Abstract

The paper summarizes one the approach to the describing the Pisarenko-Lebedev generalized long-term strength criterion, which is used in determining the equivalent stress in the Yu. Rabotnov’s kinetic equation of damageability. Finding the equivalent stress is one of the important yet difficult-to-solve problems. There are multiple long-term strength criteria, but no precise recommendations on their use, which is what makes this problem so difficult to solve. The most reasonable and universal criterion is generalized Pisarenko-Lebedev generalized long-term strength criterion. The authors proposed a simple and easy-to-use method to find the equivalent stress when using the Pisarenko-Lebedev generalized strength criterion. This method for concretizing the Pisarenko-Lebedev generalized long-term strength criterion, in the first approximation accounts for alterations in the plastic properties of the material as a function of the loading time, temperature, and stresses, enabling the research to account for the prevalence of viscous or brittle fracture, which in its turn enables more accurate damage and time-to-rupture predictions. More detailed experimentation to test this criterion and its concretization method requires further research based on in-site experiment data.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Ensuring the long-term strength of various structures subjected to non-isothermal loading is an important problem of the mechanics of deformable solids. To assess the long-term strength of such structures, one must find the accurate history of their stress-strain state, taking into account the occurring elastic and plastic strain, the creep, and the subsequent degradation of mechanical properties. With the calculation output at hand, it is possible to identify dangerous zones in the first approximation and to use the criteria of long-term strength to assess the safe life of the structure [1]. However, such long-term strength assessment of a structure in a complex and inhomogeneous stress state is going to be rather approximate. Accurate determination of the strength of a structure in a complex inhomogeneous stress state requires a generalized statement of problem, based on the use of continuous fracture mechanics proposed by Rabotnov [2, 3]. This approach implies adding the scalar parameter of creep-related damageability of the material to the governing equations describing the stress-strain state of a structure. To describe the processes of damage accumulation in the material, the kinetic equation of damage proposed by Rabotnov [2] is used:

where ωC is the scalar damage parameter; C and Q—parameters dependent on temperature and determined from long-term strength curves obtained from uniaxial tension tests of standard samples at fixed temperatures; σeq—equivalent stress, which is one of the criteria for long-term strength.

As a rule, such problems are solved by numerically. The process of loading a structure is divided into short intervals, while the structure itself is divided into small elements such that their stress state becomes homogeneous. These data must then be used to describe the interval-specific stress-strain state and the degree of damage to the structural elements. The strain history can then be traced from interval to interval until rupture.

2 Research Goal

The goal hereof is to:

-

Analyze the known approaches to describing the Pisarenko-Lebedev generalized long-term strength criterion, which is used in determining the equivalent stress in the Rabotnov kinetic equation of damageability;

-

Choose a method for concretizing the Pisarenko-Lebedev generalized long-term strength criterion;

-

Choose a concretization method and validate the results of simulating the stress-strain state of a flat plate as obtained by using this criterion.

3 Materials and Methods

Finding the stress-strain state of a structure in the context of creep-related damageability of material is a problem covered in numerous papers, e.g., [4,5,6]. Finding the equivalent stress is one of the important yet difficult-to-solve problems. There are multiple long-term strength criteria, but no precise recommendations on their use, which is what makes this problem so difficult to solve. The most reasonable and universal criterion is generalized Pisarenko-Lebedev generalized long-term strength criterion [7]:

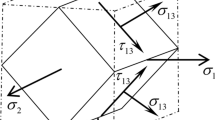

here σeq is the equivalent stress; χ—material plasticity coefficient [7], σi—stress intensity, which, in a plane stressed state, is determined by the expression \( \sigma_{\text{i}} = \sqrt {\sigma_{1}^{2} - \sigma_{1} \sigma_{2} - \sigma_{2}^{2} } \), σ1 and σ2—main normal stresses.

When assessing the long-term strength of a structure, the corresponding χ parameter can be found by testing the long-term strength of solid cylindrical specimens subjected to uniaxial tension and compression, or by torsional testing of thin-walled tubular specimens. These characteristics are calculated by the formulas [7, 8]:

where

- \( \sigma_{\text{LT}}^{T} \):

-

is the long-term tensile strength limit;

- \( \sigma_{\text{LT}}^{T} \):

-

is the long-term compression strength limit;

- \( \tau_{\text{LT}} \):

-

is the long-term net shear (torsion) strength limit.

The problem of applying this long-term strength criterion is the lack of experimental data on the long-term compressive and torsional strength of materials.

In papers [6, 9], the parameter χ is a function of the intensity of tangential stresses and temperature; as such, it is found from the condition that long-term strength diagrams must coincide for uniaxial tension σ(t*) and pure torsion τ(t*), whereby is found by the expression:

where the stresses σ and τ are picked for the same time point t*. For the selected time point t*, the corresponding average mean intensities of the tangential stresses S are found from the diagrams of long-term tensile strength and pure torsion. This procedure is repeated for different values χ of at different fixed temperatures T. This is done to obtain the dependence χ = f (S, T), which is further used to find the equivalent stress. Apparently, this method implies complex and prolonged tensile and purely torsional testing of tubular specimens, which sometimes might be impractical.

The authors hereof believe that the Pisarenko-Lebedev long-term strength criterion can be used to account for changes in the material damage types if the parameter is assumed to be a function of stresses, temperature, and creep duration.

In [10], the authors proposed a simple and easy-to-use method to find the χ parameter when using the Pisarenko-Lebedev generalized strength criterion. In this case, the χ parameter for this or that material is deemed to equal the relative residual contraction at break ψ. A similar approach is proposed for finding the χ parameter when making long-term strength calculations. To that end, denote this parameter as χC and assume that χC = ψC where ψC—is the relative residual contraction of a solid round specimen, obtained by testing it for creep and long-term strength at a constant stress and temperature. Tests for creep and long-term strength of standard cylindrical metal/alloy specimens made reveal the following pattern: at high stress levels significantly exceeding the ultimate strength of the material, the intragranular fracture (viscous fracture) prevails, accompanied by localized intensive creep, whereby a neck emerges. The relative residual contraction of the specimen, obtained by creep tests, is nearly identical to the relative residual contraction value obtained by the standard tensile test of solid cylindrical specimens, as they are instant-strained to rupture at the same temperature.

At the same time, if the stress is low and barely exceeds the creep strength of the material, intergranular strain and fracturing prevail, with the specimen being intensively embrittled without forming a neck; fracturing occurs at low accumulated creep over a long time. Relative residual contraction is nearly zero. Based on these observations and on the first-approximation assumption that the relative residual creep contraction of a fractured specimen is linearly dependent on the tensile stresses, one can construct a simple dependence for fixed temperatures.

In this case, the relative residual constriction ψC will take values close to zero. Based on these observations and assuming that the relative residual constriction during creep of the sample during fracture linearly depends on the tensile stresses level at which the tests take place, it is possible to construct a linear relationship for fixed temperatures ψC = f (σ):

where

- ψC:

-

is the relative residual contraction of a standard specimen of circular cross-section, obtained by testing for creep and long-term strength at a constant stress σ at a fixed temperature T;

- Ψ:

-

is the relative residual contraction, obtained by stretching a standard specimen of circular cross-section at its instantaneous deformation at the same temperature;

- σS:

-

is the material strength limit;

- \( \sigma_{{0.2/10^{5} }} \):

-

is the material creep limit at a given temperature.

For most structural materials, reference books contain all data necessary for applying the ratio (6) in long-term strength calculations [8]. Figures 1 and 2 show the relative residual contraction at creep as a function of stress (the solid line); these curves were plotted by the proposed method for steel 20 and for 12X18H9T austenite steel. Besides, the same curves show (in dark circles) the ψC experimental values for the same materials as obtained for various normal stresses at the same temperatures [8]. The curves reveal that experimental data match very well the calculations by the proposed method.

Thus, the approach proposed herein implies using the following formula to find the element and loading interval-specific equivalent stress:

here, ψC is found as per (6). The statement of problem is complemented with the following mechanical properties of the material as observed at fixed temperature within its normal operating range for this structure: ultimate strength, creep strength, and relative residual contraction.

4 Experimental Results

To verify the adequacy of the proposed method of concretizing the Pisarenko-Lebedev generalized long-term strength criterion, the research team tested a single-layer plate with a circular hole, heated uniformly to 500 ℃ and exposed to pressure on the top, see Fig. 3. The steel 20 plate had the following dimensions: R = 110 mm, r = 65 mm, δ = 10 mm. Multiple calculations were run at pressures of 7–12 MPa; however, pressure was never changed within a single test.

The time to fracture as a function of pressure was studied in terms of four different long-term strength criteria, see Fig. 4 for the main results.

Figure 4 shows the curves of the time to fracturing onset as a function of pressure within 9–12 MPa; the curves were plotted using four different long-term strength criteria.

Notably, using the Johnson criterion produces the minimum estimated time to rupture (brittle fracture), and while the Katz criterion returns the maximum estimated time to rupture (plastic fracture) [11]. Thus, using any long-term strength criterion will produce a value within the range limited by the Johnson and Katz values. The Sdobyrev criterion is a half-sum of these two, and the Sdobyrev curve is near the middle.

As the equivalent stress is taken (Fig. 4):

-

1.

maximum principal stress (the Johnson’s criterion): \( \sigma_{\text{eq}} = \sigma_{1} \);

-

2.

stress intensity (the Katz’s criterion): \( \sigma_{\text{eq}} = S\sqrt 3 \);

-

3.

the Sdobyrev’s criterion: \( \sigma_{\text{eq}} = 0,5 \cdot \left( {\sigma_{1} + S\sqrt 3 } \right) \);

-

4.

the Pisarenko-Lebedev’s long-term strength generalized criterion: \( \sigma_{\text{eq}} = \psi_{\text{C}} S\sqrt 3 + (1 - \psi_{\text{C}} ) \cdot \sigma_{1} \).

The finding here is that the chosen long-term strength criterion affects the estimated time to rupture, with the effect being greater for lower loads and longer loading. The proposed way to concretize the Pisarenko-Lebedev generalized long-term strength criterion allows to account for the altered plastic properties of the material (the embrittlement); such alteration occurs as creep develops.

Figure 4 shows that the curves 3 (the Stobyrev criterion) and 4 (the Pisarenko-Lebedev generalized criterion) are nearly identical in coordinates and intersect at 10.2 MPa. Stresses affecting the most loaded points of the plate at such pressure are about 150 MPa, or ψ = 50%. Further, curve 4 approaches curve 2 (the Katz criterion), which means viscous fractures rather than brittle fractures prevail. At lower pressures, the Pisarenko-Lebedev criterion is close to the Johnson criterion results-wise. For instance, at 7 MPa time to fracture is 10,000 h per the Johnson criterion, 70,000 per Katz, and 12,500 per Pisarenko-Lebedev.

Analysis of the stresses in the most heavily loaded points shows such stresses do not reach the ultimate strength, meaning that brittle fractures rather than viscous fractures will prevail. Difference in time to rupture at 7 MPa is vastly different for the Johnson criterion and the Katz criterion: It is about 60,000 h or 7 times. This is why using non-modified criteria returns unreliable results.

5 Conclusions

The proposed method for concretizing the Pisarenko-Lebedev generalized long-term strength criterion in the first approximation accounts for alterations in the plastic properties of the material as a function of the loading time, temperature, and stresses, enabling the research to account for the prevalence of viscous or brittle fracture, which in its turn enables more accurate damage and time-to-rupture predictions. More detailed experimentation to test this criterion and its concretization method requires further research based on in-site experiment data, with some of such experiments being discussed in [12]. The research team behind this paper plans to carry out such research further on.

References

Volegov PS, Gribov DS, Trusov PV (2015) Damage and destruction: classical continual theories. Phys Mesomech 18(4):68–87

Rabotnov YN (1966) The creep of structural elements. Science, Moscow

Khokhlov AV (2017) Criterion of destruction and long-term strength curves, generated by the defining relation of the nonlinear theory of heredity Yu. N. Rabotnov. Her Mech Eng 6:39–46

Aliev MM, Shafieva SV, Gilyazova SR (2015) Criterion of long-term strength for materials of different resistance. Mater Sci Sess Sci Almetyevsk State Oil Inst 1(1):254–257

Arutyunyan RA (2015) High-temperature embrittlement and long-term durability of metallic materials. In: Proceedings of the Russian academy of sciences. Solid mechanics, vol 2. pp 96–105

Shevchenko YN, Terekhov RG, Braikovskaya NS, Zakharov SM (1994) Investigation of the processes of destruction of body elements as a result of material damage during creep. App Mech 30(4):21–30

Lebedev AA (2010) The development of theories of strength in the mechanics of materials. Strength Probl 5:127–146

Pisarenko GS, Yakovlev AP, Matveev VV (2008) Materials resistance handbook. Delta, Kiev, p 816

Galishin AZ (2004) Determination of thermo-viscoplastic state of shells of revolution taking into account the material damageability in creep. Appl Mech 40(5):71–79

Belov AV, Neumoina NG (2014) On the use of Pisarenko-Lebedev generalized strength criterion in strength calculations for non-isothermal loading processes. Int J Appl Basic Res 9:8–10

Polivanov AA (2004) Axially symmetric elasto-plastic deformation of multilayered shells of rotation with an account of material damage at a creep, abstract of dissertation, Volgograd

Belov AV (1989) Axially symmetric elasto-plastic stressed–strained state of shells of rotation with an account of material damage at a creep, abstract of dissertation, Kiev

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Belov, A.V., Polivanov, A.A., Neumoina, N.G. (2020). Selecting Criterion of Long-Term Strength in Assessing Durability of Constructions Operating Under Non-isothermal Loading Processes. In: Radionov, A., Kravchenko, O., Guzeev, V., Rozhdestvenskiy, Y. (eds) Proceedings of the 5th International Conference on Industrial Engineering (ICIE 2019). ICIE 2019. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-22063-1_23

Download citation

DOI: https://doi.org/10.1007/978-3-030-22063-1_23

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-22062-4

Online ISBN: 978-3-030-22063-1

eBook Packages: EngineeringEngineering (R0)