Abstract

In this study, selective precipitation of thorium and rare-earth elements was investigated. The leach liquor contains Th, Ce, La, Nd, Pr, and Sm. Precipitation process was realized by using oxalic acid and selectivity of process was provided with the addition of oxalic acid at different volumes. The concentration of oxalic acid and settling duration were selected as parameters. The pH change of leach liquor was controlled during the experiments. The precipitation order was identified as Th, Sm, Nd and Pr, Ce, and La due to increasing of the oxalic acid volume. The precipitation efficiencies were calculated with remaining metals in leach liquor. The elemental analysis of solutions was realized with Inductively Coupled Plasma—Optical Emission Spectrometer (ICP—OES), and the phase analysis of the precipitates was realized with X-ray diffractometer (XRD).

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

The rare-earth elements (REEs) are a group of metallic elements that share similar chemical properties. The lanthanides, scandium, and yttrium were defined as the REE. According to their similarity, they exist together in minerals and separating them to create a problem for scientific and industrial applications [1]. World trends were changed into green energy, and the REEs have important roles in green energy applications. Due to this change, the demand for REEs was increased [2]. The REEs can be found in more than 250 minerals, but only 200 of them have more than 0.01% REEs. The most important minerals for the industry were bastnaesite, monazite, xenotime, and parasite. These four minerals have 95% of the world REEs reserve [1, 3]. Bastnaesite and monazite are the primary sources for the light REEs (Ce, La, Nd, Pr, and Sm). Xenotime is the main source for the heavier REEs. Y is the principal REE and Gd, Dy, Ho, Er, and Yb are the other REEs in the xenotime. Monazite contains Th up to 20 wt%, and bastnaesite also contains Th in small amounts [4].

The traditional REE production routes consist of ore preparation, roasting, leaching, solvent extraction, and precipitation. Solvent extraction process has three stages: extraction, scrubbing, and stripping. These stages were repeated several times for separating REEs [5].

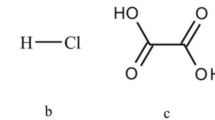

Some researchers were tried to precipitate REEs after leaching but in these studies, they were focused on leaching stage and precipitation of REEs all together. After this process, a REE’s mixture can be obtained from the sulfate solution as oxalates on the basis of Eq. (1) [6]. A general reaction can be written as below: Eq. (2).

Thorium can be separated from REEs in the solvent extraction process. Precipitation of Th and REEs was generally applied after stripping from organic solutions. For precipitating most of the REEs that obtained from Mongolian Apatite Ore by H2SO4, oxalic acid/total REE’s molar ratio determined as 0.3 [7]. REE affinity for oxalic acid is high if Th is not in solution, but REEs are precipitated together with oxalic acid. The RE-oxalate compounds can be calcined to obtain RE-oxides. RE-oxides are an important commercial compound for REEs [8].

The aim of this study is investigating the selective precipitation potential of the Th and complex REE’s leach liquor with oxalic acid. After addition of the oxalic acid, solutions were filtered and ICP–OES analysis was realized on cleaned solutions. On the basis of the results, a possible precipitation route was determined.

Experimental Procedure

Materials

The leach liquor was provided by the General Directorate of Mineral Research & Exploration (MTA), Turkey. The leach liquor was leached from roasted Eskişehir—Beylikova complex ore by 3M hydrochloric acid, 2 h leaching time, and ambient temperature leaching conditions. Oxalic acid (99% w/w) was obtained from Sigma-Aldrich.

Method

Oxalic acid solution was prepared as 1N. A sample of 63 g oxalic acid (H2C2O4·2H2O) was dissolved in 1000 mL distilled water and this solution was used for all experiments. Firstly, 100 mL leach liquor was used for experiments. The oxalic acid was added in 10 mL steps, and precipitation was observed at 20 mL oxalic acid addition. First solid/liquid separation was realized at 20 mL oxalic acid addition , and the filter cake was weighed after drying. The precipitate weights were too low for the analysis. The liquor amount was raised to 500 mL for an accurate determination of where precipitation started. For 500 mL leach liquor, oxalic acid volumes were selected as: 20, 40, 60, 150, 200, 250, 300, 400, 500 mL. After the addition of oxalic acid, solutions settled for 15 min. When the last solid/liquid separation was done, the waste solution was settled for 12 h and observed after 12 h.

Characterization

Elemental analysis of the liquor and solutions were realized with Agilent 720 series Radial, Inductively Coupled Plasma—Optical Emission Spectrometry (ICP—OES) and phase analysis of the precipitates were analyzed with Rigaku D/max 2200, X-ray Diffractometer (XRD).

Results and Discussion

Leach Liquor

Initial pH value of the leach liquor was measured as −0.64 and remained below zero for all steps. ICP—OES analysis of HCl leach liquor is given in Table 1.

After Precipitation

After precipitation , filter cakes were dried at ambient temperature for 48 h. Dried filter cakes were weighed, and the results are given in Table 2. The two heaviest precipitates were obtained at 150 and 250 mL oxalic acid additions .

The decreasing metal amount vs. oxalic acid volume graphs is given in Fig. 1. The y-axis of Fig. 1 was calculated using Eq. (3).

In Eq. (3), c is the present concentration and ci is the initial concentration of each metal.

As can be seen in Fig. 1, 70% of Th precipitates with the addition of the 60 mL oxalic acid and all Th precipitates with the addition of 150 mL oxalic acid. All Sm was precipitated with 200 mL oxalic acid addition . Nd and Pr were precipitated together. Almost all Ce was precipitated at 250 mL oxalic acid addition, and La was precipitated at 500 mL oxalic acid addition.

Phase analysis of the 250 mL oxalic acid addition is given in Fig. 2. Precipitate with 250 mL oxalic acid addition has four RE-oxalate phases. Precipitates that filtered with under 150 mL oxalic acid addition have not enough amount of solids for XRD analysis.

Elemental analysis of the final solution is given in Table 3. As can be seen, Sm has the highest precipitation efficiency and La has the lowest precipitation efficiency.

Conclusions

In this study, selective precipitation of Th and REEs with oxalic acid was investigated. The obtained results are summarized below:

-

The pH value of the leach liquor remained below zero for all investigated oxalic acid additions .

-

Th can be separated from REEs with oxalic acid precipitation process with 3/25 oxalic acid/leach liquor volume ratio.

-

Precipitation order for the REEs determined as Sm > Nd = Pr > Ce > La.

-

Ce, La, Nd, Pr, Sm, and Th precipitation efficiencies from HCl leach liquor are 98, 89.5, 99, 99.3, 100, and 98.9%, respectively.

References

Krishnamurthy N, Gupta CK (2015) Extractive metallurgy of rare earths. CRC Press, Boca Raton

Güneş H, Obuz HE, Oğur E, Çapraz F, Alkan M (2018) Rare-earth elements recovery from Nd–Fe–B hard magnets by hydrometallurgical processes. Springer, Cham

Obuz HE, Günes H, Kara A, Ugurluer D, Babuccuoglu Y, Alkan M (2018) Leaching kinetics of rare-earth elements from complex ores by acidic solutions. Cham

Zhu Z, Pranolo Y, Cheng CY (2015) Separation of uranium and thorium from rare earths for rare earth production—a review. Miner Eng 77:185–196. https://doi.org/10.1016/j.mineng.2015.03.012

Zhang J, Zhao B, Schreiner B (2016) Separation hydrometallurgy of rare earth elements. Springer, Berlin

Sadri F, Rashchi F, Amini A (2017) Hydrometallurgical digestion and leaching of Iranian monazite concentrate containing rare earth elements Th, Ce, La and Nd. Int J Miner Process 159:7–15

Battsengel A, Batnasan A, Narankhuu A, Haga K, Watanabe Y, Shibayama A (2018) Recovery of light and heavy rare earth elements from apatite ore using sulphuric acid leaching, solvent extraction and precipitation. Hydrometallurgy 179:100–109. https://doi.org/10.1016/j.hydromet.2018.05.024

Ibrahim TMM, El-Hussaini OM (2007) Production of anhydrite–gypsum and recovery of rare earths as a by-product. Hydrometallurgy 87(1):11–17. https://doi.org/10.1016/j.hydromet.2006.11.017

Acknowledgements

The authors would like to acknowledge the General Directorate of Mineral Research & Exploration (MTA), Turkey. This study is supported from The Scientific and Technological Research Council of Turkey (Project No: TÜBİTAK 117M202). This study contains information about one part of this TÜBİTAK project.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Güneş, H., Obuz, H.E., Alkan, M. (2019). Selective Precipitation of Th and Rare-Earth Elements from HCl Leach Liquor. In: Azimi, G., Kim, H., Alam, S., Ouchi, T., Neelameggham, N., Baba, A. (eds) Rare Metal Technology 2019. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-05740-4_9

Download citation

DOI: https://doi.org/10.1007/978-3-030-05740-4_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-05739-8

Online ISBN: 978-3-030-05740-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)