Abstract

An accurate calibration of a constitutive model for finite element analysis is as important as an adequate choice of the constitutive model itself. The calibration strategy and the experimental database have determinant roles for the success of this stage. Over recent years, the increasing use of full-field measurement techniques has changed significantly the amount of data that compose the experimental database and suppressed some of the design constraints of the mechanical tests. These techniques enable to capture complete displacement/strain fields during a mechanical test, a feature that has been conveniently used to explore heterogeneous mechanical tests. The use of full-field measurements and heterogeneous tests has proven to be an interesting approach to calibrate complex models with a high number of material parameters, such as the case of anisotropic plasticity models. Usually, the inverse strategies selected to identify the material parameters from heterogeneous fields are based on the so-called finite element model updating (FEMU) method, which is known for being computationally demanding. Nevertheless, novel inverse strategies, such as the virtual fields method, have demonstrated much better results in terms of the computational cost without deterioration of the calibration results. Therefore, the aim of the present study, in the framework of full-field measurements, is to explore the combination of a previously designed heterogeneous test and the virtual fields method (VFM). The heterogeneous test consists of a uniaxial standard test with an optimized specimen shape, called butterfly shape. This specimen was specifically designed to obtain a wide range of strain paths and strain amplitudes and has given promising results when combined with a FEMU-based strategy. A set of virtual fields is developed to combine the butterfly test and the VFM. This set is tested with virtual experimental data generated and the sensitivity of the VFM to the number of virtual fields is confirmed. Moreover, experimentally acquired full-field measurements of butterfly test for a DC04 mild steel are used to assess the performance of this calibration strategy. An anisotropic plasticity model composed by Hill’48 and Swift’s law is calibrated.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Calibration of constitutive models

- Anisotropic metal plasticity

- Heterogeneous test

- Full-field measurements

- Virtual fields method

Introduction

The use of numerical simulation tools to support the mechanical design of a manufacturing process or a part has long been employed by the industry. The demands for better accuracy of these tools led to the development of more and more complex constitutive models to mimic the real mechanical behaviour of materials. Nevertheless, before using any of these models, a calibration phase is required, in which the material parameters of the model are adjusted to have a close prediction of the material in hands. The predictive capabilities of constitutive models largely depend on this phase. Moreover, the applicability of the models is also dependent on the experimental effort required for this phase. Frequently, the need for a large and diversified set of experimental tests to calibrate a constitutive model restrains the use of more advanced and accurate constitutive models [1].

The advent of full-field measurement techniques (e.g. Digital Image Correlation, DIC in short [2]) is changing significantly the calibration process of constitutive models. These techniques allow access to dense maps of data (displacements, strains, etc.) from a single mechanical test, which after post-treatment can be used to retrieve the material parameters of a selected constitutive model. Moreover, these techniques enable the use of complex sample geometries to test the mechanical behaviour of materials, which, if correctly designed, produce heterogeneous strain fields with enough information to extract several material parameters from a single test. However, to extract the material parameters from this type of data, it is required to solve an inverse problem that is time-consuming. Therefore, the quest for both efficient inverse methods and appropriate test geometries has been intense in the past few years. Nevertheless, inverse methods and new test geometries for mechanical testing are usually developed and validated separately and consequently, the symbiosis between these two is not fully explored.

In this work, a heterogeneous test specially optimized to calibrate constitutive models [3, 4] for sheet metal plasticity is combined with the Virtual Fields method (VFM) [5]. This heterogenous test, called butterfly test, is firstly presented as well as the experimental data previously acquired for a DC04 mild steel [4]. This study focuses on the selection of a set of virtual fields suitable for the above-mentioned test, as well as the influence of the number of virtual fields used. Finally, the performance of the VFM combined with the data acquired from a single butterfly test is assessed. An anisotropic model composed by Hill’48 yield criterion and Swift’s hardening law is selected to be calibrated.

The Virtual Fields Method

The virtual fields method is an inverse method which relies on the principle of virtual work and kinematic full-field measurements to retrieve constitutive material parameters. Due to the nature of the principle of virtual work, this method can be applied to any constitutive model. In the case of non-linear models, such as elasto-plastic models, the inverse problem is solved by minimizing the squared difference of the gap between internal and external virtual work, with respect to the sought constitutive parameters and for different time steps. The objective function, in the large strain framework and assuming static equilibrium, can be written as:

where P is the first Piola-Kirchhoff stress tensor that is a function of the constitutive parameters ξ and the experimental strain field εexp. \( \overline{\mathbf{T}} \) is the first Piola-Kirchhoff stress vector calculated on the boundary \( {\Gamma}_0^{\mathrm{f}} \) where surface forces are applied. U∗ can be any kinematically admissible virtual field and GradU∗ is the respective gradient calculated with respect to the reference coordinates of the body. dV and dS are the infinitesimal volume and area of the body in the reference configuration Ω0. nv and nt are the number of virtual fields selected and time steps considered, respectively. This large strain formulation is a convenient description to write the principle of virtual work, since for the computation of the internal and external work the geometric quantities are defined on the reference configuration. More details on this formulation can be found in [6].

One of the key parts of this method are the virtual fields selected to build the objective function, which can be any continuous and differentiable function. Nevertheless, these functions are usually selected from a set of kinematically admissible functions, i.e. it is required that the virtual fields vanish on the boundaries of prescribed displacement. In this work, the virtual fields are developed manually, which is addressed in the section Manually Defined Virtual Fields. The other key part of this method is the reconstruction of the stress field from the strain field εexp, which is derived from the measured displacement field. Usually, the displacement field is acquired on the surface of the specimen and, therefore, to reconstruct the stress field, the plane stress conditions are assumed. Moreover, to reconstruct the stress field, it is necessary to adopt a priori a constitutive model to make the link between strains and stresses. In this work, the adopted constitutive model is defined by: (1) linear isotropic elastic behavior (generalized Hooke’s law) and; (2) plastic behaviour described by the orthotropic Hill’48 yield criterion and isotropic hardening (Swift’s law). The calibration of the plastic part of the model is the focus of the present work, whereas the material parameters that govern elastic part are assumed to be known. Regarding the plastic behaviour, the equivalent Hill’48 yield criterion assumes the following form in plane stress conditions:

where σxx, σyy and σxy are the components of the stress tensor with respect to the anisotropic material axes. F, G, H and N are the constitutive parameters that must be calibrated. Nevertheless, the relation G + H = 1 is assumed which leaves only F, G and N to be identified. The isotropic hardening law (Swift’s law) has the following form:

where σ0, K and n are the material parameters. \( {\overline{\varepsilon}}^{\mathrm{p}} \) is the equivalent plastic strain. Thus, the adopted model contains 6 material parameters which must be identified according to the studied material.

The methodology presented in this section was implemented in an in-house code using the programming language Fortran. This code contains bilinear shape functions to derive the strain field from the measured displacement field. Due to the non-linearity of the model, the stress reconstruction is performed using an algorithm of the type Backward-Euler return [7]. The minimization of the objective function is conducted by the gradient-based Levenberg-Marquardt optimization method.

The Butterfly Test

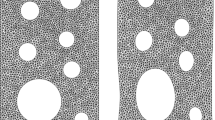

The butterfly test was first proposed by Souto et al. [3]. The geometry of the specimen was numerically designed through a shape optimization procedure which aimed a heterogeneous test to calibrate complex constitutive models for sheet metals. The optimization process was governed by an objective function that rated the information provided by the test in terms of range and diversity of strain states and strain level reached. The final geometry was able to produce a spectrum of strain states ranging from simple shear to plane strain. More recently, this final geometry was adapted by Aquino et al. [4] to facilitate the cutting process of the specimen. This adapted specimen was experimentally validated using special grips (Fig. 5.1a), and an attempt to calibrate a complex anisotropic constitutive model was performed through the inverse method FEMU. The specimen was obtained from 0.7 mm thick sheet metal of a DC04 mild steel. The tests were performed on a common tensile machine. The DIC-system employed to carried out the measurements was the ARAMIS 3D 5M system developed by GOM. Figure 5.1b shows the strain distribution in the principal strain space for a displacement of the tool equal to 7.1 mm. As can be seen, the adapted geometry produces a range of strains from simple shear to plane strain.

In this work, the same experimental data used by Aquino et al. [4] is adopted. The displacement fields acquired for the specimen with the rolling direction orientated along the traction axis are used. These displacements fields are projected onto a 2D mesh generated by the Abaqus software (Fig. 5.2a) that represents one-fourth of specimen, in order to be processed by the VFM. A total of 398 steps from the load/displacement history of the grip are considered (Fig. 5.2b). Only the load history between the two red dots is considered, because most of the points in the early stages of the test have a low value of strain and were highly affected by noise. Yet, larger load histories were analysed, and the results were not significantly affected.

Manually Defined Virtual Fields

In non-linear cases, the VFM relies on the minimization of Eq. (5.1) to retrieve the constitutive parameters. As mentioned before, the virtual fields selected to build the objective function have a fundamental role in the results of the identification. Currently, there are three main approaches to select a suitable set of virtual fields, two of them rely on automatic procedures to select the virtual fields and require a low-level of user’s intervention [6, 8]. The other approach, called manually defined virtual fields, depends exclusively on the user’s intervention, since it is the user that must develop the suitable set according to the boundary conditions of the test. This last strategy has been the most used and its main advantages are the computational cost and the ease of implementation. For these reasons, this is the strategy adopted in the present work.

Generally, the manually defined virtual fields are developed using polynomial and/or periodic functions. These functions are manipulated to generate kinematically admissible virtual fields [5]. In terms of objective function, the components of the virtual field gradient can be seen as weights for the components of the stress tensor. Specially in anisotropic plasticity, all the components of the stress tensor contain information about the yield criterion, hence must be considered within the identification process. Based on these considerations, a set of 8 virtual fields is developed and the influence of the number of virtual fields on the identification results is assessed. The developed virtual fields can be written as:

where W and L are the maximum value of the width and length of the zone of interest (ZOI) of the specimen surface in the reference configuration (see Fig. 5.2a). X and Y are the coordinates in the reference configuration. In case of static equilibrium, the first virtual field is the only one that gives a non-zero value of internal virtual work, which should be balanced with the external virtual work. It also gives maximum weight to the normal component of the stress tensor in the y-direction and neglects the remaining components. The other virtual fields distribute the weight between two components, normal and shear components.

In order to assess the influence of the number of virtual fields in the identification process, virtual experimental data generated by finite element (FE) analysis is used. A two-dimensional FE model representing one-fourth of the butterfly test is built assuming plane stress conditions. A displacement of 1.5 mm is prescribed to a rigid tool, which is modelled assuming tie contact with the irregular boundary on top of the specimen (see Fig. 5.2a). A reference set of material parameters representing a mild steel is adopted and its values are listed in Table 5.1. The test is simulated in Abaqus standard software and the displacement field of a total of 375 load steps is retrieved to build the objective function (Eq. (5.1)).

A total of 8 identifications with an increasing number of virtual fields are performed. The presented virtual fields are added to the objective function in order to enrich the identification process. The results are presented in Fig. 5.3, in which the value of the optimized parameter is normalised by the respective reference value. The results show that for one virtual field (Eq. (5.4)) the errors are the highest, particularly for the yield criterion parameters. Nevertheless, the results are significantly improved when the second virtual field (Eq. (5.5)) is added and tend to stabilize for 5 virtual fields. For a total of 8 virtual fields, the maximum error attained is lower than 1.5% and corresponds to the parameter n.

This confirms that the number of virtual fields plays an important role in the accuracy of the VFM. Moreover, the set of the developed virtual fields is able to retrieve simultaneously the hardening law and yield criterion parameters using a single virtual butterfly test. This also demonstrates that the butterfly test provides a heterogenous strain field that contains enough information to identify the present model.

Identification of Material Parameters: Results and Analysis

In this section, it is assessed the performance of the VFM combined with the experimental database acquired from the butterfly test to calibrate the constitutive model composed by Hill’48 yield criterion and Swift’s hardening law. According to the results of the previous section, the 8 virtual fields presented are used to build the objective function. Moreover, since the optimization method is a gradient-based, the sensitivity to the initial set of parameters given to start the optimization process is also assessed. The initial sets are arbitrarily chosen.

The obtained set of parameters is presented in Table 5.2. Regardless of the initial set of parameters, the results converged always for the same solution set shown in Table 5.2. Moreover, Table 5.2 also shows the yield stress values and plastic anisotropic parameters calculated based on the retrieved parameters. The plastic anisotropic coefficient at 0 degrees (rolling direction) presents a value characteristic of mild steel [9], whereas the other two coefficients present values lower than the characteristic ones of this material.

The evolution of the internal virtual work calculated using the parameters of Table 5.2 and the first virtual field (Eq. (5.4)), and the evolution of the external virtual work calculated based on the measured load are presented in Fig. 5.4a. The evolutions of the internal and external virtual works show a good agreement. Nevertheless, the internal virtual work evolution suffers from minor oscillations, which can result from the presence of noise in the full-field measurements.

In order to check the validity of the retrieved parameters, the butterfly test is simulated with a two-dimensional FE model assuming plane stress conditions and using the retrieved parameters. The results of the force evolution for the FE model are compared with the measured load in Fig. 5.4b. Note that the results are plotted for the displacement of point A (see Fig. 5.4b), in order to minimise the impact of a possible sliding under the grips. Figure 5.4b shows a good agreement between the two load curves and a slight overestimation of the displacement at the end of the test. These results confirm that the material behaviour for the rolling direction is well captured by the constitutive model and its retrieved material parameters.

Conclusions

The present work is a first attempt to link an optimized heterogenous mechanical test with VFM. The aim is to propose a strategy to identify all the parameters of an anisotropic constitutive model using a single test. A set of manually defined virtual fields to link the VFM and the butterfly test is proposed. This set is analysed using virtual experimental data, generated according to the adopted constitutive model. The analysis shows the dependence of the VFM on the number of virtual fields used to build the objective function. In this specific case, for a number superior to 5 virtual fields, there is a reasonable error (maximum error lower than 1.5%) in the identification results. Finally, the constitutive model composed by Hill’48 yield criterion and Swift’s hardening law is calibrated using experimental data from a single test on a mild steel. The results revealed insensitivity of the VFM to the initial set of parameters used to start the identification process. Regarding the retrieved parameters, its performance is assessed through the predicted anisotropic plastic coefficients and FE analysis of the test. The predicted anisotropic plastic coefficient for the rolling direction is characteristic of mild steel, but the remaining coefficients suggest that the model was unable to predict them. The FE analysis of the test with the retrieved material parameters confirm this conclusion. The load curve predicted by the FE model shows a good agreement with the experimentally measured load, meaning that the overall behaviour of the material for the rolling direction was well captured. Nevertheless, a thorough study on the influence of the DIC parameters on the acquired data from the butterfly test should be performed.

References

S. Bruschi, T. Altan, D. Banabic, et al., Testing and modelling of material behaviour and formability in sheet metal forming. CIRP Ann. Manuf. Technol. 63, 727–749 (2014)

M.A. Sutton, J.-J. Orteu, H. Schreier, Image Correlation for Shape, Motion and Deformation Measurements (Springer, Boston, 2009)

N. Souto, A. Andrade-Campos, S. Thuillier, Mechanical design of a heterogeneous test for parameters identification. Int. J. Mater. Form. 10(3), 353–367 (2017)

J. Aquino, A. Andrade-Campos, S. Thuillier, Design of heterogeneous mechanical tests – numerical methodology and experimental validation. Strain 55, e12313 (2019)

F. Pierron, M. Grédiac, The Virtual Fields Method: Extracting Constitutive Mechanical Parameters from Full-Field Deformation Measurements (Springer, New York, 2012)

A. Marek, F.M. Davis, M. Rossi, F. Pierron, Extension of the sensitivity-based virtual fields to large deformation anisotropic plasticity. Int. J. Mater. Form. 12, 457–476 (2019)

M. Crisfield, Non-Linear Finite Element Analysis of Solids and Structures, vol 1 (Wiley, Chichester, 1991)

F. Pierron, S. Avril, V.T. Tran, Extension of the virtual fields method to elasto-plastic material identification with cyclic loads and kinematic hardening. Int. J. Solids Struct. 47(22), 2993–3010 (2010)

S.L. Zang, S. Thuillier, A. Le Port, P.Y. Manach, Prediction of anisotropy and hardening for metallic sheets in tension, simple shear and biaxial tension. Int. J. Mech. Sci. 53, 338–347 (2011)

Acknowledgements

The authors acknowledge the financial support of FCT under the projects PTDC/EME-APL/29713/2017 (CENTRO-01-0145-FEDER-029713), PTDC/EMS-TEC/6400/2014 (POCI-01-0145-FEDER-016876), PTDC/EME-EME/31243/2017 (POCI-01-0145-FEDER-031243) and PTDC/EME-EME/30592/2017 (POCI-01-0145-FEDER-030592) by UE/FEDER through the programs CENTRO 2020 and COMPETE 2020, and UID/EMS/00481/2013-FCT under CENTRO-01-0145-FEDER-022083. The authors also would like to acknowledge the Région Bretagne (France) for its financial support. J.M.P. Martins is also grateful to the FCT for the PhD grant SFRH/BD/117432/2016.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Society for Experimental Mechanics, Inc.

About this paper

Cite this paper

Martins, J.M.P., Thuillier, S., Andrade-Campos, A. (2020). Calibration of Anisotropic Plasticity Models with an Optimized Heterogeneous Test and the Virtual Fields Method. In: Baldi, A., Kramer, S., Pierron, F., Considine, J., Bossuyt, S., Hoefnagels, J. (eds) Residual Stress, Thermomechanics & Infrared Imaging and Inverse Problems, Volume 6. Conference Proceedings of the Society for Experimental Mechanics Series. Springer, Cham. https://doi.org/10.1007/978-3-030-30098-2_5

Download citation

DOI: https://doi.org/10.1007/978-3-030-30098-2_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-30097-5

Online ISBN: 978-3-030-30098-2

eBook Packages: EngineeringEngineering (R0)