Abstract

In this study, the effect of homogenization heat treatment on precipitation and recrystallization kinetics as well as geometry of recrystallized grains during subsequent annealing of direct chill cast hot rolled and twin-roll cast AA 3105 strips was investigated. For this purpose, homogenization heat treatment was conducted on AA 3105 strips after cold rolling with an equivalent strain of 0.66. Homogenized and non-homogenized strips were then cold rolled with an equivalent strain of 1.06. Results reveal that homogenized twin-roll cast AA 3105 strip exhibits lower recrystallization temperature as compared to that of non-homogenized one and finer as well as quasi-equiaxed grains through particle-stimulated nucleation mechanism after soft annealing. On the other hand, for direct chill cast hot rolled AA 3105 strip, homogenization heat treatment leads to lower recrystallization kinetics.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

With the fact that desired final microstructure can vary based on application [1, 2], grain structure evolution during subsequent annealing of cold rolled 3xxx aluminum alloys has been of great importance since it affects the formability and corrosion resistance of final sheets. 3xxx aluminum alloys with manganese as a main alloying element are widely used in many applications such as container, packaging, architecture, automobile industry owing to their excellent specific strength , corrosion resistance and formability [3,4,5]. On the other hand, Mn has a limited solubility in Al and rapid solidification during casting results in supersaturation of Mn as well as a small portion of Mn-bearing intermetallics [6,7,8]. Mn can easily concurrently precipitate from supersaturated solid solution leading to recrystallization inhomogeneity during any subsequent heat treatment. At the same time, concurrent precipitation of Mn-bearing particles may also affect the texture evolution [8, 9] and recrystallization as well as precipitation kinetics during subsequent heat treatment [10]. Numerous studies have been attempted to characterize nucleation behavior of cold rolled 3xxx aluminum series. It has been reported that recrystallization inhomogeneity during subsequent heat treatment can be eliminated by intermediate (homogenization ) annealing prior to cold rolling [8, 11,12,13] and rapid heating during recrystallization annealing [14]. Homogenization renders to achieve fine quasi-equiaxed grains and faster recrystallization through decreased supersaturation of Mn and coarsening the Mn-bearing precipitates , which encourage particle-stimulated nucleation . All studies have shown that softening and precipitation kinetics as well as grain structure evolution during subsequent heat treatment are strongly influenced by initial microchemistry (Mn content in solid solution, size and amount of Mn-bearing particles). Therefore, to obtain the desired microstructure and texture , it is essential to control the initial microchemistry .

In the light of this short review, the focus of this study is to investigate the effect of initial microchemistry of AA 3105 alloy on the recrystallization and precipitation kinetics during subsequent annealing. For this purpose, to obtain different initial microchemistry states direct chill cast hot rolled and twin-roll cast AA 3105 strips were used and each strip were processed with two different thermo-mechanical processes.

Experimental Studies

The materials used in the scope of this study were twin-roll cast (TRC) strips and direct chill cast hot bands (DC, followed by homogenization and hot rolling) of commercial grade AA 3105 alloy with chemical compositions given in Table 1. The thicknesses of as-received TRC and DC samples were 6.0 and 7.0 mm (coiling thickness), respectively. The as-received samples were cold rolled (CR) with an equivalent strain (εeq) of 0.66 and exposed to homogenization heat treatment (HT) in an air circulating furnace at 580 °C for 8 h. Homogenized samples were cold rolled with an equivalent strain of 1.06 and subsequently heat treated in an air circulating pre-heated furnace at different temperatures and durations. For comparison, non-homogenized as-received materials were also processed with the same strain and subsequently heat treated. In total, four different thermal mechanically processed samples were compared (i) cold rolled (εeq = 0.66), homogenized and cold rolled (εeq = 1.06) TRC, (ii) directly cold rolled (εeq = 1.06) TRC, (iii) cold rolled (εeq = 0.66), homogenized and cold rolled (εeq = 1.06) DC and (iv) directly cold rolled (εeq = 1.06) DC.

The softening and precipitation behaviors during subsequent annealing were examined by tensile test , electrical conductivity (EC) measurements and microstructural investigations. The electrical conductivity measurements were conducted at room temperature on as-received as well as homogenized, cold rolled and subsequently annealed samples at 60 kHz. Results of electrical conductivities were evaluated by averaging the results of 12 successive measurements . Microstructural surveys were conducted by optical microscope on the longitudinal cross-sections of subsequently annealed samples under polarized light after preparing the specimens according to the standard metallographic methods etching with Barker’s solution.

Results and Discussion

Electrical conductivity measurement results of as-received, cold rolled (εeq = 0.66) and homogenized samples are shown in Table 2.

Among the as-received materials, DC exhibits higher EC than that of TRC. EC of as-received TRC strip was measured as 23.9 mS/m and was found to slightly decrease with cold rolling, and increase with homogenization heat treatment. In contrary to TRC, homogenization heat treatment after an equivalent strain of 0.66 led to lower EC for DC. It has been reported that Si and Cu have less influence on EC as compared with Mn and Fe. Therefore, lower EC of as-received TRC strip indicates supersaturation of Mn in solid solution owing to high cooling rate encountered in twin-roll casting and increased EC of homogenized TRC strip can be associated with reduced concentration of Mn in solid solution and thus precipitation of Mn-bearing particles. At the same time, higher EC of as-received DC material indicates large amount of precipitates present and can be attributed to the homogenization heat treatment conducted after direct chill casting . However, homogenization conducted after cold rolling (εeq = 0.66) results in lower EC indicating the dissolution of Mn-bearing precipitates and diffusion of Mn to solid solution [9].

Figure 1 plots the variation of yield strength (YS) and increase in EC of all samples as a function of annealing time at different temperatures. As can be seen in Fig. 1, EC increases during subsequent annealing conducted after cold rolling (εeq = 1.06). Non-homogenized TRC sample shows a significant increase in EC with annealing time. Marked increase in EC of non-homogenized TRC sample indicates faster diffusion of Mn from supersaturated solid solution leading to concurrent precipitation of Mn-bearing particles during annealing. However, homogenized TRC and both DC samples exhibit a slight increase in EC with annealing time. This observation can be attributed to less amount of Mn in solid solution due to formation of Mn-bearing particles during homogenization . Among the DC samples, homogenized one after cold rolling (εeq = 0.66) shows higher increase in EC indicating that precipitation is stronger than non-homogenized sample due to higher initial Mn content in solid solution.

On the other hand, as annealing temperature and time increase YS of all samples decrease. Non-homogenized TRC sample shows the slowest softening kinetics. It was reported that concurrent precipitation of Mn-bearing particles during annealing slows and retards the softening. Therefore, with the significant increase in EC, slow softening kinetics of non-homogenized TRC sample can be attributed to concurrent precipitations of Mn-bearing particles during subsequent annealing. Among the homogenized TRC and both DC samples, non-homogenized DC sample, which has lower Mn content in solid solution and thus lower potential for concurrent precipitation , exhibits the highest softening kinetics during subsequent annealing.

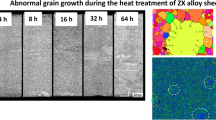

Figure 2 shows typical etched cross sectional optical microscope images of recrystallized samples during subsequent annealing. Microstructural investigations revealed that non-homogenized TRC sample exhibits coarse elongated grains where homogenized TRC and both DC samples represent finer as well as quasi-equiaxed grains . Coarse elongated grains of non-homogenized TRC sample can be explained by concurrent precipitates . It was reported that concurrent precipitations in parallel direction to rolling inhibit grain growth in normal direction [8, 11, 13]. On the other hand, quasi-equiaxed grains of homogenized TRC and both DC samples can be attributed to particle-stimulated nucleation .

Typical etched cross sectional optical microscope images of recrystallized samples during subsequent annealing, a Homogenized TRC annealed at 330 °C for 2 h, b non-homogenized TRC annealed at 410 °C for 2 h, c homogenized DC annealed at 330 °C for 2 h and d non-homogenized DC annealed at 310 °C for 1 h

Conclusions

The results of this study can be summarized as follows:

Softening behavior and precipitation kinetics of twin-roll cast and direct chill cast hot rolled AA 3105 strips during subsequent annealing are affected by microchemistry (amount of Mn in solid solution and precipitation state) and thus previous heat treatment processes.

In general, higher annealing temperature leads to faster precipitation kinetics. Non-homogenized twin-roll cast AA 3105 strip exhibits more pronounced increase in electrical conductivity indicating that more Mn-bearing particles concurrently precipitate from supersaturated solid solution during subsequent annealing.

Concurrent precipitation from solid solution slows and retards the softening. This is more obvious in non-homogenized twin-roll cast AA 3105 strip which shows the slowest softening kinetics. Homogenization heat treatment enhances the softening kinetics of twin-roll cast AA 3105 strips reducing the supersaturating of Mn content in solid solution. However, homogenization heat treatment slows softening kinetics of direct chill cast hot rolled AA 3105 strip at a constant temperature through providing more Mn content in solid solution and thus higher potential for current precipitation during subsequent annealing.

Non-homogenized twin-roll cast exhibits coarse elongated recrystallized grains due to concurrent precipitation of Mn-bearing particles which inhibit grain growth in normal direction during subsequent annealing. On the other hand, homogenized twin-roll cast and both direct chill cast hot rolled strips possess quasi-equiaxed recrystallized grains due to particle-stimulated nucleation .

References

Huang K, Zhang K, Marthinsen K, Loge RE (2017) Controlling grain structure and texture in Al-Mn from the competition between precipitation and recrystallization. Acta Materialia 141:360–373.

Tangen S, Sjølstad K, Furu T, Nes E (2010) Effect of concurrent precipitation on recrystallization and evolution of the P-texture component in a commercial Al-Mn alloy. Metallurgical and Materials Transaction A 41A:2970–2983.

Muggerud AMF, Mørtsell EA, Li Y, Holmestad R (2013) Dispersoid strengthening in AA3xxx alloys with varying Mn and Si content during annealing at low temperatures. Materials Science and Engineering A 567:21–28.

Huang L, Huang G, Cao L, Wu X, Jia Z, Xia M, Liu Q (2017) Influence of pre-recovery on the subsequent recrystallization and mechanical properties of a twin-roll cast Al-Mn alloy. Materials Science and Engineering A 682:63–72.

Li YJ, Arnberg L (2003) Quantitative study on the precipitation behavior of dispersoids in DC-cast AA3003 alloy during heating and homogenization. Acta Materialia 51:3415–3428.

Martins JP, Carvalho ALM, Padilha AF (2009) Microstructure and texture assessment of Al-Mn-Fe-Si (3003) aluminum alloy produced by continuous and semicontinuous casting processes. J. Mater. Sci. 44:2966–2976.

Tilak RV, Morris JG (1985) Studies of the effect of thermomechanical treatments on the supersaturation content of strip-cast aluminum alloy 3004. Materials Science and Engineering 73:139–150.

Liu WC, Morris JG (2005) Evolution of recrystallization and recrystallization texture in continuous-cast AA 3015 aluminum alloy. Metallurgical and Materials Transactions A 36A:2829–2848.

Wang WX, Ma M, Li HL, Zhang JX, Liu WC (2015) Effect of preheat treatment on the texture evolution during cold rolling of AA 3003 aluminum alloy. Journal of Materials Engineering and Performance 24(11):4283–4289.

Chen XP, Mei L, Li S, Shang LM (2018) Effects of homogenisation treatment on microstructure and grain refinement of Al-1.2 Mn alloy. Materials Science and Technology 34(4):493–501.

Liu J, Banovic SW, Fields RJ, Morris JG (2006) Effect of intermediate heat treatment on microstructure and texture evolution of continuous cast Al-Mn-Mg alloy sheet. Metallurgical and Materials Transactions A 37A:1887–1898.

Liu W, Ma M, Yang F (2013) Effect of the heat treatment on the cube recrystallization texture of Al-Mn-Mg aluminum alloy. Metallurgical and Materials Transactions A 44A:2857–2868.

Sun N, Patterson BR, Suni JP, Simielli EA, Weiland H, Allard LF (2006) Microstructural evolution in twin roll cast AA 3105 during homogenization. Materials Science and Engineering A 416:232–239.

Liu WC, Li Z, Man CS (2008) Effect of heating rate on the microstructure and texture of continuous cast AA 3105 aluminum alloy. Materials Science and Engineering A 478:173–180.

Acknowledgements

Authors wish to thank Mr. Nihat Yılmaz and Mr. Hikmet Kayaçetin, technicians of Assan Alüminyum Laboratory, for their valuable help with metallographic studies and mechanical tests.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Gülver, M., Meydanoglu, O., Işıksaçan, C. (2019). Softening Behavior of Direct Chill and Twin-Roll Cast AA 3105 Alloy. In: Chesonis, C. (eds) Light Metals 2019. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-05864-7_140

Download citation

DOI: https://doi.org/10.1007/978-3-030-05864-7_140

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-05863-0

Online ISBN: 978-3-030-05864-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)