Abstract

5 meV Ni++ and Fe++ ion irradiations were performed to investigate radiation-induced precipitates evolution in a cold-worked 316 austenitic stainless steel at high doses and temperatures. The irradiation conditions were 23 dpa at 380 °C, 130 dpa at 380 °C, 23 dpa at 500 °C, and 15 dpa at 600 °C. TEM selected electron diffraction (SAED), TEM dark-field imaging and energy dispersive spectroscopy (EDS) mapping were used as complementary techniques to determine crystallography, morphology and chemical composition of radiation-induced precipitates. The precipitates were predominantly in form of the Ni–Si rich γ′ phase at all irradiation conditions. The EDS analysis further determined Ni–Si–Mo–P and Ni–Si–Mn rich precipitates after irradiation at 380 and 600 °C, respectively. The precipitates were found close to saturated state between 23 and 130 dpa at 380 °C irradiation conditions. A different effect of higher irradiation temperatures was found between 500 and 600 °C. In case of the irradiation to 23 dpa at 500 °C, the average size of precipitates was similar to irradiations at 380 °C, but the density was lower. However, the precipitates revealed large size and very low density following the irradiation to 15 dpa at 600 °C. The original dislocation network introduced by cold-working was found as dominant sink for intra-granular solute radiation-induced segregation (RIS) and possibly took place as primary nucleation site of radiation-induced precipitates at irradiation temperatures 380 and 500 °C. At the temperature 600 °C, the RIS at dislocation network almost vanished and the main nucleation sites became twin boundaries as more energetically favorable intra-granular sinks.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Radiation-induced damage

- Neutron irradiation

- Self-ion irradiation

- Austenitic stainless steels

- PWR

- Baffle-bolts

- TEM

- EDS

Introduction

High neutron irradiation doses exceeding 100 dpa are estimated for reactor vessel internal (RVI) components such as baffle-bolts [1] when the pressurized water reactor (PWR) life extension beyond 60 years will take place. Irradiation conditions causing radiation damage in PWR baffle-bolts include neutron dose rates between 1 × 10−8 and 4 × 10−8 dpa/s and temperatures between 310 and 370 °C, as it was estimated in [2]. At such conditions, there are no literature data of the general radiation-induced microstructure of a cold-worked 316 austenitic stainless steel (CW 316SS) irradiated to a dose above 100 dpa. If the radiation hardening of austenitic stainless steels is predominantly caused by Frank dislocation loops whose evolution is saturated after small doses about 5 dpa [3], the radiation-induced interstitial clusters and precipitates may play a crucial role in the further evolution of microstructure and mechanical properties at high doses. However, the information about radiation-induced precipitates evolution is still limited even from intermediate doses and the mechanism of their evolution is still not well understood.

The main current literature data of radiation-induced precipitates developed in CW 316SS under neutron irradiations are listed in Table 1. In case of the PWR in-core environment, the data consist of TEM results from segments of PWR flux thimble tubes irradiated in the dose range of 1–80 dpa at temperatures of 290–320 °C and dose rates of 2 × 10−9 to 1.5 × 10−7 dpa/s (regarding position of samples in reactor core) [4, 5]. In intermediate doses, there exist several studies of radiation-induced precipitates in CW 316SS of baffle-bolt material irradiated in a PWR environment . They are represented by atom probe tomography (APT) results from a PWR baffle-bolt removed after 17 years of reactor service, which produced the final neutron dose 12 dpa at irradiation temperature 360 °C and dose rates about 2 × 10−8 dpa/s [2, 6], or by a comprehensive TEM study of effects of irradiation condition gradients to evolution of microstructure in the Tihange PWR baffle bolts irradiated to doses 7.5, 12.2 and 19.5 dpa at temperatures between 320 and 343 °C and dose rates between 1 × 10−8 and 4 × 10−8 dpa/s [2, 7]. The missing high dose neutron data from the PWR environment can be surveyed in a shorter period of time by accelerated neutron irradiations in fast breeder reactors (FBR) with a higher neutron dose rate on the order of 10−7 dpa/s. There are TEM studies of the baffle-bolt CW 316SS material irradiated by fast neutrons [8,9,10,11,12] that can be correlated with the PWR intermediate or high dose irradiations. However, even the fast reactors still cannot accumulate the high dose in short period of time desired for the investigation.

Self-ion irradiations with a dose rate on the order of 10−3 dpa/s and with precisely controlled experimental conditions of ion accelerators can be used favorably instead the time consuming, difficult and expensive irradiations in nuclear reactors. The high dose rate of self-ions shortens the irradiation times of 100 dpa from decades to days and these experiments are low cost and do not produce activated samples. In contrast with these advantages, self-ion irradiations have to be coupled with mathematical models, simulations and microstructure benchmarks to match proper irradiation conditions equivalent to a real in-core nuclear reactor environment with a dose rate 5 or more orders of magnitude lower. In last decades, the self-ion irradiations have been widely used to understand basic irradiation effects in materials or to support fast breeder reactor irradiations. Currently, self-ions are being used to simulate the high dose neutron damage including radiation-induced precipitates of RVI structural materials for reactors of the 4th generation [13] and now for commercial PWR reactors including austenitic stainless steels [14].

The microstructure investigations of the fine-scale radiation-induced precipitates of secondary phases in austenitic stainless steels are predominantly performed with use of TEM techniques. However, the fine precipitates are generally “lost” within hardly distinguishable radiation damage visible at TEM bright-field (BF) conditions. Furthermore, TEM SAED usually does not reveal any oriented spot patterns because of the small size and low density of precipitates. This results in difficult or even impossible TEM dark-field (DF) imaging or SAED crystal identification of the precipitates. During a last decade, the APT technique was introduced to analyze microchemistry of the precipitates in atomic scale [4, 6, 14]. This technique allows determining of the size and chemistry very precisely, but it cannot resolve crystal structure or detect vacancies. Moreover, APT maps always represent very small volume limited by needle-shape APT samples. It was found out that all these problems can be overcame with use of three complementary techniques: TEM SAED, TEM-DF imaging (both at two-beam diffraction conditions) and EDS mapping with use of a state-of-the-art ChemiSTEM system, which allows large tilts of sample without a loss of fast EDS spectrum acquisition. Due to this novel approach it was possible to reveal and identify the microstructure and microchemistry of the precipitates systematically at large areas of interest, which is presented in this paper.

Experimental

Material

The material of interest in this study was a 20% cold-worked 316 austenitic stainless steel used for baffle-bolts of a French PWR . Chemical bulk composition of the steel is given in Table 2. The microstructure of the CW 316SS in non-irradiated condition was characterized by TEM in [8]. The material had heavily deformed microstructure with a large amount of deformation twins and microtwins and a dense dislocation network. The same heat of CW 316SS was irradiated in Russian FBR BOR-60 up to dose 46 dpa at an irradiation temperature of 320 °C within the Cooperative IASCC Research (CIR) Program [9, 10]. This allowed a direct correlation of radiation damage evolved during the self-ion and neutron irradiation (will be presented in an upcoming publication). The radiation-induced damage after the self-ion and neutron irradiations revealed dense population of Frank dislocation loops and only short dislocation segments instead of the original dense dislocation network, no presence of cavities, fine-scale radiation induced precipitates and RIS of solutes at grain boundaries.

Self-ion Irradiation

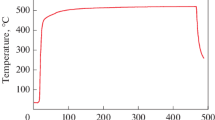

The samples for the self-ion irradiations were prepared in the form of TEM bars 20 × 3 × 1.5 mm in size, Fig. 1a, cut out from the bulk material by electric-discharge machining. The surface selected for irradiation was mechanically and electrochemically polished to produce a mirror-like surface without a mechanically induced damage layer. The samples were irradiated with 5 meV Ni++ and Fe++ ions in 1.7 MV General Ionex Tandem Accelerator at Michigan Ion Beam Laboratory (MIBL). A specially designed copper heating stage and temperature monitoring using thermal imaging camera system ensured the irradiation temperature was varied no more than ±10 °C from target temperature. Details of the stage set-up and temperature control can be found e.g. in [15]. The ion beam was focused to a spot with diameter of 3 mm (FWHM) and raster-scanned over 10 mm length in the central part of TEM bars, Fig. 1a. The raster-scanning was performed across the samples at a frequency of 2061 Hz in the vertical direction and 255 Hz in the horizontal direction. This frequency interval lays in an irradiation regime with no thermal annealing and little or no in-cascade annealing which may still produce lower amount of radiation-induced defects in comparison with defocused ion beams [16]. SRIM-2008 software [17] with a selected Kinchin–Pease (K–P) option and defined displacement energy 40 eV for Fe and Cr as recommended by Stoller et al. [18] was used to calculate damage rate and penetration depth of 5 meV Ni++ and Fe++ ions, Fig. 1b. The calculated damage depth of Ni++ ions was circa 2.2 μm with a peak of damage rate at 1.6 μm, which was in agreement with later TEM observations, Fig. 1c. The penetration profile of Ni++ ions showed almost no implantation up to a depth of about 0.75 μm and most of the ions penetrated in a range from 0.75 to 2.5 μm. A target depth for dose calculation and microstructure characterization was established to be 0.5 μm and 0.3–0.7 μm, respectively, to minimize the effects of sample surface and implanted ions. Based on measured ion beam current and calculated damage rate, the resulting dose rate in the target depth was approximately 1 × 10−3 dpa/s for Ni++ ions. The total damage depth of Fe++ ions was about 0.5 μm smaller and resulting in slightly higher dpa rate in the same target depth compared to Ni++ ions. The used self-ion irradiation conditions were 23 dpa at 380 °C (Fe++), 130 dpa at 380 °C (Ni++), 23 dpa at 500 °C (Ni++) and 15 dpa at 600 °C (Ni++).

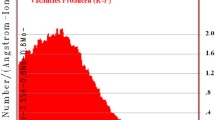

Schematic drawing of a TEM bar and a cross-section FIB lamella within the ion irradiated surface (a). Damage rate and penetration profiles of 5 meV Ni++ and Fe++ ions calculated by SRIM2008 for CW 316SS (b). A TEM bright-field image of self-ion irradiated CW 316SS to 130 dpa at 380 °C, the red dashed area defines the target depth for TEM characterization of radiation-induced damage (c)

Post-irradiation TEM Sample Preparation and Microanalysis

TEM samples were performed by focused ion beam (FIB) “lift-out” technique in form of cross-section thin lamellae to assure the irradiated microstructure could be studied at the target depth, Fig. 1a. The lamellae were attached to copper or molybdenum grids. The FIB devices used were TESCAN LYRA3 and FEI HELIOS NanoLab 660. Results of transmission electron microscopy were obtained with use of field emission gun scanning transmission electron microscope (FEG-STEM) operating at 300 keV, FEI TITAN THEMIS 60–300 at CEITEC—Brno University of Technology. The presence of radiation-induced precipitates was proved firstly by TEM-DF imaging with use of extra spots with enhanced intensity under two-beam diffraction conditions near different zone axes, and secondly by STEM-EDS mapping with use of FEI ChemiSTEM system including high brightness Schottky X-FEG electron gun and SUPER-X EDS spectrometer consisting from four 30 mm2 SDD windowless detectors. The statistical measures of the precipitates were based on measurements of at least 340 precipitates at TEM-DF images and 450 precipitates STEM-EDS maps at 380 °C condition. Substantially lower number of precipitates was measured at 500 and 600 °C condition due to lower density. The thickness of lamellae in the target depth (300–700 nm) was measured by electron energy loss spectroscopy (EELS) in STEM mode when a lamella was not tilted (0°). The determined thickness of lamellae was used for calculation of density of precipitates. The error in density was asymmetrical, since it was estimated from total thickness error caused by a thickness variation of a particular lamella introduced by its tilt (up to ±20° in alpha and beta tilt) to achieve appropriate diffraction conditions for simultaneous determination of precipitates in SAED, TEM dark field and STEM-EDS maps, by wedge-shape of a lamella introduced by final FIB polishing, and by the used EELS technique itself. The error in average size of precipitates was calculated as a standard deviation of measured particles. The quantification of precipitates was performed with software ImageJ. The size of precipitates was measured manually from TEM-DF images and automatically from EDS maps with use of Ferret diameter. An electron beam size and beam step was always below 0.5 nm in the STEM mode, so the resolution of EDS maps was also about 0.5 nm or below. The chemical composition was measured in weight (wt.) %, calculated from X-ray intensities via standard-less Cliff-Lorimer k-factor method implemented in the used analytical software Velox.

Results and Discussion

The CW 316SS irradiated by self-ions to 23 dpa and 130 dpa at 380 °C revealed TEM SAED patterns with extra spots near austenite matrix reflections in two-beam diffraction conditions at austenite zone axis [011], Fig. 2a, or with extra spots positioned in 1/2 distance between (000) beam spot and austenite reflections in two-beam diffraction conditions at austenite zone axis [013], Fig. 3a, or [112] and [114] (these are not presented in this paper). The two-beam diffraction conditions were given when the sample was tilted about 10° out from the particular austenite zone axis pole to an ideal direction, in case of zone axis [011] and [013] it was g = [113]γ. That caused decreased intensity of most of matrix spots and enhanced intensity of extra spots, which were invisible or very weak if the sample was oriented directly at the zone axis pole. The consequent TEM-DF imaging with use of these extra spots illuminated fine-scale precipitates in high intensity and contrast. The precipitates discovered had round or elliptical shape and they were homogenously dispersed within the austenitic matrix. However, they showed certain agglomeration in small volumes, as it is depicted in higher magnification in Figs. 2b and 3b. The presence of the extra spots near austenitic matrix reflections was discussed in several papers, e.g. in [12, 19,20,21]. They correspond to a Ni–Si rich intermetallic γ′ phase (Ni3Si) with ordered FCC structure (Pm3m) and lattice parameter a0 = 0.35 nm [22], which is very close to austenite lattice parameter (a0 = 0.36 nm). Also the presence of extra spots in the 1/2 distance gives evidence of the γ′ phase as it was discussed in [11, 22]. The existence of Ni–Si rich γ′ precipitates imaged in TEM-DF was approved with use of the highly efficient STEM-EDS ChemiSTEM system. The STEM-EDS maps were acquired at the same area of the sample with the same orientation as it was aligned for SAED and TEM-DF. The resulting EDS maps clearly showed the same precipitates observed previously in the TEM-DF images and systematic profiling of chemical composition of these precipitates ascertained their pure enrichment in Ni and Si, depletion in Cr and Fe, unaltered (or rather depleted) content of Mn and Mo and unaltered content of P, Figs. 2c, d and 3c–g.

Ni–Si rich radiation-induced precipitates of γ′ phase in CW 316SS following self-ion irradiation to 23 dpa at 380 °C. The SAED and TEM-DF image (a, b) and STEM-EDS map (c) from the same area. The used extra spots for TEM-DF are encircled in the SAED pattern. Example of chemical composition of one precipitate (ppt) is shown in a line profile (d)

Ni–Si rich radiation-induced precipitates of γ′ phase in CW 316SS following self-ion irradiation to 130 dpa at 380 °C. The SAED pattern and TEM-DF image (a, b) and STEM-EDS maps (c–f) from the same area. The used extra spots for TEM-DF are arrowed in the SAED pattern. Fe, Cr and Mo maps further illustrate the typical trend of RIS around precipitates. Example of chemical composition of one precipitate (ppt) is shown in a line profile (g)

The detailed analysis of both techniques showed that the TEM-DF images contained only a part of population of the precipitates detected in EDS maps. It may suggest that whole volume of precipitates not necessarily fulfilled the chosen diffraction condition in the TEM-DF mode, and/or, that precipitates were present in more orientations within one single grain. In addition, the STEM-EDS technique enabled to determine embryos of precipitates in form of clusters of solute elements without a specific crystal orientation and this also increased the measured density. The difference may play a crucial role in irradiation benchmarks when TEM-DF precipitates data are compared with the other techniques. The resulting underestimation of TEM-DF technique in values of average size and density is obvious from the new results TEM-DF and STEM-EDS measurements compared in Table 3 and further from TEM-DF and APT data presented in literature and compared in Table 1. This phenomenon is also documented by size distribution of precipitates obtained with use of both TEM-DF and STEM-EDS techniques, Fig. 4.

After a dose of 23 dpa at 380 °C, the average size and density of the precipitates was 5.2 nm and 1.8 × 1022 m−3 (measured from TEM-DF images) and 8.9 nm and 5.7 × 1022 m−3 (measured from EDS maps). These results are not far (considering the measurement error) from previous measurements with use of APT, where the average size and density was 4 nm and 1 × 1022 m−3 [14]. After a dose of 130 dpa at 380 °C, the average size and density of the precipitates was 4.1 nm and 1.8 × 1022 m−3 (measured from TEM-DF images) and 7.9 nm and 4.3 × 1022 m−3 (measured from EDS maps). Thus the average size was about 1.8× higher and density was about 2.8× higher if they were measured from EDS maps. The average size and density were very close (within the measurement error) between the self-ion irradiations to 23 and 130 dpa at 380 °C, if the TEM-DF or STEM-EDS results are compared separately. Also the plots of the number density in Fig. 4 showed similar size distribution of precipitates determined from TEM-DF images or STEM-EDS maps, where the peak maximum was about 3.8 or 6.8 nm, respectively, and the distribution had slightly broaden tail to higher values in both cases. It indicates that the population of radiation-induced precipitates was already saturated about the dose 23 dpa and stayed unchanged up to the dose 130 dpa. The saturation could arise in an earlier dose in accordance with the saturation dose of the solute RIS at grain boundaries [23].

The results of the radiation-induced precipitates average size and density after self-ion irradiation to 23 and 130 dpa at 380 °C are comparable with literature data of neutron irradiated CW 316SS in PWR environment (Table 1). The average size is in good agreement (considering the measurement error) with values obtained from TEM and APT investigations of the baffle-bolts irradiated to 12 dpa at 343–365 °C [6, 7] and thimble tube segments irradiated to 74 dpa at 305 °C [4, 5]. The density is comparable rather with TEM results, since the APT revealed about 10× higher density than STEM-EDS maps. The comparison with neutron irradiated CW 316SS in FBR environment shows that the FBR irradiations at temperatures 300–320 °C produced precipitates with similar average size and density as self-ion irradiation [10, 12], but the FBR irradiations at higher temperatures about 380 °C produced precipitates with substantially bigger average size [11].

With respect to the detected extra spots in SAED patterns and determined pure enrichment in Ni and Si, the ascertained radiation-induced precipitates were predominantly in the form of γ′ phase after the self-ion irradiations to doses of 23 and 130 dpa at 380 °C. In addition, Ni–Si–Mo–P rich clusters were spotted about 20–40 nm from a Cr–Mo rich primary precipitates (possibly χ phase) in CW 316SS irradiated to 130 dpa, as it is documented in Fig. 5a–c. These fine clusters, about 9 nm in diameter, are very similar to a Ni–Si rich cluster examined by ATP in neutron irradiated CW 316SS [6], which revealed Mo and P segregation on its interface. The existence of the Mo–P rich clusters nearby the Mo rich primary precipitates may suggest influence of local chemical composition to the evolution of these clusters. The radiation-induced precipitates in CW 316SS can be represented also in the form of G-phase, which is a complex silicide (T6Ni16Si6, where “T” is a transition element) with FCC structure (Fm3m) and lattice parameter a0 = 1.12 nm [22]. The composition matching G-phase was identified by APT in case of bigger clusters enriched in Ni–Si–Mn following PWR irradiation [5] and its presence was unambiguously determined by TEM following FBR irradiations [11, 22, 24, 25]. Therefore, presence of the G-phase was always examined carefully via evaluation of SAED patterns and STEM-EDS maps in the self-ion irradiated samples. However, SAED patterns did not revealed any corresponding spots and, excepting the Ni–Si–Mo–P rich clusters, all radiation-induced clusters and precipitates were found enriched only in Ni and Si and depleted in Cr and Fe with unaltered (or rather depleted) content of Mn and Mo after the doses 23 and 130 dpa at 380 °C.

STEM-EDS maps (a, b) showing Ni–Si-Mo-P rich precipitates (arrowed ppt) nearby Cr–Mo rich primary precipitates (possibly χ phase), Ni–Si rich precipitates of γ′ phase, and Ni–Si rich zones segregated along the dislocation segment (DS) in CW 316SS following self-ion irradiation to 130 dpa at 380 °C. Chemical composition of the two Ni–Si–Mo–P rich precipitates and the dislocation segment is shown in line profiles (c, d)

Beside the Ni–Si rich precipitates and clusters, the STEM-EDS maps ascertained a solute segregation along dislocation segments of the original dislocation network in the form of zones enriched in Ni and Si and depleted in Fe, Cr, Mo and Mn, Fig. 5a, d. This finding is in agreement with the previous study of the same CW 316SS irradiated by self-ions to 130 dpa at 380 °C [14], where APT atom maps ascertained Ni–Si rich zones in the form of a dense network corresponding with the original dislocations introduced by the cold-working. The same intra-granular solute segregation was found in the neutron irradiated CW 316SS baffle-bolts by APT [6] and TEM [7], or in a CW 316SS irradiated by 10 meV Fe++ ions to 10 dpa at 350 °C [26]. The dense original dislocation network was possibly the dominant intra-granular site where the solute atoms segregated via the RIS mechanism and formed clusters and precipitates within the austenite matrix. The assumption that the formation of radiation-induced precipitates was driven by the RIS mechanism at intra-granular sinks in form of dislocations is supported by the same trend of RIS measured at high-energy random grain boundaries or twin boundaries following self-ion irradiations to 23 and 130 dpa at 380 °C (RIS at grain boundaries will be presented in an upcoming publication) and neutron irradiations [5, 9, 10], where the enrichment in Ni and Si and depletion in Fe, Cr, Mo and Mn also took place. Another favorable site for RIS and nucleation of Ni–Si rich clusters or precipitates in CW 316SS could be Frank dislocation loops, as it was determined by APT in CW 316SS irradiated by neutrons, protons or Fe++ ions [5, 26, 27]. However, any RIS or clusters along Frank loops have not been determined in the CW 316SS irradiated by self-ions to 23 and 130 dpa at 380 by the comparison of “rel-rod” TEM-DF images of Frank loops with TEM-DF images and STEM-EDS maps of precipitates at the same area. If the solute RIS at Frank loops evolved in this material, it was in significantly lower intensity than at primary dislocations. Since the self-ion irradiated CW 316SS did not revealed presence of cavities, it can be excluded their influence to nucleation and growth of the precipitates at the used irradiation conditions.

After the self-ion irradiation to doses of 23 dpa at 500 °C and 15 dpa at 600 °C, the STEM-EDS maps ascertained Ni–Si rich radiation-induced precipitates with considerably lower density in comparison with irradiations at 380 °C, as it is documented in Fig. 6a–c. Probably because of the low density, the precipitates did not reveal any specific SAED patterns and even blind imaging by putting an objective aperture to a place of appropriate spot positions did not showed any precipitates in TEM-DF. At an irradiation temperature of 500 °C, Fig. 6a, the precipitates ascertained in STEM-EDS maps had average size about 6.6 nm, similar as at 380 °C. Their chemical composition followed the same trend of RIS as at 380 °C, thus they were enriched in Ni and Si, depleted in Fe, Cr, Mo and Mn and unaltered in P, Fig. 6d. The precipitates were dispersed more sparsely with density about 0.3 × 1022 m−3, what is more than 10× less than at 380 °C. The precipitates revealed strong nucleation at twin boundaries, Fig. 6b, what may suggests the higher temperature allowed migration of point defects to longer distances towards more energetically favorable sinks than dislocation segments or Frank loops. However, the Ni–Si rich zones along dislocation segments were still distinct and dominant intra-granular site for RIS. The irradiation to 15 dpa at 600 °C induced large Ni–Si rich radiation-induced precipitates with average size about 13.6 nm. They were dispersed within the austenite matrix with very low density about 0.03 × 1022 m−3 and segregated rather along twin boundaries Fig. 6c. In most cases, their chemical composition was similar as measured at lower temperatures. However, enrichment in Mn was found in the case of an intra-granular precipitate, as it is documented in Fig. 6e. This finding implies possible nucleation of G-phase at these irradiation conditions. The precipitation of G-phase was ascertained in CW 316SSs irradiated by neutrons in the same temperature regime [22, 24, 25 ]. The 600 °C irradiation also revealed different RIS at dislocation segments, where zones were broader and weaker in Ni–Si segregation, or completely vanished. The microchemistry of the CW 316SS after 15 dpa at 600 °C studied by STEM-EDS maps demonstrated the effect of the high temperature regime, which rapidly enhanced mobility of point defects. In comparison to self-ion irradiations at lower temperatures, the precipitates were coarsened and the segregation of Ni–Si rich zones along dislocation segments was suppressed at the expense of RIS at more energetically favorable sinks. Even though the precipitates could not be identified from the SAED patterns at 500 and 600 °C, it is possible to assume they were in the form of γ′phase, if they were enriched only in Ni and Si, and in the form of G-phase, if they were enriched in Mn (as measured at 600 °C condition).

Ni–Si rich radiation-induced precipitates and Ni–Si rich zones along dislocation segments (a) and a Ni–Si rich random grain boundary (GB) and clusters at a twin boundary (TW) formed by RIS (b) in CW 316SS following 23 dpa at 500 °C. Large Ni–Si rich and Ni–Si–Mn rich precipitates along a twin boundary (left) and in matrix, respectively, following 15 dpa at 600 °C (c). Chemical composition of marked precipitates (ppt1, ppt2) are shown in line profiles (d, e)

Conclusions

5 meV Ni++ and Fe++ self-ion irradiations to 23 dpa at 380 °C, 130 dpa at 380 °C, 23 dpa at 500 °C, and 15 dpa at 600 °C were performed to study evolution of radiation-induced precipitates in a PWR baffle-bolt CW 316SS at high doses. Three complementary TEM techniques including TEM SAED, TEM-DF imaging, and STEM-EDS mapping were used to resolve crystal structure, morphology and microchemistry of the precipitates.

-

The study determined that the self-ion irradiation to 23 and 130 dpa at 380 °C induced fine-scale Ni–Si rich precipitates with crystal structure and chemical composition corresponding with γ′phase. In addition, Ni–Si–Mo–P rich precipitates were determined close to Mo rich primary precipitates at the dose of 130 dpa.

-

The nature, size and density of determined radiation-induced precipitates following self-ion irradiation to 23 and 130 dpa at 380 °C is in good agreement with previous TEM and APT results from CW 316SS irradiated in the PWR in-core environment to intermediate and high neutron doses.

-

The dens original dislocation network introduced by cold-working prior the irradiation was found as a dominant intra-granular sink for RIS of solutes and possibly as a primary site for nucleation and growth of radiation-induced precipitates via RIS mechanism at irradiation temperatures of 380 and 500 °C.

-

The radiation-induced precipitates were found saturated between doses of 23 and 130 dpa at 380 °C. The preexisting dislocation network could have direct influence on the saturation of precipitates. The saturation could arise in an earlier dose in accordance with the saturation dose of RIS at grain boundaries.

-

Ni–Si rich precipitates with sparser dispersion and nucleated at energetically more favorable twin boundaries were determined after the dose of 23 dpa at 500 °C, when the higher temperature increased mobility of point defects.

-

Substantially larger Ni–Si rich precipitates with low density were determined at the dose of 15 dpa at 600 °C. The effect of the original dislocation network almost vanished during this irradiation and the precipitates predominantly nucleated at twin boundaries. Mn enrichment was found in a coarse intra-granular Ni–Si rich precipitate indicating presence of G-phase. It is in agreement with neutron irradiated CW 316SS in the FBR environment at the same temperature regime. Precipitates nucleated at twin boundaries revealed pure enrichment in Ni and Si.

References

S.J. Zinkle, G.S. Was, Acta Mater. 61, 735–758 (2013)

E.P. Simonen, F.A. Garner, N.A. Klymyshyn, M.B. Toloczko, Response of PWR Baffle-Former Bolt loading to swelling, irradiation creep and bolt replacement as revealed using finite element modeling, in Proceedings of the 12th International Conference on Environmental Degradation of Materials in Nuclear Power System—Water Reactors (2005)

S.M. Bruemmer, E.P. Simonen, P.M. Scott, P.L. Andresen, G.S. Was, J.L. Nelson, J. Nucl. Mater. 274, 299–314 (1999)

K. Fukuya, K. Fujii, H. Nishioka, Y. Kitsunai, J. Nucl. Sci. Technol. 43, 159–173 (2006)

K. Fujii, K. Fukuya, J. Nucl. Mater. 469, 82–88 (2016)

A. Etienne, B. Radiguet, P. Pareige, J.-P. Massoud, C. Pokor, J. Nucl. Mater. 382, 64–69 (2008)

D.J. Edwards, E.P. Simonen, F.A. Garner, L.R. Greenwood, B.M. Oliver, S.M. Bruemmer, J. Nucl. Mater. 317, 32–45 (2003)

B.W. Arey, D.G. Atteridge, S.M. Bruemmer, Production of Tailored Alloys to Isolate Metallurgical Variables Promoting IASCC (EPRI, Palo Alto, CA, 2006)

D.J. Edwards, E.P. Simonen, S.M. Bruemmer, Characterization of Neutron-Irradiated 300-Series Stainless Steels (EPRI, Palo Alto, CA, 2006) (EP-P14516/C7130)

D.J. Edwards, S.M. Bruemmer, Characterization of CIR II Irradiated Stainless Steels (EPRI, Palo Alto, CA, 2008) (EP-P19021/C9406)

A.R. Laborne, P. Gavoille, J. Malaplate, C. Pokor, B. Tanguy, J. Nucl. Mater. 460, 72–81 (2015)

M. Ernestová, J. Burda, J. Kočík, E. Keilová, J. Michalička, C. Pokor, Influence of the neutron spectrum on the sensitivity to IASCC and microstucture of CW 316 material, in Fontevraud 8—Contribution of Materials Investigations and Operating Experience to LWRs’ Safety, Performance and Reliability, France, Avignon (2014)

Z. Jiao, G.S. Was, J. Nucl. Mater. 425, 105–111 (2012)

Z. Jiao, G.S. Was, J. Nucl. Mater. 449, 200–206 (2014)

G. Gupta, Z. Jiao, A.N. Ham, J.T. Busby, G.S. Was, J. Nucl. Mater. 351, 162 (2006)

E. Getto, Z. Jiao, A.M. Monterrosa, K. Sun, G.S. Was, J. Nucl. Mater. 465, 116e126 (2015)

J.F. Ziegler, J.P. Biersack, SRIM2008 Program (IBM Corp, Yorktown, NY, 2008)

R.E. Stoller, M.B. Toloczko, G.S. Was, A.G. Certain, S. Dwaraknath, F.A. Garner, Nuclear instruments methods Phys. Res., Sect. B 310 75–80 (2013)

W. Van Renterghem et al., J. Nucl. Mater. 413, 95–102 (2011)

T. Toyama, Y. Nozawa, W. Van Renterghem, Y. Matsukawa, M. Hatakeyama, Y. Nagai, A. Al Mazouzi, S. Van Dyck, J. Nucl. Mater. 418, 62–68 (2011)

J. Michalicka, A. Hojna, E. Keilova, J. Kocik, TEM radiation damage investigation of neutron irradiated baffle-to-former bolt extracted from a decommissioned WWER-440 reactor, in Proceedings of the 16th International Conference on Environmental Degradation of Materials in Nuclear Power System—Water Reactors (2013)

E.H. Lee, P.J. Maziasz, A.F. Rowcliffe, in The Metallurgical Society of AIME, ed. by J.R. Holland, et al. (Warrendale, PA, 1981), pp. 191–218

G.S. Was, T. Allen, Mater. Charact. 32, 239–255 (1994)

P.J. Maziasz, J. Nucl. Mater. 169, 95–115 (1989)

P.J. Maziasz, J. Nucl. Mater. 205, 118–145 (1993)

A. Etienne et al., J. Nucl. Mater. 406, 244–250 (2010)

Z. Jiao, G.S. Was, Acta Mater. 59, 1220–1238 (2011)

Acknowledgements

The authors gratefully acknowledge Drs. Ovidiu Toader and Fabian Naab for their assistance in conducting the self-ion irradiations, Drs. Steve Bruemmer and Dan Edwards for providing EPRI reports and valuable comments, and Dr. Ondrej Man for help with FIB sample preparation. The research could be performed thanks to support of facilities provided by the Michigan Ion Beam Laboratory and the Electron Microbeam Analysis Laboratory at University of Michigan, the CEITEC Nano Research Infrastructure at Brno University of Technology [MEYS CR (ID LM2015041)], the Tescan Orsay Holding in Brno [MIT CR (4.2 PT03/586)], and the Institute of Materials of Czech Academy of Science in Brno [MEYS CR (No. LM2015069)]. Financial support was provided by DOE under contract DE-FG07-07ID14894.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Michalička, J., Jiao, Z., Was, G. (2019). Radiation-Induced Precipitates in a Self-ion Irradiated Cold-Worked 316 Austenitic Stainless Steel Used for PWR Baffle-Bolts. In: Jackson, J., Paraventi, D., Wright, M. (eds) Proceedings of the 18th International Conference on Environmental Degradation of Materials in Nuclear Power Systems – Water Reactors. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-04639-2_36

Download citation

DOI: https://doi.org/10.1007/978-3-030-04639-2_36

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-04638-5

Online ISBN: 978-3-030-04639-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)