Abstract

Condition monitoring is a central aspect in the health assessment and maintenance of industrial machinery. Vibration analysis is the most widely used technique for fault detection in rotating machinery. However, the technique can become difficult to apply in the case of machinery with non-stationary duty cycles due to the time-varying characteristics of the machine vibrations. The vibration signature of an incipient fault in rotating machinery is typically weak when compared to other sources of excitation. Due to these limitations, many methods have been proposed to increase the signal to noise ratio (SNR) of the signals as well as their applicability to non-steady operation. These include the separation of the random fault signatures from the deterministic components in the signal as well as techniques based on optimising the filtering of the signal to increase SNR. This work presents a method for extracting weak fault signatures from non-stationary signals using a reference signal from a parallel operating component on the same machine. The method, which is based on wavelet de-noising, employs a reference signal to adapt noise thresholds in the time and scale domain. Tests were performed using simulated non-stationary vibration signals. The proposed technique is shown to be effective at increasing the SNR when combined with envelope analysis to detect and diagnose faults.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Faults in rolling-element bearings are among the most common types of failures in rotating machinery. As such, there is a significant base of research regarding the detection and diagnosis of these fault using measured vibration signals (Randall and Antoni 2011). However, due to the low relative power of the fault signature compared to other sources of vibration many different signal processing techniques have been employed to increase the SNR. This can prove to be difficult due to the non-stationary nature of many types of rotating machinery. Machines that undergo changes in operational conditions (i.e. speed and load) will produce vibrations that cannot be considered to be stationary or cyclostationary in either the angle or the time domain. This is due to interactions between the angle and time dependant characteristics of the signal (Abboud et al. 2016b).

One common technique for the detection and diagnosis of bearing faults is envelope analysis. In which, the envelope or amplitude modulation of a high frequency band of the signal is analyzed in the frequency domain to reveal the frequency of repeated impulses that can be correlated with the bearing characteristic frequencies (Randall 2004). When preforming envelope analysis, it is generally desirable to perform some preliminary steps to remove non fault related components from the envelope spectrum. The removal of deterministic components from the original signal can help enhance the SNR of the inherently random fault signature, this can be done by using techniques such as synchronous averaging or linear prediction filtering (Kay and Marple Jr. 1981; McFadden and Toozhy 2000). This can however be difficult for non-stationary signals due to the nature of the deterministic signal components however some techniques have been developed to deal with this such as cepstrum pre-whitening (Borghesani et al. 2013) and the generalized synchronous average (Abboud et al. 2016a).

Wavelet de-noising, sometimes referred to as wavelet shrinkage, is another technique that can be used to increase the SNR of the raw vibration signal. Using wavelets to remove white noise from signals was first proposed by Mallat (1991), (Mallat and Hwang 1992). It was shown that the local extrema of the wavelet transform modulus can form an approximate solution to the reconstruction of signals. This is due to the redundancy of information in the wavelet transform modulus. Wavelet shrinkage using the SureShrink method was then proposed by Donoho and Johnstone (1995). This allows the removal of background noise components of the signal using a simple thresholding technique in the wavelet domain. The de-noised signal can then be reconstructed from the remaining peak values of the wavelet transform modulus. Donoho also proposed a soft thresholding technique in which all of the wavelet coefficients are shrunk by the threshold level (those less than the threshold are set to zero), (Donoho 1995). Other thresholding techniques such as the NeighCoeff method, in which the neighbouring coefficients are taken into account, can also be used (Cai and Silverman 2001).

Wavelet de-noising has been used to enhance signals for bearing fault detection. Qiu et al. (2006) compared wavelet thresholding to wavelet filtering for rolling element bearing prognostics. It was found that filtering works better for impulsive signals, whereas thresholding works best on smooth signals. However, Bertot et al. (2014) found that using the thresholding technique on the signal envelope rather than the broadband signal works well for bearing faults. In Ref. (Zhen et al. 2008) the Neighcoeff thresholding method was extended to use both inter and intra scale dependency for detection of bearing faults using a customized wavelet. Mishra et al. (2016) used stochastic/deterministic wavelet de-noising along with short duration angle synchronous averaging and envelope analysis to diagnose bearing faults. Wang et al. (2010) applied the Neighcoeff method to a dual tree wavelet transform to detect cracked gear teeth and bearing faults.

2 Wavelet Denoising Using a Reference Signal

The method proposed in this work is based on wavelet de-noising, however it uses a reference signal to adapt the thresholds in the time and scale dimensions. In doing so, this method significantly reduces the power of random white noise, as well as all signal components that are shared between the original signal and the reference signal. Using the reference signal to adapt the thresholds over time also allows this method to quickly adapt to changing non-stationary signals. In this work the threshold levels for the de-noising process are taken to be the nearest local extrema of the wavelet transform modulus of the reference signal. Shared elements between the signal and the reference can generally be considered to have the same frequency and amplitude characteristics. However, their phase may be different, and it is for this reason that the threshold must be based on local extrema, as the wavelet decomposition of two phase shifted versions of the same signal will not be identical. As mentioned earlier the local extrema forms an approximate solution to the reconstruction of functions from the wavelet transform modulus (Mallat 1991; Mallat and Hwang 1992). The proposed method is combined with envelope analysis to detect faults in bearings. Figure 1 shows a flow chart for the proposed method. As mentioned earlier Bertot et al. (2014) found that preforming de-noising on the envelope signal rather than the raw signal works well, however since in this case we have a priori information about the structure of the noise (gained form the reference signal) this may not be the case. In using this technique it is necessary to include a reference signal that closely models the signal to be analyzed. An application where this is possible is for parallel machinery. When two or more machine components are operating in parallel (mechanically identical with the same speed and load) vibration measurements will be statistically similar with nearly identical deterministic components, allowing one to be used as a reference signal for the other.

The proposed method of de-noising using a reference signal is similar to another common method known as Adaptive Noise Cancellation (ANC). In ANC an adaptive Finite Impulse Response (FIR) filter is used to modify a reference noise signal to minimize the time domain residual between the signal and the modified reference. In both cases the reference signal must be closely related to the noise, however the proposed method assumes that the reference signal and the noise have nearly identical local extrema in the wavelet domain whereas ANC does not. Using ANC, noise components in the signal that are related to the reference by a linear transfer function can be removed (Randall and Antoni 2011). Jena et al. (2014) used ANC along with an adaptive wavelet algorithm to detect gear faults. To do this, the reference signal was a signal from the same gearbox, running in a healthy state and was run at a constant speed. In this work the proposed wavelet de-noising scheme is compared to ANC.

3 Simulated Signals

In this work, simulated signals are used to validate the proposed method, as well as to assess the effects of the different tunable parameters on the methods ability to increase the signal to noise ratio of the signal. A simulated signal is used because a known fault signature can be placed in the signal allowing the SNR to be easily calculated both before and after the de-noising process. The model for the signals used was proposed in (Abboud et al. 2017). However, the amplitudes were modulated by the intake power (speed and load), rather than just the speed as given in the original model. The form of the healthy simulated signal (X(t)) is given in Eqs. 1–4.

d(t) is the deterministic component shown in Eq. 2, r(t) is the random component given in Eq. 3 and b(t) is the background noise given in Eq. 4.

Where M is the modulation function, which is the intake power, ω(t) is the input speed, L(t) is the load (input torque), ai and φi are the amplitude and phase of the ith Fourier coefficients respectively, z1 and z2 are the number of teeth on the input and output gears respectively, W(t) is white noise with unit standard deviation and H is a Linear Time Invariant (LTI) system that represents the signal transfer path.

The Bearing signal follows that given in (Abboud et al. 2017) where the fault signature is a train of impulse response functions spaced with respect to a known ball pass order and the angular frequency with an added 1% random deviation. The amplitude of the responses were also modulated by the intake power.

In this work two different signals were generated one healthy and one faulted. Since the two signals are meant to represent the component signal and a reference from a parallel operating machine they were constructed to have similar statistics but not be identical. A 10% random deviation in the amplitude of the signal components was added such that they are not strictly identical. The phases for the individual signal components were also set to be different, as it is highly unlikely that they would be identical in a real world situation. The signals do however share the same speed and load ramps (Fig. 2). The frequency responses of the different LTI systems are also identical for each signal. The generated signals have a sampling frequency of 10 kHz.

3.1 Results with Simulated Signal

The SNR was calculated using the squared envelope spectrum of the signal where the SNR is the ratio of the power of the known ball pass order with respect to the average power of the entire envelope spectrum. Using this metric, results for the de-noising method were directly compared for each case.

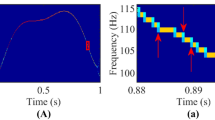

The original faulted signal before de-noising has a SNR of 11.09 when calculated as stated above. The envelope spectrum is shown in Fig. 3A. The ball pass order can clearly be seen in the spectrum, however there are a number of other peaks that are not a result of the fault. Using the de-noising method proposed in this work the SNR increases to 14.26, and the spectrum can be seen in Fig. 3B. In this case the peak at the fault frequency is the largest peak revealed by the envelope.

A factor that affects the results of the proposed technique is the type and order of the wavelet used for decomposition. The SNR for several different wavelets can be seen in Fig. 4A. This shows the best results using a Fejer-Korovkin (FK) wavelet. Other key parameters for this method are the order of the wavelet used and the decomposition level. The change in SNR of the de-noised signal with respect to the wavelet order and the decomposition lever are shown in Fig. 4B for the FK wavelet. This shows a maximum SNR of just over 25 for a decomposition level of 5 and a wavelet order of 22.

As previously discussed, a wavelet de-noising algorithm can employ a hard or soft thresholding method. In all the results so far a soft thresholding technique has been used. When switching to hard thresholding the SNR of the de-noised signal decreases to 21.8.

3.2 Wavelet De-noising vs. ANC

As was discussed earlier it is possible to make a direct comparison between the proposed method and adaptive noise cancellation. Both remove additive noise from a signal through the use of a reference signal. ANC was applied to the simulated signals following the theory given in (Jena et al. 2014) and did not produce good results. This can be seen in Fig. 5, where the SNR is plotted with respect to the filter length. In this work a Recursive Least Squares filter was used with a forgetting factor of 0.9. This showed a significant decrease in performance compared to the raw signal especially for filters with a length greater than three. This is likely due to the highly random nature of the signals noise, as ANC may work better for removal of more deterministic signal components.

4 Conclusions

A method for extracting a fault signature from vibration signals using a reference signal is proposed. The proposed method uses wavelet shrinkage to eliminate elements from the signal that are shared with the reference signal. This method was shown to increase the SNR of a simulated signal, as well as favorable performance when compared to ANC. In future works the effects of the different parameters associated with the wavelet decomposition on the overall effectiveness of the method must be further investigated. This method will also be tested on real experimental data from parallel operating components. Moreover, the sensitivity of the method to minor differences in the structure of the reference signal relative to the original signal must be investigated, as this has the possibility to greatly limit the number of possible applications.

References

Abboud D, Antoni J, Sieg-Zieba S, Eltabach M (2016a) Deterministic-random separation in nonstationary regime. J Sound Vib 362:305–326. https://doi.org/10.1016/j.jsv.2015.09.029

Abboud D, Antoni J, Sieg-Zieba S, Eltabach M (2017) Envelope analysis of rotating machine vibrations in variable speed conditions: a comprehensive treatment. Mech Syst Signal Process 84:200–226. https://doi.org/10.1016/j.ymssp.2016.06.033

Abboud D, Baudin S, Antoni J, et al (2016b) The spectral analysis of cyclo-non-stationary signals. Mech Syst Signal Process 75:280–300. https://doi.org/10.1016/j.ymssp.2015.09.034

Bertot EM, Beaujean P-P, Vendittis D (2014) Refining envelope analysis methods using wavelet de-noising to identify bearing faults. In: Bregon A, Daigle MJ (eds) European Conference of the PHM Society. PHM Society, Nantes France, pp 119–126

Borghesani P, Pennacchi P, Randall RB et al (2013) Application of cepstrum pre-whitening for the diagnosis of bearing faults under variable speed conditions. Mech Syst Signal Process 36:370–384. https://doi.org/10.1016/j.ymssp.2012.11.001

Cai TT, Silverman BW (2001) Incorporating information on neighbouring coefficients into wavelet estimation. Sankhya Indian J. Stat. Ser. B 1960–2002(63):127–148

Donoho DL (1995) De-noising by soft-thresholding. IEEE Trans Inf Theory 41:613–627. https://doi.org/10.1109/18.382009

Donoho DL, Johnstone IM (1995) Adapting to unknown smoothness via wavelet shrinkage. J Am Stat Assoc 90:1200–1224. https://doi.org/10.2307/2291512

Jena DP, Sahoo S, Panigrahi SN (2014) Gear fault diagnosis using active noise cancellation and adaptive wavelet transform. Meas J Int Meas Confed 47:356–372. https://doi.org/10.1016/j.measurement.2013.09.006

Kay SM, Marple SL Jr (1981) Spectrum analysis - a modern perspective. Proc IEEE 69:1380–1419. https://doi.org/10.1109/PROC.1981.12184

Mallat S (1991) Zero-crossings of a wavelet transform. IEEE Trans Inf Theory 37:1019–1033. https://doi.org/10.1109/18.86995

Mallat S, Hwang WL (1992) Singularity detection and processing with wavelets. IEEE Trans Inf Theory 38:617–643. https://doi.org/10.1109/18.119727

McFadden PD, Toozhy MM (2000) Application of synchronous averaging to vibration monitoring of rolling element bearings. Mech Syst Signal Process 14:891–906. https://doi.org/10.1006/mssp.2000.1290

Mishra C, Samantaray AK, Chakraborty G (2016) Rolling element bearing defect diagnosis under variable speed operation through angle synchronous averaging of wavelet de-noised estimate. Mech Syst Signal Process 72–73:206–222. https://doi.org/10.1016/j.ymssp.2015.10.019

Qiu H, Lee J, Lin J, Yu G (2006) Wavelet filter-based weak signature detection method and its application on rolling element bearing prognostics. J Sound Vib 289:1066–1090. https://doi.org/10.1016/j.jsv.2005.03.007

Randall RB (2004) State of the Art in Monitoring Rotating Machinery - Part 1. Sound Vib38:14–21 + 13

Randall RB, Antoni J (2011) Rolling element bearing diagnostics-a tutorial. Mech Syst Signal Process 25:485–520. https://doi.org/10.1016/j.ymssp.2010.07.017

Wang Y, He Z, Zi Y (2010) Enhancement of signal denoising and multiple fault signatures detecting in rotating machinery using dual-tree complex wavelet transform. Mech Syst Signal Process 24:119–137. https://doi.org/10.1016/j.ymssp.2009.06.015

Zhen L, Zhengjia H, Yanyang Z, Yanxue W (2008) Customized wavelet denoising using intra- and inter-scale dependency for bearing fault detection. J Sound Vib 313:342–359. https://doi.org/10.1016/j.jsv.2007.11.039

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Helm, D., Timusk, M. (2019). Extraction of Weak Bearing Fault Signatures from Non-stationary Signals Using Parallel Wavelet Denoising. In: Fernandez Del Rincon, A., Viadero Rueda, F., Chaari, F., Zimroz, R., Haddar, M. (eds) Advances in Condition Monitoring of Machinery in Non-Stationary Operations. CMMNO 2018. Applied Condition Monitoring, vol 15. Springer, Cham. https://doi.org/10.1007/978-3-030-11220-2_1

Download citation

DOI: https://doi.org/10.1007/978-3-030-11220-2_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-11219-6

Online ISBN: 978-3-030-11220-2

eBook Packages: EngineeringEngineering (R0)