Abstract

The development of polymeric composites based on polymers and functional particles produces a new class of materials with properties of interest for different applications, such as materials with electrical conductivity or related to environmental care. Some examples of additives that can be applied to textiles are carbon, metal, and ceramic particles. The synthetic polymers commonly used for the formation of composite materials are polyethylene (PP), nylon-6, polypropylene (PE), polyethylene terephthalate (PET), polylactic acid (PLA), and polycarbonate (PC), mainly. The most widely used methods to produce polymeric compounds are: in situ polymerization, solution mixing, and melt blending. It is important to obtain polymeric compounds as they present isotropic properties and excellent compatibility between the matrix and the reinforcing phases. There are different ecological methods for the dispersion of the additives, and the interaction of the current phases, some techniques are relevant to obtain suitable material properties, such as functionalization and dispersion with ultrasonic energy of the particles in the medium. These additives can give functionality to fibers obtained from polymeric compounds. The progress of fibers using micron or nanometric size materials is of interest in different application areas. Three interesting applications that they can be used are the medical, security, and energy areas. The use of synthetic polymers by adding ceramic materials such as TiO2 and ZnO helps the photodegradation of the polymers.

Similar content being viewed by others

References

Camargo PHC, Satyanarayana KG, Wypych F (2009) Nanocomposites: synthesis, structure, properties and new application opportunities. Mater Res 12(1):1–39

Cabello C, Reyes P, Andrade M, Cadenas G, Pérez M, Cruz VJ, Ávila CA (2019) Melt-mixed thermoplastic nanocomposite containing carbon nanotubes and titanium dioxide for flame retardancy applications. Polymers 11(7):1204

Koo J (2016) Fundamentals, properties and applications of polymer nanocomposites. Cambridge University Press, Cambridge, pp 109–129

Pelto J, Verho T, Ronkainen H, Kaunisto K, Metsäjoki J, Seitsonen J, Karttunen M (2019) Matrix morphology and the particle dispersion in HDPE nanocomposites with enhanced wear resistance. Polym Test 77:105897

Diebold MP, Staley RH (2005) Quantitative determination of particle dispersion in a paint film. In: 8th Nurnberg congress, creative advances in coatings technology. Hanover Vincentz Network GmbH, Nurnberg

Grasselli MC, Lavat AE, Domanski D, Urretavizcaya G, Castro FJ, Gennari F (2004) Mechanochemical synthesis of magnesium aluminate spinel power at room temperature. J Am Ceram Soc 87(11):2020–2024

Zeng C, Lee LJ (2001) Poly (methyl methacrylate) and polystyrene/clay nanocomposites prepared by in-situ polymerization. Macromolecules 34(12):4098–4103

Mazov N, Kuznetsov VL, Krasnikov DV, Rudina NA, Romanenko AI (2011) Structure and properties of multiwall carbon nanotubes/polystyrene composites prepared via coagulation precipitation technique. J Nanotechnol 648324:1–7. https://doi.org/10.1155/2011/648324

Haggenmueller R, Gommans H, Rinzler AG, Fischer JE, Winey KI (2000) Aligned single-wall carbon nanotubes in composites by melt processing methods. Chem Phys Lett 330(3):219–225

Gallego K, López BL, Gartner C (2006) Estudio de mezclas de polímeros reciclados para el mejoramiento de sus propiedades. Revista Facultadde Ingeniería Universidad de Antioquia 37:59–70

Breitenbach J (2002) Melt extrusion: from process to drug delivery technology. Eur J Pharm Biopharm 54(2):107–117

Chokshi R, Zia H (2004) Hot-melt extrusion technique: a review. Int J Pharm Res 3:3–16

Sarwar Z, Yousef S, Tatariants M, Krugly E, Čiužas D, Danilovas PP, Martuzevicius D (2019) Fibrous PEBA-graphene nanocomposite filaments and membranes fabricated by extrusion and additive manufacturing. Eur Polym J 121:109317

Dorigato A, Brugnara M, Giacomelli G, Fambri L, Pegoretti A (2016) Thermal and mechanical behavior of innovative melt-blown fabrics based on polyamide nanocomposites. J Ind Text 45(6):1504–1515

bnKrook M, Gällstedt M, Hedenqvist MS (2005) A study on montmorillonite/polyethylene nanocomposite extrusion-coated paperboard. Packag Technol Sci 18(1):11–20

Dessouky HM, Lawrence CA (2011) Nanoparticles dispersion in processing functionalised PP/TiO 2 nanocomposites: distribution and properties. J Nanopart Res 13(3):1115–1124

Yang F, Nelson GL (2006) Polymer/silica nanocomposites prepared via extrusion. Polym Adv Technol 17(4):320–326

Ávila-Orta CA, Colunga JGM, Baquéz DB, López CER, Delgado VJC; Morones PG, González JAR (2012) U.S. Patent Application No. 13/258,930

Ávila CA (2018) Ultrasound-assisted melt extrusion of polymer Nanocomposites. In: Nanocomposites-Recent Evolutions. IntechOpen, London

Krella A (2010) Cavitation degradation model of hard thin PVD coatings. Adv Mater Sci 10(3):27–36

Mousavi SA, Feizi H, Madoliat R (2007) Investigations on the effects of ultrasonic vibrations in the extrusion process. J Mater Process Technol 187:657–661

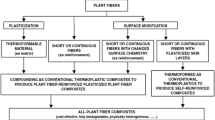

Mohammed L, Ansari MNM, Pua G, Jawaid M, Islam SM (2015) A review on natural fiber reinforced polymer composite and its applications. Int J Police Sci. https://doi.org/10.1155/2015/243947

Mittal G, Dhand V, Rhee KY, Park SJ, Lee WR (2015) A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J Ind Eng Chem 21:11–25

Sinclair R (2015) Understanding textile Fibres and their properties: what is a textile fibre. In: Textiles and fashion. Woodhead Publishing, Cambridge, pp 3–27

Xiaojian L (2019) High strength in combination with high toughness in robust and sustainable polymeric materials. Science 366(6471):1376–1379

Stoppa M, Chiolerio A (2014) Wearable electronics and smart textiles: a critical review. Sensors 14:11957–11992

Gil ES, Hudson SM (2004) Stimuli-reponsive polymers and their bioconjugates. Prog Polym Sci 29:1173–1222

Delcea M, Möhwald H, Skirtach AG (2011) Stimuli-responsive LbL capsules and nanoshells for drug delivery. Adv Drug Deliv Rev 63(9):730–747

Tzou HS, Lee HJ, Arnold SM (2004) Smart materials, precision sensors/actuators, smart structures, and structronic systems. Mech Adv Mater Struct 11(4–5):367–393

Cabane E, Zhang X, Langowska K, Palivan CG, Meier W (2012) Stimuli-responsive polymers and their applications in nanomedicine. Biointerphases 7(1–4):9

Hu JL (2016) Introduction to active coatings for smart textiles. In: Active coatings for smart textiles. Woodhead Publishing, Duxford, pp 1–7

Borlase S (2016) Smart grids: infrastructure, technology, and solutions. CRC Press, Boca Raton

Koncar V (2016) Smart textiles and their applications. Woodhead Publishing, Amsterdam

Zhang Y, Geng X, Tan Y, Li Q, Xu C, Xu J, Wang H (2020) New understanding of the damage of SARS-CoV-2 infection outside the respiratory system. Biomed Pharmacother 127:110195

Scott RA (2005) Textiles for protection. Elsevier, Burlington

Schneegass S, Amft O (2017) Introduction to smart textiles. Smart textiles. Springer, Cham, pp 1–15

Chen G, Li Y, Bick M, Chen J (2020) Smart textiles for electricity generation. Chem Rev 120:3668–3720

Yilmaz ND (2018) Smart textiles: wearable nanotechnology. Scrivener, Hoboken

Medellín-Banda DI (2019) Enhancement of the thermal conductivity of polypropylene with low loadings of CuAg alloy nanoparticles and graphene nanoplatelets. Mater Today Commun 21:100695

Li A, Zhang C, Zhang YF (2017) Thermal conductivity of graphene-polymer composites: mechanisms, properties, and applications. Polymers 9:437

Jayaraman S, Grancaric AM, Kiekens P (2006) Intelligent textiles for personal protection and safety. IOS Press, Amsterdam

Bernardes M (ed) (2011) Developments in heat transfer. BoD–Books on Demand. https://books.google.es/books?hl=es&lr=&id=3uqPDwAAQBAJ&oi=fnd&pg=PR13&dq=Bernardes+M+(ed)+(2011)+Developments+in+heat+transfer.+BoD%E2%80%93Books+on+Demand&ots=32rtJuEzBT&sig=rIp1pwxIcH23yqvycwGk77URrXA

Rotari E, Negara C (2016) Possibilities and applications of smart textiles. MATEC Web of Conferences 112:04025. https://doi.org/10.1051/matecconf/201711204025

Cui H-W, Katsuaki S, Hiroshi U (2015) Highly stretchable, electrically conductive textiles fabricated from silver nanowires and cupro fabrics using a simple dipping-drying method. Nano Res 8.5:1604–1614

Torres Alonso E (2018) Graphene electronic fibres with touch-sensing and light-emitting functionalities for smart textiles. Flex Electron 2:25

Castano LM, Flatau AB (2014) Smart fabric sensors and e-textile technologies: a review. Smart Mater Struct 23:53001

Weng W, Chen P, He S, Sun X, Peng H (2016) Smart Electronic Textiles. Angew Chem Int Ed 55:6140–6169

Amanda F, Maddy S (2015) E-textiles in clinical rehabilitation: a scoping review. Electronics 4:173–203

Cabello C, Caicedo C, López L, Andrade M, Delgado VJ, Orta CÁ (2019) Revisión de métodos para la obtención de textiles técnicos. Textiles técnicos y su obtención. Revista Iberoamericana de Polímeros 20(3):105–117

Hu J, Meng H, Li G, Ibekwe SI (2012) A review of stimuli-responsive polymers for smart textile applications. Smart Mater Struct 21(5):053001

Hu JL, Narayana H (2016) Review of memory polymeric fibres and its potential applications. Adv Res Text Eng 1, 2, 1010:1–7. http://ira.lib.polyu.edu.hk/handle/10397/72097

Liu ZF (2015) Hierarchically buckled sheath-core fibers for superelastic electronics, sensors, and muscles. Science 349:400–404

España-Sánchez BL, Ávila-Orta CA, Neira-Velázquez MG, Solís-Rosales SG, González-Morones P (2012) Preparation of polymer nanocomposites with enhanced antimicrobial properties. MRS Online Proc Libr Arch 1479:57–62

Akwada DR, Akinlabi ET (2019) 5 Mechanical properties of bamboo yarn a biodegradable composite material for structural work. Adv Compos Biodegrad Compos 10:81–11. https://books.google.com.mx/books?hl=es&lr=&id=wXacDwAAQBAJ&oi=fnd&pg=PA81&dq=Akwada+2019&ots=KwHs80pAti&sig=KFZLesVGsFmv8v3i-LVfbqWxShk&redir_esc=y#v=onepage&q=Akwada%202019&f=false

Tomljenović A, Erceg M (2016) Characterisation of Textile and Oleaginous Flax Fibrous and Shives Material as Potential Reinforcement for Polymer Composites Lastnosti vlaken in pezdirja iz predivnega in oljnega lana kot potencialnega materiala za ojačitev polimernih kompozitov. http://www.tekstilec.si/wp-content/uploads/2017/01/350-366.pdf

Ozen E, Kiziltas A, Kiziltas EE, Gardner DJ (2013) Natural fiber blend-nylon 6 composites. Polym Compos 34(4):544–553

Bourmaud A, Ausias G, Lebrun G, Tachon ML, Baley C (2013) Observation of the structure of a composite polypropylene/flax and damage mechanisms under stress. Ind Crop Prod 43:225–236

Gauthier R, Joly C, Coupas AC, Gauthier H, Escoubes M (1998) Interfaces in polyolefin/cellulosic fiber composites: chemical coupling, morphology, correlation with adhesion and aging in moisture. Polym Compos 19(3):287–300

Arbelaiz A, Cantero G, Fernandez B, Mondragon I, Ganan P, Kenny JM (2005) Flax fiber surface modifications: effects on fiber physico mechanical and flax/polypropylene interface properties. Polym Compos 26(3):324–332

Kalia S, Sharma S, Bhardwaj B, Kaith BS, Singha AS (2008) Potential use of graft copolymers of mercerized flax as filler in polystyrene composite materials. Bioresources 3(4):1010–1019

Ochi S (2012) Tensile properties of bamboo fiber reinforced biodegradable plastics. Int J Composite Materi 2(1):1–4

Cristaldi G, Latteri A, Recca G, Cicala G (2010) Composites based on natural fibre fabrics. Woven Fabric Eng 17:317–342

Porras A, Maranon A (2012) Development and characterization of a laminate composite material from polylactic acid (PLA) and woven bamboo fabric. Compos Part B 43(7):2782–2788

Farahbakhsh N, Roodposhti P, Ayoub A, Venditti R, Jur JS (2015) Melt extrusion of polyethylene nanocomposites reinforced with nanofibrillated cellulose from cotton and wood sources. J Appl Polym Sci 132:41857

Haigler CH, Betancur L, Stiff MR, Tuttle JR (2012) Cotton fiber: a powerful single-cell model for cell wall and cellulose research. Front Plant Sci 3:104

Polat O, Lorenz TJ, Phan D, Trokhan PD (2008) Method for making a fibrous structure comprising cellulosic and synthetic fibers. US7354502B2. https://patentimages.storage.googleapis.com/3b/13/74/e765112e9da61b/US7354502.pdf

Pantaloni D, Darshil S, Baley C, Bourmaud A (2020) Monitoring of mechanical performances of flax non-woven biocomposites during a home compost degradation. Polym Degrad Stab 177:109166

Bourmaud A, Fazzini M, Renouard N, Behlouli K, Ouagne P (2018) Innovating routes for the reused of PP-flax and PP-glass non woven composites: a comparative study. Polym Degrad Stab 152:259–271

Rwawiire S, Tomkova B, Gliscinska E, Krucinska I, Michalak M, Militky J, Jabbar A (2015) Investigation of sound absorption properties of bark cloth nonwoven fabric and composites. Autex Res J 15(3):173–180

Moghaddam MK, Safi S, Hassanzadeh S, Mortazavi SM (2016) Sound absorption characteristics of needle-punched sustainable Typha/polypropylene non-woven. J Text Inst 107(2):145–153

Garcia L, Castell P, Peinado V, Muniesa M, Fernandez A (2014) Improvement of mechanical properties of poly (lactic acid) by integration of sepiolite nanoclays: effect of ultrasonication on clay dispersion. Mater Res Innov 18:85–89

El-Dessouky HM, Lawrence CA (2011) Nanoparticles dispersion in processing functionalised PP/TiO2 nanocomposites: distribution and properties. J Nanopart Res 13:1115–1124

Worsley DA, Searle JR (2002) Photoactivity test for TiO2 pigment photocatalysed polymer degradation. Mater Sci Technol 18(6):681–684

Sedghi R, Shariati M, Zarehbin MR, Soorki AA (2017) High-performance visible light-driven Ni-ZnO/rGO/nylon-6 & Ni-ZnO/rGO/nylon-6/ag nanofiber webs for degrading dye pollutant and study their antibacterial properties. J Alloys Compd 729:921–928

Peng G, Li Q, Yang Y, Wang H, Li W (2008) Effects of nano ZnO on strength and stability of unsaturated polyester composites. Polym Adv Technol 19(11):1629–1634

Sudrajat H, Babel S (2016) A new, cost-effective solar photoactive system N-ZnO polyester fabric for degradation of recalcitrant compound in a continuous flow reactor. Mater Res Bull 83:369–378

Gilja V, Vrban I, Mandić V, Žic M, Hrnjak-Murgić Z (2018) Preparation of a PANI/ZnO composite for efficient photocatalytic degradation of acid blue. Polymers 10(9):940

Lee SL, Chang CJ (2019) Recent developments about conductive polymer based composite photocatalysts. Polymers 11(2):206

Zhang Y, Wang X, Wang C, Zhai H, Liu B, Zhao X, Wei Y (2019) Facile preparation of flexible and stable superhydrophobic non-woven fabric for efficient oily wastewater treatment. Surf Coat Technol 357:526–534

Mazzon G, Zahid M, Heredia-Guerrero JA, Balliana E, Zendri E, Athanassiou A, Bayer IS (2019) Hydrophobic treatment of woven cotton fabrics with polyurethane modified aminosilicone emulsions. Appl Surf Sci 490:331–342

Zhang YR, Chen JT, Hao B, Wang R, Ma PC (2020) of cellulose-coated cotton fabric and its application for the separation of emulsified oil in water. Carbohydr Polym 240:116318. https://doi.org/10.1016/j.carbpol.2020.116318

Guo W, Wang X, Huang J, Zhou Y, Cai W, Wang J, Hu Y (2020) Construction of durable flame-retardant and robust superhydrophobic coatings on cotton fabrics for water-oil separation application. Chem Eng J 398:125661. https://doi.org/10.1016/j.cej.2020.125661

Zhu T, Li S, Huang J, Mihailiasa M, Lai Y (2017) Rational design of multi-layered superhydrophobic coating on cotton fabrics for UV shielding, self-cleaning and oil-water separation. Mater Des 134:342–351

Diao Z, Wang L, Yu P, Feng H, Zhao L, Zhou W, Fu H (2017) Super-stable non-woven fabric-based membrane as a high-efficiency oil/water separator in full pH range. RSC Adv 7(32):19764–19770

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this entry

Cite this entry

Cabello-Alvarado, C.J., Andrade-Guel, M.L., Medellín-Banda, D.I., Melo-Lopez, L., Ávila-Orta, C.A. (2021). Polymer Composites: Smart Synthetic Fibers Approach in Energy and Environmental Care. In: Kharissova, O.V., Martínez, L.M.T., Kharisov, B.I. (eds) Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications. Springer, Cham. https://doi.org/10.1007/978-3-030-11155-7_146-1

Download citation

DOI: https://doi.org/10.1007/978-3-030-11155-7_146-1

Received:

Accepted:

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-11155-7

Online ISBN: 978-3-030-11155-7

eBook Packages: Springer Reference Chemistry and Mat. ScienceReference Module Physical and Materials ScienceReference Module Chemistry, Materials and Physics