Abstract

This paper outlines the approach and key findings of systematic studies into the use of various surface cleaning materials on a range of accelerated-aged sensitive oil paint surfaces, carried out through the Cleaning Modern Oil Paints (CMOP) project. Studies involved the use of recently introduced options such as adjusted pH and conductivity waters, spreadable gels, rigid gels, silicone emulsifiers, and mineral spirits-based microemulsions, with additional explorations into the effects of application methods. The evaluation methodology encompassed star diagrams designed to capture observations made during cleaning tests, and paint surface evaluations using digital microscopy, colour and gloss assessment, and ATR-FTIR analysis. In most cases, the most promising free solvents were subsequently incorporated into spreadable and rigid gels, water-in-oil microemulsions and silicone emulsions, tailoring the approach to further minimise undesirable effects where possible. Cleaning system residues were also investigated using visual inspection, microscopy and ATR-FTIR analysis, with a selection of samples further investigated using a pyrolysis on-line micro-reaction sampler and XPS analysis. The combined results offer information on the advantages and risks associated with each cleaning material, and an approach to optimising wet systems for the cleaning of sensitive oil painted surfaces.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

2.1 Introduction

Collaborative research into the cleaning of modern painted surfaces is beginning to inform approaches to soiling removal that may offer lower risk options for solvent and mechanically sensitive unvarnished paint films [3, 8]. Building on earlier research on acrylic paints [4] and the use of polysaccharide gels [25], this study evaluates adjusted pH and conductivity waters [6], rigid gels, silicone emulsifiers [10], and mineral spirits-based microemulsions [17], for the surface cleaning of prepared sensitive oil paint samples; with additional explorations into the effects of application methods. Complementary studies using similar methodologies on naturally aged oil paintings are detailed by Gilman et al. [7].

The combined results of systematic studies on prepared and accelerated aged Winsor and Newton (W&N) oil paints are summarised via cleaning system type, involving evaluations of cleaning tests using star diagrams to capture a range of key empirical observations, digital microscopy (Hirox) and infrared spectroscopy (ATR-FTIR). Potential residues of cleaning materials were also investigated via visual inspection, microscopy and ATR-FTIR analysis. A selection of cleaned samples were then further investigated for residues using a pyrolysis on-line micro-reaction sampler and X-ray Photo Electron Spectroscopy (XPS). These studies highlight pigment-dependent behaviours with respect to cleaning and offer potentially useful approaches to soiling removal for these often challenging paint surfaces.

2.2 Methodology

2.2.1 Paint Samples

Samples were prepared using a Sheen instruments [Surbiton UK] film caster to a dry thickness of 100–150 μm onto titanium white and chalk oil-primed canvas pieces [Belle Arti 536 medium fine linen, 508gm, Jackson’s Art Supplies London UK]. Based on previous studies [13] three W&N artist quality oil paint colours known to form water-sensitive paint films were selected (French ultramarine, yellow ochre, cadmium yellow), with one non-water-sensitive paint (titanium white) also selected. All paints contained magnesium carbonate which is known to contribute to water sensitivity via the formation of water-soluble magnesium sulphate heptahydrate (epsomite) salts [21]. To induce water-sensitivity, the samples were cured under ambient conditions for 6 weeks prior to being accelerated light aged (Philips TL-D/840 super 80, 58-watt, long tubes, 4000 K) at elevated relative humidity (70–80%) and 30 degrees centigrade, under an average ~3500 lux illumination with the ultraviolet (UV) component filtered out. Samples were monitored using a deionised water-moistened standard swab to assess the development of water sensitivity, which in some cases required up to 2.5 months exposure.

After ageing, the French ultramarine and yellow ochre paints had developed thin UV-fluorescing medium skins (<5 microns thick) which proved sensitive to deionised water (i.e. pigment pickup was noted) within 3–8 lightly moistened swab rolls, resulting in the surfaces appearing more matte. After ageing, ATR-FTIR analysis showed that both the French ultramarine and yellow ochre paints had more intense and broad hydroxy infrared absorption bands at ~3400 cm−1 and a new band at 1330 cm−1 attributed to the O-H in-plane bending vibration of alcohols. This is indicative of the formation of polar lipid oxidation products [12] at the paint surface. A high humidity environment is known to promote oxidation of oils [9] and it has been noted that French ultramarine and iron-oxide based oil paints may become more oxidised than other colours [14]. This suggests that the artificial ageing conditions employed promoted oxidation, resulting in the formation of higher levels of polar hydroxy-containing species, which may – at least in part – explain the sensitivity of these two paints.

The titanium white and cadmium yellow paints did not develop visible medium skins. However, the cadmium yellow paints had a general matte appearance and were susceptible to subtle shifts in gloss after swab rolling. Pigment pickup was also observed for all water-sensitive colours after between 16–25 swab rolls. Epsomite was detected (only) on the cadmium yellow samples (which may account to some extent for the matte appearance of this paint), based on the presence of characteristic ATR-FTIR spectral absorptions: a broad and intense S-O stretch at 1096 cm−1 and other characteristic bands including 986, 1466 and 3390 cm−1. Whilst the possibility of the formation of water-soluble cadmium sulphate was also considered [20], the closest reference IR spectrum match was to magnesium sulphate heptahydrate. After ageing, the cadmium yellow paints had developed infrared absorption bands at 1710 cm−1 and 1320 cm−1 which can be attributed to the formation of carboxylic acid groups. This occurred in conjunction with a reduction in the intensity of C=O ester absorption bands at 1745 and 1165 cm−1 [24], which suggests that the ageing conditions promoted the hydrolysis of glyceride ester bonds and the formation of free carboxylic acid groups. It is possible, though not yet explored, that the accelerated ageing conditions, in conjunction with the photo-oxidation of cadmium yellow pigment, may have resulted in the formation of sulphuric acid which catalysed the hydrolysis of the oil medium [20].

After ageing, the samples were soiled using an artificial soil mixture [16], containing insoluble macroscopic solids (iron oxide, silica, kaolin), microscopic particles (carbon black), water reactive solids (cement type I), water swellable- or soluble- organics (gelatine powder, soluble starch), and apolar soluble organics (olive oil, mineral oil). For this study, the mixture was modified by reducing the carbon black and oil components by ~50% to avoid creating too dark or thick oil layers on sample surfaces. The soil was suspended in Shellsol D40 mineral spirits [Kremer Pigmente, Germany], and applied using an airbrush [Badger 250®, Amazon UK], with an area masked off with Melinex® to create an unsoiled control. After soiling, the French ultramarine, yellow ochre and cadmium yellow samples were further aged under the same conditions apart from a reduction in RH (to 50%) for 3 weeks; and the titanium white samples for 7 weeks, to encourage stronger adhesion between the applied soil and paint surfaces.

2.2.2 Cleaning Materials

The cleaning systems were selected from both established [25] and recently introduced options [10, 17, 22]; which are being increasingly widely used in conservation [2].

The cleaning materials were grouped into classes as follows:

-

Free aqueous solutions: included as the most efficient solvent for removing soiling; primarily acting on the kaolin, cement, gelatine and starch portions of the artificial soil mixture. Options included pH and conductivity adjusted waters derived from research into acrylic paints [6]. Adjusted waters were set to a pH range of 4.0, 4.5, 5.0, 5.5 and 6.0, at a conductivity of 1.0 mS/cm using ammonium hydroxide and acetic acid, which are believed to form volatile residues.Footnote 1

Previous work [4] suggested that higher conductivity solutions did not offer detectable advantages for soiling removal, and that pH ranges between 4 and 6 resulted in minimised surface changes to sensitive oil paint samples; though it was also noted that lower pH values could result in reduced cleaning efficacy. The addition of 0.5% w/w. nonionic alcohol ethoxylate surfactants such as ECOSURF™ EH-6 and ECOSURF™ EH-9Footnote 2 [4, 16] enhance soiling pickup and may also interact with carbon black [10]. Chelators such as citric acid (pKa values 5.62, 4.34, 2.91), ethylenediaminetetraacetic acid (EDTA) (pKa values 10.27, 6.16, 2.67, 2.0) and diethylenetriaminepentaacetic acid (DTPA) (pKa values 10.42, 8.76, 4.42, 2.56, 1.79) were chosen from the Modular Cleaning ProgrammeFootnote 3 for their ability to sequester the metal ions present in the artificial soil, including Fe3+, Mg2+, and Ca2+. Citric acid is a strong chelating agent for Fe3+ (log K1 = 11.4) and at the concentration used, would also chelate the Mg2+ (log K1 = 3.4) and Ca2+ (log K1 = 3.6) ions present [18, 19]. The stability constants (log K1) for Fe3+, Mg2+, and Ca2+ ions for EDTA are 25.1, 8.7, and 10.6 respectively, and for DTPA, 28.6, 9.3 and 19.1 respectively, making them stronger sequestering agents than citric acid for these ions. All chelators were used at 1% w/v. concentration, with the pH adjusted using 10% w/v. sodium hydroxide in deionised water. Where required, clearance was carried out using adjusted waters set to the same pH as the cleaning system, using dilute ammonium hydroxide and acetic acid.

-

Free non-polar solvents: primarily act on the apolar soluble organic components (added oils) of the artificial soil and possibly the carbon black; and included aliphatic hydrocarbon solvents such as Shellsol D40 used alone, and with up to 2% w/w. added anionic surfactant NaDOSS (dioctyl sulfosuccinate, sodium salt)Footnote 4 [4]; as well as silicone solvents including hexamethyldisiloxane (HMDS) and cyclopentasiloxane (D5) [10]. The action of these solvents was compared to deionised water to assess their effects as clearance solvents (data not shown). Any option with added surfactant was cleared with the corresponding neat solvent.

-

Water-in-oil (W/O, or reverse) microemulsions: were designed to offer enhanced cleaning efficacy through the suspension of aqueous dispersed phases within a non-polar (low-swelling) solvent continuous phase [17]. Series 3b systems based on Shellsol D40 and NaDOSS surfactant were selected as potential options, based on previous investigations [4]. These systems act on many aspects of the applied soil simultaneously through solvent-soiling interactions, however in addition, the microemulsion droplet size (below ~100 nm) enhances cleaning activity through increased surface area [17]. These systems were cleared using Shellsol D40 with 2.5% w/w added propan-2-ol [17].

-

Silicone-based Pickering emulsifiers: were introduced for the controlled aqueous cleaning of a range of sensitive surfaces [10], with earlier products such as Velvesil Plus and KSG-210/240 [Shin-Etsu, Japan] showing potential for cleaning sensitive oil paints [4]. Shin-Etsu’s KSG 350z (Kremer Pigmente, Germany), is used in this study with silicone solvents and optimised aqueous phases at varied proportions [10, 11, 15]. This material can offer advantages for sensitive paints through viscosity, its modifiability with respect to emulsifying both polar and non-polar solvents in addition to its inherent non-polarity. The aqueous phase (usually included between 10 and 50% w/w.) is emulsified into the system as the key active ingredient, though the silicone components will also act to some extent on silicone oils, and possibly the two oils included in the artificial soil. In addition to the % aqueous phase used, the emulsion droplet size also influences cleaning activity as per microemulsions.

-

Rigid hydrogels: Agar/agarose and gellan gum [Special Ingredients, UK] were prepared as 2–3% w/w. mixtures, heated to ~95 °C and uploaded with the best performing tailored aqueous systems. For these rigid hydrogels, the main advantage is reduced mechanical action [25], where the removal of soiling is achieved through dissolution and absorption via capillary action [2]. For these gels, citric acid was used as a non-volatile buffer, even where the associated chelating properties were not required. Where used, surfactants were added when the gel had cooled to a temperature below the surfactant cloud point.Footnote 5 The prepared gels were applied at room temperature, for up to 10 min, with excess water blotted from the gel surface prior to application. Clearance was carried out using either deionised water hydrogels or with adjusted water applied with a rinsed makeup sponge, which tended to minimise associated swelling.

-

Application methods: Hand rolled cotton swabs, brushes, soft cosmetic sponges – e.g. Muji™ (blotting excess solvent before use), application through wet strength tissue [Spider’s wet-strength Tarantula tissue]Footnote 6, application through silicone solvent barriers (D5), and combinations of these were also explored with the primary aim of reducing the mechanical action applied to these sensitive paint surfaces.

2.2.3 Evaluation Methodology

2.2.3.1 Star Diagrams

Star diagrams offer a systematic, comparative way of capturing the empirical parameters used to evaluate cleaning tests, which can then form part of a conservation treatment record. The parameters evaluated in this study are described in Table 2.1, which included: relative dirt removal efficacy (e.g. how soil-free the surface is after the cleaning and clearance steps had been performed), relative pigment/colour pickup (e.g. judged by inspecting the application tool(s) after use), gloss integrity (e.g. judging the dry paint surface by eye after cleaning relative to the unsoiled control), clearance (e.g. effectiveness of the cleareance step as judged by eye), relative application time (e.g. as determined for each method) and relative amounts of swelling/blanching noted (e.g. as judged by eye and/or using microscopy). Star diagrams (Excel radar charts) were first used for dry cleaning studies [5] and have been further refined for wet cleaning evaluations [4]. For this study, the application time parameter was expanded to accommodate the range of application methods used. It is important to note that for this complex study the results described are based on the observations of one trained individual onlyFootnote 7, hence the outcomes do not represent definitive guidance.

2.2.3.2 Instrumentation

Digital microscopy images were taken using a Hirox digital microscope (Hirox, Japan) mounted onto a photo stand with a ring-light diffuser. The microscope zoom lens (MXG-2500REZ) was set to 100 and 1000x magnification. Images were processed using Hirox software.

Gloss measurement was carried out using a Rhopoint Novo-Gloss Trigloss glossmeter, using a 60° angle, carried out in triplicate where possible.

ATR-FTIR spectroscopy was carried out using a Thermo Scientific Nicolet iZ10 system with bench diamond and germanium ATR crystal accessories. Samples were allowed to dry for at least a week post-cleaning prior to analysis. Data was processed using Omnic 9 software.

XPS analysis was carried out using monochromatised Al (Kα) X-rays (1486.6 eV) in a Thermo K-Alpha spectrometer. All samples were analysed using a 300–400 μm beam to ensure that only the paint surface was analysed. Analyses were performed in triplicate, around two weeks after treatment. The high intensity carbon 1 s and oxygen 1 s peaks were curve fitted using reference values to determine atomic %. Data were interpreted using CASA XPS software and reported as atomic % to remove measurement dependent signal variations from XPS peak intensities.Footnote 8

Pyrolysis with on-line gas chromatography-mass spectrometry (PyGCMS) was performed using a micro-furnace Multi-Shot Pyrolyzer EGA/Py-3030D [Frontier Lab] coupled with a gas chromatograph 6890 Agilent Technologies [Palo Alto, USA] and a 5973 Agilent Mass Selective Detector [Palo Alto, USA], single quadrupole. Paint samples were heated to 150 °C for 10 minutes. An HP-5 ms capillary silica column (30 m, 0.25 mm, film thickness 0.25 μm, Agilent Technologies, USA), connected to a deactivated silica precolumn (2 m, 0.32 mm, Agilent Technologies, USA) was used with a split ratio of 1:10. The GC oven was set at 70 °C then ramped to 300 °C at 20 °C/min, with a 15-minute isothermal hold. Surface scrapings of a 1 cm2 paint surface area were used to compare the peak areas of both cleared and non-cleared surfaces. Analyses were performed in triplicate, 2 weeks after treatment.

2.3 Results and Discussion

2.3.1 Free Aqueous Solvents

2.3.1.1 Adjusting pH and Conductivity (Adjusted Waters)

A series of cleaning tests were carried out using hand-rolled cotton swabs to explore the effect of pH adjusted waters. Across the range of samples, lowering the pH to 4.5–6.0, was found to reduce unwanted changes such as pigment pickup and gloss change on paints with medium skins (i.e. French ultramarine (Fig. 2.1) and the yellow ochre samples), which may relate to a reduction in the ionisation of acidic functionalities on the paint surface. It was noted however that using waters at the lower pH range tended to reduce cleaning efficacy, which may relate to changes in the interfacial tension of the cleaning solution, influenced by concentration and speciation of the ions present in solution, and the solution pH [1]. For example, the pKa of acetic acid is 4.75, hence at pH values lower than the 4.75, acetic acid will generally not be ionised. Despite a reduction in cleaning efficacy noted for the yellow ochre (not shown) and French ultramarine paints, lowering the pH proved beneficial for reducing pigment pickup and gloss change. However, for the titanium white and cadmium yellow paints there appeared to be no clear advantage to using adjusted waters set to below pH 5 or 5.5.

2.3.1.2 Adding Surfactants

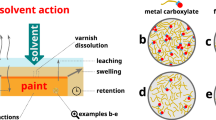

As expected, the addition of 0.5% w/w. ECOSURF™ EH-6/EH-9 nonionic ethoxylate surfactant increased the soiling removal efficiency and reduced contact time. However, as the paint surface required a clearance procedure using the equivalent pH adjusted water, this occasionally negated any advantage. It was noted however that the addition of surfactant generally reduced the magnitude of gloss change when compared to adjusted waters alone. While the results naturally varied to some degree, the ECOSURF™ EH-6 (HLB 10.8), at 0.5% w/w. at pH 6.0 proved optimal for the cadmium yellow samples; 0.5% EH-9 (HLB 12.5), at pH 4.5/5 for the French ultramarine samples, and 0.5% EH-9 at pH 5/6 for the yellow ochre samples, which had relatively heavily imbibed soiling as shown in Fig. 2.2. This suggests that exploring the addition of low levels of nonionic surfactant at varying pH values may be useful; however it is noted that specific relationships between the paint surface, soiling layers and surfactant types have yet to be systematically explored.

Free aqueous systems swab-applied to a sensitive W&N yellow ochre oil paint sample evaluated using digital microscopy at 1000×. The 0.5% w/w. ECOSURF™ EH-9 option set to pH 5.5 proved optimal for minimising surface change on this sample (a) Unsoiled control (b) Deionised water (c) Adjusted water pH 5.0, 1 mS/cm (d) 0.5% w/w. ECOSURF™ EH-6, pH 5.0, 1 mS/cm (e) 0.5% w/w. ECOSURF™ EH-6, pH 6.0, 1 mS/cm (f) 0.5% w/w. ECOSURF™ EH-9, pH 5.5, 1 mS/cm (optimal)

2.3.1.3 Adding Chelators

Three chelators were evaluated including citric acid, EDTA and DTPA, used at 1% w/v. and tailored to the desired pH using a 10% w/v sodium hydroxide (NaOH) solution. Except perhaps for the titanium white samples, this group prove too active when applied using a swab. The addition of chelators increased cleaning efficacy as expected, and reduced contact time for the titanium white and French ultramarine paints; however, for the cadmium yellow and ochre paints, these systems were poor with respect to maintaining gloss integrity when compared to pH adjusted water and surfactant options. This may relate to the vulnerability of Cd2+ and Fe3+ ion-containing pigments to these chelating agents. In addition, due to the pKa values of the chelators used, the cleaning efficacy of the solutions were noticeably reduced below pH 6. There appeared to be little difference in the overall performance of the chelators used in this study, however Gillman et al. [7] noted that EDTA options tended to cause less pigment pickup and facilitated a more even cleaning action on a group of matte, naturally aged paintings with varied soiling compositions. For the group of W&N samples the weaker binding citrate chelators set at pH 5–6 proved acceptable for the titanium white and French ultramarine samples, however this system resulted in unacceptable gloss changes for both the cadmium yellow and yellow ochre paints.

2.3.1.4 Summary of Free-Aqueous Systems

These initial tests, carried out using liquid aqueous solutions applied using hand rolled cotton swabs, were designed to assess their effect on the four paint samples with the aim of determining the lowest-risk aqueous conditions for each paint. For this study, the ‘most promising’ options were determined via balancing soiling removal efficacy with swelling, pigment pickup and gloss change for each sample type. On occasion, reducing the solution pH resulted in less swelling of the paint film and less disturbance of medium skins, however this also reduced the soiling removal efficacy; hence in those cases surfactant was added and/or the pH was adjusted upwards to increase the cleaning efficacy.

Gloss readings taken after cleaning suggested that the yellow ochre and French ultramarine paints (both with visible medium skins), were the most susceptible to gloss change, with the most significant reduction at a pronounced 30 units (Fig. 2.5). The titanium white and cadmium yellow paints appeared least affected, with less than 5 gloss unit shifts noted, which reflects (at least in part) an absence of medium skins on these two colours. However, pigment pickup was most pronounced for the cadmium yellow samples (epsomite-rich) with deionised water, which was minimised to some extent when the pH was reduced to 5.5. For the cadmium yellow paints, all of the free aqueous systems resulted in the removal of epsomite as determined through digital microscopy and/or ATR-FTIR analysis where removal was indicated via reduction in the broad absorption band at ~1095 cm−1 (data shown in Fig. 2.4). In essence, none of these sensitive paints were satisfactorily cleaned using the free-aqueous systems, which were typically too aggressive; however the best performing options taken forward for use in microemulsions and/or silicone emulsions are listed in Table 2.2.

Upper - phase diagram for KSG-350z emulsion applications on the sensitive W&N cadmium yellow (CY) paint using: 10% 350-z; 40% D5; 50% aqueous phase applied by brush, with 7 different aqueous phases. Lower – ATR-FTIR spectrum of the: soiled control CY paint top), the soiled sample after cleaning with deionised water (second from top), the soiled sample after cleaning and clearing using the optimised KSG-350z system (third from top) and a reference spectrum for magnesium sulphate heptahydrate/epsomite (bottom). Note that application time has now been incorporated into the star diagram (see Table 2.1)

2.3.2 Rigid Hydrogels

For this group of samples, the agar and gellan gels restricted visual access to the paint surface, did not remove soiling efficiently and tended to cause swelling, blanching, pigment pickup and gloss change. Similarly to the free aqueous systems, reducing the pH of these gels reduced paint swelling to some extent and facilitated slightly longer contact times with the paint surface; however soiling removal at low pH remained poor, and the addition of surfactants and chelating agents tended to make the action too aggressive. For example, the use of agar gel set to pH 4.5–5.5 proved somewhat useful for minimising swelling and gloss changes to the French ultramarine paints, however soil removal remained poor. It is noted however, that Gillman et al. [7] found both agar and gellan gels at 2–3% w/w. with 1% w/w. added EDTA useful for removing soil from naturally aged paintings; which may be due to the different nature of the soiling layers in addition to the older, less medium-rich paint layers.

2.3.3 Non-polar Organic Solvents

Compared to deionised water, the free-liquid aliphatic hydrocarbon Shellsol D40 and silicone solvents HMDS and D5 did not cause significant gloss changes or significant pigment pickup. However as expected, they did not function well as cleaning agents and required longer contact times. In Gillman et al. [7], the use of iso-octane (2,2,4-trimethylpentane) afforded a slight reduction in the tendency to pick up pigment when compared to Shellsol D40 for some paint passages investigated.Footnote 9

2.3.4 Water-in-Oil Microemulsions

In previous work [4], the Shellsol D40-based W/O (reverse) microemulsions [17] Series 3b group were noted as promising for sensitive oil paint surfaces. In this study, the effect of varying surfactant proportion, aqueous phase proportion and aqueous phase modifications (adjusting pH, adding surfactant) have been further explored. Cleaned samples were evaluated for soiling removal efficacy, surface change and surfactant residues. To compare the effects of the proportion and character of the aqueous phase on cleaning efficacy, several microemulsions were preparedFootnote 10 containing 40, 30, 20 and 10% w/w. aqueous content. Each was applied via systematic 10-swab roll applications, and cleared with the appropriate hydrocarbon solvent with 2.5% w/w. added propan-2-ol. The results, shown through two examples in Fig. 2.3, confirmed that decreasing the water content from 40% to 10% resulted in less pronounced changes to paint surfaces, and particularly when the aqueous content was ≤20%. Adjusted aqueous phases set to pH 4.5, 5.0, and 6.0 were also explored alongside deionised water and a solution containing 0.5% w/w. ECOSURF™ EH-6, at pH 6. As shown in Fig. 2.3, modifying the aqueous phase also had an effect; in some cases, lowering the pH reduced unwanted gloss change and pigment pickup. The effects appeared to be less noticeable when the aqueous content was 10% or less; and in all cases, abrasion was noted with cotton swab applications. A slight improvement was however noted in the gloss integrity where adjusted waters were used for the yellow ochre sample, where the deionised water appeared to slightly disturb the medium-skin (see Fig. 2.3).

Within a W/O microemulsion, modifying the aqueous phase with added surfactant, such as 0.5% w/w. ECOSURF™ EH-9 (or EH-6) did not appear to enhance cleaning efficacy or improve the overall cleaning outcome. Regarding the addition of chelators, initial indications were that citrates (Na-citrate or TAC) offer the most stable microemulsion options within the lower water content (~10%) options. It is possible to use EDTA or DTPA within these systems, however the region where stable microemulsions form on the phase diagram [17] may be somewhat reduced, and has yet to be mapped. It is also likely that a microemulsion incorporating stronger chelators would prove to be too active for these paint surfaces.

Comparisons were also made (not shown) between microemulsions with different levels of the NaDOSS surfactant phase [ME3b-18 (70% surfactant phase) and ME3b-24 (10% surfactant phase)] using the same quantity of aqueous phase (10% by weight). Promisingly, the higher % surfactant phase content did not appear to contribute significantly toward soil removal efficacy, suggesting that keeping surfactant levels low does not hinder the cleaning efficacy of these systems. The higher % surfactant ME3b-18 option was more viscous and had a smoother action but tended to leave visible surfactant residues in the form of glossy rings which required further clearance. Using ATR-FTIR analysis, residues were detected on samples where the surfactant proportion was 40% and above (see Residues). It is noted that the effects of the use of these and other microemulsions on the physical properties of oil paints has yet to be explored.

As some abrasion was visible when using swabs directly on these paints, the swabbing of W/O microemulsions through a wet-strength tissue barrier was also evaluated. However, in addition to preventing visual access to the paint surface, the tissue barrier did not prevent swelling and/or pigment loss and resulted in ineffective soil removal. Gillman et al. [7] however, reported some success using this method on older oil paint films. Using makeup sponges with microemulsions (while wearing gloves) resulted in a less abrasive action, however the sponge was eventually affected by the Shellsol D40 solvent, raising concerns around sponge residues. Loading microemulsions into soft sponges could be advantageous for these types of paints, should appropriate sponges become available.Footnote 11

2.3.5 Silicone Emulsifiers

The initial set of Shin-Etsu KSG-350z silicone emulsifiers evaluated were based on published formulations using 10% KSG-350z (at 30–60% optimised aqueous phase) by weight [11]. For this study, a second group based on 25% KSG-350z were created to form options with reduced aqueous contents of 30–40%. All silicone emulsifier systems were made by weight, first by blending the emulsifier with D5 silicone solvent, followed by dropwise additions of the aqueous phase. The mixture was then stirred vigorously to create the emulsion, followed by being forced through blunt-end luer lock syringe needles of two different gauges (wider bore then narrow bore) prior to use [23]. In general, these systems were slow acting and required prolonged contact with paint surfaces. As expected, higher proportions of the aqueous phase enhanced the cleaning efficacy and reduced the working time required. It was noted that an aqueous content of 50 or 60% by weight significantly improved cleaning efficacy over the 30 or 40% equivalents; and that below 30%, the cleaning efficacy was poor. In general, formulations with moderate (30–50%) proportions of aqueous phase were chosen to help minimise paint surface change. Optimal application involved pre-wetting the surface with D5 solvent (which also enhanced cleaning efficacy), applying the prepared emulsifier by brush followed by light agitation on the paint surface. Clearance was carried out using D5-dipped cosmetic sponges as often as required (average 3 applications), then repeated using the faster evaporating HMDS solvent. For the paint samples evaluated, increasing the proportion of the aqueous phase proved more important to the final result than small adjustments to the character of the aqueous phase.

Figure 2.4 (upper) shows the star diagram results of the silicone emulsion applications on the epsomite-rich cadmium yellow paint film, where the optimal system was determined as a 10% KSG-350z emulsion with a 50% aqueous phase containing 1% citric acid and 0.5% ECOSURF™ EH-9, adjusted to pH 6 using an NaOH solution. Evaluation of the cleaned paint films using ATR-FTIR spectroscopy (Fig. 2.4, lower) revealed that epsomite was removed from the paint surface to a similar extent as a swabbed deionised water application. Adjusting the aqueous phase pH did not appear to make a significant difference to either the swelling behaviour, or paint gloss integrity for the cadmium yellow paints, though the addition of both the ECOSURF™ EH-9 surfactant and citric acid enhanced soiling removal and reduced application time.

For the particularly water-sensitive French ultramarine paint, the 25% KSG option with an aqueous phase at 40% modified to include 1% (w/w) citric acid and 0.5% (w/w.) ECOSURF™ EH-9, at pH 6.0 tended to reduce pigment loss and swelling, and minimised surface disruption (data not shown). Table 2.3 lists the optimised silicone emulsifier systems for each paint type. Differences in the optimal emulsifier formulation tended to reflect the relative degree of surface soil-adhesion. In general, reducing the aqueous phase content tended to reduce swelling, reduce gloss shift and decrease pigment pickup, while also increasing application time and decreasing cleaning efficacy. Gloss changes resulting from the KSG systems were comparable to many of the optimal systems (see Fig. 2.5), however these systems did not completely prevent disruption to thin medium skins on the French ultramarine samples, due to the mechanical action required.

2.3.6 Application Methods

Table 2.4 summarises key observations made on the use of different application methods on these paint films. Reduced gloss change and pigment pickup was most evident when swabs were not used with all paint types apart from the Titanium white (data not shown) which appeared less affected by the application method. Figure 2.5 includes the gloss change data recorded for the French ultramarine samples where swabbing clearly resulted in the highest gloss change. Several of the sponge-applied systems; the systems applied through D5, the KSG-350z emulsifiers (12–22) and low water content microemulsions (25–27) all resulted in reduced gloss change when compared to the swabbed samples. Where present, epsomite was removed to some extent by all systems, and medium skins were also disrupted, albeit to a lesser extent when methods other then free-solvent swabbing were used. The occasional increase in gloss may indicate the successful retention of the thin medium skin, and/or the presence of residual cleaning materials such silicone emulsifiers or NaDOSS surfactant (see Residues).

2.3.7 Residues

Potential cleaning system residues were explored through visual observation, microscopy, ATR-FTIR, XPS and via a pilot study into the retention of D5 solvent using PyGCMS. Overall, there were no residues detected with microscopy or ATR-FTIR, except in cases where the measurement focussed on microemulsion surfactant tidelines (visible to the naked eye) when the surfactant-phase was included above 40% w/w.Footnote 12 Additionally, no silicone residues were detected using ATR-FTIR for the KSG-350z systems with emulsifier contents of both 10% and 25% by weight. For the highly surface-sensitive XPS analysis [26], the quantitative elemental composition in atomic per cent and associated chemical states were determined at the surface of unsoiled cadmium yellow samples, including untreated control areas as well as areas cleaned with KSG emulsions and Shellsol-D40 microemulsions, with appropriate clearance steps.

In Fig. 2.6 (upper), the silicon (Si) concentration (relative to the control), appears enriched for many of the test sites. The Si binding energies detected were typical of siloxanes, indicating the presence of residues of silicone emulsifiers and/or silicone solvents on paint surfaces. This data also suggests that the ability to clear the surface of siloxanes (see columns 3-5 from the left) did not differ significantly with the use of D5, HMDS and D5/HMDS blends, as the Si concentrations remain similar. This was also supported by preliminary data obtained with PyGCMS (not shown) where D5 solvent was detected after 2 weeks within yellow ochre paint films cleaned with neat KSG 350z (with and without a D5 clearance step). Figure 2.6 (lower), indicates that deionised water and the (50% aqueous-phase containing) silicone emulsifiers removed any inherent sodium (Na) from paint surfaces during cleaning, whereas the HMDS and D5 silicone solvents did not (the levels appear similar to the control). The Series 3b-24 microemulsion (10% aqueous phase) appears to leave behind NaDOSS surfactant monolayers which, similarly to the silicone-treated surfaces, requires further exploration around the potential consequences of the use of these materials (and others) on the future soiling and cleaning behaviour of treated paint films. It is also noted that the atomic % sodium (Na) amount is significantly less than the siloxane (Si) remaining on the same paint film. The Na results also suggest there is little benefit to clearing the NaDOSS-based microemulsions using Shellsol D40 with added 2.5% w/w propan-2-ol when compared to using D40 alone. Similar to the FTIR data obtained (Fig. 2.4), reduced magnesium was also noted via XPS after cleaning (data not shown), confirming that epsomite was removed by all of the aqueous-containing systems evaluated, except where the HMDS and D5 silicone solvents had been applied neat. Although this data is preliminary, the XPS data results suggest that the 50% aqueous-phase silicone emulsifiers removed marginally more epsomite than the 10% aqueous-phase ME3b-24 microemulsion, presumably due to the higher aqueous content and extended application times required when using the KSG materials; whereas the epsomite reduction for the ME3b-24 and deionised water applications appeared comparable.

XPS data in atomic % for various materials on cleaned cadmium yellow paints (upper) Si (from silicone [siloxane] solvents and emulsifiers) at the surface; (lower) Na (from NaDOSS surfactant) at the surface. The hatched bars on the Silicon graph indicate Si originating from the inorganic silica; the filled bars correspond to Si originating from siloxanes only

2.3.8 Optimal Systems for Each of the W&N Paints

The tenacity of the artificial soil varied significantly with paint colour, where the soil was noticeably less well-adsorbed for the non-water-sensitive titanium white paints than each of the more sensitive colours. This presumably reflects differences in the surface character of the paints, including softness, physical coherence, hydrophilicity, degree of oxidation, the presence of soluble salts, ionic character and other factors which require further investigation.

For the relatively robust titanium white sample(s) which did not have visible medium skins, the series 3b microemulsions (particularly 3b-5, 40% aqueous phase) resulted in optimum soil-removal efficacy, however other acceptable cleaning outcomes were also achieved using swab-applied aqueous options containing either citric acid chelating agent (1% w/w. at pH 6.0) or surfactant (0.5% w/w. ECOSURF™ EH-6 or 0.5% w/w. ECOSURF™ EH-9). For this paint, sponge application slightly reduced the cleaning efficacy, and the D5 silicone solvent barriers and/or KSG emulsifiers resulted in the least efficient soil removal. This could be enhanced by increasing the proportion of the aqueous phase and/or adjusting the application method/time.

The yellow ochre paints, which were characterised by medium-skins, enhanced oxidation and heavily imbibed soiling, could not be cleaned effectively with any of the systems evaluated, with only the lightly bound soiling being removed prior to pigment pickup and other undesirable changes becoming evident. As the medium-rich surface of this paint film was highly vulnerable to swelling and mechanical action, substituting swabs with cosmetic sponges and/or using KSG-350z silicone emulsifiers significantly minimised changes to these paint surfaces. Further work exploring the use of slightly raised pH aqueous phases within KSG emulsions could prove beneficial for encouraging the removal of imbibed soiling.

For the epsomite-rich cadmium yellow paints, optimal cleaning outcomes were achieved using the silicone emulsifier systems (50% aqueous phase with added 0.5% ECOSURF™ EH-6 or 0.5% ECOSURF™ EH-9 surfactant), cleared using sponges loaded with D5 then HMDS, as well as tailored aqueous systems applied using cosmetic sponges, e.g., 0.5% ECOSURF™ EH-9 pH adjusted to 5.5, cleared with adjusted water set to pH 5.5.Footnote 13 Both systems facilitated effective soil removal without causing visible changes to the surface; however, as stated earlier, for all the options evaluated, any epsomite present was at least partially removed during cleaning, and trace levels of silicone emulsifer residues were noted using XPS (Fig 2.6).

Similarly, for the highly water-sensitive French ultramarine blue paints, characterised by medium skins, enhanced oxidation and the risk of significant gloss change, the use of cosmetic sponges and silicone emulsifiers enabled a helpful degree of soil removal. Lowering the aqueous phase pH to 4.5 reduced undesirable effects further, and chelating agents offered an increase in soiling removal efficacy. Other slight enhancements were made where surfactants and chelating agents were used in combination. Optimal systems included sponge-applied 1% w/w. citric acid, pH 6; cleared with sponge-applied adjusted water at pH 6.0; and KSG-350z (40% aqueous phase, 1% w/w. citric acid, pH 6.0 with additional 0.5% w/w. ECOSURF™ EH-9). In addition to tailoring the cleaning options for each paint, further reductions in gloss change were achieved through the use of sponges, D5 barriers, KSG-350z emulsions and low % aqueous content microemulsions.

2.4 Conclusions

These combined evaluations may help guide conservators towards soiling removal strategies for water-, mechanical action- and solvent- sensitive painted surfaces. The approach used, involving exploring: the character of the paint surfaces, the effects of adjusting and optimising of the active aqueous phases prior to incorporation into gels and emulsions, as well as exploring the effects of application methods, proved beneficial to the cleaning outcomes achieved for each of the four paints evaluated. For the three sensitive paints in particular, this process improved the cleaning outcomes, including enhanced soiling removal, reduced pigment pickup and the reduction of undesirable surface changes.

The moderately- and highly-sensitive paints benefitted from reduced mechanical action (using sponges and brushes), reduced aqueous exposure though controlling access and penetration (using D5 barriers, tissue, gels, microemulsions and emulsions), as well as from the tailoring of aqueous phases (via setting the pH to ~4.5–6, by adding 0.5% w/w. nonionic surfactant, and by adding up to 1% w/w. chelator). All of these modifications helped reduce pigment pickup, resulted in reduced gloss shifts and minimised surface (such as medium skin) disruption. Reducing the aqueous pH to 4.5–5 also resulted in lower levels of pigment pickup for the French ultramarine blue and cadmium yellow paints, however the cleaning efficacy also tailored off due to the pKa(s) of the acids used, which in some cases necessitated the addition of surfactants. The hydrogels evaluated offered poor cleaning efficacy and resulted in the swelling of the W&N paint films; however, agar and gellan gum options proved more useful for naturally aged oil paintings with lighter soiling layers and minimal medium skins [7].

The Shellsol D40 microemulsions proved most beneficial with a 10% w/w. aqueous phase, with additional gains made through adjusting the character of the aqueous phase. NaDOSS residues were confirmed in cleaning tidelines using ATR-FTIR when the surfactant phase content was above 40%. Trace levels of Na (from the NaDOSS surfactant) were detected on uppermost cleaned and cleared paint surfaces via XPS, most likely present as a monolayer. The silicone emulsifier KSG-350z proved beneficial at between 10–25% emulsifier content, with 35–50% aqueous phase adjusted with added surfactant and/or chelator, brush-applied and sponge cleared using neat silicone solvents. XPS analysis also confirmed the presence of siloxane residues on cleaned and cleared samples, and that the benefits of a double (D5, HMDS) clearance step were minimal. In all cases, the impact of trace cleaning system residues and solvent retention on the re-soiling and re-treatability of these paints is of key interest and remains to be explored.

Notes

- 1.

Acetic acid boiling point is 118 °C (https://pubchem.ncbi.nlm.nih.gov/compound/acetic_acid#section=Color-Form) and ammonium hydroxide solution is 38 °C (https://pubchem.ncbi.nlm.nih.gov/compound/ammonium_hydroxide#section=Taste). Accessed 21.3.19.

- 2.

- 3.

http://cool.conservation-us.org/byauth/stavroudis/mcp/. Accessed 14.1.19.

- 4.

https://en.wikipedia.org/wiki/Docusate. Accessed 14.1.19.

- 5.

The effect of any added ionic materials on the surfactant cloud point was not considered.

- 6.

http://www.cxdglobal.com/productdetails.aspx?id=309&itemno=PASWTT0100. Accessed 6.2.19.

- 7.

The cleaning tests, star diagrams, FTIR-ATR and microscopy evaluations were carried out by Dr. Judith Lee as part of the Cleaning of Modern Oil Paints (CMOP) project at Tate, London.

- 8.

XPS analysis was carried out as part of the CMOP project at Winnats Scientific (UK) through the University of Pisa, Italy. PyGCMS analysis was carried out at the University of Pisa, Italy.

- 9.

This has also been noted by the authors when using isooctane-based microemulsions.

- 10.

Series 3b-5 (30% D40, 40% aqueous, 30% NaDOSS), 3b-10 (50% D40, 30% aqueous, 20% NaDOSS), 3b-16 (60/20/20), and 3b-22 (60/10/30) or 3b-24 (80/10/10). The NaDOSS is made up as a 65% w/w. solution in Shellsol D40.

- 11.

http://www.nanorestart.eu/. Accessed 6.2.19. Note that trials of organo-gels and microemulsions are underway at Tate.

- 12.

Tidelines are primarily a feature of the small cleaning tests carried out and are generally removed when cleaning over a larger scale.

- 13.

The cadmium yellow paints tended to be more vulnerable toward the use of chelating agents in comparison to the surfactants.

References

Álvarez F, Vázquez G, Sánchez-Vilas M, Sanjurjo B, Navaza JM (1997) Surface Tension of Organic Acids + Water Binary Mixtures from 20 °C to 50 °C. Journal of Chemical & Engineering Data 1997 42 (5) 957–960

Angelova L, Ormsby B, Townsend JH, Wolbers R Eds (2018) Gels in the Conservation of Art. Archetype Publications London: p. 381

Casoli A, Cremonesi P, Héritier P-A, Volpin S (2019) Analytical study to monitor the effectiveness of a combined liquid-dispensing and micro-aspiration system for the cleaning of modern oil paintings. These proceedings, Chapter 40

Chung JY, Ormsby B, Lee J, Burnstock A, van den Berg KJ (2017) An Investigation options for surface cleaning unvarnished water-sensitive oil paints based on recent developments for acrylic paints. In ICOM-CC 18th Triennial Conference Preprints, Copenhagen, 4–8 September 2017. Paris: International Council of Museums

Daudin-Schotte M, Bisschoff M, Joosten I, van Keulen H, van den Berg KJ (2013) Dry Cleaning Approaches for Unvarnished Paint Surfaces. New Insights into the Cleaning of Paintings: Proceedings from the Cleaning 2010 International Conference, Universidad Politecnica de Valencia and Museum Conservation Institute, edited by Mecklenburg, Marion F., Charola, A. Elena, Koestler, Robert J. Smithsonian Contributions to Museum Conservation. Washington, DC: Smithsonian Institution: 209–219

Dillon CE, Lagalante AF, Wolbers RC (2014) Acrylic emulsion paint films: The effect of solution pH, conductivity, and ionic strength on film swelling and surfactant removal. Studies in Conservation 59(1): 52–62

Gillman M, Lee J, Ormsby B, Burnstock A (2019) Water-sensitivity in modern oil paintings: Trends in phenomena and treatment options. These proceedings, Chapter 38

Hintz M, van den Berg KJ, Stols Witlox M, Steyn L (2019) Improving the surface cleaning of water sensitive oil paint by use of alternative application methods. These proceedings, Chapter 44

Labuza TP, Dugan Jr RL (1971) Kinetics of lipid oxidation in foods. C R C Critical Reviews in Food Technology 2:3: 355–405

Lagalante AF & Wolbers RC (2016) The cleaning of acrylic paintings: new particle-based water-in-oil emulsifiers. Colore e Conservazione Proceedings: 107–114

Lagalante A, Wolbers R (2017) Particle-based silicone cleaning emulsions: studies in model paint systems for the clenaing of water sensitive artworks. In Gels in the Conservation of Art, Lora Angelova, Bronwyn Ormsby, Joyce H Townsend and Richard Wolbers (Eds). Archetype Publications, London: 193–199

Lazzari M, Chiantore O (1999) Drying and oxidative degradation of linseed oil. Polymer Degradation and Stability 65:2: 303–313

Lee J, Bonaduce I, Modugno F, La Nasa J, Ormsby B, van den Berg KJ (2018) Scientific investigation into the water sensitivity of twentieth century oil paints. Microchemical Journal, Vol. 138: 282–295

Lee J, Ormsby B, Burnstock A, van den Berg KJ (2019) Modern oil paintings in Tate’s collection: a review of analytical findings and reflections on water-sensitivity. These proceedings, Chapter 39

Myers JM, Cushman M (2019) Analysis of cleaning efficacy and clearance of silicone-based Pickering-type emulsions used in the cleaning of water-miscible oil paints. These proceedings, Chapter 43

Ormsby B, Soldano A, Keefe MH, Phenix A, Learner T (2013) An Empirical Evaluation of a Range of Cleaning Agents for Removing Dirt from Artists’ Acrylic Emulsion Paints. AIC Specialty Group Postprints 23: 77–87

Ormsby B, Keefe MH, Phenix A, von Aderkas E, Learner T, Tucker C, Kozak C (2016) Mineral Spirits-based Microemulsions: A Novel Cleaning System for Acrylic and Other Modern Painted Surfaces. Journal for the American Institute for Conservation 55:1:12–31

Perrin D, Dempsey B (1974) Buffers for pH and Metal Ion Control. Springer Netherlands: 105

Phenix A, Burnstock A (1992) The removal of Surface dirt on Paintings with Chelating agents. The Conservator 16:1:28–38

Pouyet E, Cotte M, Fayard B, et al (2015) Appl. Phys. A 121: 967. https://doi.org/10.1007/s00339-015-9239-4

Silvester G, Burnstock A, Megens L, Learner T, Chiari G, van den Berg KJ (2014) A cause of water-sensitivity in modern oil paint films: the formation of magnesium sulphate. Studies in Conservation 59:1: 38–51

Stavroudis C (2012) More from CAPS3: Surfactants, silicone-based solvents, and microemulsions. WAAC Newsletter, Volume 34, Number 3

Stavroudis C (2016) Silicone-Based Solvents in Conservation. As free solvents and components of gel systems, and microemulsions. Colore e Conservazione Proceedings: 178–184

van der Weerd J, Van Loon A, Boon J (2005) FTIR Studies of the Effects of Pigments on the Aging of Oil. Studies in Conservation 50(1): 3–22

Volk A, van den Berg KJ (2014) Agar – A New Tool for the Surface Cleaning of Water Sensitive Oil Paint? In van den Berg K.J et al. (eds) Issues in Contemporary Oil Paint. Springer: 389–406.

Winnats Scientific Services, Unpublished report, 1D8UP02 XPS Analysis of Paints and Pigments 2018

Acknowledgements

This research was undertaken as part of the Cleaning Modern Oil Paints project (2015–2018) supported by Heritage Plus, a Joint Programming Initiative of the European Commission. The authors would like to thank the following people and institutions: all CMOP partners and associate partners; Winnats Scientific, UK; Chris Stavroudis, US; Ian Garret, UK; and the Tate Conservation and Research Departments. The digital microscopy images were taken using a HIROX KH-8700 digital microscope, the purchase of which was supported in part by the Horizon2020 funded NANORESTART project (agreement 646063).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Ormsby, B., Lee, J., Bonaduce, I., Lluveras-Tenorio, A. (2019). Evaluating Cleaning Systems for Use on Water Sensitive Modern Oil Paints: A Comparative Study. In: van den Berg, K., et al. Conservation of Modern Oil Paintings. Springer, Cham. https://doi.org/10.1007/978-3-030-19254-9_2

Download citation

DOI: https://doi.org/10.1007/978-3-030-19254-9_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-19253-2

Online ISBN: 978-3-030-19254-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)