Abstract

Application of the computed tomography (CT) within industry has been rising in recent years due to its non-destructive abilities and accuracy. Nevertheless, there are some challenges related to CT scanning, such as presence of artefacts. The aim of this research is to investigate to what extent the application of some advanced algorithms can influence the accuracy of the X-ray CT images. In this paper, after a brief overview of different existing methods used for reduction of different types of artefacts, preliminary research of a new approach for CT image enhancement is presented. It is based on a hybrid methodology using two different methods - Fuzzy Clustering and Region Growing - joined in order to exploit their advantages. Results show that the proposed methodology contributes to CT image enhancement, with borders of segmented objects on CT images more easily extracted.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

High demands in the industry for fast and accurate product measurement is pushing the development of new systems that are used for those purposes. One such system is the X-ray computed tomography (CT) and its use in the industry field, especially for the metrology and manufacturing applications [1]. X-ray CT system, due to its non-destructive abilities and high accuracy, found its place in such high demanding field with its constant development and improvement [2]. However, X-ray CT systems are prone to different types of artefacts [3, 4], due to numerous factors included [5]. But, from the hardware side of X-ray CT, there have been numerous research investigating the possibilities of suppression of these artefacts from the software side as well. Today, software support plays an important role as is provides a qualitative and quantitative side of processing and interpretation of X-ray CT results. This allows an accurate visualization and application of different types of dimensional measurements to be performed. However, one of the biggest challenges that X-ray CT systems are facings are presence of artefacts on the obtained results as they have a big influence on the quality of generated CT data [6]. They present artificial structures that are found in the X-ray CT results and that don’t correspond to the real data [7]. In the field of metrology artefacts can seriously affect, or even prevent acquisition of reliable measurement data. They may appear as variations in shades of gray, or as a deviation in the reconstructed data. The presence of these artefacts can have a great influence the obtained results, i.e. reconstructed 3D models, which can make them unreliable for any further analysis [7].

2 Literature Review

When it comes to application of different methods, in order to deal with artefacts and their influence on the X-ray CT results, there have been many different solutions and research directions. There are numerous factors that influence the CT dimensional measurements such as surface quality, material, acquisition parameters, CT machine setup, etc. [8]. One such parameter is also surface roughness of the material, which is shown to have a strong influence on CT dimensional measurements [6].

In addition to those factors, numerous methods have been developed such as MAR methods (Metal Artefact Reduction), region growing, active contours method and others that reported more or less successful elimination, or at least reduction of negative impacts in order to obtain reliable and accurate measurement results [9, 10]. When it comes to MAR methods, sinogram in-painting technique shows to be one of the preferable techniques used to remove unwanted streaking artefacts caused by metal implants which degrade the image quality. And this technique often consists of interpolating the missing projection data, but the result is often a loss of image quality with additional artefacts in the whole image [11,12,13]. Many authors also investigated and discussed about industrial X-ray CT accuracy [14] and measurement uncertainty [15]. Also projection-based MAR for industrial 3D X-ray computed tomography was investigated [7], as well as scatter correction methods applied in dimensional X-ray CT [8]. For enhancement and development of new methods for surface extraction new methods have also been developed by implementing graph cuts method [16], multi-level Morse complex [17], or 3D Canny algorithm with sub-voxel resolution [18].

Development and application of various methods for analysis and processing of information from CT images is an active research topic for a long period of time. These methods span from different fields and have been used for different purposes [19, 20]. Among these methods are solutions that deal with specific problems related to the removal/reduction of artefacts, or image enhancement. In spite of some of developed approaches of this kind, there is still space for the development of new improved methods related to reducing the impact of artefacts and improving borders extraction on resulting X-ray CT images. Application of artificial intelligence methods (namely fuzzy logic) for analysis and processing of the generated CT image data is applied for a long period of time in different fields [21, 22]. It aims to improve the 2D image by enhancing the object borders and thus eliminate/reduce negative impacts present on image. In addition to fuzzy logic, application of other methods such as region growing, active contours method and others are all used for their application in image processing and handling [23]. Their application has shown to give elimination or at least reduction of negative impacts in order to obtain reliable and accurate measurement results.

3 Research Methodology

3.1 The Nature of the Research

Fuzzy logic, more specifically Fuzzy C-means (FCM) clustering method proved to be a very popular method when it comes to image processing and analysis by many researchers in various fields, because it is not confined to a single area of application. Although, today there are many different solutions and implementations of this method, there is still a room for the improvement connected to application of this method. This also includes its integration and/or combining with other methods in order to develop hybrid approaches with emphasized positive features of single methods.

3.2 Materials

The need for this research is based on a fact that X-ray CT images that are impaired with presence of artefacts and/or the use of inappropriate parameters are present in today’s application of X-ray CT systems. This influences the proper surface extraction and interpretation of results from acquired X-ray CT images. Because of these problems, different methods have been developed that deal with improvement and enhancement of these results, especially those closely related to the field of coordinate metrology and dimensional accuracy. Improvement of processing algorithms for CT image reconstruction, through the integration of FCM and region growing (RG) methods for the purpose of development of a new hybrid approach, has a significant potential. This potential lies in advantages of these methods that can be synergized through their integration, while their disadvantages can be reduced.

3.3 Methods

The main goal of this research is to develop a new method which will feature an improved processing and analysis of generated X-ray CT images, and consequently enable surface reconstruction of dimensionally more accurate surface 3D models. The special focus, during the development of this model, will be on its application on impaired CT images with poorly displayed objects borders on them.

Preliminary research in this area suggests that the development of such model would contribute in improving the quality of boundary extraction by enhancing the contrast (borders) between certain objects present on images. FCM method plays a big role in enhancement of the pixels of interest, while for the segmentation and generation of 2D binary images the RG method is used (Fig. 1). In this way this approach is primarily focusing on the successful extraction of the objects borders on the image, and thus improving accuracy of reconstructed surface 3D models.

The experimental data was acquired using an industrial X-ray CT system NIKON XT H 225 located at University of Zagreb, Faculty of Mechanical Engineering and Naval Architecture in Zagreb, Croatia (Fig. 2).

4 Results and Discussions

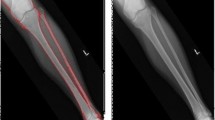

Multi-material components (MMCs) are usually parts which are manufactured from several different materials, for example, polymers and metal components, or composite materials with some metal components present. One of the factors which severely limit the application of CT system for the surface reconstruction and analysis of these components is the presence of artefacts. In order to investigate the present implementation of the above algorithm, X-ray CT dataset was obtained by an industrial X-ray CT system with which an MMC part was scanned - a steel hex screw mounted in a plastic housing.

MMC components are a particularly interesting case for research due to the presence of different materials with different densities. However, different thicknesses of materials, and above all, different structure and density of the material lead to a larger or smaller absorption of the X-rays. As such, it strongly influences proper edge detection, resulting with presence of artefacts. These obtained images are not adequate for further analysis and data extraction (surface 3D model) due to poor pixel intensity that influence the visibility of an object on the CT images. Therefore, any subsequent analysis and diagnosis may become invalid in terms of dimensional analysis. In order to achieve improvement of these results, the application of the proposed hybrid model provides adequate processing, extraction and displays real structure of the 3D model from X-ray CT data. A single image containing M8 steel hex screw mounted inside a plastic housing was used for analysis of the proposed algorithm, and it is shown on Fig. 3.

Steel is a material that has a high density and, within MMC, it can present a problem for the X-ray CT systems due to its higher density and the need for greater penetrating power of the X-rays, while the surrounding plastic has a much lower density.

The first step in this approach is the application of FCM method in order to adequately enhance the contrast of the border between the object of interest (hex screw) and the background (plastic housing). The input parameters which are used for FCM method are number of clusters C and the membership degree (i.e. fuzzification) m. After that, the RG method is used for boundary detection of object present on X-ray CT image (Fig. 4a, b and c).

In order to perform image analysis, and show influence of application of FCM method, two 2D profile lines on two images were compared (original image and image processed by FCM) in order to determine the differences between them. This 2D profile on the image is drawn along the arbitrary path and is consisting of the segments of the predefined path of the line. Each segment of the line profile is calculated by the number of points (profile points) which correspond to the pixels density of the image.

Profile is calculated along the path of the 2D line (Fig. 5a). This 2D line calculates the pixels intensity along the defined path. It can be observed that there is a normalization of the pixel intensity, as well as an increase in their contrast which is enhanced by applying FCM method. From the graph in Fig. 5b it can also be seen that higher values of contrast have a positive effect on the enhanced visibility, which contributes to an easier and better segmentation using RG method.

Figure 6a and b shows the segmentation before and after implementation of the RG method.

On the basis of the above-described results of preliminary analysis of the hybrid method which combines FCM and RG methods, it is shown that it shows good results that requires further investigations.

5 Conclusions

The research presented in this paper aims at development of a new methodology to improve the segmentation and analysis of X-ray CT images in the area of industrial metrology. By combining various concepts and methods from the field of visual computer techniques, the additional information is obtained, where the use of these methods aids in accurate reconstruction of objects boundaries. Presented results of preliminary analysis of the proposed hybrid methodology, which combines fuzzy clustering with region growing methods, are very promising and present a good foundation for further investigations.

References

Durakbasa, N.M., Bauer, J.M., Bas, G., Kräuter, L.: Towards a sophisticated approach to cost oriented automation and intelligent metrology in the advanced manufacturing. IFAC-PapersOnLine 51(30), 54–59 (2018)

Akdogan, A., Vanli, S., Durakbasa, N.: Re-engineering of manufacturing parts by computed tomography data. In: Proceedings of the 12th International Conference on Measurement and Quality Control - Cyber Physical Issue IMEKO TC 14 2019, pp. 114–121 (2019)

ISO 15708-1:2017: Non-destructive testing – radiation methods for computed tomography – Part 1: Terminology (2018)

ISO 15708-2:2017: Non-destructive testing – radiation methods for computed tomography – Part 2: Principles, equipment and samples (2018)

Townsend, A., Pagani, L., Blunt, L., Scott, P.J., Jiang, X.: Factors affecting the accuracy of areal surface texture data extraction from X-ray CT. CIRP Ann. Manuf. Technol. 66(1), 547–550 (2017)

Aloisi, V., Carmignato, S.: Influence of surface roughness on X-ray computed tomography dimensional measurements of additive manufactured parts. Case Stud. Nondestruct. Test. Eval. 6, 104–110 (2016)

Amirkhanov, C., Heinzl, M., Reiter, J., Kastner, M.E.: Gröller: Projection-based metal-artifact reduction for industrial 3D X-ray computed tomography. IEEE Trans. Vis. Comput. Graph. 17(12), 2193–2202 (2011)

Baer, M., Hammer, M., Knaup, M., Schmidt, I.: Scatter correction methods in dimensional CT. iCT 14(1), 41–46 (2012)

Krumm, M., Kasperl, S., Franz, M.: Reducing non-linear artifacts of multi-material objects in industrial 3D computed tomography. NDT E Int. 41(4), 242–251 (2008)

Bartscher, M., Hilpert, U., Goebbels, J., Weidemann, G.: Enhancement and proof of accuracy of industrial computed tomography (CT) measurements. CIRP Ann. Manuf. Technol. 56(1), 495–498 (2007)

Boas, F.E., Fleischmann, D.: CT artifacts: causes and reduction techniques. Imaging Med. 4(2), 229–240 (2012)

Chen, Y., Li, Y., Guo, H., Hu, Y., Luo, L., Yin, X., Gu, J., Toumoulin, C.: CT metal artifact reduction method based on improved image segmentation and sinogram in-painting. Math. Probl. Eng. 2012, 1–19 (2012)

Heinzl, C., Kastner, J., Georgi, B., Lettenbauer, H.: Comparison of surface detection methods to evaluate cone beam computed tomography data for three dimensional metrology. In: International Symposium on Digital industrial Radiology and Computed Tomography (DIR 2007), Lyon, pp. 21–29 (2007)

Dewulf, W., Kiekens, K., Tan, Y., Welkenhuyzen, F., Kruth, J.: Uncertainty determination and quantification for dimensional measurements with industrial computed tomography. CIRP Ann. Manuf. Technol. 62(1), 535–538 (2013)

Gayou, O.: Influence of acquisition parameters on MV-CBCT image quality. J. Appl. Clin. Med. Phys. 13(1), 1–12 (2012)

Haitham Shammaa, M., Ohtake, Y., Suzuki, H.: Segmentation of multi-material CT data of mechanical parts for extracting boundary surfaces. Comput. Aided Des. 42(2), 118–128 (2010)

Nagai, Y., Ohtake, Y., Suzuki, H.: SegMo: CT volume segmentation using a multi-level Morse complex. Comput. Aided Des. 107, 23–36 (2019)

Yagüe-Fabra, J.A., Ontiveros, S., Jiménez, R., Chitchian, S., Tosello, G., Carmignato, S.: A 3D edge detection technique for surface extraction in computed tomography for dimensional metrology applications. CIRP Ann. Manuf. Technol. 62(1), 531–534 (2013)

Budak, I., Mirkovic, S., Sokac, M., Santosi, Z., Puskar, T., Vukelic, D.: An approach to modelling of personalized bone grafts based on advanced technologies. Int. J. Simul. Model. 15(4), 637–648 (2016)

Drégelyi-Kiss, Á., Durakbasa, N.M.: Measurement error on the reconstruction step in case of industrial computed tomograph. In: Proceedings of the International Symposium for Production Research 2018, Vienna, pp. 309–323 (2018)

Heil, U., Gross, D., Schulze, R., Schwanecke, U., Schomer, E.: Metal artifact reduction in x-ray computed tomography: inpainting versus missing value. In: IEEE Nuclear Science Symposium and Medical Imaging Conference, Sidney, pp. 2675–2677 (2011)

Hiller, J., Hornberger, P.: Measurement accuracy in X-ray computed tomography metrology: Toward a systematic analysis of interference effects in tomographic imaging. Precis. Eng. 45, 18–32 (2016)

Jiménez, R., Comps, C., Yagüe, J.A.: An optimized segmentation algorithm for the surface extraction in computed tomography for metrology applications. Procedia Eng. 132, 804–810 (2015)

Acknowledgements

This paper presents the results achieved in the framework of the Project no. 114-451-2723/2016-03 funded by the Provincial Secretariat for Higher Education and Scientific Research, and within the project TR - 35020, funded by the Ministry of Education, Science and Technological Development of Republic of Serbia. Project IKARUS supported parts of presented research (European Regional Development Fund, MIS: RC.2.2.08-0042, Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Sokac, M., Santosi, Z., Vukelic, D., Katic, M., Durakbasa, M.N., Budak, I. (2020). Enhancement of Images from Industrial X-Ray Computed Tomography Systems by Hybrid Approach. In: Durakbasa, N., Gençyılmaz, M. (eds) Proceedings of the International Symposium for Production Research 2019. ISPR ISPR 2019 2019. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-31343-2_12

Download citation

DOI: https://doi.org/10.1007/978-3-030-31343-2_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-31342-5

Online ISBN: 978-3-030-31343-2

eBook Packages: EngineeringEngineering (R0)