Abstract

Photovoltaic and wind turbine energy systems have a pivotal role to meet the growth in power demand. The power generated from the renewable energy sources has main advantages of the absence of harmful emissions and infinite availability. The integration of photovoltaic systems into the power grid is expected to increase with the continuous reduction in the capital cost of these systems. The photovoltaic systems are exposed to extreme ambient conditions such as solar radiations, wind, humidity and thermal stresses. Cables in the photovoltaic systems are of great importance since they provide the link between the main components of the photovoltaic systems so, the reliability, efficiency and lifetime of the photovoltaic systems affected greatly by the functionality of these cables. This research presents a study of the insulation condition of Cross-Linked Polyolefin insulation based photovoltaic cable samples exposed to elevated temperature of 120 ℃ for four cycles. The analysis based on the measurement of the insulation capacitance, insulation resistance and the dissipation factor or tangent delta after each cycle as a function of frequency ranged from 100 Hz to 500 kHz. The results showed that the capacitance had a slight change with increasing the ageing period while the insulation resistance and the dissipation factor were more affected.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Electric power utilities face many challenges from the huge development towards an extensive integration of different renewable energy sources into the power grid such as photovoltaic (PV) energy systems [1]. Taking into consideration the PV source reliability, availability, visibility and other factors such as the stability of the power grid, the integration process should guarantee the mutual benefits between the two energy sources. A typical PV system comprises of solar panels which convert the incident of solar radiations into DC power, inverter which provide the interface between the solar panel and the utility network, batteries and charge controller as main components [2]. The design of the PV system components should be done accurately to obtain maximum output power and minimum losses in the system. The PV cables are used to connect between the components of the PV system. PV cable management is of a great importance aspect of the safety and lifetime of the PV system. This is primarily due to the usage of exposed cables in the PV array since the PV system is installed outdoors on rooftops and open fields where harsh ambient conditions such as solar radiation, wind, humidity, and hot & cold temperatures stress exposed components as modules and cables [3]. Theses harsh ambient conditions affect the insulation integrity of the cables used in the PV systems where insulation degradation becomes more significant affecting the overall PV system [2]. For this reason, the functionality of these cables should be guaranteed over a long period since the estimated thermal lifetime of theses cables is about 25 years [4,5,6,7]. In this research, samples of Cross-Linked Polyolefin (XLPO) insulation-based PV cables were subjected to accelerated thermal aging to investigate the effect of thermal stresses on the insulation integrity. The evaluation of the insulation state carried out by measuring the insulation capacitance, insulation resistance and the dissipation factor (tanδ) using a precision component analyzer with output voltage of 5 V over a range of frequency from 100 Hz to 500 kHz.

2 Experimental Work

2.1 Specimens

The measurement of the insulation parameters was carried out on samples of low voltage PV cable. The cable consists of three main parts, fine wire tin-plated copper conductor with cross sectional area of 4 mm2, inner and outer insulation made of XLPO as in Fig. 1. The cable technical specifications are given in Table 1.

2.2 Accelerated Aging Procedure

Before starting the thermal aging, the samples have been preconditioned in an oxygen-controlled oven to remove any moisture from the samples as shown in Fig. 2. The preconditioning was for one day at temperature of 70 ℃. After that, the samples were kept at room temperature for one day. Before starting the thermal aging, a benchmark measurement for the capacitance, insulation resistance and tanδ was carried out. The accelerated thermal aging was at a temperature of 120 ℃ for different periods of 240, 480, 720 and 960 h. Between each period, the measurements were carried out to clearly investigate the effect of different aging periods. For the measurement of the capacitance, Insulation Resistance (IR) and tanδ the samples were covered with an aluminum foil so, the measurement was between the conductor and the aluminum foil at room temperature. All the measurements carried out in Faraday cage to eliminate any interference during the measurement.

3 Results and Discussion

Figure 3 depicts the capacitance, the insulation resistance (IR) and tanδ of unaged samples over the whole frequency range (100 Hz to 500 kHz). The values of the capacitance and IR decreased with increasing the frequency as shown in Fig. 3a and b respectively while Fig. 3c shows that the values of tanδ increased moving to the higher frequencies showing how the leakage current dominate in the insulation at higher frequencies.

Figure 4 illustrates the capacitance after the thermal aging. The capacitance had the same profile as the unaged case i.e., the capacitance values decreased with increasing the frequency. Besides, after the first aging cycle (240 h), the capacitance decreased slightly below the baseline measurement over the whole frequency range showing that the dielectric insulation lost around 2% of its electrical capacitance [8]. While it increased after the second cycle (480 h) showing that the insulation starts to retain its original capacitance since the decrease in the capacitance became 1.2%. Moving to the third and fourth cycles (720 and 960 h) respectively, the insulation recovered its original capacitance since only 0.1% and 0.22% difference after the third and fourth cycles respectively [9].

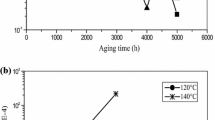

The plot of the insulation resistance is shown in Fig. 5. Like the capacitance, the insulation resistance had the same profile of the unaged case i.e., the higher values of IR were shifted to the lower frequency range. Also as shown in Fig. 5, starting from 100 Hz towards 2 kHz, the IR values increased with increasing the aging period while the IR values were less affected with the aging period increased for the frequency range from 5 kHz to 500 kHz.

Basically, the dielectric dissipation factor is an indication for the losses in the dielectric material. The active losses in the dielectric are conduction losses (Pc), polarization losses (Pp) and ionization losses (Pi). The conduction losses depend on the insulation resistance. The dissipation factor is dependent on the applied electric field, frequency, insulation resistance of the dielectric material and temperature [8, 10]. The dissipation factor is calculated as follows,

Where IR and IC are the leakage and charging current respectively and ω is the angular frequency. Figure 6 depicts the dissipation factor of the aged and unaged samples. The tanδ values decreased with increasing the aging period starting from 100 Hz to 2 kHz and this can be explained by the increase of the insulation resistance which leads to reduction in the leakage current (IR) for the same frequency range as shown in Fig. 5. After the fourth cycle (960 h), the tanδ values increased with increasing the frequency from 5 kHz to 500 kHz due to the decrease in the insulation resistance after this cycle for the same frequency range showing more leakage current passing through the insulation.

4 Conclusion

In this work, low voltage XLPO insulation based low voltage photovoltaic cable samples were thermally aged at temperature of 120 ℃ for four aging cycles 240, 480, 720 and 960 h. The capacitance, insulation resistance and dissipation factor were investigated to find out the integrity of the insulation after the thermal aging. The measurements were carried out using precision components analyzer with frequency range from 100 Hz to 500 kHz.

The results showed that, the capacitance decreased after the first thermal cycle and it increased with increasing the aging period. The change in the capacitance after the end of the fourth cycle was very slight, 0.22% of its original value before aging.

The values of the insulation resistance increased with aging period increased for frequency range from 100 Hz to 2 kHz and it decreased moving to the high frequency range showing more conduction losses in the insulation. Consequently, the profile of the dissipation factor was correlated to the insulation resistance profile. For frequency range from 100 Hz to 2 kHz, the dissipation factor values decreased with the aging period increased while it increased moving to the high frequency range showing more leakage current passed through the insulation.

Chemical investigations are needed to provide more explanations to the obtained results.

References

Colli, A.: Failure mode and effect analysis for photovoltaic systems. Renew. Sustain. Energy Rev. 50, 804–809 (2015)

Ekici, S., Kopru, M.A.: Investigation of PV system cable losses. Int. J. Renew. Energy Res. 7, 807–815 (2017)

Parise, G., Martirano, L., Parise, L.: Life monitoring tool of insulated cables in photovoltaic installations. IEEE Trans. Ind. Appl. 50, 2156–2163 (2014)

Parise, G., Rubino, G.: A comparison of the ANSI/IEEE and the CENELEC/IEC approaches to overload protection of insulated power cables. IEEE Trans. Ind. Appl. 33, 1362–1366 (1997)

Parise, G., Martirano, L.: Circuits operation control and overloads protection: power cables equivalent ampacities. IEEE Trans. Ind. Appl. 36, 22–29 (2000)

Parise, G., Martirano, L.: Life loss of insulated power cables: a “count hours” device. In: 2001 IEEE Industrial and Commercial Power Systems Technical Conference. Conference Record (Cat. No. 01CH37226), pp. 91–95. IEEE (2002)

Parise, G., Martirano, L.: System management strategy to monitor insulated power cables. In: Conference Record of the 2004 IEEE Industry Applications Conference, 39th IAS Annual Meeting, pp. 1755–1759 (2004)

Kumru, C.F., Arikan, O., Kocatepe, C., Kalenderli, O.: Investigation of effect of temperature variation in a high voltage cable on electrical insulation. In: 2013 International Symposium on High Voltage Engineering, pp. 1104–1109 (2013)

Celina, M., Gillen, K.T., Wise, J., Clough, R.L.: Anomalous aging phenomena in a crosslinked polyolefin cable insulation. In: Radiation Physics and Chemistry, pp. 613–626 (1996)

Asipuela, A., Mustafa, E., Afia, R.S.A., Adam, T.Z., Khan, M.Y.A.: Electrical condition monitoring of low voltage nuclear power plant cables: tanδ and capacitance. In: 2018 International Conference on Power Generation Systems and Renewable Energy Technologies (PGSRET), pp. 1–4. IEEE (2019)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Afia, R.S.A., Mustafa, E., Tamus, Z.Á. (2020). Thermal Aging of Photovoltaic Cables Based Cross-Linked Polyolefin (XLPO) Insulation. In: Németh, B. (eds) Proceedings of the 21st International Symposium on High Voltage Engineering. ISH 2019. Lecture Notes in Electrical Engineering, vol 598. Springer, Cham. https://doi.org/10.1007/978-3-030-31676-1_24

Download citation

DOI: https://doi.org/10.1007/978-3-030-31676-1_24

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-31675-4

Online ISBN: 978-3-030-31676-1

eBook Packages: EngineeringEngineering (R0)