Abstract

The biomechanical characterization of Urinary Bladder is essential to create new therapeutic tools as artificial tissue replacement or electrical stimulators. In this paper, we applied a linear model, the so-called viscoelastic Voigt’s model to calculate the viscosity and elasticity in three regions of a bladder under the experimental condition of tensile stresses. Additionally, we acquired the tridimensional surface of urinary bladders by a cloud of points that were processed in digital format. Viscosity and elasticity are represented on the surface reconstruction. Three bovine bladders were processed with an average sample viscosity of 89.33 × 10−6 Ns/mm2 and average elasticity of 1.3 × 10−3 N/mm, the isotropic condition was evaluated. The digital representation includes a cloud of points of 9 × 106 elements on average. These results are the base of a future computational simulation platform.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Urinary bladder (UB) is a hollow organ which stores urine (up to 400 mL), UB can keep pressure nearly constant due to the stress relaxation property of its wall [1]. The stress urinary incontinence (SUI) is a problem that affects the adult population. The involuntary loss of urine during coughing or physical activity is caused by weak pelvic floor or urethral sphincter. Developing new therapies requires the knowledge of mechanical properties of UB, for instance, the use of implantable electronic stimulators and the use of engineered tissue for substitution [2]. For this reason, it is necessary to develop methods for the calculation of biomechanical parameters of the tissue, that allows us to understand its behavior under mechanical stress condition. We propose a method to derive the biomechanical parameters of elasticity and viscosity for UB tissue under tensile conditions, considering a linear dynamic Voigt’s model [3], this information is associated to the digital representation of the UB surface. The process includes the sample preparation, the standardization of the capture routine, and the mechanical test conditions.

2 Methodology

2.1 Cloud of Points Acquisition of UB Surface

The experiments were run, using three male bovine bladders from an abattoir within less than two hours of slaughtering the animal. Bladders were frozen for transportation at –2 °C. The defrosting occurred at room temperature for two hours. For each of the three experiments the bladder cleans and fills up with water up to maximum volume, then empties to distend. Connective tissue and adipose tissue were removed from the outer surface of UB. Bladder was continuously hydrated with saline solution at 0.9%. The organ is allocated over a solid three-dimensional base structure that emulates the anatomy of UB, such structure was designed and printed with Polylactic Acid (PLA). Marker points were added to the outer surface of the UB, two points on each region, separated 1 cm, to identify the part used for the tensile test. The point cloud of the bladder’s surface was obtained using a 3D scanner EinScan-SE from SHINING 3D and the software EinScan-S series v2_7.0.6 installed in a Laptop with a RAM of 16 GB, i7 processor, graphic memory 4 GB NVIDIA with a spatial resolution of 0.2 mm. The cloud of points filled with a triangular mesh geometry. The mesh was configured with high resolution (0.17 mm) and sharpen texture, filled and saved as a 3D object.

2.2 Mechanical Characterization of the Tissue

We dissect the UB sample considering the methodology described in [1]. UB is divided in three parts: superior, middle and inferior, see Fig. 1a. We designed a template (Fig. 1b) to achieve size standardization of every sample cut from the UB with measures (test area of 150 mm2 and a grip zone of 352.5 mm2). The UB muscular tissue was dissected by placing the printed template (3D printed) over the tissue and cutting around it. Thickness of each sample is registered. The stress-strain testing involved a 200 N loads using a stress machine Univert by Cellscale TM, data acquisition occurred at a period of 1 ms. Stress-strain curves were obtained using Microsoft Excel and Mathworks Matlab a2017.

Mechanical Model and Parameter Identification.

Voigt’s model was used for the characterization of the UB mechanical parameters [3], with a viscosity parameter (η), parallel to an elastic component (E). The strain (ε) is considered the same for both elements and the total stress (σ) is the summation of independent stresses for each component Eq. (1). The transfer function of the differential equation is considered for the parametric identification Eq. (2), the data of stress and strain from the tensile test was used in the Identification System toolbox of Matlab for this purpose.

3 Results and Analysis

The surface reconstruction process is shown in Fig. 2. Figure 2a shows the UB before of the cleaning and distension process. The samples had an average maximum volume of 300 ml. Figure 2b shows the cleaned sample during the scanning, UB is allocated over a printed base of 200 ml capacity. Meshing the sample resulted in the reconstructed surface shown in Fig. 2c. We compare the measures from the digital representation with the real sample to assess if the reconstruction was accurate. Size of this UB resulted in 74.5 × 126.32 × 78.65 mm.

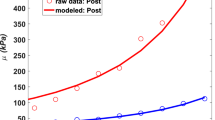

After the scanning process, the samples for tensile testing were dissected as is shown in Fig. 1(a), one sample for each section of the bladder: upper, middle and the lower region are obtained, Fig. 1a. In Fig. 1b the printed template to cut the samples is showed, as well as the samples for each region. Figure 1c shows the tensile test experimental setup. To calculate the stress, the thickness is measured in order to calculate the cross-sectional area. This area has a value of 45.835 mm2 on average. In Fig. 3 an example of the obtained stress-strain graphics is presented, as can be seen the tissue sample endured a maximum force of approximately 0.077 N/mm2 with a displacement of 43 mm. After this point, the sample breaks, which is observed in Fig. 3 when the stress falls.

Stress and Strain time series were used by the system identification toolbox, we obtained elasticity (E) and the damping constant (η). We obtained that the lower region has the most elastic tissue (1.76 × 10−3 N/mm) of the three regions and the upper the most viscous one with 2 × 10−4 Ns/mm2, similar results have been found by other authors [4, 5], but with different magnitudes due to the use of porcine bladder instead of bovine. The average values of the samples resulted in 1.3 × 10−3 N/mm for the elastic constant and 89.33 × 10−6 Ns/mm2 for the viscos constant.

4 Conclusions

A cloud point of the surface bovine UB was obtained using tridimensional scanning, it was possible to reconstruct the UB surface. The viscosity and elasticity parameters were characterized for tissue samples of bladder, using a linear dynamic mechanical model; the lower region had the most elastic tissue, and the upper region the most viscous, under isotropic conditions. A current research is carried out considering the anisotropy of the tissue and, frequency response.

References

Jokandan, M.S.: Bladder wall biomechanics: a comprehensive study on fresh porcine urinary bladder. J. Mech. Behav. Biomed. Mater. 79, 92–103 (2018)

Ouyang, Z., Sperry, Z.J., Barrera, N.D., Bruns, T.M.: Real-time bladder pressure estimation for closed-loop control in a detrusor overactivity model. IEEE Trans. Neural Syst. Rehabil. Eng. 27(6), 1209–1216 (2019)

Park, J., Lakes, R.S.: Biomaterials: An Introduction, 3rd edn. Springer, New York (2007)

Morales-Orcajo, E., Siebert, T., Böl, M.: Location-dependent correlation between tissue structure and the mechanical behaviour of the urinary bladder. Acta Biomater. 75, 263–278 (2018)

Barnes, S.C., Shepherd, D.E.T., Espino, D.M., Bryan, R.T.: Frequency dependent viscoelastic properties of porcine bladder. J. Mech. Behav. Biomed. Mater. 42, 168–176 (2015)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Guzman-Diaz, K., Alvarado-Gonzalez, A., Herrera, D., Hernandez-Reynoso, A., Rodríguez-Reynoso, S., Garcia-Gonzalez, A. (2020). Surface Representation of the Urinary Bladder and Bio-mechanical Analysis by Linear Dynamic Model. In: González Díaz, C., et al. VIII Latin American Conference on Biomedical Engineering and XLII National Conference on Biomedical Engineering. CLAIB 2019. IFMBE Proceedings, vol 75. Springer, Cham. https://doi.org/10.1007/978-3-030-30648-9_122

Download citation

DOI: https://doi.org/10.1007/978-3-030-30648-9_122

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-30647-2

Online ISBN: 978-3-030-30648-9

eBook Packages: EngineeringEngineering (R0)