Abstract

This study examined the physical/mechanical properties of selected artists’ oil paints. Samples included paint outs of pure paint as well as samples paints that have been modified. Dynamic mechanical analysis (DMA) and nanoindentation were used to investigate mechanical properties. DMA tests indicated appreciable differences in glass transition temperature (Tg) within each sample set. The effect of the paint modifications could be observed in terms of changes in the glass transition temperatures. Carried out at ambient temperature and controlled relative humidity conditions, the nanoindentation testing included determination of modulus values, before and after 24 h immersion in aliphatic hydrocarbon solvent, of the underside surfaces of yellow ochre and cadmium yellow paint samples. The ultramarine oil paint sample tested by nanoindentation at different relative humidities showed that the paint softened significantly by sorption of water, indicating vulnerability to permanent deformation at high moisture levels. Moisture sorption isotherms confirmed significant increases in water uptake above 60% relative humidity, especially for ultramarine. These results explain why conservators experience very different effects of temperature and moisture-based treatments.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Modern artists’ oil paint

- Dynamic Mechanical (Thermal) Analysis (DMA)

- Nanoindentation

- Dynamic Vapour Sorption (DVS)

- Mechanical properties

1 Introduction

It is well known that artists’ oil paints―effectively filled polymer systems [20]―may differ considerably in their material properties depending on a variety of intrinsic factors including: binder composition; the nature of pigments/extenders; driers; and other additives. Similarly, oil paints may be differently affected by extrinsic factors such as ageing, changes in the environmental conditions, or exposure to conservation treatments like cleaning. Knowledge of the mechanical properties of paints and the way those properties change with variations in moisture content and temperature can inform active conservation treatments and passive preventive conservation measures.

The mechanical properties of artists’ oil paints have been studied extensively by Mecklenburg and his co-workers using tensile testing to generate load/extension curves from which values for (elastic) modulus and tensile strength could be determined (eg. [10]). It is recognised, however, that oil paints, when cured, may be more or less viscoelastic depending on some of the intrinsic factors mentioned above. They may behave more glassy (elastic) or more viscous (plastic) depending on temperature and/or the rate of loading. If an oil paint shows a distinct softening (reduction in elastic modulus) when subjected to a temperature ramp, as it changes from the glassy state to the leathery/rubbery state, a glass transition temperature (Tg) may be determinable. The value of the Tg indicates the state in which the material likely exists at any operating temperature.

Within art conservation, research into the viscoelastic behavior of oil paints commenced with the influential study by Hedley, Odlyha and co-workers that was set in the context of cleaning. A specific point of interest was the long-term impact on paint properties of exposure to solvents and water [8]. As the first study in this subject area to use dynamic methods of thermal mechanical analysis, Hedley’s group demonstrated the potential for significant changes to the mechanical properties of some oil paints caused by extraction (leaching) of plasticizing soluble components of the binder phase. Using the method of Dynamic Load Thermal Mechanical Analysis (DLTMA), this work documented the temperature-dependent softening transitions of a sample of commercial oil paintFootnote 1. Three transitions were observed, the onset of the lowest-temperature one occurring at −20 °C. This transition was identified as the major change from glassy to viscoelastic state. It was attributed to “the glass transition temperature (Tg) of linseed oil itself”.

The question of the temperature range over which artists’ oil paints underwent the transition from glassy to leathery behaviour remained effectively unstudied experimentally for some time after Hedley and Odlyha’s initial explorations; the main contribution on the topic was the review by Michalski [14]. Despite the “spotty collection of data” reported in the literature, Michalski concluded that there was sufficient evidence “to piece together the glassy/rubbery transition of oil paint” and that “the fundamental glass/rubber transition for oil paint starts near −30 °C (−22 °F) and ends before 0 °C (32 °F) for linseed, walnut and poppy oil, with or without pigments, with or without aging.” On this evidence, one would expect most oil paints to be in the rubbery/leathery (viscoelastic), not glassy, state at room temperature. The topic of the Tg of artists’ oil paint was revisited by Phenix [18], using DMA (Dynamic Mechanical Analysis) introduced by [8] two decades earlier.Footnote 2 Depending primarily on their pigment content and condition, the paints tested varied considerably in their thermo-mechanical properties, some showing effectively no distinct glass transition in the near-ambient temperature range, while others showed strong glass transitions with a narrow Tg peak and a considerable change of modulus that could be either above or below room temperature. However, only a very few paints had Tg values―as indicated by the temperature of the maximum value of the 1 Hz tan δ trace―that were below zero. The lowest value measured was ca. −4 °C for alizarin crimson in cold-pressed linseed oil.

Mechanical properties of paints, determined by tensile testing, have also been shown to vary with the degree of drying/curing and subsequent ageing, as well as pigmentation [5, 6, 10]. These very different properties are essential to conservation decisions such as flattening, consolidation and cleaning. Conservators know from experience that some pigments produce soft and flexible paint films and, therefore, are easier to deform when flattening deformations than for example paints that contain lead or zinc pigments. Earth pigments generally have a tendency to hydrolyse, which makes them sensitive to cleaning treatments [11]. In addition, modern commercial paints have shown to be sometimes problematic due to the addition of organic modifiers such as metal soaps, fatty acids, or oils that are only semi-drying [1, 9], not to mention inorganic extenders that are prone to chemical alteration by exposure to airborne pollutants to produce water-soluble salts [3]. Even without the presence of any hygroscopic, water-soluble salts, the mechanical properties of oil paints are known to be influenced by moisture content, water essentially having a plasticizing effect. This is known from practical experience of treating oil paintings, but it has also been demonstrated experimentally, albeit to a limited extent [9].

All of the topics considered above―the magnitudes of elastic (storage) and viscous (loss) moduli of oil paints of different formulation and condition; the temperature- and moisture content-dependency of those moduli― warrant further investigation. New instrumentation, particularly nanoindentation conducted under controlled environmental conditions, allows those properties to be explored at the sub-microscopic level [19, 22].

Conducted as part of the EU Heritage Plus project Cleaning Modern Oil Paintings (CMOP), the aim of the present study was to examine the mechanical properties of selected commercial Winsor & Newton oil paints. Conventional tensile testing was not a viable approach given the nature of the paint samples available to the CMOP group which were constrained by their size, their surface conformation and their mounting onto polyester support from which they could not be removed in many instances. The challenge for the study, therefore, was to find alternative approaches to probe the samples for parameters that characterized the respective physical/mechanical properties of each paint type. It was also desired that the test methods could provide information on changes in surface (versus bulk) properties that may be caused by cleaning liquids, or by shifts in temperature or relative humidity (RH). Given these constraints and aspirations, it was therefore decided to explore the use of nanoindentation paired with dynamic vapour sorption to analyse mechanical properties of selected paints, alongside conventional time-temperature testing by DMA.

2 Materials and Methods

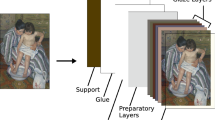

2.1 Test Samples

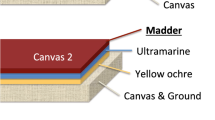

The oil paint samples tested here were prepared at the Cultural Heritage Agency of the Netherlands (RCE) in 2006, and have been described previously in Mills et al. [16]. The pigments were ultramarine (UL), cobalt blue (CB), cadmium red (CR), cadmium yellow (CY), raw sienna (RS) and zinc white (ZW). A number of modifications had been made to the tube paints before they were painted out: 2% of aluminum stearate (-AS), 2% of zinc stearate (-ZS), 2% of fatty acids (-FA), 10% of linseed oil (-LN), 10% of alumina hydrate (-AH) were added to the different pure paints; oil was extracted from pure paints by use of filter paper (-EX). For more on sample preparation see Mills et al. [16]. These modifications introduced variations in physical properties that would challenge the instrumental testing. The paint films were applied onto, and usually inseparable from, a 100 μm polyester support (Melinex) providing a technical constraint for the mechanical testing. They were relatively uneven in surface. Since 2006 they had been stored in daylight and indoor conditions climatized for human comfort until February 2012, when they were unmounted and kept in darkness. The samples chosen for this study have not been artificially aged.

As most of the samples are prepared as brushed paint-outs, the brush strokes result in striations on the surface which can hinder the indentation testing. To lessen this effect, the smooth underside of the material that had been in contact with the plastic substrate was examined. Furthermore, yellow ochre (YO) which was prepared using a drawdown method by Mecklenburg in 1999 was also analyzed using indentation. The paints studied vary in their intrinsic physical properties, ranging from soft and pliable to stiff and brittle (see Table 32.1).

2.2 Dynamic Mechanical Analysis (DMA)

The Dynamic Mechanical Thermal Analysis was done using a similar method as reported by [18], which allowed determination of the glass transition temperatures of oil paints supported on polyester film. Testing was performed using a Triton Technology DMA 2000 instrumentFootnote 3 in single cantilever bending mode, with samples ca. 9 mm wide and a nominal sample gauge length of 5 mm. The DMA tests reported here are time/temperature scans in air: the sample was subjected to a sinusoidal oscillating stress whilst the temperature was progressively increased. Initial cooling from ambient was effected by circulating liquid nitrogen through the DMA measuring head. The starting temperature for each experiment were in the region of −20 °C, (well below the Tg of the paints under consideration) with the endpoint of the ramp at 50 °C. The heating rate was 2 °C per minute. The amplitude/displacement of the vibration was 30 μm. The thermal scans were carried out using vibration frequencies of 1 Hz and 10 Hz, though only the 1 Hz data are reported here.Footnote 4 Two or three repeat tests were done for each sample type. The samples were conditioned to the prevailing room environment (approximately 50% RH, 24 °C) prior to testing.

In these time/temperature scans, three main parameters are determined in relation to temperature: storage (elastic) modulus (E′), loss (viscous) modulus (E″) and tan δ, where: tan δ = E″/ E′.

2.3 Dynamic Vapour Sorption (DVS)

Water sorption isotherms were acquired using an Aquadyne DVS from Quantachrome Instruments fed with 99.999% pure nitrogen gas at a flow rate between 30 mL per minute and 200 mL per minute. The samples tested were approximately 1 cm by 1 cm dried Winsor & Newton paints on the polyester support. The instrument was programmed to record sample mass every 5 min at discrete RH steps; (30, 50, 70, 90, 70, 50, 30% RH) at 21 °C for the pure paint samples and the polyester support alone. For samples which were modified, a less time consuming scan was conducted to achieve an overview of their response. In this case, the instrument was programmed to record the sample mass once every 5 min at the following RH-steps; 50, 75, and 90% RH at 21 °C. As this overview showed no changes compared to the pure paints, the full RH scan was not done. Since ZW did not show significant change of mass with changed RH, a broader scan was made and hysteresis was not tested. Thus for ZW the programme was 10, 30, 50, 60, 70, 80, and 90% RH at 21 °C. Equilibrium was attained in most RH-steps except at the higher values. Sorption isotherms were calculated with the equilibrium mass at 50%RH as a reference point for the other equilibrium masses. For most RH conditions, the criteria for moving onto the next RH step was a mass change lower than 0.004% per minute with minimum and maximum measuring times of 600 and 650 min, respectively; for extreme RH levels (10, 30 and 90%), the minimum and maximum measuring times were increased to 800 and 850 min, respectively.

2.4 Ultra Nanoindentation Tester (UNHT)

Typical Instrumented Indentation Testing (IIT) consists of a probe, with a well-defined geometry, pressed into the surface of a sample producing a load-penetration curve that serves as the “mechanical fingerprint” of the material [7, 23]. Depending on the response of material, be it viscoelastic or otherwise, various iterations of an indentation scheme can be employed. However, there are three common stages of the indentation process: (1) loading, (2) pause, and (3) unloading. When a material exhibits viscoelastic behaviour, a sinusoidal load variation at a selected frequency can be superimposed upon the quasi-static loading process [17]. By analysing the response of a material to such load variations, its stiffness, which is represented by the dynamic reduced storage modulus (Er′), can be defined. In the limit of linear viscoelasticity, Er′ can be calculated by using Sneddon’s stiffness equation to relate stiffness and damping of material [21].Footnote 5

For these tests, three pure samples (UL, CY, and YO) were characterized using an Ultra Nanoindentation Tester (UNHT) (Anton Paar, USA) equipped with a Berkovich (three-sided pyramidal) diamond indenter contained within a climatic chamber (Climats, France). A predetermined indentation depth of at least 6 μm was achieved by applying a predefined load at a constant strain rate of 0.4 s−1 with a sinusoidal load (amplitude of 10% of the maximum load and a frequency of 10 Hz) superimposed on the primary loading scheme. Upon reaching a depth of 6 μm, the load was held constant for 120 s, followed by unloading of the sample at a constant speed of 300 mN/min. The stiffness of the sample is directly proportional to the maximum applied load required to establish an appropriate indentation depth. The experimental procedure consisted of a series of indentations with a range of maximum loads to obtain the predetermined indentation depth. At least seven indents were carried out for each test condition.

To better understand how conservation procedures and treatments affect paint properties, two indentation studies were carried out to examine the effects of water sorption and immersion. Though immersion is not considered a conservation treatment, it can assist in revealing the most extreme response of a material to a solvent. The softening of UL by water sorption was examined by sequentially exposing the material to a range of relative humidity levels (35, 50, 60, 70, and 83% RH). For each level of RH, the sorption data from the DVS tests were used in order to establish the time to equilibrium prior to testing. The effects of immersion in n-heptane on the mechanical properties of CY and YO were also investigated. The test samples (10 × 10 mm) were prepared by separating the paint-outs from the polyester support and adhering the topside of each sample to a microscope slide using cyanoacrylate adhesive, exposing the flat underside for indentation. The reduced storage modulus was used to evaluate the effects of sorption and immersion on the samples.

3 Results and Discussion

3.1 Dynamic Mechanical Analysis (DMA)

The DMA results are focused on CR, CY and UL (Fig. 32.1) as well as the variants of CR and CY. The maxima of the tan δ peaks, signifying the respective glass transitions of each paint type, are listed in Table 32.2. Additionally, the effects of adding or extracting binder in these two paints is shown in Fig. 32.2 (CR, CRLN, CRLN) and Fig. 32.3 (CY, CYLN, CYEX).

DMA of pure Winsor & Newton paints conditioned to ambient climate: variation in 1 Hz tan δ with temperature; temperature range −20–50 °C, ramp rate 2°/min. The Tg is taken as the temperature corresponding to the maximum value of tan δ at 1 Hz, here: Cadmium red, CR (red trace): 2 °C, Ultramarine, UL (blue trace): 9 °C, Cadmium yellow, CY (yellow trace): 14 °C

DMA of medium-modified Winsor & Newton cadmium red oil paints: variation in 1 Hz tan δ with temperature; temperature range −20 °C–50 °C, ramp rate 2°/min. Cadmium red, CR, (red trace): 2 °C; medium extracted from cadmium red, CREX (green trace): 6 °C; and linseed oil added to cadmium red, CRLN (Yellow trace): −4 °C

DMA of medium-modified Winsor & Newton cadmium yellow oil paints: variation in 1 Hz tan δ with temperature; temperature range −20–50 °C, ramp rate 2°/min. Cadmium yellow, CY (yellow trace): 15 °C; Binder extracted from cadmium yellow, CYEX (green trace): 34 °C; and linseed oil added to cadmium yellow, CYLN (brown trace) 15 °C

Figure 32.1 shows that the different pure paints have quite different mechanical responses to temperature. CR is clearly the softest, most plastic of the three, with a Tg of 2 °C and the largest tan δ peak. The UL and CY paints transition from glassy to rubbery/leathery at higher temperatures (9 and 14 °C, respectively), but still below ambient temperature.

Figure 32.2 illustrates the influence of adding or extracting oil from the CR oil paints. Adding 10% oil shifts Tg to lower temperature and increases the magnitude of the softening transition. Extracting oil shifts Tg to higher temperature. Tg values listed in Table 32.2 for all the CR paints show that adding metal soaps effected minimal change to the softening transition temperature, whereas the addition of alumina hydrate made it slightly higher. The addition of oil and fatty acids made the transition temperature lower, as might be expected with a decrease in the relative pigment volume concentration (PVC).

Figure 32.3 illustrates the tan δ traces for similar variants of the CY paints. The positions of the tan δ maximum is effectively the same (15 °C) for both the pure CY and that paint with 10% oil added (CYLN), though the magnitude of the softening transition is somewhat larger for the latter paint, presumably on account of the larger binder proportion. The CYEX (oil extracted) is appreciably more glassy than the other two paints, with a tan δ maximum (Tg) of 34 °C, well above ambient temperature.

Table 32.2 shows that adding metal soaps to CY increased the softening transition temperature just like the addition of alumina hydrate for both CY and CR. The addition of oil lowered the transition temperature for CR, whereas fatty acids made the transition temperature higher for CY and lower for CR. For both paints, the extraction of binder made the transition temperature higher.

For the various test paints studied, measured Tg values lay in the significant range of −5 and 36 °C. Dynamic mechanical analyses showed that Tg is affected by both pigments and additives. At temperatures common for art collections, the differently-formulated paints will therefore vary in stiffness and be elastic or viscous. At room and storage temperatures, some oil paints may experience state change between glassy and rubbery/leathery, and each paint type within a painting can be more or less viscous depending on its formulation. The addition or extraction of binder means a change in PVC. This parameter has implications for properties at different temperatures as the extraction of binder clearly shifted the transition temperature to a higher level. The addition of oil changed the properties of the CR resulting in a more pronounced state change at a lower temperature. The addition of metal soaps increased the softening temperature for CY but not for CR. Exactly how the metal soaps cause such a difference in Tg for one paint and not for the other is uncertain and warrants further study.

3.2 Dynamic Vapour Sorption (DVS) and Nano-indentation (UNHT)

Moisture sorption measurements were carried out at a range of RH values for the pure paint samples described in the experimental section (see Table 32.1), except for YO which was added to the study later. Furthermore, as done for DMA, modifications of cadmium red (CR, CRAS, CRZS, CREX, CRLN, CRFA, CRAH) were tested. The polyester support was tested alone and showed no moisture absorption.

In Fig. 32.4, it is shown that the paint samples responded very differently to changes in RH. While ZW was unaffected by a humidity of 90% RH, UL adsorbed as much as 12% moisture (excluding the mass of the polyester supports they were cast on). The fact that dried oil paint can take up moisture to such a high degree is somewhat surprising since oil, per se, is hydrophobic. However, a film of dried oil is a product of oil autoxidation during curing and ageing [15], which can change the properties of the material. Because of the large sorption of moisture in UL, it was decided to also test the changes in stiffness corresponding to the uptake of water vapour.

No hysteresis was observed in the sorption isotherms in Fig. 32.4. The paint samples in Fig. 32.4 (as well as the samples not shown) were almost unaffected by changes in humidity under 60% RH, indicating no significant moisture sorption. Above 60 or 70% RH, most samples showed increased moisture sorption, with the exception of ZW. The modifications to CR had no effect on the sorption characteristics of the paint.

The indentation results shown in Figs. 32.5 and 32.6 examined the effects of water sorption and immersion in n-heptane on selected samples. Measurements were carried out in a climatic chamber. Figures 32.5 shows the effect of water sorption on the stiffness of UL; the stiffness of the UL sample (which is conveyed by the applied load and Er′) is indirectly proportional to the change in mass caused by the water sorption measured with DVS. Figure 32.5a depicts the measured load and subsequent penetration depth into the UL sample during exposure to discrete RH conditions. To ensure that the tests reached the predetermined depth (6 μm), the applied load was adjusted for each RH step. Indentations performed at 35% RH required a load which was 4 times greater than the load needed at 50% RH to reach the desired testing depth; similarly, much smaller loads were required when the sample was exposed to high RH conditions. This necessary adjustment in the testing parameters signals a change in the mechanical properties of UL and, more specifically, its sensitivity to water. Figure 32.5b summarized the Er′ of UL determined at each RH with comparison to its corresponding percent mass change determined by DVS. Note that nano-indentation tests were not performed above 83% RH. At this humidity UL becomes deliquescent and difficult to characterize in a quantitative way. Known to be water sensitive, UL becomes softer, which is indicated here by a low value of moduli when exposed to higher humidity conditions.

Graph of (a) applied load (left axis) and Indentation Depth (right axis) versus relative humidity and of (b) reduced storage modulus (left axis) and change in mass (right axis) for ultramarine. Each data point represents an average of seven measurements, with error bars representing the standard deviation. Prior to indentation testing, samples were conditioned at each RH, with equilibration times determined from the sorption data

Graph of reduced modulus measured before and after immersion in n-heptane followed by a minimum of two weeks of drying for cadmium yellow (yellow) and yellow ochre (brown). Each bar represents an average of seven measurements, with error bars representing the standard deviation. Listed above each bar is the maximum applied load used during indentation

Indentation tests were also performed to monitor the change in mechanical properties after immersion. CY and YO samples were chosen for this test because they have a similar stiffness. The samples were immersed in n-heptane for 24 h and allowed to dry for two weeks. Figure 32.6 depicts the average of 7 measurements obtained before and after immersion of CY and YO, while also listing the maximum indentation load (mN). As shown in Fig. 32.6, the mechanical properties of both CY and YO display a higher stiffness (larger Er′) after immersion. This behaviour may be attributed to extraction of plasticizing, non-polar low molecular weight components of the paint binder as a result of the solvent immersion process. However, additional testing is needed to clarify the physical/chemical mechanisms by which the samples are changing.

4 Conclusions

This study explored different ways of monitoring the physical properties of Winsor & Newton oil paints. The paints had dried for 11 years, except for the yellow ochre sample which dried for 18 years. Their behaviour was studied while the samples were on a polyester substrate. Glass transition, moisture sorption and stiffness at different relative humidity levels and before and after immersion in n-heptane were examined.

The assumption that oil paints generally have a Tg below 0 °C (32 °F) was challenged by the present DMA results which confirmed previous findings by Phenix [18]. The DMA results showed that addition of metal soaps and pigment volume concentration can affect the glassy-to-viscoelastic state transition in modern oil paints, and transitions as high as 36 °C were measured in cadmium yellow with a high pigment volume concentration. This indicates that modern oil paints can change properties when exposed to changes in temperature within the typical temperature range of museums or historic houses.

The amount and effect of moisture sorption on the stiffness of the test paints was also examined by DVS and nano-indentation. DVS measurements showed that the oil paints adsorbed moisture to different extents above 60% RH. Winsor & Newton ultramarine (UL) showed the highest moisture sorption which resulted in dramatic softening as seen by indentation. The stiffening of cadmium yellow (CY) and yellow ochre (YO) after immersion in n-heptane was furthermore demonstrated.

Nano-indentation is a relatively new technique within the conservation field and the presented results demonstrated that it is sufficiently sensitive to trace alterations in the mechanical properties of oil-based paints resulting from water sorption and immersion. Nano-indentation allows for the quantitative analysis of samples too small for other mechanical characterization techniques. Due to its high sensitivity, and spatial resolution, it can provide unique information useful for practitioners managing the care of artistic materials.

The results shown here indicate that for each paint a change in temperature or humidity can result in very different effects on mechanical properties. This complex situation means that for each work of art different areas of the paint layer can be either soft and viscous or stiff and brittle at a given temperature and relative humidity. It seems that 60% RH marks a transition above which the paints can change properties rapidly.

Notes

- 1.

Test paint film of Grumbacher Burnt Sienna (linseed oil binder) prepared in 1978 by M. Mecklenburg.

- 2.

See Sect. 32.2.2 for instrumental details of DMA. Theoretical and experimental treatments of viscoelasticity have derived vector-based descriptors of mechanical properties in terms of complex modulus (E∗), storage or elastic modulus (E’), and viscous or loss modulus (E”), where E∗ = E’ + iE”. Usually this relationship is expressed as G∗ = G’ + iG” where the G terms represent the corresponding shear moduli of the material. A further useful parameter, tan δ, is the ratio G”/G’ [5]. The most common DMA test is a thermal scan during which changes in the parameters of G’, G” and tan δ are measured as the temperature is increased at a set rate. The temperature at which any thermal transition occurs will depend on the frequency of the applied periodic stress. Conventionally, the temperature at the peak in the tan δ trace at 1 Hz is taken as the Tg of polymers ([4, 6]: 509). A comprehensive critical overview of the determination of Tg using DMA is provided by [2].

- 3.

- 4.

In all the time-temperature DMA scans reported in this study, the 10Hz δ maxima were at higher temperatures than the corresponding 1Hz data, which confirms this is the glass transition.

- 5.

Er′ can be calculated by:

$$ {E_r}^{\prime }=\frac{\sqrt{\pi }}{2}\frac{1}{\beta}\frac{1}{\sqrt{A_{\mathrm{p}}}}\;\frac{P_0}{h_0}\cos \delta $$where β is a geometric factor of the indenter tip, Ap is the projected contact area, δ is the phase shift, P0 is the amplitude of harmonic load, and h0 is the amplitude of harmonic displacement.

References

BOON, J.J., and HOOGLAND, F.G. 2014. Investigating Fluidizing Dripping Pink Commercial Paint on Van Hemert’s Seven-Series Works from 1990–1995. In Issues in Contemporary Oil Paint VAN DEN BERG, K.J, et al. (Eds). Cham: Springer. 227–246.

CHARTOFF, R. P., WEISSMAN, P. T. and SIRCAR, A. 1994. The application of dynamic mechanical methods to Tg determination in polymers: an overview. Assignment of the Glass Transition. ASTM International.

COOPER, A., BURNSTOCK, A., van den BERG, K. J., & ORNSBY, B. 2014. Water sensitive oil paints in the twentieth century: a study of the distribution of water-soluble degradation products in modern oil paint films. Issues in contemporary oil paint. Springer. 295–310.

DUNCAN, J. 2008. Principles and applications of mechanical thermal analysis. Principles and Applications of Thermal Analysis, 2. In GABBOTT, P., Ed. Oxford: Blackwell. 119–163.

ERHARDT, D., TUMOSA, C. S. & MECKLENBURG, M. F. 2005. Long-term chemical and physical processes in oil paint films. Studies in conservation, 50, 143–150.

GEARING, J. 1999. Dynamic mechanical (thermal) analysis. In BROWN, R. 1999. Handbook of polymer testing: physical methods, CRC press. New York: Marcel Dekker. 501–531.

HAY, J. L., and PHARR, G., M. 2000. Instrumented Indentation Testing. In KUHN, H. and MEDLIN, P., Eds., ASM Handbook Volume 8, Mechanical Testing and Evaluation. Materials Park, Ohio: ASM International. 232–243.

HAGAN, E., CHARALAMBIDES, M., LEARNER, T. J., MURRAY, A. & YOUNG, C. Factors Affecting the Mechanical Properties. Modern Paints Uncovered: Proceedings from the Modern Paints Uncovered Symposium, 2007. Getty Publications, 227-.

HEDLEY, G. & ODLYHA, M. The moisture softening of paint films and its implications for the treatment of fabric supported paintings. First published in: Traitement des supports. Travaux interdisciplinaires. Paris, 2, 3 et 4 novembre 1989, 1989. ARAAFU, 157–162. Reprinted in: VILLERS, C. (ed.); HEDLEY, G. Measured Opinions: Collected papers on the conservation of paintings. London: UKIC 1993: 99–102.

HEDLEY, G; ODLYHA, M; BURNSTOCK, A; TILLINGHAST, J; and HUSBAND, C A study of the mechanical and surface properties of oil paint films treated with organic solvents and water. In Book. Cleaning, retouching and coatings: technology and practice for easel paintings and polychrome sculpture: preprints of the contributions to the Brussels Congress, 3–7 September 1990. Mills, John S.; and Smith, Perry (Editors). International Institute for Conservation of Historic and Artistic Works, London, United Kingdom (1990) pp. 98–105

LEE, J., BONADUCE, I.., MODUGNO, F., LA NASA, J., ORMSBY, B., VAN DEN BERG, K.J. 2018. Scientific investigation into the water sensitivity of twentieth century oil paints. Microchemical Journal, 138: 282–95.

MECKLENBURG, M. F., TUMOSA, C. S., ERHARDT, D., VANDIVER, P. B., MASS, J. L. and MURRAY, A. 2005. The changing mechanical properties of aging oil paints. In Materials Issues in Art and Archaeology VII: Symposium held November 30-December 3, 2004, Boston, Massachusetts, U.S.A. Materials Research Society Symposium Proceedings, V. 852. VANDIVER, P. B., MASS, J. L. and MURRAY, A., Eds. Warrendale, PA: Materials Research Society. 13–24.

MECKLENBURG, M. F., TUMOSA, C. S. & VICENZI, E. P. 2013. The influence of pigments and ion migration on the durability of drying oil and alkyd paints. In New Insights into the Cleaning of Paintings (Cleaning 2010), Proceedings from the Cleaning 2010 International Conference, Universidad Politécnica de Valencia. MECKLENBURG, M. F., CHAROLA, A. E. and KOESTLER, R. J., Eds. Washington DC: Smithsonian Institution Scholarly Publications. 59–67.

MICHALSKI, S. 1991. Paintings: Their response to temperature, relative humidity, shock, and vibration. Art in Transit: Studies in the Transport of Paintings, National Gallery of Art, Washington DC, 223–248.

MILLS, J. S. and WHITE, R. 1999. The Organic Chemistry of Museum Objects, 2nd ed. Oxford: Butterworth.

MILLS, L., BURNSTOCK, A., DE GROOT, S., MEGENS, L., BISSCHOFF, M., VAN KEULEN, H., DUARTE, F., and VAN DEN BERG, K. 2008. Water sensitivity of modern artists’ oil paints. In ICOM Committee for Conservation 15th Triennial Conference, 22–26 September 2008, New Delhi: Preprints, Bridgland, J., Ed. Paris: ICOM Committee for Conservation. 651–659.

OLIVER, Warren Carl, and George Mathews PHARR. 2004. “Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology.” Journal of Materials Research 19 (1): 3–20. https://doi.org/10.1557/jmr.2004.19.1.3.

PHENIX, A. 2011. Thermal mechanical transitions in artists’ oil paints and selected conservation materials: a study by Dynamic Mechanical Analysis (DMA). Postprints of the Paintings Specialty Group, American Institute for Conservation meeting, Los Angeles, 2009. BUCKLEY, B., Ed. Washington DC: American Institute for Conservation. 72–89.

SALVANT, J., BARTHEL, E. and MENU, M. 2011. Nanoindentation and the micromechanics of Van Gogh oil paints. Applied Physics A: Materials Science and Processing, 104, 509–515.

SATO, K. 1976. The mechanical properties of filled polymers. Progress in Organic Coatings, 4, 271–302.

SNEDDON, I.N. 1965. The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. International Journal of Engineering Science 3 (1): 47–57.

VANLANDINGHAM, M. R., CHANG, N. K., DRZAL, P., WHITE, C. and CHANG, S. H. 2005. Viscoelastic characterization of polymers using instrumented indentation. I. Quasi-static testing. Journal of Polymer Science Part B: Polymer Physics, 43: 1794–1811.

VANLANDINGHAM, Mark R. 2003. Review of Instrumented Indentation. Journal of Research of the National Institute of Standards and Technology, 108 (4): 249–265.

Materials:

Artists’ oil paints, Winsor & Newton Artiststs’ Oil Colour, Harrow, UK

Hydrated alumina, purum, Brocades-Stheeman & Pharmacia, Amsterdam, before 1993

Aluminium stearate; technical grade, British Drug Houses Ltd, Poole UK, c.1993

Zinc stearate; technical grade, Aldrich 30, 756-4, Steinheim Germany

Fatty acids; heptadecanoic acid 98n/n, Aldrich [506-12-7], Milwaukee WI, USA

Linseed oil; koudgeslagen, De Bonte Hen, Zaandam, Netherlands c. 1992

Acknowledgements

This project received support from Heritage Plus, a Joint Programming Initiative of the European Commission and the Getty Conservation Institute.

The authors also wish to thank Lise Steyn, Bronwyn Ormsby, Klaas Jan van den Berg, Mikkel Scharff, Jørgen Wadum, Tom Learner, Ilaria Bonaduce, Aviva Burnstock, and Marion F. Mecklenburg.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Andersen, C.K., Freeman, A., Mortensen, M.N., Beltran, V., Łukomski, M., Phenix, A. (2019). Mechanical and Moisture Sorption Properties of Commercial Artists’ Oil Paint by Dynamic Mechanical Thermal Analysis (DMA), Nanoindentation, and Dynamic Vapour Sorption (DVS). In: van den Berg, K., et al. Conservation of Modern Oil Paintings. Springer, Cham. https://doi.org/10.1007/978-3-030-19254-9_32

Download citation

DOI: https://doi.org/10.1007/978-3-030-19254-9_32

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-19253-2

Online ISBN: 978-3-030-19254-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)