Abstract

Tribology, or friction, lubrication, and wear behaviors between sliding countersurfaces, is a subset of rheology. The current consensus is that tribological behaviors of foods may be linked to friction-related food textural attributes. Because friction-related behaviors cannot be determined by traditional rheometry, tribological data may better correlate to friction-related textural attributes than rheological data (Malone ME, Appelqvist IAM, Norton IT, Food Hydrocoll 17:763–773, 2003a; Prakash S, Tan DDY, Chen J, Food Res Int 54:1627–1635, 2013). Indeed, semisolid foods are palated during consumption, and the motions of the oral surfaces during palating involve one surface sliding against another, generating friction-related sensations. However, textural attributes involve complex, temporal sensations (Prakash S, Tan DDY, Chen J Food Res Int 54:1627–1635, 2013; Hutchings JB, Lillford PJ, J Texture Stud 19:103–115, 1988; Lenfant F, Loret C, Pineau N, Hartmann C, Martin N, Appetite 52:659–667, 2009), making universal relationships between semisolid food tribological behaviors and sensory attributes difficult to determine. Furthermore, it can also be challenging to isolate the contribution of a single food component to semisolid food friction behaviors, particularly if the friction behaviors of the food change under oral conditions (e.g. the presence of saliva). While several basic relationships have been established, such as a direct relationship between sensory astringency from tannins and friction coefficient in the presence of saliva, much work is needed to fully understand the universal relationships among semisolid food composition and structure, instrumental friction measurements, and textural attributes.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Tribology Basics

Tribology comprises the study of friction, lubrication, and wear behaviors between two sliding surfaces. In the engineering, material science, and medical fields, tribometry has been used since the middle of the twentieth century to evaluate performance and lifetime of bearing surfaces, coatings, and lubricants. However, tribological analysis of semisolid and fluid food products has only recently been shown significant attention, gaining traction in the first decade of the twenty-first century and becoming increasingly popular since. The current goal of food tribological measurements is to uncover key factors impacting food texture that cannot be measured by traditional rheometry. This can allow better prediction of food texture through instrumental analysis. Unfortunately, tribological behaviors are sensitive to many parameters and tribological testing adopted from other fields for use with foods may hinge on assumptions that are violated in a food tribological system. A sound understanding of basic tribological principles and careful control of the tribological system is needed for accurate, repeatable food friction measurements.

1.1 Lubricated Sliding

1.1.1 Friction Coefficient

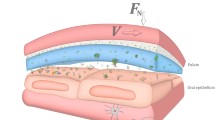

The primary focus of tribological studies of semisolid foods is their friction and lubrication behaviors. When two hard surfaces slide against each other in relative motion, friction is the force that opposes sliding motion (Fig. 1). The amount of friction force between the two surfaces can be described by Eq. 1:

Here, μ is friction coefficient (unitless), FF is friction force (N), and FN is applied normal load (N). While friction force is typically measured directly by the testing apparatus, it is a function of the sliding surface material and physicochemical properties, as well as any lubricant used between the sliding surfaces and the environmental conditions during the test (e.g. temperature, humidity). In semisolid food tribological testing, the food product acts as a lubricant between the two sliding surfaces. Under these conditions, Eq. 1 can be used to calculate the friction coefficient of the food under the testing conditions.

Because friction is a system property, food friction coefficients are highly dependent on the testing apparatus and environment. This will be further discussed in later sections.

1.1.2 Stribeck Curve

The Stribeck curve , which is a plot of friction coefficient versus sliding speed, was developed primarily for measuring performance of Newtonian lubricants on hard sliding surfaces (Joyner (Melito) et al. 2014a, b). Under these conditions, friction between the two sliding surfaces is classified in one of three regimes: boundary, mixed, and hydrodynamic (Fig. 2) (Prakash et al. 2013; Stokes 2012; Greene et al. 2013). In the boundary regime, which occurs at low sliding speeds, the asperities in the sliding surface have significant contact and bear most of the applied normal load, resulting in incomplete separation of the sliding surfaces and a relatively high, constant friction coefficient. Here, the properties of the sliding surfaces have a dominant effect on friction behavior.

As sliding speed increases, fluid pressure builds in the contact zone between the surfaces. The increase in pressure pushes the sliding surfaces farther apart, although they still have some contact between their asperities. This increasing surface separation results in more of the normal load being carried by the lubricant, causing the friction coefficient to decrease with increasing sliding speed. At the end of the mixed regime, the friction coefficient reaches a minimum and the sliding surfaces have minimal contact.

Increasing sliding speed further causes a transition to the hydrodynamic regime. In this regime, the fluid pressure in the contact zone is sufficient to fully separate the sliding surfaces and all load is carried by the fluid. Friction increases with sliding speed because of viscous drag; highly viscous lubricants can produce friction coefficients greater than those in the boundary regime. Thus, lubricant viscosity plays a key role in friction behaviors of systems exhibiting hydrodynamic sliding (Chen and Engelen 2012).

1.1.3 Using the Stribeck Curve in Food Tribology

Studies of lubricated sliding in many engineering fields focus on Newtonian lubricant performance in hydrodynamic sliding on hard surfaces, such as performance of lubricants on engine pistons and ball bearings. However, food tribology studies use soft surfaces, defined as deformable materials with Young’s modulus in the kPa to low MPa range, similar to the modulus of soft oral surfaces (Dresselhuis et al. 2008a; Payan and Perrier 1997), and most food products exhibit non-Newtonian behavior. Additionally, it is not always possible to evaluate food products over a range of sliding speeds sufficient to generate all three regimes of sliding behavior (Joyner (Melito) et al. 2014c). Therefore, friction behaviors of foods do not always follow the Stribeck curve shape; example friction profiles for food products are shown in Fig. 3. This complexity in friction behavior can make the friction profiles both difficult to interpret and difficult to relate to fundamental food properties or textural attributes.

However, there are several steps that can be taken to simplify data analysis, including correction for dissimilar and non-Newtonian viscosities. Viscosity corrections are important because viscosity can have a profound effect on friction results (Stokes et al. 2013). Because higher-viscosity fluids are more able to support applied normal loads in the contact zone, these fluids display hydrodynamic behavior at lower sliding speeds compared to lower-viscosity fluids (Chen and Stokes 2012). This effect has been observed for multiple food products (Joyner (Melito) et al. 2014a; de Vicente et al. 2005a; Li et al. 2018). It is possible to account for the effect of viscosity on friction coefficient by plotting friction coefficient versus sliding speed multiplied by viscosity (Fig. 4a, b) (de Vicente et al. 2005a). For Newtonian materials, the viscosity correction is straightforward. However, most foods have non-Newtonian viscosity profiles, and the shear rate in the gap changes with both sliding speed and gap height. This makes the viscosity correction more complex, as the shear rate and thus apparent viscosity of the lubricant in the contact zone will change over the duration of the test. One approach to simplify the viscosity correction is to assume that the food has a viscosity plateau at shear rates >100,000 s−1; these high shear rates are typical of those experienced during tribological measurements. This viscosity can be measured using a parallel plate setup with a narrow gap (50–100 μm) (Davies and Stokes 2008). Correcting data for viscosity differences allows more accurate comparison of samples with significantly different viscosities (Fig. 4b). It also allows superpositioning of similar samples at different concentrations to create an entire Stribeck curve when testing apparatus do not allow for creation of a full Stribeck curve for any one sample (Fig. 4c) (de Vicente et al. 2005a).

Stribeck curve showing correction for differences in lubricant viscosity for sample foods ((a) before correction, (b) after). This correction can be used to (c) superposition curves of materials with similar components but different concentrations. Note that different data are used for (a) and (b) than for (c)

When analyzing food tribological data, one must keep in mind the assumptions underpinning the Stribeck curve. Most food tribological tests violate both the assumption that the hard surfaces are used for testing and the assumption that the lubricant is Newtonian. Therefore, food tribological data should be interpreted with care. Potential pitfalls of interpretation of food tribological data are further discussed in Sects. 2.4, 3.2, 3.3, and 3.4.

1.2 Factors Impacting Friction

Perhaps the most important fact to know about friction is that friction is a system property, not a material property (Schipper et al. 2007). This also holds true for other tribological behaviors, i.e. lubrication and wear. Any changes to the system will change the friction behavior. Thus, there are numerous factors that impact friction, including countersurface hardness, roughness, and surface chemistry; amount of lubricant; lubricant viscosity profile, composition, particle size, particle shape, and physicochemical properties; applied normal load; sliding speed; and environmental conditions during the test. While the precise effects on friction are system-dependent, several general statements about system parameters on friction behavior can be made:

-

Attractive interactions between countersurfaces or between the countersurface and lubricant increase friction (de Vicente et al. 2005b; Crockett 2014; Gong and Osada 1998)

-

When soft surfaces are used, contact area is load-dependent (Bongaerts et al. 2007a; Prinz et al. 2007; Myant et al. 2010a), and the load selected for testing can significantly impact friction coefficients

-

Very rough and very smooth surfaces tend to produce higher friction coefficients than surfaces with moderate roughness (Chojnicka-Paszun and De Jongh 2014; Pettersson and Jacobson 2003; Derler et al. 2007)

-

Lubricants with higher viscosity exhibit hydrodynamic behavior at lower sliding speeds compared to lower-viscosity lubricants (Bongaerts et al. 2007a; Campbell et al. 2017; De Vicente et al. 2006)

-

Larger and rougher particles increase friction coefficient (Yakubov et al. 2015a; de Wijk and Prinz 2005; Liu et al. 2016a), provided they are not too large to be excluded from the gap (Yakubov et al. 2015b; Garrec and Norton 2012; Malone et al. 2003b)

2 Semisolid Food Tribological Measurements

A wide variety of instruments have been used to measure the tribological behaviors of foods. Commonly used instruments include the Mini-Traction Machine (MTM ; specifically designed for friction measurements), rheometers with specialized attachments, and uniaxial compression equipment with specialized attachments (Prakash et al. 2013). The specific setup of the friction test is dependent on the individual instrument and attachment, and each setup has different capabilities, advantages, and disadvantages.

2.1 Testing Geometry

Tribological testing geometries have three main movement types, linear sliding, rotational sliding, and rolling. Of these movement types, rotational sliding and rolling are most commonly used in tribological studies as of 2019, but there has been some study of food friction behaviors under linear sliding, including how acceleration and deceleration in reciprocating linear sliding impacts friction coefficients (Campbell et al. 2017).

In semisolid food tribology, the most common geometry used is a ball(s)-on-plate setup (Fig. 5). The food is spread on the plate in a thin layer and the ball(s) is(are) rotated on the plate. In the MTM setup, the plate is rotated and the ball is held stationary; the ball may also be set to rotate in place as the sliding occurs. The ball(s) is(are) generally considered to be a point contact on the plate, although this is not necessarily the case if the plate and balls are made of soft materials. Still, the ball(s) do(es) provide a relatively small, elliptical contact area, which is important for the assumptions underpinning friction coefficient calculations using Hertzian theory (Adams and Nosonovsky 2000).

2.2 Testing Surfaces

Food tribological studies typically use soft surfaces in an effort to mimic oral surfaces (Nguyen et al. 2015). It is desirable to mimic oral surfaces because food tribological data are mainly used to better understand influences on food textural attributes that do not relate well to rheological properties, such as grittiness, mouthcoating, and smoothness (Prakash et al. 2013; Chen and Stokes 2012). Soft surfaces that have been used for food products include elastomers (e.g. neoprene) (Nguyen et al. 2015; Chojnicka et al. 2008a, 2009; Zinoviadou et al. 2008), whey protein isolate gels (Joyner (Melito) et al. 2014a, c), polydimethylsiloxane (PDMS) (Li et al. 2018; Selway and Stokes 2013; Dresselhuis et al. 2007; Yakubov et al. 2015c; Joyner (Melito) and Damiano 2015; Liu et al. 2016b), Transpore tape (Nguyen et al. 2015, 2016; Godoi et al. 2017), and porcine oral tissue (Dresselhuis et al. 2008a; De Hoog et al. 2006). Of these surfaces, PDMS is the most commonly used because it can be modified in terms of surface chemistry (Dresselhuis et al. 2007; Ranc et al. 2006), roughness (Bongaerts et al. 2007a), and elastic modulus (Dresselhuis et al. 2008a), allowing it to more easily mimic properties of the tongue and soft palate. PDMS is naturally hydrophobic but can be made hydrophilic with plasma treatments if desired (Bongaerts et al. 2007a). The roughness of the PDMS surface can be controlled by adjusting the surfaces roughness of the mold into which PDMS is cast. Typically, PDMS plates used in food tribological studies have a ratio of 10:1 base:crosslinker and smooth surfaces.

PDMS is a relatively inert material, so does not readily interact with food materials. However, it is still possible for foods with a greater affinity for the PDMS surface than the other food components to adhere to PDMS, resulting in the formation of a layer of that component on the PDMS surface. This surface layer can have a dramatic impact on friction behaviors (Tsui et al. 2016). For example, foods containing liquid fat can deposit a layer of fat onto the PDMS plate over time, which can noticeably decrease friction profiles. Cleaning the plates with an effective solvent, such as petroleum or ethyl ether, to remove fat buildup, minimizes the impact of surface layer buildup. However, it is still recommended that the sliding surfaces be changed after approximately 5 runs to limit the impact of surface wear and fouling on food tribological measurements.

2.3 Measurement Parameters

When performing tribological testing of food products, sliding speed and normal load are the two variables of primary interest. Temperature and test duration can also be controlled. Typically, tribological testing is performed at 25 or 37 °C; these temperatures correspond to shelf storage and oral temperatures, respectively. Tests at 25 °C can also be used to evaluate friction behaviors that are served cold and have a short residence time in the mouth. This short residence time does not allow the food to warm to body temperature before swallowing. For example, yogurt, which has a serving temperature of about 8 °C, is at approximately 25 °C when swallowed because it has an oral residence time of <10 s.

Matching the temperature of the food at serving or during consumption allows more accurate determination of relationships between tribological and sensory data. While it would also be helpful to measure tribological behaviors over similar timescales as those observed for oral processing (<10s for fluid and semisolid foods (de Wijk et al. 2006a)), it is impractical to do so because of the limitations of current instrumentation. To generate a Stribeck curve with a reasonable degree of data precision and accuracy, one must collect at least 5 points per decade of sliding speed and allow sufficient time at each sliding speed for the instrument to reach steady-state before data collection. As a result, these tribological tests can have a duration of 15–60 minutes. This timescale difference should be taken into consideration during testing and data analysis, particularly for time-sensitive samples that can change significantly during the duration of the test. Using a single sliding speed rather than a sliding speed range does allow one to examine food tribological behaviors on similar timescales to those of oral processing. However, this type of test is comparable to single-point viscosity testing; the test should be run at several sliding speeds to generate a more complete picture of the material’s tribological behaviors at short timescales.

Sliding speed is typically varied between 0.01 to 100 mm s-1 to generate data for the Stribeck curve. However, if changes to friction behaviors over time are to be evaluated, the sliding speed can be held constant and friction coefficient recorded over time. This setup is especially of interest when evaluating changes to food friction behaviors upon addition of saliva (Selway and Stokes 2013; Vardhanabhuti et al. 2011). The applied load of the ball(s) against the plate is typically set to a given value and the sliding speed of the ball(s) relative to the plate is typically varied to generate Stribeck-type data. Sliding speeds of 10–100 mm s-1 are often of interest in food tribological studies; this sliding speed range is typically considered to be representative of oral sliding speeds (Malone et al. 2003a; Prinz et al. 2007; Campbell et al. 2017; Steele and Van Lieshout 2009; de WIjk and Prinz 2006). Additional considerations for selection of sliding speeds include the capabilities of the instrument and the quality of the data. Data collected at high sliding speeds (>100 mm s-1) may be inaccurate if the sample is ejected from the testing geometry or the instrument is not capable of generating high sliding speeds. Data collected at very low sliding speeds (<0.01 mm s-1) may be inaccurate due to lack of instrument precision and stick-slip or startup phenomena. This is particularly true when testing on soft surfaces such as elastomer plates. In ball-on-plate stick-slip with rotating balls, the balls stick to the plate at low rotational speeds (Tsui et al. 2016). However, because the plate deforms as the ball attachment rotates, the balls appear as if they are moving even though the surfaces are not moving relative to each other. After the elastic limit of the soft plate is reached, the plate stops stretching and the balls slide on the plate, often with a higher velocity than desired for the measurement. The instrument will correct the sliding speed, slowing the balls and causing the process to repeat until the sliding speed increases to the point at which there is insufficient time for the plate and balls to adhere, and the balls will slide smoothly over the plate. Stick-slip behavior often manifests as either a gradual increase in friction coefficient at the beginning of the test or noisy data (Fig. 6).

In the great majority of food tribological testing, the normal force is held constant. Typical values of normal force are 1–3 N, which is based on the reported values of contact pressures during oral processing (3–27 kPa) (Bongaerts et al. 2007a; De Vicente et al. 2006; Hayashi et al. 2002). The normal force should be great enough to generate friction but not so great that it causes rapid wear of the sliding surfaces. Wear of the sliding surfaces during the test or over multiple replicates can cause artifacts in the data. However, the soft surfaces used in food tribological testing are relatively resistant to wear under typical testing conditions. Regular replacement of the testing surfaces (e.g. after every 4–6 runs) minimizes surface wear and data artifacts related to surface wear.

2.4 Data Analysis

Current studies of food tribological behaviors have two primary goals: better understanding of what factors contribute to friction behaviors and determination of how friction behaviors relate to sensory attributes. Analyzing tribological data can include mean comparison of friction coefficients at selected sliding speeds, correlation of tribology data to rheological, sensorial, or microstructural data, and qualitative comparisons. Qualitative comparison of tribological data is relatively common in food tribology studies and generally involves comparing the relative shapes of food friction profiles and relative magnitudes of friction coefficients at different sliding speeds. While qualitative comparison generally considers the entire friction profile, it is not possible to determine if the entire profile of each sample is statistically different from that of a second sample or just visually different. This is particularly problematic for samples with large standard errors. Comparing means of friction coefficients determines if the samples are statistically similar for each data point. This method adds statistical rigor to the analysis but does require each point to be compared individually, making the analysis cumbersome. Correlation of tribological data to other data has similar issues. Although correlation analyses can determine whether two parameters are related (e.g. friction coefficient and grittiness score), only one friction coefficient value is used in the correlation analysis. This is typically friction coefficient at oral sliding speed, approximately 30 mm s−1 (Steele and Van Lieshout 2009). However, this sliding speed may not be relevant to the parameter to which the tribological data are being correlated. Certain oral movements may be performed at faster or slower speeds, or over a range of speeds. Furthermore, sliding speeds during industrial processing may be much higher or lower than oral sliding speeds, depending on processing parameters. Therefore, care must be taken in both selecting appropriate tribological data for correlation analysis and interpretation of the analysis results.

One method of incorporating more of a large data set into a mean separation or correlation analysis is to model the data set with an equation or set of equations and use the equation parameters (e.g. coefficient values) for the analysis. This is analogous to modeling flow profile data with an equation for viscosity and comparing the constants in the equation. However, there are no standard models for either the entire Stribeck curve or parts of the Stribeck curve that are applicable to non-Newtonian lubricants on soft surfaces. Additionally, these models tend to be highly complex and require property data that are not readily available for the materials used in food studies. On the other hand, it is possible to empirically model tribological data and use model parameters for correlation or mean separation analyses. Ultimately, the choice of whether or not to use a model for tribological data analysis is dependent on the goals of the study and the resources available to the research group.

Tribological data for foods can be noisy because of the soft testing surfaces that deform and relax under an applied load. This changes the actual load on the surface, requiring the testing apparatus to continually adjust the applied normal load to maintain the target value. Unfortunately, the limitations of adjustment speed and precision of most testing apparatuses used in food tribology result in potentially large fluctuations in normal force. Although the formula for friction coefficient accounts for normal load (Eq. 1), these fluctuations can affect data validity because changes in applied load can change the contact area of soft surfaces (Joyner (Melito) et al. 2014c, d; De Hoog et al. 2006). While the data can be corrected to account for actual contact area assuming elastic (Hertzian) contact (De Vicente et al. 2006) and Johnson-Kendall-Roberts (JKR) contact theory (Greene et al. 2013), this is often difficult because the instantaneous contact area is not known. To reduce the noise, the data should be screened for normal force and all data outside of a set range around the set normal force should be removed (Fig. 7). A range of ±5–10% around the set normal force is generally sufficient to reduce noise from large normal force fluctuations (Joyner (Melito) et al. 2014c, d). This screening procedure allows for more accurate comparison among samples. However, a relatively high data density (>20 points per individual sliding speed tested) is recommended to perform this screening procedure (Joyner (Melito) et al. 2014d) so that there is still sufficient data density after screening to support statistical analyses.

3 Semisolid Food Tribological Behaviors

There has been significant interest in semisolid food tribological behaviors over the last decade. This interest is primarily driven by the desire to better understand drivers behind semisolid food textures. Although viscosity behaviors can explain certain semisolid food sensory attributes related to viscosity, such as thickness (Van Aken et al. 2007; Akhtar et al. 2005; Kokini 1987; Dickie and Kokini 1983), they cannot fully explain many sensory attributes that are key to consumer liking. These attributes, such as smoothness (Malone et al. 2003a; Chen and Stokes 2012; Kokini 1987; Laiho et al. 2017), chalkiness (Joyner (Melito) et al. 2014a), astringency (Chen and Stokes 2012; Vardhanabhuti et al. 2011), mouthcoat (Laiho et al. 2017; Nguyen et al. 2017), slipperiness (Chen and Stokes 2012), grittiness/roughness (Prakash et al. 2013), and the somewhat controversial creaminess (Chen and Stokes 2012; Laiho et al. 2017; Sonne et al. 2014; Kokini and Cussler 1983; de Wijk and Prinz 2007), have been found to relate to tribological behaviors. Because many of these terms are friction-related, it is generally hypothesized that they are related to semisolid food friction behaviors. Accordingly, the friction behaviors of custards (Godoi et al. 2017; de Wijk and Prinz 2007; De Wijk et al. 2004, 2006b), mayonnaise (de Wijk and Prinz 2007; Giasson et al. 1997), yogurts (Selway and Stokes 2013; Laiho et al. 2017; Nguyen et al. 2017; Sonne et al. 2014; Morell et al. 2017; Laguna et al. 2017), white sauce (de Wijk and Prinz 2007), ice cream (Kokini and Cussler 1983), and cream cheese (Nguyen et al. 2016; Kokini and Cussler 1983) have been studied; these studies have focused on relating semisolid food friction behaviors to rheological behaviors (Joyner (Melito) et al. 2014a; Selway and Stokes 2013; Liu et al. 2016b; Nguyen et al. 2016, 2017; Laguna et al. 2017), microstructural features (Liu et al. 2015, 2016b; Laiho et al. 2017; Sonne et al. 2014), particle size (Nguyen et al. 2016; Laiho et al. 2017; Laguna et al. 2017), and sensory attributes (Laiho et al. 2017; Kokini and Cussler 1983; de Wijk and Prinz 2007; Laguna et al. 2017). But because friction is a system property and semisolid food friction is dependent on a multitude of parameters, the relationships between food friction and other properties and behaviors are not always straightforward and there are few relationships that are truly universal.

3.1 Key Factors Impacting Semisolid Food Friction Behaviors

3.1.1 Formulation

Fat plays a major role in food friction behaviors. An excellent lubricant, fat significantly decreases food friction coefficient values (Chojnicka et al. 2009; Selway and Stokes 2013; Sonne et al. 2014; Chojnicka-Paszun et al. 2012). In fact, tribological testing can differentiate among foods with different fat content but similar rheology (Joyner (Melito) et al. 2014a; Selway and Stokes 2013; Nguyen et al. 2016). These behaviors have been found to relate to sensory attributes such as fattiness/fatty mouthfeel (Liu et al. 2015; Dresselhuis et al. 2008b), creaminess (de Wijk and Prinz 2005; Chojnicka-Paszun et al. 2012), and oral viscosity (Sonne et al. 2014). However, it has been observed that above a certain fat content, the specific fat content being dependent on sliding speed, increased fat content caused no changes in friction behavior (de Wijk and Prinz 2005). It was hypothesized that the contact area became completely filled with fat at a certain fat contentration, so there was no effect of further increasing fat content (Malone et al. 2003a). Additionally, care must be taken when relating fat-related friction behaviors to fat-related sensory behaviors, as the ability to differentiate samples with different fat content is dependent on surface selection and human sensitivity for differentiating fat content does not necessarily align with instrumental sensitivity (Chojnicka-Paszun et al. 2012).

The lubricating properties of fat are thought to strongly impact food texture attributes; formulating lower-fat foods can be challenging because fat replacers often do not mimic the lubrication properties of fat, even if they can replicate fat functional behaviors. For example, polysaccharide-based fat replacers tend to promote hydrodynamic behavior over the range of sliding speeds tested in food tribology (Joyner (Melito) et al. 2014a), while fat shows boundary and mixed behavior (Sonne et al. 2014) . It has been found that fat replacers with smaller particle size that provide higher viscosity and lower friction coefficients are more successful in mimicking both friction and sensory behaviors of full-fat semisolid foods (Sonne et al. 2014). Additionally, the level of fat replacer is key to frictional properties, and the level of fat replacer needed to replicate friction behaviors of fat is dependent on the specific fat replacer (Brennan and Tudorica 2008).

In addition to total fat content, solid fat content, type, binding to the food matrix, and deposition on sliding surfaces is also important to friction behavior. In food gels, high solid fat content, lower binding to other ingredients and higher fat content reduced friction and increased fatty mouthfeel; however, only binding and total fat content related to sensory attributes (Liu et al. 2015). Bound fat droplets in emulsions had higher friction coefficients and less fatty mouthfeel than emulsions made with unbound fat droplets (Camacho et al. 2015). Fat deposition on sliding surfaces can be due to shear-induced coalescence of fat droplets in the contact zone, with the resulting coalesced droplets remaining in the valleys between asperities after the sliding contact passes (Chojnicka-Paszun et al. 2012). To date, there is little information in the literature about how fat impacts food friction beyond the amount of fat added. Further work is needed in this area to determine the precise role that fat plays in food lubrication.

Proteins provide structure to semisolid foods, typically through formation of a network that traps water, fat, and small molecular weight solids. Protein concentration, type, and content has been found to impact the friction behaviors of yogurts; friction increases with increased total protein, particularly at higher sliding speeds (Sonne et al. 2014). A higher casein to whey ratio generally decreased friction coefficient in yogurts (Laiho et al. 2017; Sonne et al. 2014), with a significant interaction with total protein content (Sonne et al. 2014). These effects are likely due to changes in food microstructures: higher whey protein content tends to produce a coarse, particulate network made of whey protein aggregates (Laiho et al. 2017). Whey protein aggregates in solution have been shown to increase friction coefficients, particularly at lower sliding speeds. In contrast, fibrillar proteins such as egg ovalbumin can align with the shear field in the contact zone, allowing them to interact with the contact surafces and reduce friction on rougher surfaces (Chojnicka et al. 2008a). Small protein aggregates can also decrease friction coefficients: microparticulated whey protein particles reduced friction in solutions and emulsion-filled gels. These results were attributed to the ball-bearing effect of microparticulated whey protein particles (Liu et al. 2016c), which is further discussed in Sect. 3.2. To date, much of the tribological literature concerning food product ingredients and their influence on food friction behaviors has focused on the effects of fat content, and type and concentration of hydrocolloids, especially starch. More work is needed to improve the understanding of the influence of protein type, concentration, and conformation on fluid and semisolid food friction behaviors.

Polysaccharides , which are typically evaluated in solution, generally exhibit both high adhesion to the sliding surfaces and low friction coefficients (Crockett 2014). While this may seem contradictory, it is the manner in which polysaccharides adhere to the sliding surfaces that can cause this effect. Polysaccharides interact with each other and sliding surfaces through hydrogen bonding. If the affinity of the polysaccharide for the sliding surface is higher than for itself or the solvent, it will adhere to the surface. However, the presence of water can dissolve polysaccharide-polysaccharide hydrogen bonds, allowing the chains to easily slide past each other and reducing friction.

The charge on polysaccharides has a significant impact on friction behavior. Charged polysaccharides can interact with surfaces through electrostatic interactions, whereas neutral polysaccharides mainly interact with surfaces through hydrophobic interactions and hydrogen bonding (Crockett 2014). Hydrogen bonds are weaker electrostatic interactions and hydrophobic interactions; for good lubrication, these forces need to be balanced. The polysaccharide–surface interactions need to be strong enough to prevent the polysaccharide chains from being excluded from the gap at low sliding speeds. On the other hand, attractions that are too strong prevent water from properly solvating the polysaccharide chains, increasing their interactions and thus increasing friction (Crockett 2014).

Polysaccharide conformation and concentration are additional factors that impact their friction behaviors. Polymers that cannot physically fit into the contact area do not contribute to friction behaviors; this was observed for guar gum solutions at lower sliding speeds (Malone et al. 2003b). Extended coil and rigid rod and conformations were more likely to influence friction behaviors of hydrocolloid solutions, as they can fit into the contact area (Garrec and Norton 2012). Starch–locust bean gum solutions showed lower friction coefficients than solutions of locust bean gum alone, particularly in the boundary region. These results were likely due to the ability of the starch granules to fit into the contact area even at low sliding speeds; guar gum did not fit into the contact area at low sliding speeds (Zinoviadou et al. 2008). Increased concentration generally decreased friction coefficient of polysaccharide solutions at moderate sliding speeds (Yakubov et al. 2015b; Garrec and Norton 2012), although friction coefficients may increase at low sliding speeds due to exclusion of polymers from the contact area (Garrec and Norton 2012). The effects of conformation and concentration can combine, such as the effects seen in a study on native and gelatinized rice starch (Liu et al. 2016a). Friction coefficients were higher for native rice starch versus gelatinized rice starch, likely due to the more irregular shape and increased hardness of the starch granules. Friction coefficients also increased with increased concentration of both native and gelatinized rice starch. For the native rice starch, the concentration effects were due to an increased amount of rough particles. For the gelatinized rice starch, the effects were attributed to the “stickiness” of leached amylose that caused surface–surface adhesion and increased friction (Liu et al. 2016a).

Interactions of polysaccharides with food components can alter friction behaviors as well. For example, addition of starch reduced friction coefficients in high-protein yogurts, which was related to the smoother mouthfeel reported in sensory analysis (Morell et al. 2017). These effects were attributed to the deposition of starch onto the sliding surfaces (Morell et al. 2017). Yogurts made with different hydrocolloids (carrageenan, gelatin, starch, and/or xanthan gum) showed significantly different friction behaviors, which were attributed to different interactions of the hydrocolloids with the protein network in the yogurt microstructures (Nguyen et al. 2017). It should be noted that most of the work on polysaccharide tribology focuses on solutions of individual polysaccharides, and there is only a small amount of information in the literature on the effects of polysaccharide interactions with other food components and the subsequent impact on semisolid friction behaviors. Further study of this area is needed for a better understanding of the impact of starch on more complex foods.

The importance of food–saliva and food component–saliva interactions should not be understated; these interactions will be discussed in Sect. 3.1.4. In general, breakdown of starch through interaction of saliva can have a dramatic impact on friction behaviors of semisolid foods, significantly changing friction coefficients and potentially changing the shape of the entire friction curve (Joyner (Melito) et al. 2014a; De Wijk et al. 2006b).

3.1.2 Measurement Protocol

As previously discussed, friction behaviors are highly dependent on system conditions. This includes the shape of the sliding surfaces (e.g. sphere, ring, cylinder, flat plate), contact area, sliding speed, constant versus changing velocity of the sliding surfaces, pressure in the contact area, amount of rotation of one or both of the sliding contacts, surface roughness and chemistry of the contacts, temperature, and humidity (Stokes 2012; Greene et al. 2013; Prinz et al. 2007; De Hoog et al. 2006; Ranc et al. 2006; Lu et al. 2006). All of these parameters can affect the specific composition of the material in the contact area, material rheology during the test, and interactions between the material and sliding surfaces.

The composition of the material in the contact is not necessarily the composition of the bulk semisolid food. Surface separation in the contact area is typically <1 um (de Vicente et al. 2005a), which can be smaller than particles in semisolid foods. If the particles are easy to deform, they may be able to fit into small gaps. On the other hand, more rigid particles may not be able to enter the gap, reducing their overall contribution to friction behavior at lower sliding speeds.

While it is difficult to directly measure the composition of the food in the gap, it may be estimated by determining particle diameters of the different particles present in the food and comparing those to the gap in the contact area. This method requires some knowledge about the ability of the particles to deform under the conditions as well as the gap between the sliding surfaces at different sliding speeds. Unfortunately, it is not always possible to determine particle deformability, nor are the calculations for determining gap height simple because deformation of soft surfaces changes the actual contact area. Another, simpler way to estimate composition of the food in the gap is to by testing different formulations of the food, each made with one or more components omitted. If the friction behavior of the original food is the same as that of the food formulated with one or more components omitted, one can assume that either the omitted components are not present in the gap or do not significantly contribute to friction behaviors (see Fig. 8 for an example of this). This method can also be used to estimate the gap between the sliding surfaces at different sliding speeds, provided the particle sizes of the food components are known.

Similar to composition, the rheological behaviors of semisolid foods in the contact are can be significantly different than bulk rheological behaviors. Because the fluid film in the contact area is typically 0.5–2 um (de Vicente et al. 2005a; Yakubov et al. 2015b; Myant et al. 2010b) and contact pressures are 60–350 kPa (Myant et al. 2010b; Chojnicka et al. 2008b), the semisolid food is exposed to much higher shear rates (>10,000 s−1) than are measured in a standard measurement of viscosity profile (Selway and Stokes 2013). Thus, it is necessary to measure viscosity at very high shear rates to properly understand the rheological behaviors of semisolid foods under tribological testing conditions. These high shear measurements can be performed with either a capillary rheometer or by using parallel plates with a narrow gap (<100 um) (Davies and Stokes 2008). Parallel plates with a 100 um gap can be used to reach shear rates of >10,000 s−1 (Davies and Stokes 2008), similar to shear rates experienced in the contact area in a tribological test. The gap is also large enough to minimize the effects of plate misalignment and inertia, provided the appropriate calculations are used to correct for these factors. Corrections for misalignment (Eq. 2) and normal stress changes due to inertia (Eq. 3) are as follows (Davies and Stokes 2008):

Here, η is corrected apparent viscosity (Pa.s), ηM is measured apparent viscosity (Pa.s), δ is gap height (mm), ε is gap height error (mm), ΔFN, inertia is the change in normal force due to inertial effects from high shear rates (N), ρ is the density of the fluid (kg m−3), Ω is angular velocity (s−1), and R is radius of the parallel plate (m). It should be noted that a 100 um gap is sufficient for measurement of semisolid foods with particles with 10 um diameter. If the food has larger particles, they may stick in the gap, resulting in inaccurate measurement (Davies and Stokes 2008). In this case, a larger gap needs to be used. Accordingly, the rule of thumb for parallel plate gap height is a 10:1 gap height:largest particle diameter. However, using larger gaps means that the maximum achievable shear rate is decreased. This issue can be addressed by using a rheometer capable of geometry counterrotation, such as those manufactured by Anton Paar (MCR7XX series), which doubles the maximum achievable shear rate, or by modeling the available viscosity data and using the model value for viscosity in the contact zone. Sometimes, it is appropriate to assume that the viscosity in the gap is an infinite shear viscosity, particularly at low sliding speeds where the gap between the sliding surfaces is small. If this assumption is made, the data for generating the model should be generated from as wide a shear rate range as possible, the appropriate corrections applied for inertia and plate misalignment, and the viscosity data critically examined to ensure that the infinite shear plateau is not due to a high-shear measurement artifact or selection of an inappropriate viscosity model.

Contact surface–food interactions can have significant impact on tribological behaviors. Testing hydrophobic (e.g. high-fat) foods on hydrophobic surfaces results in low friction coefficients in the boundary and mixed regimes, while testing those same foods on hydrophilic surfaces results in higher friction coefficients, or vice versa (Bongaerts et al. 2007a). This is because of the ability of foods to spread well on surfaces with similar hydrophobicity, which gives them good lubricating ability. This phenomenon can be predicted somewhat with the contact angle of a quiescent drop of the food on the surface. Low contact angles correspond to high spread of the droplet, leading to good lubrication (Ranc et al. 2006). However, this effect becomes negligible in hydrodynamic sliding, as the bulk fluid behavior dominates the friction response in the contact zone (Bongaerts et al. 2007a).

In addition to overall hydrophobicity similarity, affinity of food components for the contact surfaces can influence friction behaviors. If a particular food component has a higher affinity for the contact surface than the bulk food, it will deposit onto the contact surface, eventually forming a surface layer (Malone et al. 2003b). If this surface layer causes the sliding surfaces to adhere, friction will increase. If the surface layer causes the sliding surfaces to repel each other or allows the surfaces to slide past each other more easily, friction will decrease (Gong and Osada 1998). For example, deposition of fat onto PDMS plates can create a slippery fatty layer that can decrease friction coefficient. The rate at which this layer forms is dependent on the testing conditions and the specific affinity of the compound for the contact surface rather than the bulk food. Interferometry techniques can be used to estimate the rate of layer formation (Myant et al. 2010b). Other potential contact surface–food interactions include entrainment of small particles in asperities, absorption of food components onto the contact surface, repulsion of food components from the contact surface, and chemical reactions between the food and the contact surface. The latter two issues can be minimized by selection of nonabsorptive, nonreactive contact surfaces, such as PDMS. The first issue can be minimized by reducing asperity height of the contact surfaces. Normally, particle entrapment in large asperities is not an issue in food tribology because the plates used are prepared in smooth molds. However, if one wishes to mimic the rougher surface of the tongue, it is important to keep in mind how the asperities may trap food particles and impact food friction behaviors.

3.1.3 Viscosity Profile

Semisolid foods have widely varying viscosities, ranging from ~100 mPa.s to over 10 Pa.s. A large variation in viscosity among samples necessitates the sliding speed corrections discussed in Sect. 1.1.3 for proper comparison of different semisolid food samples.

In addition to the variation in viscosity, semisolid foods generally exhibit non-Newtonian behavior, including shear-dependency and yield stress. They may also have zero shear and infinite shear viscosity plateaus. All of these behaviors can affect their friction behaviors , and the effects will change depending on the shear rate in the gap between the sliding surfaces. While the shear rate in the gap does decrease with increased sliding speed due to increased pressure that forces the sliding surfaces apart, shear rates in the contact zone are still quite high compared to the shear rates used in a traditional shear rate sweep. Understanding the viscosity behaviors of semisolid foods under these high shear rates is important for understanding how their particular non-Newtonian behaviors impact tribological data. Flow behaviors that characterize semisolid foods at lower shear rates may be significantly different than those that appear at the high shear rates experienced during tribological testing. In addition, phenomena that occur only in narrow gaps under high shear, such as slip and depletion of material at the sliding surfaces, can significantly impact rheological behavior (Davies and Stokes 2008). Therefore, it is important to not only account for different viscosity values, but also to measure viscosity profiles under high shear rates as discussed in Sect. 3.1.2.

Viscosity profiles may also impact selection of geometry for measuring friction coefficients. Thinner samples may flow to the bottom of pitched or vertical plates, resulting in sample starvation in the gap and incorrectly large friction coefficients. Samples with a relatively high yield stress may be pushed out of the sliding path of ball geometries and be unable to flow back into the contact zone due to their yield stress. High-viscosity samples may have significantly higher viscous drag than lower-viscosity samples, which could result in artificially higher friction coefficients because of the higher torque required to move the sliding surface(s). Preliminary trials are often needed to ensure accurate, repeatable measurements on a specific geometry with a specific food.

3.1.4 Saliva

The use of saliva in testing of food rheological and tribological behaviors has gained increasing attention in the literature over the last decade. Because saliva can cause significant changes to food structures during oral processing, including emulsion and starch breakdown (Van Aken et al. 2007), food properties during chewdown and bolus formation are often quite different from those of the original food (Stokes et al. 2013; Chen 2009; Pascua et al. 2013). Additionally, saliva forms a lubricating layer on the oral surfaces, which comprises a bound layer directly on the oral surfaces and a surface layer that mixes with food during oral processing (Chen and Engelen 2012). Both saliva itself and food–saliva interactions can play a major role in food tribological behaviors during oral processing, which can have significant impact on oral textures.

Secreted by the parotid, sublingual, and submandibular glands, human saliva is composed of approximately 98–99% water; the remainder comprises alpha-amylase and other digestive enzymes, ions, and proteins such as alpha-amylase, immunoglobulins, mucins, and other glycoproteins (Kupirovič et al. 2017; Carpenter 2013). Saliva flowrate and composition changes dramatically from rest to consumption of food, from an average of about 0.3 mL/min to up to 7 mL/min, respectively (Humphrey and Williamson 2001). The flowrate and composition of saliva can also change based on many factors, including hunger, stimulus in the oral cavity, nature of the stimulus, health status, medication, and time of day (Humphrey and Williamson 2001; Dawes 1975; Dawes 1996). Regardless of these factors, it is the non-water components that give saliva its notable viscoelastic behavior, although they are only a small fraction of saliva’s composition (Bongaerts et al. 2007b). However, although the bulk viscosity has some contribution to the lubricating abilities of saliva (Gibbins and Carpenter 2013), viscoelasticity was found to have little impact on saliva friction behaviors, particularly at lower sliding speeds (Bongaerts et al. 2007b). It is the amphiphilic nature of these proteins that allows saliva to form films on oral surfaces (Bongaerts et al. 2007b; Lindh et al. 2001, 2002a, b; Christersson et al. 2000; Shi and Caldwell 2000).

Saliva friction and lubrication behaviors on oral surfaces are impacted by both its interaction with oral surfaces and the presence of certain food components. As previously stated, saliva forms two layers on oral surfaces: a bound layer and a surface layer. In the bound layer, called the pellicle, small molecular weight proteins and non-proline sections of larger proteins adhere to the contact surface primarily through hydrophobic interactions (Stokes 2012; Lindh et al. 2002a; Gibbins et al. 2014). This layer is difficult to remove and serves as an anchor for the surface layer. The surface layer is composed of the hydrophilic portions of glycosolated proteins such as mucins (Macakova et al. 2010; Cárdenas et al. 2007a; Cárdenas et al. 2007b). Because of its viscoelastic behavior and low viscosity (~2 mPa.s) (Chen and Engelen 2012; Stokes and Davies 2007), this surface layer provides good lubrication (Chen and Engelen 2012), keeping the oral surfaces from sticking to each other when one is not eating or drinking. It also helps food to move along the oral surfaces during oral processing (Chen and Engelen 2012).

Addition of saliva can cause multiple physicochemical changes to semisolid foods, and these changes can significantly alter friction profiles (see Sect. 3.1.4). Therefore, many studies on food friction–texture relationships have elected to add either human saliva (Joyner (Melito) et al. 2014a; Selway and Stokes 2013; De Wijk et al. 2006b; Morell et al. 2017) or an artificial saliva containing mucins and amylase in a buffer solution (Morell et al. 2017; Laguna et al. 2017) to foods and testing the friction behaviors of the resulting mixture. Addition of saliva decreases friction coefficients of yogurt (Morell et al. 2017) and starch-based custards (De Wijk et al. 2006b), and can dramatically alter friction profiles of acid milk gels (Joyner (Melito) et al. 2014a).

Food-saliva interactions have been related to multiple oral texture sensations. In particular, astringency, defined as a dry, puckering feeling in the mouth after consumption of food, (Vardhanabhuti et al. 2011; Gibbins and Carpenter 2013) and creaminess have generated interest over the past decade because they are thought to be more closely tied to thin film and friction behaviors rather than bulk rheology. However, neither of these attributes have simple relationships to friction behavior. Astringency–friction relationships appear to be dependent on the specific mechanism for the astringent sensation. As of 2019, there have been four different mechanisms proposed for astringency: (1) aggregation of salivary proteins due to complexation with food components that form particles that cause a rough or gritty sensation, (2) disruption of the pellicle and exposure of the oral surfaces, (3) disruption of the mobile saliva layer and subsequent loss of lubrication provided by that layer, and (4) exposure of receptors on the oral surface that produce an astringent sensation when bound to food components (Gibbins and Carpenter 2013). Activation of these mechanisms appears to be dependent on the specific compounds in the food, and multiple mechanisms can occur simultaneously. For example, polyphenols complex with proline-rich proteins to form aggregates, resulting in an astringent mouthfeel (Prinz and Lucas 2000). Whey proteins have similar astringency mechanisms (Beecher et al. 2008; Andrewes et al. 2011; Ye et al. 2011). However, mixtures of saliva and epicatechin showed no difference in friction behavior from saliva alone, indicating that epicatechin, which is perceived as astringent, does not complex with saliva in the same way as polyphenols or whey proteins.

Astringency is not always related to tribological behaviors, even with addition of saliva (Vardhanabhuti et al. 2011). Several studies on relatively simple fluid systems (e.g. solutions of β-lactoglobulin (Vardhanabhuti et al. 2011), red wine (Brossard et al. 2016), epigallocatechin gallate (Rossetti et al. 2009), and alum (Vardhanabhuti et al. 2011)) have found relationships between food friction profiles and strength of astringent sensation. However, in studies on more complex systems, such as yogurt, relationships between instrumental friction and astringent sensations were not straightforward, and no direct correlation between the two were found (Morell et al. 2017). Additionally, mixing astringency-mediating substances, such as milk or maltodextrin, with astringent compounds does not necessarily result in reduced friction coefficients when the mixtures are evaluated in the presence of saliva (Rossetti et al. 2009). There is still much to be discovered about astringency mechanisms, particularly those in complex foods, and their role in food friction behaviors.

Temporal changes of food products upon addition of saliva can be observed through friction measurements. During the measurement, food can either be added to an adsorbed saliva film on one of the sliding surfaces (generally the plate) (Selway and Stokes 2013) or saliva can be added to the food. In these tests, sliding speed is held constant and changes to the friction coefficient are observed over time. The changes to friction coefficient and duration of the changes are specific to the interactions between the saliva and food product components. Addition of saliva to yogurt caused a nearly instantaneous increase to a plateau value in friction coefficient, but addition of saliva to custards showed a slow increase in friction coefficient over about 10 min to a plateau value (Selway and Stokes 2013). Fat content impacted the degree of friction coefficient increase: higher-fat yogurt and custard samples showed notably less increase in friction coefficient (Selway and Stokes 2013). Beta-lactoglobulin showed increased friction coefficient upon addition of saliva, with a much more rapid increase in friction at pH = 3.5 compared to pH = 7.0 (Vardhanabhuti et al. 2011). This result was in agreement with astringency perceptions of whey protein solutions (Beecher et al. 2008; Andrewes et al. 2011; Ye et al. 2011), as previously discussed. Temporal investigations of food–saliva mixtures are not yet commonplace in the literature but can reveal valuable information of how foods change in the presence of saliva. Indeed, the information from this method of tribological testing can be used to better understand temporal sensory attributes and the mechanisms behind these attributes.

3.2 Relationships to Structural Features

Dispersed particles in foods can have significant influence on food tribological behaviors, with particle size and shape being the most influencing factors on friction coefficient. Unsurprisingly, rougher, larger particles can increase friction coefficients (de Wijk and Prinz 2005, 2006; Krzeminski et al. 2014), provided they are not excluded from the gap. For example, exclusion of protein particles from the gap resulted in fat content influencing friction coefficients at lower speeds and protein content influencing friction coefficient at higher speeds (Sonne et al. 2014). Furthermore, whey protein particle size has been directly correlated with friction coefficient (Laiho et al. 2017).

Smaller, rounder particles can lower fiction coefficients (de WIjk and Prinz 2006). In fact, particles that are round, smooth, and relatively hard, such as soluble starch granules, can exhibit rolling behavior in narrow gaps, such as the contact zone in tribological measurements. This rolling behavior, termed the ball bearing effect, can significantly reduce friction due to the combination of sliding and rolling that promotes surface slip (Yakubov et al. 2015b). The ball bearing effect has been found in starch solutions (Zhang et al. 2017), liquid and semisolid foods containing microparticulated whey protein (Liu et al. 2016b), and yogurts containing starch (Morell et al. 2017). Even without this ball bearing effect, smoother particles have been shown to reduce friction coefficients in mayonnaise and custards (de Wijk and Prinz 2005).

Structural features and changes to those features under testing conditions can have a major impact on friction behaviors. Decreased microstructure homogeneity and larger void volumes were shown to increase friction coefficients in yogurts with increased whey protein content (Laiho et al. 2017). On the other hand, cream cheese with lower fat content had lower spreadability and higher rigidity and friction coefficients, which was attributed to fewer fat globules dispersed in a more compact protein matrix. The lower-fat samples also showed large, gelled aggregates compared to the higher-fat samples (Ningtyas et al. 2017). Charged food polymers, such as anionic polysaccharides, can reduce friction by binding to testing surfaces and forming a lubricating layer (Macakova et al. 2010). This effect is similar to the lubrication mechanism of saliva. Rapid breakup of starch granules under tribological testing can also reduce friction coefficient due to the ball bearing effect (Zhang et al. 2017). Similarly, breakdown of the gel matrix in emulsion filled gels was hypothesized to be the cause of differences in friction behaviors of these gels; different breakdown pathways would release different components, which would have varied effects on friction behaviors (Liu et al. 2016a). Aside from breakdown due to shear forces, disruption of semisolid food microstructures due to the addition of saliva may be responsible for differences in the rate of change of friction coefficient (Selway and Stokes 2013), as discussed in Sect. 3.1.4.

Phase separation that is local to the contact area, or dynamic phase separation, may result in significantly different friction behaviors among samples with similar bulk rheological behavior. For example, a high-fat sample may undergo dynamic phase separation, resulting in the contact area being filled with fat and a subsequent decrease in friction coefficient (Selway and Stokes 2013). This has been observed in emulsions with varying sensitivity to coalescence: coalesced emulsions had lower friction coefficients than more stable emulsions (Dresselhuis et al. 2008b).

3.3 Relationships to Rheological Behaviors

The primary focus on rheology–tribology behaviors in semisolid foods to date has been on the relationship between viscosity and friction regime. As discussed in Sects. 1.1.3 and 3.1.3, increased viscosity promotes transition into mixed and hydrodynamic sliding at lower sliding speeds, and a viscosity correction can assist in more accurate comparisons among samples.

Although viscosity can be important in terms of specific behaviors at a given sliding speed, it does not necessarily relate to all tribological differences observed in foods. For example, acid milk gels (Joyner (Melito) et al. 2014a), yogurts (Selway and Stokes 2013), and custards (Selway and Stokes 2013) with similar viscosities showed significantly different friction profiles, potentially due to differences in composition and surface-related interactions (Selway and Stokes 2013). Furthermore, rheological and tribological behaviors may not be related because they evaluate different mechanical behaviors. No correlation was found between rheological and tribological behaviors of commercial yogurts (Selway and Stokes 2013; Huc et al. 2016) or custards (Selway and Stokes 2013); the analyses were proposed to be complimentary for assessing instrumental indicators of textural attributes (Huc et al. 2016). In general, rheological and tribological analyses are generally performed in an effort to better understand drivers of sensory texture rather than determine rheology–tribology relationships; there is little focus on food rheology–tribology relationships in the literature as of 2019.

Relationships between rheological behaviors and tribological behaviors may be due to structural features that impact both behaviors. For example, gelatinized starch solutions that break down under shear show reduced friction coefficient and lower viscoelastic moduli values (Zhang et al. 2017). Emulsion breakdown can result in higher viscosity due to droplet flocculation and reduced friction coefficients due to accumulation of the oil phase in the contact zone (Van Aken et al. 2007). Structural evaluation, especially under high-shear conditions, should be incorporated into any food tribological evaluation for a better understanding of the drivers of friction behaviors.

3.4 Relationships to Texture Attributes

One of the key drivers of food tribological studies is the desire to use tribology to more fully understand food textural attributes. This is particularly true of semisolid foods, which have textures that can be difficult to relate to traditional rheometry data. Accordingly, studies published on semisolid food tribology–sensory relationships have examined what specific texture attributes relate to friction (de Wijk and Prinz 2005; Nguyen et al. 2017; Sonne et al. 2014; De Wijk et al. 2006b; Morell et al. 2017; Laguna et al. 2017; Huc et al. 2016), what measurement protocols provide friction data that either better differentiates samples that can be differentiated by sensory analysis but not rheological analysis (Chojnicka-Paszun and De Jongh 2014; Nguyen et al. 2015; Selway and Stokes 2013) or provide closer approximation to oral processing (Tsui et al. 2016; Huc et al. 2016), and how addition of saliva during tribological measurements impacts friction–texture relationships (Joyner (Melito) et al. 2014a; Selway and Stokes 2013; Morell et al. 2017).

As friction is a system property, it is not surprising that the relationships between semisolid food friction behaviors are highly dependent on semisolid food composition and testing conditions. Addition of starch to high-protein yogurts reduced friction coefficients and increased smoothness and creaminess perception (Chapter 12). These relationships are likely related to the structural features that control friction behaviors (discussed in Sect. 3.2): structural features can control both friction and sensory behaviors. Addition of saliva to acid milk gels made with different hydrocolloids resulted in better alignment of friction profiles with friction-related sensory attributes, such as smoothness and astringency, compared to friction profiles of acid milk gels tested without saliva (Joyner (Melito) et al. 2014a). Emulsions that were more sensitive to coalescence had higher creamy and fatty mouthfeel and lower friction coefficients (Dresselhuis et al. 2008b). Creaminess has also been found to be related to yogurt particle size and friction coefficient (Laiho et al. 2017; Sonne et al. 2014), as has graininess (Krzeminski et al. 2014). Similarly, reduced roughness and increased creaminess is related to lower friction coefficients in custards (de Wijk and Prinz 2005). However, friction and texture measurements do not always align. Yogurts with added whey protein concentrate were perceived as astringent, but friction coefficients were not impacted by whey protein concentrate (Morell et al. 2017). In addition, friction behaviors were not in line with yogurt and cream cheese mouthfeel and afterfeel as evaluated by an untrained panel (Laguna et al. 2017).

It can be difficult to relate semisolid food friction behaviors and texture attributes due to the complex nature of the foods in question. While a few general relationships can be made, such as lower friction coefficient, decreased roughness, and increased smoothness, friction–sensory relationships in semisolid foods are not usually straightforward. Because structural features can control both friction behaviors and sensory attributes, evaluating semisolid food microstructure, friction behaviors, and textural attributes can elucidate relationships among these data groups—or at least reasons why there are no relationships. Unfortunately, there are not many studies that consider the fuller picture of semisolid food structure, rheological and friction behaviors, and texture. Most studies focus on two of these three categories. More work is needed to better establish the relationships among semisolid food structure, function, and texture.

4 Yogurt Tribology

As of 2019, major consumer trends for yogurt include clean label, high protein, presence of probiotics or prebiotics, lower sugar, drinkable products, and non-traditional (e.g. savory) flavors (Prepared Foods 2018; Loria 2017; Mordor Intelligence 2018). While consumers demand greater health benefits and formulations with fewer, simpler ingredients, they do not want to sacrifice flavor or texture. These demands present a major challenge for yogurt manufacturers because many of these formulation changes result in less desirable textures. Removal of polysaccharide stabilizers, which provide viscosity and texture, can cause a watery, low-viscosity yogurt with little body in the mouth (Tribby 2008; Ares et al. 2007; Sandoval-Castilla et al. 2004). Adding protein or fiber to yogurt can result in a chalky, powdery, or astringent mouthfeel (Morell et al. 2017; Saint-Eve et al. 2006; Isleten and Karagul-Yuceer 2006; Drake et al. 2000). This is particularly true of casein (Isleten and Karagul-Yuceer 2006; Drake et al. 2000) and milk protein concentrates, which are difficult to disperse at room temperature (Meena et al. 2017; Crowley et al. 2014). Although rheometry can be used to detect changes in yogurt viscosity, yield stress, and viscoelastic behaviors, it is often difficult to fully understand drivers of yogurt texture with only rheological measurements. Tribometry has shown some success in determining additional factors that impact yogurt texture; however, additional study is needed to fully understand yogurt structure–function–texture relationships.

Yogurt comprises milk and two bacterial cultures (Lactobacillus delbrueckii ssp. bulgaricus and Streptococcus thermophilus); it also commonly contains sugars, stabilizers and texturing agents, flavor, and fruit pieces. All of these ingredients can impact yogurt friction behaviors, with the specific effects dependent on the level of addition and the interaction of the ingredient with the other components in the yogurt system, as well as the interaction of the ingredient on sliding surfaces. Many of the effects of these ingredients are covered in Sect. 3. Because of the complexity of the effects of ingredients on yogurt systems (Selway and Stokes 2013), may studies use model systems, such as acid milk gels (Joyner (Melito) et al. 2014a) or highly simplified plain yogurts (e.g. milk, cultures, and 1–2 other ingredients) in an effort to isolate the specific effects of individual ingredients on overall yogurt behavior. While these model systems can be useful for this purpose, it may be difficult to translate the results to a full yogurt system: friction is a system property and can be impacted not only by ingredients, but also by interactions among the ingredients or between the ingredients and the sliding surfaces.

Addition of saliva can have a major impact on yogurt friction behaviors, particularly yogurts containing starch. Understanding how saliva affects yogurt friction profiles can aid in understanding differences in yogurt texture profiles. Friction profiles of yogurt–saliva mixtures can have notably different shapes than friction profiles of yogurt alone, including shifting from one sliding regime to another. An example of this is shown in Fig. 9: acid milk gels, a yogurt analog, that contained starch showed hydrodynamic behavior without saliva and a complex friction profile that did not exhibit a classical Stribeck shape.

Different formulations of acid milk gels tested (a) without saliva and (b) with saliva. (Joyner (Melito) et al. 2014a)

While great progress has been made in the last few decades on understanding how yogurt friction behaviors impact their textural properties, much more work remains to fully map how yogurt tribological behaviors relate to their structure, rheological behaviors, and texture attributes. Future work on yogurt friction should include determination of appropriate sliding speeds for evaluating yogurt friction properties, the specific composition of material in the contact area during different sliding speeds, and the precise effects of saliva on yogurt structure during oral processing and how those effects impact friction behavior. All of this information will allow a more fundamental understanding of why yogurts have specific mouthfeels and how to formulate healthier yogurts with enjoyable textures.

References

Adams, G. G., & Nosonovsky, M. (2000). Contact modeling — forces. Tribology International, 33, 431–442.

Akhtar, M., Stenzel, J., Murray, B. S., & Dickinson, E. (2005). Factors affecting the perception of creaminess of oil-in-water emulsions. Food Hydrocolloids, 19, 521–526.

Andrewes, P., Kelly, M., Vardhanabhuti, B., & Foegeding, E. A. (2011). Dynamic modelling of whey protein–saliva interactions in the mouth and relation to astringency in acidic beverages. International Dairy Journal, 21, 523–530.

Ares, G., et al. (2007). Influence of gelatin and starch on the instrumental and sensory texture of stirred yogurt. International Journal of Dairy Technology, 60, 263–269.

Beecher, J. W., Drake, M. A., Luck, P. J., & Foegeding, E. A. (2008). Factors regulating astringency of whey protein beverages. Journal of Dairy Science, 91, 2553–2560.

Bongaerts, J. H. H., Fourtouni, K., & Stokes, J. R. (2007a). Soft-tribology: Lubrication in a compliant PDMS-PDMS contact. Tribology International, 40, 1531–1542.

Bongaerts, J. H. H., Rossetti, D., & Stokes, J. R. (2007b). The lubricating properties of human whole saliva. Tribology Letters, 27, 277–287.

Brennan, C. S., & Tudorica, C. M. (2008). Carbohydrate-based fat replacers in the modification of the rheological, textural and sensory quality of yoghurt: Comparative study of the utilisation of barley beta-glucan, guar gum and inulin. International Journal of Food Science and Technology, 43, 824–833.

Brossard, N., Cai, H., Osorio, F., Bordeu, E., & Chen, J. (2016). “Oral” tribological study on the astringency sensation of red wines. Journal of Texture Studies, 47, 392–402.

Camacho, S., Liu, K., van der Linden, A., Stieger, M., & van de Velde, F. (2015). Formation, clearance and mouthfeel perception of oral coatings formed by emulsion-filled gels. Journal of Texture Studies, 46, 399–410.

Campbell, C. L., Foegeding, E. A., & van de Velde, F. (2017). A comparison of the lubrication behavior of whey protein model foods using tribology in linear and elliptical movement. Journal of Texture Studies, 48, 335–341.

Cárdenas, M., et al. (2007a). Human saliva forms a complex film structure on alumina surfaces. Biomacromolecules, 8, 65–69.

Cárdenas, M., Elofsson, U., & Lindh, L. (2007b). Salivary Mucin MUC5B could be an important component of in vitro pellicles of human saliva: An in situ ellipsometry and atomic force microscopy study. Biomacromolecules, 8, 1149–1156.

Carpenter, G. H. (2013). The secretion, components, and properties of saliva. Annual Review of Food Science and Technology, 4, 267–276.

Chen, J. (2009). Food oral processing- a review. Food Hydrocolloids, 23, 1–25.

Chen, J., & Engelen, L. (2012). Food oral processing: Fundamentals of eating and sensory perception. (p. 320). West Sussex, UK: John Wiley & Sons.

Chen, J., & Stokes, J. R. (2012). Rheology and tribology: Two distinctive regimes of food texture sensation. Trends in Food Science and Technology, 25, 4–12.

Chojnicka, A., De Jong, S., De Kruif, C. G., & Visschers, R. W. (2008a). Lubrication properties of protein aggregate dispersions in a soft contact. Journal of Agricultural and Food Chemistry, 56, 1274–1282.

Chojnicka, A., de Jong, S., de Kruif, C. G., & Visschers, R. W. (2008b). Lubrication properties of protein aggregate dispersions in a soft contact. Journal of Agricultural and Food Chemistry, 56, 1274–1282.

Chojnicka, A., Sala, G., DeKruif, C., & van de Velde, F. (2009). The interactions between oil droplets and gel matrix affect the lubrication properties of sheared emulsion-filled gels. Food Hydrocolloids, 23, 1038–1046.

Chojnicka-Paszun, A., & De Jongh, H. H. J. (2014). Friction properties of oral surface analogs and their interaction with polysaccharide/MCC particle dispersions. Food Research International, 62, 1020–1028.

Chojnicka-Paszun, A., de Jongh, H. H. J., & de Kruif, C. G. (2012). Sensory perception and lubrication properties of milk: Influence of fat content. International Dairy Journal, 26, 15–22.

Christersson, C. E., Lindh, L., & Arnebrant, T. (2000). Film-forming properties and viscosities of saliva substitutes and human whole saliva. European Journal of Oral Sciences, 108, 418–425.

Crockett, R. (2014). Friction and adhesion of polysaccharides. Tribology Online, 9, 154–163.

Crowley, S. V., et al. (2014). Heat stability of reconstituted milk protein concentrate powders. International Dairy Journal, 37, 104–110.

Davies, G. A., & Stokes, J. R. (2008). Thin film and high shear rheology of multiphase complex fluids. Journal of Non-Newtonian Fluid Mechanics, 148, 73–87.

Dawes, C. (1975). Circadian rhythms in the flow rate and composition of unstimulated and stimulated human submandibular saliva. The Journal of Physiology, 244, 535–548.

Dawes, C. (1996). Factors influencing salivary flow rate and composition. Saliva Oral Health, 2, 27.

De Hoog, E. H. A., Prinz, J. F., Huntjens, L., Dresselhuis, D. M., & Van Aken, G. A. (2006). Lubrication of oral surfaces by food emulsions: The importance of surface characteristics. Journal of Food Science, 71, E337–E341.

de Vicente, J., Stokes, J. R., & Spikes, H. A. (2005a). The frictional properties of Newtonian fluids in rolling-sliding soft-EHL contact. Tribology Letters, 20, 273–286.

de Vicente, J., Stokes, J. R., & Spikes, H. A. (2005b). Lubrication properties of non-adsorbing polymer solutions in soft elastohydrodynamic (EHD) contacts. Tribology International, 38, 515–526.

De Vicente, J., Stokes, J. R., & Spikes, H. A. (2006). Soft lubrication of model hydrocolloids. Food Hydrocolloids, 20, 483–491.

de Wijk, R. A., & Prinz, J. F. (2005). The role of friction in perceived oral texture. Food Quality and Preference, 16, 121–129.

de WIjk, R. A., & Prinz, J. F. (2006). Mechanisms underlying the role of friction in oral texture. Journal of Texture Studies, 37, 413–427.

de Wijk, R. A., & Prinz, J. F. (2007). Fatty versus creamy sensations for custard desserts, white sauces, and mayonnaises. Food Quality and Preference, 18, 641–650.

De Wijk, R. A., Prinz, J. F., Engelen, L., & Weenen, H. (2004). The role of alpha-amylase in the perception of oral texture and flavour in custards. Physiology & Behavior, 83, 81–91.

de Wijk, R. A., Wulfert, F., & Prinz, J. F. (2006a). Oral processing assessed by M-mode ultrasound imaging varies with food attribute. Physiology & Behavior, 89, 15–21.

De Wijk, R. A., Prinz, J. F., & Janssen, A. M. (2006b). Explaining perceived oral texture of starch-based custard desserts from standard and novel instrumental tests. Food Hydrocolloids, 20, 24–34.

Derler, S., Schrade, U., & Gerhardt, L.-C. (2007). Tribology of human skin and mechanical skin equivalents in contact with textiles. Wear, 263, 1112–1116.

Dickie, A. M., & Kokini, J. L. (1983). An improved model for food thickness from non-Newtonian fluid mechanics in the mouth. Journal of Food Science, 48, 57–61.

Drake, M. A., Chen, X. Q., Tamarapu, S., & Leenanon, B. (2000). Soy protein fortification affects sensory, chemical, and microbiological properties of dairy yogurts. Journal of Food Science, 65, 1244–1247.