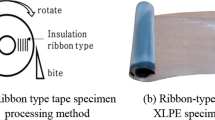

Tan-delta measurement setup consists of a high voltage divider and fibre optically linked measuring equipment. The tan-delta controller unit takes measurement of tan-delta values and sends this information to the TDA compact that analyses the voltage and current and calculates the tan-delta of the cable under the test. The test experiments on the cable samples of 11 kV nominal rated single core XLPE power cable was performed in accordance to the IEC 60502-2 [11].

The cable heating process was performed by injecting current through the cable conductor. A 5 kVA, 0–300 V auto transformer was used to control the circulating current in the cable conductor by means of an injection current transformer.

The thermal stability was obtained before the measurement was taken. Temperature logger was used to measure the temperature of the dielectric. The probe of the logger was connected to the dielectric material. The measured data were protected against distortion by wrapping a tape over the XLPE cable sample terminals. Figure 2 shows the cable sample with stress-graded terminations.

The dissipation factor measurement at a nominal voltage of 10 kV was carried out at conductor temperatures between 20 °C and 70 °C at an interval of 5 °C on the XLPE cable samples at a very low frequency (VLF) of 0.1 Hz and a nominal voltage frequency of 50 Hz.

At a VLF of 0.1 Hz, it consumes less (500 times) power to test the same cable sample compared to 50 Hz. Also, the sensitivity of the measurement is an advantage. Figure 3 shows the VLF measurement device.

The experimental setup is as shown in Fig. 4 below.

4 Results and Discussion

The value of tan-delta as well as other parameters of dielectric for the given specimens of material are not strictly constant and depend on various factors such as frequency, temperature, humidity and voltage. Hence, the influence of temperature is analysed.

The test results (50 Hz frequency), as shown in Figs. 5 and 6, depict a non-linearity with change in temperature for both the two cases respectively: aged and unaged cable samples (with stress-graded terminations and without terminations). The storage modulus increases with temperature up to a peak value, after which it plateaus with further increase in temperature.

The common thread in the key findings of other researcher on the tan-delta is that it varies significantly and non-linearly with temperature variation. In the tested cable samples, it was observed that the value and the location of the peaks depends on the dielectric material and the test voltage frequency.

The peaks in the conduction current as a function of temperature and the corresponding tan-delta peak can be explained in terms of the hoping conduction mechanism in polymer. At low temperatures, below the Tg, as the temperature increases, the conductivity increases gradually in accordance with the Arrhenius Eq. (2). The continuous increase in the temperature results in thermal expansion of the polymer that causes a reduction in the carbonyl sites distribution density.

A continuous increase in temperature beyond the peak reduces the conduction current. As the temperature approaches the polymer glass transition range, there is the onset of diffusional motion of large chain segments of the polymer. The hoping mechanism of conduction is consequently distorted, resulting in significantly increased conduction.

The lower tan-delta value was recorded in all the tested cable samples at 20 °C and this is due to the free movement of the rubber chain segments under dynamic stress-strain cycle at higher dissipation of energy and higher internal friction.

At 50 Hz frequency, the stress-graded terminations in an aged cable sample insulation strengthened the polymer and this exhibits less creep than the cable sample without termination.

The tan-delta curve of the cable sample without terminations has two peaks and the second peak is slightly higher, this is probably due to the formation of polymer at the amorphous interphase. The same was observed in an unaged cable sample but with a lesser magnitude. As the temperature increases, the tan-delta reduces after each peak.

The terminations on the cable sample improves the toughness, tensile, flexural and interlaminar shear strength. The curve (Figs. 5 and 6) increased very quickly, stabilised and then reduced gradually.

The tan-delta curve of an aged cable samples (50 Hz frequency) shows two broad peaks at 35° and 60 °C, while the unaged cable sample peaks are at 40° and 60 °C. The behaviour associated with broad peak is the characteristic of a crosslinking process. The two distinct relaxation peaks correspond to the two-transition temperature. There was a gradual increase in the damping peak maxima for samples without termination towards a higher temperature as compared to cable samples with terminations as shown in Figs. 5 and 6. This is related to the crosslinking density.

At a VLF of 0.1 Hz, the magnitude of tan-delta increases as the frequency decreases making measurement easier. In aged cable samples (Fig. 7) at a VLF of 0.1 Hz, the magnitude of the tan-delta was constant for both conditions (with stress-graded terminations and without terminations). The repeated measurements give the same result.

The tan-delta of an unaged cable sample (with stress-graded terminations and without terminations) at a VLF of 0.1 Hz shows a constant value with temperature variation.

The tan-delta value of the cable sample with termination is higher than that of the cable sample without termination; this value remains constant with temperature as shown in Fig. 8.

The behaviour of tan-delta in cable samples with stress-graded termination polymer insulated cables is attributable to the semiconducting layer’s electro-thermal characteristics.

These provide structural adhesive, loading bearing materials with high modulus and strength that can transmit stress without a loss of structural integrity.

The stress-graded terminations have an influence on the tan-delta values. The tan-delta curve shows one pick at 35 °C for the aged cable sample and 40 °C for an unaged cable sample. As the temperature increases, the tan-delta value decreases.

It is shown that insulation storage modulus undergoes the characteristic steep decrease at 40 °C.

5 Conclusion

It is significant to recognise the importance of a cable system as a whole by including terminations and splices; hence, the investigation of how the dielectric loss measurement of XLPE power cable responded to changes in the insulation temperature as well as the influence of terminations.

It is evident that tan-delta measurements of polymer insulation are influenced by insulation temperature.

On the cable samples with terminations, the polymer metrix enhanced the creep resistance at various stress and temperature levels.

The dynamic behaviour of the cable sample at 50 Hz is similar, it reaches broad peak at 35 °C and 40 °C. This is considered low with respect to the service temperature.

At a VLF of 0.1 Hz, the magnitude of tan-delta for aged and unaged cable samples follows the same trend and this remain constant as the temperature increases, as shown in Figs. 7 and 8.

The study corroborates the findings of other researchers on the effect of temperature and terminations on the polymer insulation as summarised earlier in the introduction.

References

Hernadez-Meija, J.C., Haley, R., Hampton, N., Hartlein, R.: Characterisation of ageing for MV power cable using low frequency tan delta diagnostic measurements. IEEE TDEI. 16(3), 862–870 (2009)

Sarathi, R., Das, S., Venkataseshaiah, C., Yoshimura, N.: Investigation of growth of electrical trees in XLPE cable insulation under different voltage profile. In: Annual Report Conference on Electrical Insulation and Dielectric Phenomena, pp. 666–669 (2003)

Stark, W., Goering, H., Michel, U., Bayerl, H.: Online monitoring of thermoset post-curing by dynamic mechanical thermal analysis DMT. Polym. Test. 28, 561–566 (2009)

Margem, F.M., Monteiro, S.N., Neto, J.B., Sanchéz Rodriguez, R.J., Soares, B.G.: The dynamic-mechanical behavior of epoxy matrix composites reinforced with ramie fibers. 15(2) (2010). Rio de Janeiro

Wetton, R.E., Marsh, R.D.L., Duncan, J.C., Foster, G.M.: Effect of physical ageing of polymers on dielectric permittivity and loss values over wide temperature and frequency ranges. In: Proceedings of the 6th International Conference on Dielectric Materials, Measurements and Applications, Manchester, pp. 65–68 (2002)

Dang, C., Pélissou, S.: Some technical consideration on very low frequency cable diagnostic. In: Proceedings of IEEE Transmission & Distribution Conference and Exposition, Dallas, Texas, vol. 3, pp. 639–642 (2003)

Aurairatch, A.: A preliminary study of loss factor (tan δ) in dielectric of cable produced in Thailand, MSc thesis, King Monkut’s Institute of Technology, North Bangkok, Thailand (2006)

Pelissou, S., St-Onge, H., Wertheimer, M.R.: Electrical conduction of polyethylene below and above its melting point. IEEE Trans. Electr. Insul. 23(3), 325–333 (1988)

Ponniran, A., Kamarudin, M.S.: Study on the performance of underground XLPE cables in service based on tan delta and capacitance measurements. In: 2nd IEEE International Conference on Power and Energy (PECon 2008), pp. 39–43 (2008)

Beyer, M., Steingrber, M.: The influence of pretreatment on the loss behaviour of water tree retardant XLPE insulation materials. In: Proceedings of the 3rd International Conference on Properties and Applications of Dielectric Materials, Tokyo, Japan, pp. 152–155 (1991)

International Standard IEC 60502-2: Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1.2 kV) up to 30 kV (Um = 36 kV) – Part 2: Cables for rated voltages from 6 kV (Um = 7.2 kV) up to 30 kV (Um = 36 kV)

Crine, J.P.: Electrical, chemical and mechanical processes in water treeing, dielectrics and electrical insulation. IEEE Trans. Dielectr. Electr. Insul. 5, 681–694 (1998)

Acknowledgements

The authors would like to thank the Vaal University of Technology for the use of facilities to complete the research work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Adeniyi, A.O., Walker, J. (2020). Temperature Dependency of Dielectric Loss Measurements of XLPE Power Cables at 0.1 Hz and 50 Hz. In: Németh, B. (eds) Proceedings of the 21st International Symposium on High Voltage Engineering. ISH 2019. Lecture Notes in Electrical Engineering, vol 599. Springer, Cham. https://doi.org/10.1007/978-3-030-31680-8_81

Download citation

DOI: https://doi.org/10.1007/978-3-030-31680-8_81

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-31679-2

Online ISBN: 978-3-030-31680-8

eBook Packages: EngineeringEngineering (R0)