Abstract

Underground mining is considered as one of the most hazard-prone industries, and serious work-related fatalities have arisen as a consequence of processes related to it; this chapter deals with occupational hazards and related risk factors. Artificial neural network-based risk assessment approach in underground copper and zinc mine case study is proposed. Occupational health and safety (OHS) history dates back to ancient human history ever. Mankind date was obliged to do business in order to sustain life. OHS studies aim to increase the safety standard with reducing risk level in an acceptable degree. Safe workplaces with respect to OHS increase health, safety, and welfare standards of whole workers. Throughout the world major hazards categorized as physical, chemical, biological, psychosocial, and ergonomic risks can be observed. Although technological developments provide rapid growth in almost all industries, it can be observed that there is a lack of attention being paid and advanced occupational safety practices in the mining industry. A case study is carried out in one of the largest underground mining companies using neuro-fuzzy approach. Neuro-fuzzy logic-based risk assessment study supplies opportunity to provide more adequate decision-making process and gives meaningful classifications of hazard. Neuro-fuzzy approach is a combination of advantages of artificial neural networks and fuzzy logic. It gives more appropriate and comprehensive risk assessment in OHS. After all the neuro-fuzzy approach is applied for classification of risk types in each department of the copper and zinc mine, the necessary control measures for each department and for a whole system are presented. In the study, adaptive neuro-fuzzy inference system (ANFIS)-focused model is applied to the copper and zinc mine risk analysis problem based on three-step neuro-fuzzy approach. Improvements are shown on the study to show the efficiency and flexibility of the method. The main target by integrating the neuro-fuzzy logic application into the risk analysis is to obtain a more effective risk assessment and getting better results than the conventional models used. In conclusion, besides its theoretical contribution, obtained results of this study contribute toward improving occupational safety levels of copper and zinc mine with more comprehensive risk assessment process.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Multi-criteria decision-making

- Risk assessment

- Occupational safety and health

- Analytic hierarchy process

- L-matrix ANFIS

- IoT

1 Introduction

The Internet of Things (IoT) is defined as a unique network around the world, where uniquely addressable objects are formed and the objects in that network communicate with each other through a specific protocol. It is also possible to define this concept as a system of devices that communicate and communicate with each other through a variety of communication protocols and by sharing information with an intelligent network [1]. Since safety is one of the most important and prone concepts for occupational safety and health in mining, proactive-based IoT applications supported risk analysis can be adapted to the system in mining sector [2]. IoT sensors and devices can be used to improve total safety level [3]. Investigation of proper way with wireless sensor network features is done to monitor outdoor environment [4]. According to wireless network ability, changing environment conditions can be explored and adopted [5]. The system can help to minimize hazards and environmental problems such as water pollution and fires. Environmental monitoring with IoT can also provide cost-efficient and proper solutions [6].

Risk analysis of any workplace is first step to check and observe total safety level. There are many quantitative and qualitative risk assessment tools to analyze reasons of accidents in various industries and features of the workplace conditions in sources. Multi-criteria decision-making-based method is one of the most important methods [4]. In these methods, decision-makers often have difficulty in accurate rating and assessment in a danger related with risk parameter. Therefore, implementing potential risk assessment methods can show satisfactory results in terms of incomplete risk data or high uncertainty. In this study the ways that combine multi-criteria decision-making method and fuzzy sets are accepted to model the structure [5]. One of the important advantages of fuzzy multi-criteria decision-making methods is relatively assessing the risk parameters by using fuzzy numbers instead of insignificant numbers [6]. Chart 1 shows a comparative summary about a range of new researches related with fuzzy multi-criteria decision-making methods in occupational health and safety risk assessment [7,8,9,10,11,12,13,14,15].

In the underground mining, the work environment becomes more appropriate with the OHS, and the occupational accidents and occupational diseases are affected positively by taking necessary precautions, by the worker’s feelings of trust originating from the work environment. In addition, these factors become the reasons for the improvements that cause positive effects as in the employee’s daily life as his efficiency in workplace [16]. This is also important in the aspect of improvement and continuity of the system in a similar way.

From this point of view, potential risks in mines within occupational health and safety and forming OHS risk analysis scheme and managing the necessary precautions actively by classifying emerging dangers are aimed in this study in the process of carrying out the underground mining. To improve the system precautions which are taken necessarily in accordance with detailed risk analysis.

As a part of this study, the risk assessment study based on fuzzy and neuro-fuzzy logic is carried out by using the data based on OHS risk analysis of a metal mine industry which has more than one billion production capacity and is compared to failure level of the basic risk assessment methods.

1.1 Original Contribution

Based on the data that is obtained within the study, by using neuro-fuzzy logic approach in underground mining, risk analysis is done and risk levels are estimated. Underground mining risk parameters in OHS assessing by neuro-fuzzy logic are used for the first time, and the results are compared with the results of basic risk assessment methods in the point-of-failure criterion.

Besides that, L-matrix risk assessment results and two-phase risk analysis results [17] obtained by Buckley fuzzy analytic hierarchy method and fuzzy VlseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR) methods are compared with neuro-fuzzy logic obtained by the results from risk assessments by considering the failure measures in OHS; in terms of implementing more detailed studies, the sources in this area have been enriched.

Risk assessment studies based on two or three parameters such as severity, possibility, and noticeably contributed to the resources in terms of dealing with the risks more effectively by adding different parameters that extend the content like precision of using personal protection tools, precision for not to renew the tools and ignoring the results.

The World Health Organization defines the OHS term as multidisciplined operation including four basic topics: (1) to prevent occupational accidents by protecting and improving employee’s health; (2) improving and supporting healthy and safe work, workplace, and work organizations; (3) increasing employees’ physical, mental, and social welfare; and (4) enabling the workers having fruitful lives both socially and financially [18, 19].

1.2 Occupational Health and Safety

OHS is all the studies and analyses that aim reducing the problems which may occur in all processes related with work and employees. In terms of OHS, structural difficulty of the underground mining services and precision as of divergent and rapidly changing equipment structure need to be done detailed research and analysis [20]. In workplaces employees work that are of the most important parts of underground mining services, being with unreliable factors in the aspect of OHS and lack of precautions for these factors are required to create different regulations. The underground mining organizations are part of the most dangerous group in terms of occupational accidents and occupational diseases in OHS risk classification list, and this makes compulsory to conduct detailed and effective risk analysis of underground mining services.

Making workplaces appropriate for OHS in underground mining, identifying the occupational accidents and occupational diseases, taking necessary precautions, and making employees feel safe due to working environment affect their works positively [21]. In addition these factors become the reasons for the improvements that cause positive effects as in the employee’s daily life as his efficiency in workplace. This is also important in the aspect of improvement and continuity of the system in a similar way.

Based on these results, potential risks in mine organizations within occupational health and safety and forming detailed OHS risk analysis scheme and managing the necessary precautions actively are aimed in this study in the process of carrying out the underground mining. To improve the system precautions which are taken necessarily in accordance with risk analysis, results are stated.

1.3 Occupational Health and Relevant Terms

There are many definitions of the health term in different sources. WHO which does practices on health internationally defines the health as “not only health” or disablement situation, but also, it’s a person’s wellbeing and feeling completely in safe physically, mentally, and socially [22]. This definition may change depending on country, culture, and customs. Criteria of a person being healthy cannot be explained by having physical disability or catching a disease. Besides physical aspects, being safe mentally and socially are the other criteria that make a person healthy. From this point of view, health term is the basis of occupational health [23]. During the employee’s process of being at work or workplace, not being exposed to the risks that will threaten his health and being protected from this are the occupational health term’s basic relation with health. Protecting from the dangers due to the employees’ working environment and job structure is the essential point in the definition of the occupational health term.

Occupational health is a term that searches the physical and mental situation of the employees in workplaces and aims to improve the conditions. In the aspect of occupational health, it is the most important term not to risk and protect the right to life which is among an individual’s natural and fundamental rights, causing from the workplace [24]. Besides that, it also is a compulsory part of the occupational health system to have high efficiency, increase quality standards, and create a sustainable working environment. Comprehending this term as a social culture rather than understanding it as a term just related with workplaces is significant not only in the aspect of employer-employee interaction, but also it is important for developing healthy and safe environment by all society ranks [25]. There are many national and international scale regulations with the aim of increasing the OHS culture. An individual’s work department is also substantial in accordance with explanations of the occupational health term. In terms of OHS, while doing the work that employee is in charge of, he needs to be conscious and knowledgeable, and to be able to do that, person’s nature and kind of the job needs to adjust in maximum possibility [26]. It is necessary that employees work in appropriate jobs which are suitable with their education level and physical and mental state with regard to actualizing the aims of the occupational health term. If a person works in a suitable job in that sense, opportunities of protecting from the risks will increase, and the number of the occupational accidents and its effects will be able to decrease in parallel with this.

1.4 Occupational Safety and Relevant Terms

Safety term expresses being secure. Occupational safety states that taking precautions against the risks that employees can face. Among the process of employees being at work or workplace, the unrepairable consequences that may occur because of occupational accidents show the importance of creating a safety culture term [27]. This must be changeable according to the business and job structure, but it should be aimed at spreading it to a whole society, as well. For instance, it must be aimed that while dealing with workers who are having health problems, whether work process is safe or not for underground mining sector which is considered as an important situation in this study. A worker who is not feeling safe in the working environment makes mistakes, and troubles occur in the job unavoidably [28]. Safety culture should be provided with employee-employer cooperation, and drafts, plans, and programs that serve this should be prepared periodically. It is not possible that being successful in a safe environment is constituted by only an employee or employer. Systematically, all the pieces should have effects on it and contribute to form the safety culture [29, 30].

Many occupational accidents occur every year all around the world due to the deficiencies in the implementation of OHS. According to the International Labor Organization data, more than one billion people die every year because of occupational accidents, and more people are physically or mentally hurt due to these accidents [31]. These data show how the OHS issue is significant. Based on the statistical data which is brought out by social security institution, recently, the people who die because of occupational accidents and occupational diseases have been increasing, and for this reason, it has been observed that the people who become permanently disabled are increasing, too [32]. Fatal occupational accidents increased more than 10%, when it is compared to the previous year, and in parallel with this, being permanently disabled and occupational diseases highly increased in 2014. In that case, according to statistical studies done for underground mining, currently, Turkey is rather behind the world in terms of the number of the occupational accidents in developed countries, number of the people who is permanently disabled, and number of the occupational disease rates. By taking all these into consideration, legislature regulated the laws and passed the 6331 numbered law under the title of OHS. Before passing a law special for OHS, there were legal analyses related with occupational accidents and occupational diseases by different regulations. For example, there were analyses under separate and different laws for the pecuniary and nonpecuniary damages that occur after an occupational accident. This can be resulted with faults, and it may not be possible to get positive results. Besides that, a legal obligation that includes OHS regulations and adapts it emerged in point of the European Union (EU) adaptation process and ILO directives. OHS term is suitable for chances and needy for improvement according to gathered statistical occupational accident and occupational disease data in Turkey in recent years. OHS policies are changed, and current laws are shaped in accordance with EU and ILO directives [33]. Before the legalization, OHS terms that are emphasized on the specific parts of the different laws are combined in one title.

Following the explanations of the health and safety concepts that generate the OHS concept, the differences between these two concepts have been revealed. Occupational health refers to search for developing and improving their physical and mental status, as occupational safety at work or in the workplace is the protection of employees from risks and the risks they face in the workplace. The fact that employees are in a healthy and safe environment is the main objective of these two concepts [34]. A healthy environment in terms of OHS increases the productivity of employees and the ability to work in a safe environment. Proper physical, psychological, and social workplace environment to be provided for employees is a proactive structure and is the priority of identifying and minimizing risks in advance. It should not be forgotten that the budget for the precautions to be taken by proactive approach to work accidents is much more appropriate and necessary than the damages that will happen as the result of occupational accident.

1.5 Management Concept in OHS

It is compulsory to have a managerial understanding in the system in terms of OHS structure. It would be normal to occur and growing problems in terms of occupational safety and occupational health in a business that the management is not being part of and support OHS implementation and activities. Studies on OHS indicate that the lack of a management-supported system is one of the most important reasons for the increase in job accidents. This demonstrates the importance of management understanding in the success of OHS practices. The implementation of a well-designed and experienced OHS management model means that employees are aware of the hazards and the risks are minimized; all employees are in a safe and healthy environment as a team. In addition, the productivity of employees and work will also improve. In this context, the employer must make investments for the occupational area of the OHS without any legal obligations on occupational health and safety and should not regard this as an unnecessary cost. Protecting from danger is much less costly than protection from possible consequences. It should also be kept in mind that when an appropriate environment for OHS is created, it is possible to achieve a sustainable success by reducing the number of mistakes relatively.

In places where work will be done, the target risks should be determined in advance in terms of OHS management, and occupational accidents and occupational diseases should be prevented [35]. These undesirable consequences may cause workforce and financial loss in the workplace. This workplace-based problem may cause social trauma without staying local. Soma disaster that happened on 13 May 2014 is an example of this. The human loss was far beyond financial loss, and it is clear that it is not an easy situation to overcome this trauma. As it is frequently written at workplaces and working points, a safe working environment must be created in actual implementation and management decisions. Management should inform and provide periodical trainings on OHS issues to employees. In addition, each division-specific OHS chargehand should be identified and known by all employees. An OHS plan which is prepared by the management should also be periodically checked and updated. A safe and healthy workplace means healthy and efficient work and ultimately healthy functioning. Each part of the OHS management practices should include risk assessment and practices, and teamwork should be adopted.

2 Risk Assessment in OHS

Concepts of safety, health, and welfare of whole industries’ employees in the workplace are covered by OHS [36]. Due to the poor management of OHS, the underground mining sector that is one of the most affected industries aims to raise the health and safety standards in the relevant institutions in Turkey and all around the world. Many unique hazards can be observed in mines that can potentially affect the health of workers in their departments [37]. These risks increase the accidents in the workplace, affect both the safety of employees and the environment antagonistically, and reduce the efficiency and work performance. OHS practices are not fully implemented in practice, and necessary diligence has not been shown for the underground mining industry in Turkey. There is a negative correlation in economic success and occupational success in Turkey although there should be a positive correlation between OHS practices and economic success. In order to be able to see the OHS policy and compliance in the mining sector more clearly, the new OHS 6331 numbered law also stipulates the necessity of risk assessment. As a result of this reason, this study aims to provide a neuro-fuzzy logic-based OHS risk evaluation for underground mining personnel and to contribute to the development and planning of underground mining services.

On the other hand, OHS risk assessment has several approaches in the planning and management of the underground mining industry. In a literature study, the VIKOR method has been proposed to prioritize failure modes for a fuzzy FMEA based on fuzzy set theory and for general anesthesia process risk assessment [38]. One of the most common risk analysis methods is FMEA which has three parameters. In this study parameters of the FMEA are weighted by fuzzy set theory, and the risk priorities of error modes are determined by the extended VIKOR method. In another study [39] a new FMEA approach was implemented with the fuzzy analytic hierarchy process (FAHP), entropy, and fuzzy VIKOR methods in the production process of a mine. In one other study [40], a three-stage risk-based prioritization scheme is suggested to select the best care strategy for prioritizing medical devices. First, the fuzzy FMEA was implemented by taking into account various risk assessment factors. Second, seven dimensions are used to consider every aspect of hazards and risks, such as use-related hazards, age, and usage. Finally, a simple method has been used to determine the best maintenance strategy for each device based on the scores of the previous two steps. A new risk priority model has been proposed to assess the risk of failure modes based on the fuzzy set theory and the MULTIMOORA method [41]. Besides, a case study on preventing baby abduction was also presented.

Based on the studies in the literature, it is understood that the current study has contributed to the relevant resources on some aspects of underground mining risk assessment.

A fuzzy logic-based structure that removes the shortcomings of a clear risk parameter calculation and reduces the inconvenient has been used to make decisions. Unlike classical OHS risk assessment methods, decision-makers choose parameter weights with a neuro-fuzzy tongue scale. Decision makers can get benefit from neuro-fuzzy logic while establishing appropriate structure of risk assessment process neuro. Classical OHS risk assessment methods consist of either two risk parameters (e.g., decision matrix method) or three risk parameters (e.g., Fine-Kinney method, FMEA method). Increasing the number of parameters in the study will provide a more flexible usage, and a consistent and broad risk assessment model will be presented. This study is the first risk assessment study in the country where the neuro-fuzzy logic approach in occupational health and safety is applied in underground mining.

2.1 OHS Studies in Underground Mining and Current Status

Developing the standards of health and safety at the associations related to underground mining is aimed. Mines which are one of the largest employment groups in the manufacturing sector are facing serious hazards due to the risks which are technically defined previously. These risk factors are increasing the number of occupational accidents, affecting the safety of both the employees and the nature, decreasing the productivity and work performance. Although Turkey has been making significant progress in economic field and making relatively rapid growth in its own geography, OHS implementations are not carried out in a complete and active way, and adequate care has not been shown in underground mining industry. Hence, the aim of the study is to assess the risks for underground mining staff, contribute to process planning in mining, and develop the regulations. There should be an OHS policy which is approved and carried out by the executives of all the enterprises, planned periodically, and open to development and updates [42].

Planning is the first stage of OHS policy. Within the frame of this plan, all the hazards should be defined in terms of facility structure and workplaces, and the staff should be informed about this. Responsible staff should be designated for special OHS security in each department; permanent and sustainable success should be aimed. In addition to this, convenient regulations should be prepared in accordance with the facility’s structure in the medium-sized and large-scale enterprises, and template plans should be created [43].

In order to make staff learn about these regulations, trainings and seminars should be organized and tested periodically. By OHS policy, control mechanism matters. As a result of the control understanding which has gained more importance in underground mining, it has been playing a significant role in precluding the occupational accidents which could result in death. When researching the Ministry of Labor and Social Security (MOLSS)’s short-term and medium-term policies, it is stated that the main aim is to establish a data archive regarding OHS and assess these data on periodical basis [44]. As a result of these studies which will be done on sectoral basis, there will arise a better opportunity to fight against the occupational accidents and illnesses.

As exemplified in the second part, Turkey needs more active policies and follow-ups in order to move to higher positions from where it is currently in OHS field. In the studies done, it is seen that there are risks in underground field, inadequacy, and malfunctions in diagnosing occupational illnesses. The top reason underlying this inadequacy is that OHS training is not in the required position that it should be. In the facilities which carry top level of risk in hazard classifications such as underground mining, the number of training sessions should be increased and conceptualized as project. In underground mining risk assessment study, it was found that the participation and interest of the employees in trainings and researches were low. It is obvious that Turkey needs achievements in OHS policies to reach at the position aimed within the scope of Vision 2023. At this point, it would be rightful to invest in R & D works on both state and private sector basis. In order to form OHS policy as a culture, both enterprises and employees are needed to be encouraged to participate in the cooperation.

Like it happens in all the businesses, the management system is the key to reach the success in a workplace. At the same point, OHS management implementations are required to be prepared in an organizational way and be efficient in all businesses. In order to carry out the responsibilities of OHS in an efficient and successful way, management support is mandatory. These are also valid and critical for the underground mining-based OHS management system [20]. Feeling safe and being healthy for the staff working in underground mining services will lead to receive better results in studies. As the nature of the job, mining workers face many hazardous situations every day, and they try to avoid these situations as much as possible. Individually, it is not possible to keep away from the hazards in underground mining sector. Hence, establishing OHS management and control system efficiently will lead to success at the workplace and get protected against the hazards in a more efficient way.

2.2 Risk Assessment in Multi-criteria Decision-Making Methods

Risk assessment involves the data of the risk-generating elements being finalized by calculating and the analysis of their possibilities. The risk analysis, which is basically divided into two as qualitatively and quantitatively, can be actualized more efficiently by expressing more criteria than one of the complex systems thanks to the multi-criteria decision-making methods. These methods enable the decision-makers to get decision results as easily, quickly, and efficiently as possible, in case that there are multiple alternatives and multiple parameters.

2.2.1 5×5 Matrix Risk Assessment Methodology

Risk assessment is an approach, widely used in OHS risk analysis, which measures the 5×5 matrix method risk classification, also known as the decision matrix technique, based on the decision that reviews it within the dimension of both severity and probability parameters. With this method, by multiplying severity and probability, a risk value criterion is obtained.

Initially, the measurement of severity and probability is determined by this method (Charts 2 and 3). Afterward, risk matrix and decision-making table are created (Charts 4 and 5). The acceptability of the risks is interpreted according to Chart 5.

In the study, a fuzzy approach was proposed that allows experts to evaluate two parameters of the 5×5 matrix method using linguistic variables:

(1) To overcome deficiencies in calculating a clear risk score and (2) to reduce inconsistencies in decision-making. Since the conventional 5×5 matrix method is based on the weight of an equal measure for the severity and probability, it can cause limitations and inconsistencies.

3 Fuzzy Logic and ANFIS

In 1940s, neurophysiology expert Warren McCulloch and mathematician Walter Pitts conducted a research on how the neuros might work. This study is accepted as a first study on neural networks. Their study resulted with a simple neural network by using electric circuits, to describe how the neurons in the brain work. In 1950s, with the advances in computers, it became possible to simulate the hypothetical neural networks. However first studies resulted unsuccessfully. In the 1960s, the models named “ADALINE” and “MADALINE” were developed. ADALINE was developed with the aim of recognizing binary patterns, while MADALINE was applied firstly on neural network to a real-world problem. It is used firstly on an adaptive filter which supplies opportunity to eliminate echoes on phone lines. The model is still in use commercially. After 1970, development of artificial neural network (ANN) accelerated and brought solutions to important problems. The development of correlation matrix memory and multilayer perceptron were some of the developments after 1970. Today, neural networks are used in many areas. The fundamental idea of the neural networks is that, if it works in nature, it should work on computers as well. ANN has a strong nonlinear mapping ability, strong learning ability, and a high sensitivity level. An artificial neural network is a classifier modeled after the human brain. The human brain has billions of nerve cells (approximately ten billion). They form a complex and developed signal transmission network system by connecting to homogeneous cells. Cell gathers the input from all the connection points until it reaches to a certain level. After the input reaches this level, the cell sends a signal to all the cells it is connected to in the network. ANN is expected to imitate the human brain, and its working is the same as the biological neuron structure in the human brain. However, the working of ANN is based on mathematical evidence. Some neural network structures are not close to the brain in location, and some doesn’t have a biological counterpart in the brain. At the same time, neural networks have a very strong resemblance to the biological brain, and therefore neuroscience terminology is used frequently. ANN learns the relationship between the selected input and the output. Neuros are connected to each other to help this process. Each neuron processes the input taken from one or more neurons and produces output. The ANN structure is considered to be a versatile framework in which learning progresses by taking into account external or internal data passing through the system. ANN can take a few weighted inputs and summarize them, and if the combined inputs exceed a threshold, they will activate and send an output. Activation process determines which output to send, and the output is usually between 0 and 1 (or −1 and 1). Since the derivatives of the activation function are often used in network training, a few additional calculations are needed so that the derivative can be expressed by the original function value.

Although the artificial neural network is simulated from the biological model, its base unit has a simpler structure. Figure 1 shows the basis of an artificial neuron.

ya and yb input wks represent the connection weight of each input. w0 is the transfer function with a value of +1 to every neuron. This function is used as a transfer function between the input layer and the hidden layer in the system. It regulates the system output with interval [−1 1]. In the next step, mathematical calculations are conducted, majority of addition and the products of process are fed through nonlinear transmission functions to produce output. The structure of all the artificial neural network is the same, but they may differ at some points.

The most common transfer functions were shown in Fig. 1. Depending on the application, transfer functions may vary. The linear function can be selected to solve linear problems, and the result from the summation function is multiplied by a certain coefficient and calculated as output. This can be expressed as y = c.s, where the c value is invariant. Threshold function gets the value of 1 or −1. At this point, value is determined according to the set threshold level.

This can be shown as:

The sigmoid activation function is a continuous function that can be derived. While using sigmoid activation function, artificial neuron may seem like a natural neuron. This function produces output between 0 and 1.

Tangent sigmoid function is a function which is similar to sigmoid function. The difference is the point at which the output values change [−1 to 1] by giving a negative output.

While artificial neural nets are but artificial interconnections of neurons, they can learn the relationships between the inputs and outputs selected from previous experience. ANNs can also fulfill their task as parallel processing. This gives an advantage in terms of speed. A typical ANN can describe and learn the relationships between the input and the output of a nonlinear multidimensional system. ANN and the structure of multidimensional nonlinear system are shown in Figs. 2 and 3.

The main problem with the single-layered network is that they cannot classify the nonlinear functions. The complexity of the single-layered neurons isn’t large enough to address bigger classification problems. The logical depth of such problems is too great for an only perceptron to overcome. To overcome this problem, a few layered networks should be formed. These are called multilayer perceptron. The structure of the multilayer perceptron is shown in Fig. 4.

x i represents the input, w ij represents the weight, y k represents the output, and F represents the transfer function.

ANNs are superior to the conventional algorithms in terms of processing style and speed, storage structure and network prevalence, learning ability, offering error tolerance level, making use of experience, and flexibility of rule-setting.

ANN is widely used in fields such as space industry, electric-electronic, health, banking stock market and finance, defense industry, and optimization.

3.1 ANFIS

The main contribution of the fuzzy logic is that it provides calculation methodology which can deal with words, ambiguity, and level of detail. Human brain can interpret and process the incorrect and incomplete sensor information received from the organs. Similarly, fuzzy set theory can provide a systematic approach which deals with this information from a linguistic perspective. In addition, it can also make numerical calculations by using the membership function for the specified linguistic labels. The structure of fuzzy inference system (FIS) is based on fuzzy logic, fuzzy set theory, and fuzzy if-then rules. Framing of fuzzy if-then rules forms the key component of FIS. It is a very commonly used technique, and it is commonly applied in different fields such as system identification, automatic control, expert system, decision-making, model classification robotics, time series analysis, and forecasting. A fuzzy logic system consists of three basic components. These are a rule base, a data base, and a logic mechanism. Rule base consists of selected fuzzy rules, while a data base defines the membership functions of fuzzy rules. Fuzzy logic inference is modeled according to the rules to obtain a reasonable output or result. Jang introduced the adaptive network-based fuzzy inference system (ANFIS) by placing FIS within framework of customizable network. ANFIS is a neural fuzzy technique which is called adaptive network-based fuzzy inference system. ANFIS is also a neural fuzzy method in which the fusion process is carried out between the artificial neural network and fuzzy inference system. Its structure consists of a set of knots which are connected via adaptive network-oriented connections. The output of these adaptive knots depends on variable parameters related to these knots. Learning rule targets to minimize errors with update on these parameters. ANFIS methodology consists of a hybrid system which combines fuzzy logic and artificial neural network technique. While providing the artificial neural network with adaptation logic, fuzzy logic also considers the instability and ambiguity of the modeled system. By using this hybrid technique, together with the input variables, an initial fuzzy model structure is produced with the help of the rules gathered from the input and output data of the system. Afterward, neural network is used to produce the latest ANFIS model of the system and to regulate the rules of the first fuzzy model [45, 29].

3.1.1 ANFIS Structure

Basically, it is assumed that fuzzy inference system consists of two inputs and one output. The rule base includes the fuzzy if-then rules of Takagi and Sugeno. That is,

At this point x and y are the input variables, A and B are the fuzzy sets, and z is the output variable.

Generally, f(x,y) is a polynomial for the x and y variables. But, there could also be a function serving any other purpose that is able to roughly describe the input of the system within this fuzzy section. If f(x,y) has a fixed value, this forms the zero-degree Sugeno fuzzy model. This can be regarded as a special case of the Mamdani fuzzy inference system, in which each rule is indicated by a fuzzy uniqueness. If f(x,y) is a first-degree polynomial, this forms the first-degree Sugeno fuzzy model. Two rules for the first-degree Sugeno fuzzy inference system can be stated in this way:

ANFIS structure is shown schematically in Fig. 7.

Figure 7 ANFIS structure in layered representation

Layers of ANFIS structure are described as follows:

Layer 1: Every knot in this layer is square and adaptive.

X is the input related to i knot. A i is the linguistic variable related to knot function.

μ Ai(x) is the membership function of A i. μ Ai(x) can be chosen in two different ways. The first one is calculated in this way:

The second one is calculated in this way:

At this point x is input. a i, b i, and c i are precursor parameter sets.

Layer 2: Every knot in this layer is a fixed knot which calculates firing strength wi of a rule. The output of each knot is a product of all the signals it receives, and this is shown as follows:

Layer 3: Each knot in this layer has a fixed structure. Each i. knot calculates the ratio of the firing strength of i. rule to the combined firing powers of all the rules. i. output of i. knot shows the normalized firing level as shown below:

Layer 4: Each knot in this layer is an adaptive knot which has a knot function as shown below:

At this point \({\overline{w}}_i\) is the output of layer 3. p i, q i, and r i are the outcome parameter sets.

Layer 5: This layer calculates the total output as a fixed knot which calculates it as the total of the signals coming from all the inputs.

Considering the precursor parameter value, ANFIS structure can be expressed as linear combination of the resulting output parameters obtained as a result.

Here, f has a linear structure in p i, q i, and r i parameters. This structure represents the learning algorithm of ANFIS. In the forward transition of the learning algorithm, the result parameters are defined by estimating the smallest squares, while in the backward transition, error signals spread out from the output layer to the input layer. In this backward transition, gradient descent algorithm is used to update the precursor parameters.

3.2 OHS Risk Assessment in Underground Mining: A Case Study Using Multi-criteria Fuzzy Logic Approach

The mine management tries to identify some of the most important hazards in the production process in order to take the necessary precautions and to prevent the incidence of occupational accidents. A team that consists of ten decision-makers (DM1–DM7) was set up to assess the types of hazards in five sections of the mine and the entire system. Decision-makers consist of seven mining engineers. Five types of major, totally 75 hazards are defined by the DM team as (H1–H75). Risk parameters are created as "possibility, severity, and sensitivity to nonuse of personal protective equipment and non-maintenance sensitivity and unpredictability" with the help of the relevant literature review and the views of the DM team (Chart 6).

Linguistic variables which are used by seven decision-makers are shown in Chart 7 in order to evaluate the subjective significance of the risk parameters. Linguistic rating of variables is shown in Chart 7 to assess the grading of hazard types according to each risk (Chart 8).

The Buckley FAHP method, expert’s assessment of linguistic variables, was used to calculate the subjective weights of the risk parameters through bilateral comparisons, and the results are given in Chart 9. The consistency rate calculated in this study was found to be less than 0.1 according to decision-makers’ calculations. Furthermore, the binary comparison matrix can be considered appropriate, and the questionnaire is valid in terms of FAHP (Fig. 5).

After determination of the weight of five risk parameters, the fuzzy assessment of each risk parameter was applied with FVIKOR according to the hazard types in each of the six sections of the observed underground mine. In the study, the risk parameter evaluations of experts’ linguistic variables were evaluated in total for all employees (i.e., “whole system” and “whole system evaluations of 75 different hazard types” have been carried out). Then, the resulting linguistic evaluations are transformed into triangular fuzzy numbers. Afterward, the cumulative fuzzy ratings of the hazard types are obtained to determine the fuzzy decision matrix. The fuzzy decision matrix for the mining workplace is given in Chart 10.

After all, the fuzzy best f j* and fuzzy worst fj- values of all risk parameter estimates are calculated using Eqs. (8) and (9). Normalized fuzzy distance is calculated for each risk parameter of the hazard types in the workplace. Afterward, the values of R, S, and Q have been calculated for all hazard types as in Chart 10. Finally, the risk precedence order of the danger types is determined according to S, R, and Q in decreasing order. While the minimum values have the highest risk rankings, the risks closest to 1 in S, R, and Q values represent the lowest risk.

From the obtained results, it can be understood that three most important hazard types in the observed mine are (H63), (H65), and (H13) orderly. The hazard types of (H57), (H58), (H63), and (H65) have been placed in the first rows in the observed mine on the ventilation system category. There is a total of five clusters as shown in Chart 11. Cluster 1 consists of five different hazard types; (H2) represents the hazard with the highest level of risk. Cluster 2 is composed of 7 different hazard types, Cluster 3 is composed 21 different hazard types, Cluster 4 is composed of 12 different hazard types, and finally Cluster 5 is composed of 31 different hazards.

4 Implementation

In this study, ANFIS-oriented model is implemented which will deal with underground mining risk analysis problem in three stages on the basis of neuro-fuzzy approach. Using the data gathered from a mine in Turkey which has over 1000 workers with a capacity of over one million tones, risk assessment study was carried out based on neuro-fuzzy logic, and the comparison was made via classic risk assessment methods over error criterion.

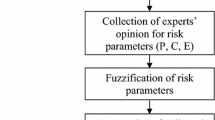

In Fig. 6 the stages of the study carried out using neuro-fuzzy logic approach are given. In order to show the implemented method’s productivity and flexibility, the obtained results will be compared via Buckley FAHP and FVIKOR two-stage risk assessment models.

Within Buckley FAHP method, there exist advantages, such as providing convenience in extension of fuzzy state and ensuring only one result. What is aimed within the implementation is to obtain a more efficient assessment with the total risk value as a measurable output by integrating neuro-fuzzy logic to risk analysis and obtain better results than classic risk assessment models.

Within the scope of methodology mentioned before, the inputs are specified as dust, unplanned power cut, explosions, chemical leakage, and ventilation system; the data set given in Appendix-A was obtained as a consequence of an elaborative cooperation by the specialists (mining engineer, occupational safety specialist, workplace doctor).

Within the frame of the first phase of the study, selection of the membership function is required to be processed with a convenient number and type for each criterion (input). Defining the number of the membership is one of the significant issues in the implementation of ANFIS model.

In case of selecting one membership function in relation of each input, the number of the parameter to be trained will be 84; for two membership functions, it will be 168; and for three membership functions, the number will be 252. Within the frame of OHS, in order to obtain a broader study, it was decided to select three membership functions. Followingly, the most suitable membership function for the model should be determined.

In the study’s process for selecting the membership function types of the inputs, analyzing the result of error values which were received for 50 cycles, it was found that gauss2mf function type gave the least error value.

At this point, the data given in Appendix are named and uploaded as train data and test data.

Following the criteria selection, the problem changed to become neuro-fuzzy system with five inputs and one output. In order to define the number and membership types of the inputs, “Generate FIS” is used. Gauss2mf membership function is selected in the option of “MF Type.” Output “MF Type” option should be selected as “linear.” As mentioned previously, it represents the first-degree Sugeno neuro-fuzzy model (Table 1).

Once the data to be trained is uploaded to ANFIS editor and tested, information about the model can be found and the value which is “Epoch 50: error = 0,000004578.” It means that for this selected membership function type and for each input, 3 triangle membership functions were trained for 50 cycles in accordance with hybrid learning algorithm, and the output value with an error value of 0,000004578 was forecasted accurately.

In ANFIS editor window structure, ANFIS model is shown (Fig. 7). On the very left side of the figure, the black nodes represent inputs; three separate second layer nodes which are connected to each node represent membership functions. There are five inputs, and each input has three membership functions that occur. The output received from the related rules is shown in the fifth layer; the risk value that the system forecasted in the fourth layer is shown in the fifth layer as the output value. In Fig. 8, the rules related to the established model are shown.

The rules descripted in the model can be edited by the specialist users within “Rule Editor.” The first ten rules of risk assessment model can be observed in Fig. 8.

It is possible to list 250 output values with the command of “evalfis” which is used in the command screen in Matlab. For this, the model should be defined and commanded as evalfis (input, model).

After building the data base which includes the risk groups for the underground mining risk analysis study, the effect of each input (risk group) over the total risk value used to be investigated. Since the risk value was expressed with a stochastic term, the process of normalizing in the obtained results was done via Excel. Due to the data used in the study and mining sector’s general structure, error tolerance values are at very low levels. Hence, the datum may differ on percentile and permille basis. The first 180 is comprised of training data set, and the last 70 is comprised of test data set. First 18 training data and first 7 test data sample can be seen below (Table 2).

The way for calculating the risk groups’ effect on the total risk values with ANFIS was investigated in OHS risk analysis study with neuro-fuzzy logic approach. The display of the inputs’ fuzzy inference interface is obtained. The structure of the inputs can be edited via membership function editor. For each input three membership functions were assigned. Low, mid, and high verbal values are assigned for these three membership functions (Figs. 9 and 10).

Risk assessment model includes 729 rules, and it comprises of 729 separate output types. For each output rule, six different verbal values are assigned as very low, medium low, low, medium high, high, and very high. The rule structure became meaningful after all the verbal value defining. The rules are displayed via “Rules” option located below “Edit” menu.

In this study, analysis of variables was carried out with the aim of observing the effect of the risk factors (dust, unplanned power cut, explosions, chemical leakage, and ventilation system) on general risk values. At this point, the effect of the inputs on the model result was observed by maintaining the model’s rule number, membership function types, and membership function number stable. In Table 3, total risk value impact assessments are shown in terms of dust risk factor with decision-makers (DM), and the assessments were made previously.

In Table 4, impact assessments over total risk value are shown in terms of unplanned power cut risk factor.

In Table 5, impact assessments on total risk value are shown in terms of explosions risk factor.

In Table 6, impact assessments on total risk value are shown in terms of chemical leakage risk factor.

In Table 7, impact assessments on total risk value are shown in terms of ventilation system risk factor.

In accordance with these assessments, the sensitivity of ANFIS on risk factors was tested, and the total risk value range results based on the factors are shown in Table 8. Accordingly, the following result was found: any change in ventilation system risk group as the highest active change can show an impact on total risk value by 0,124; similarly, any change in explosions risk group can show an impact on total risk value by 0,082; in chemical leakage risk group, it can show an impact on total risk value by 0,077; in unplanned power cut risk group, it can show an impact on total risk value by 0,049; and in dust risk group, it can show an impact on total risk value by 0,034.

5 Results and Recommendations

In underground mining risk assessment, after defining the hazard groups, since gauss2mf membership function gave the lowest RMSE level results, this function was selected and commenced. The model which was assigned and developed in the beginning was consisted of 5 inputs, 1 output, and 729 rules. The results were obtained and normalized. In accordance with the results, the precautions to be taken were formed by the specialists. Training data set is consisted of 18 data, and the test data set is consisted of 7 data.

One of the most significant elements in OHS is risk assessment. Taking the study about the risk assessment in literature in account and risk assessment is a multi-criteria decision-making problem which tackles risk value optimization and includes many criteria. In this study, risk assessment model was obtained by the studies and gap on them in literature, underground mine structure, and also specialist views. In this underground mining-based risk assessment study, after defining the mining and department-based risk groups and hazard groups, the significant order of each risk group was defined, and the data set used in risk assessment with the learning feature of ANFIS and its adaptive network-based structure resulted with less error compared to classic methods. The suggested risk assessment model can be used in district-, province-, region-, and country-wide risk assessment stages. The established model with the need of degrading the coefficient of risk of the mines which is among the most significant units of underground mining sector. It is consisted of five total inputs which have three membership functions and seven outputs. In when it will be used bigger data set, the process could take longer. In order to compare the superiority of the fuzzy logic approach on classic and fuzzy risk assessments in the presented OHS, the error values of FAHP and L-matrix output results were compared over the same data set (Table 9).

As a result, it was found that the most significant risk group of the observed mine’s whole system is ventilation system risk group and it stems from the assembly and disassembly of fans, working at height; assembly and disassembly of fans, suspension; and assembly and disassembly of fans, load lifting in itself. Explosions is the second most significant risk group, and it consists of hazards such as spreading of acidic water around, high slope, contact with acidic water in or around the sulfurous tallow, vehicle crash, damper tipping, and spilling of sulfur material on the way of transport. Chemical leakage is the third highest risk group which consists of hazards such as acidic environment, electric shock, temperature, quality of visibility, and SO2 formation. Unplanned power cut risk group is following chemical leakage with hazards such as paste fill pipeline clogging, being stuck in an elevator, stopping of the pumps, stopping of compressors, rescue chamber energy and air cutoff, cement working equipment, and stopping of the fans. Risk group which has the lowest risk score is dust with hazards of occupational disease, quality of visibility, breakdown of vehicles, and dust explosion. Figures 11, 12, 13, 14, and 15 show the priorities of each risk group.

The risk priority orders of the hazard types are obtained with parameters R,S, and Q. There is a negative correlation between parameters and risk significance. While the total value of parameters approaches to 0, corresponding risk ranked as highest risk. After obtaining risk priorities for each group, compromised risk rankings are found. Figures 16, 17, 18, 19, and 20 show the compromised rankings of hazards with respect to their groups.

After defining the risk groups’ significant order, the precautions to be taken should be defined accordingly. For this, neuro-fuzzy logic results were assessed by the specialists and the precautions to be taken. The reason behind this idea is elimination of hazards, checking the hazards in their sources, minimization of hazards, and providing the most convenient PPE.

Department-based precautions to be taken are defined. For the ventilation system, giving an advanced mine rescue training, determination of appropriate location, providing natural ventilation gas conversion structure, periodically and regular examination and improvement on transportation vehicles, procedure for working in high up, following predefined ventilation standards, availability of opened roof of the elevator from inside, providing clean air outlets, temporary lane closures with signs for workplace, providing personal escape mask, pressure tubes, giving an advanced education and authorization before works, carrying out hot work permit form, regular checks of air quality with appropriate sensors, preferring experienced mine operators and providing appropriate PPE, immobilization of equipment during transportation, regular controls, providing proper fortification standards, periodic maintenance and propitiously fixing of vehicles, providing safety lamps, filling individual identification number, and preparing general workplace inspection checklist are the major control measures with respect to occupational safety and health. For the explosions, appropriate controls and cleaning of miss-fires, providing proper fortification standards, blasting checks, training of driving to avoid crashes, giving an advanced training before works, eliminating the more dangerous explosives with less dangerous explosives to decrease risk level, preferring well-educated and certificated workers, and regular maintenance of equipment, separate transport of explosives and capsules, international lightning protection codes and standards, investigation of the geological structure of the area before explosions, providing of proper PPE, design of technical surveillance, filling individual identification number, providing safety barricading procedure, notification of all workers before explosion by mine control, building barricade start-up checklist, signal system for key points building hot work permit form, providing an explosive management plan and microseismic monitoring system, pre-work controls, obligation for vocational education, providing rock mechanics testing equipment, providing proper fortification standards that are control measures for continuous paste fill activity, remote distance control system regulations for ventilation and air-conditioned equipment, control of hazardous energy with procedure, application of job safety analysis, and preparation for compressed air and pressurized waters are necessary control measures. Chemical leakage requires following control measures, providing proper PPE procedure for transporting explosives, set up radio and camera communication system, avoiding flammable materials in transportation, installation requirements for gas and electric structure, chemical spill procedure filling individual identification number, preparation procedure of chemicals, controlling all system before starting of activity, authorized and experienced personal, appropriate vehicles, regular and systematic controls of work area, providing automatic fire suppression system, follow-up legislation, providing methodical mine rescue fire training, periodic health checks, selection and use of gloves procedure, occupational hazard analysis periodically, periodic pull test, advanced education before works, preference of cut-resistant gloves, material handling training, providing automatic fire suppression system, using specific checklist (oxygen set), periodic pull test, building hot work permit, checklist for battery voltage control panel, providing backup power lines, set up proper and effective air distribution, giving an advanced education and authorization before works, natural ventilation and radio communication system, availability of opened roof of the elevator from inside, periodic controls and maintenance of cables and panels (weekly/monthly/yearly), adequate number of safety switches, usage of the isolated cable and earth leakage circuit, grounding system, working under low voltage (24 volts), grounding of electrical panels properly, usage of safety hazard warning signs, gate transition procedure, energy insulation and locking procedure, the use of a double door system and one of them should permanently close mine rescue chamber, and previous common suggestions are major control measures for unplanned power cut risk. Speed limit enforcement (3.8 m/s), authorization and advanced education before works, follow-up legislation, surface topography measurements, providing sui and ergonomic PPE, regular cleaning of dusty areas, dust suppression system, periodic supervisory checks, usage of powder vacuum tool and main fan filter system, ambient and particular dust measurements, proper vehicle lightings, preference of reflective dress, improvement of vehicle visibility, periodic supervisory checks, washing equipment and vehicles periodically, periodic and regular cleaning on truck roads with broom and bucket, changing and improving vehicle exhaust system periodically, and cleaning mirrors and stopes are major control measures for dust.

References

Al-Turjman, F. (2017). Price-based data delivery framework for dynamic and pervasive IoT. Elsevier Pervasive and Mobile Computing Journal, 42, 299–316.

Al-Turjman, F. (2017). Energy–aware data delivery framework for safety-oriented mobile IoT. IEEE Sensors Journal, 18(1), 470–478.

Singh, A., Kumar, D., & Hötzel, J. (2018). IoT Based information and communication system for enhancing underground mines safety and productivity: Genesis, taxonomy and open issues. Ad Hoc Networks, 78, 115--129.

Al-Turjman, F., Hassanein, H., & Ibnkahla, M. (2013). Efficient deployment of wireless sensor networks targeting environment monitoring applications. Elsevier: Computer Communications Journal, 36(2), 135–148.

Al-Turjman, F., Hassanein, H., & Ibnkahla, M. (2015). Towards prolonged lifetime for deployed WSNs in outdoor environment monitoring. Elsevier Ad Hoc Networks Journal, 24(A), 172–185.

Singh, G., & Al-Turjman, F. (2016). A data delivery framework for cognitive information-centric sensor networks in smart outdoor monitoring. Elsevier Computer Communications Journal, 74(1), 38–51.

Chan, H. K., & Wang, X. (2013). Fuzzy extent analysis for food risk assessment. In Fuzzy Hierarchical Model for Risk Assessment (pp. 89–114). London: Springer.

Ottawa Charter for Health Promotion. (1986). WHO/HPR/HEP/95.1. WHO, Geneva.

Chang, D. Y. (1996). Applications of the extent analysis method on fuzzy AHP. European Journal of Operational Research, 95(3), 649–655.

Djapan, M. J., Tadic, D. P., Macuzic, I. D., & Dragojovic, P. D. (2015). A new fuzzy model for determining risk level on the workplaces in manufacturing small and medium enterprises. Proceedings of the Institution of Mechanical Engineers, Part O: Journal of Risk and Reliability, 229(5), 456–468.

Buckley, J. J. (1985). Fuzzy hierarchical analysis. Fuzzy Sets and Systems, 17(3), 233–247.

Ebrahimnejad, S., Mousavi, S. M., & Seyrafianpour, H. (2010). Risk identification and assessment for build–operate–transfer projects: A fuzzy multi attribute decision making model. Expert Systems with Applications, 37(1), 575–586.

Aragonés-Beltrán, P., Mendoza-Roca, J. A., Bes-Piá, A., García-Melón, M., & Parra-Ruiz, E. (2009). Application of multi criteria decision analysis to jar-test results for chemicals selection in the physical–chemical treatment of textile wastewater. Journal of Hazardous Materials, 164(1), 288–295.

Cooper, M. D. (2000). Towards a model of safety culture. Safety Science, 36, s.113.

Gorman, T., Dropkin, J., Kamen, J., Nimbalkar, S., Zuckerman, N., Lowe, T., Szeinuk, J., Milek, D., Piligian, G., & Freund, A. (2013). Controlling health hazards to hospital workers. New Solutions, 23, 1–67.

Grassi, A., Gamberini, R., Mora, C., & Rimini, B. (2009). A fuzzy multi-attribute model for risk evaluation in workplaces. Safety Science, 47(5), 707–716.

Gul, M., & Ak, M. F. (2018). A comparative outline for quantifying risk ratings in occupational health and safety risk assessment. Journal of Cleaner Production, 196, 653–664.

Gul, M., & Guneri, A. F. (2016). A fuzzy multi criteria risk assessment based on decision matrix technique: A case study for aluminum industry. Journal of Loss Prevention in the Process Industries, 40, 89–100.

Gul, M., Celik, E., Aydin, N., Gumus, A. T., & Guneri, A. F. (2016). A state of the art literature review of VIKOR and its fuzzy extensions on applications. Applied Soft Computing, 46, 60–89.

Guneri, A. F., Gul, M., & Ozgurler, S. (2015). A fuzzy AHP methodology for selection of risk assessment methods in occupational safety. International Journal of Risk Assessment and Management, 18(3–4), 319–335.

Hu, A. H., Hsu, C. W., Kuo, T. C., & Wu, W. C. (2009). Risk evaluation of green components to hazardous substance using FMEA and FAHP. Expert Systems with Applications, 36(3), 7142–7147.

Jamshidi, A., Rahimi, S. A., Ait-Kadi, D., & Ruiz, A. (2015). A comprehensive fuzzy risk-based maintenance framework for prioritization of medical devices. Applied Soft Computing, 32, 322–334.

John, A., Paraskevadakis, D., Bury, A., Yang, Z., Riahi, R., & Wang, J. (2014). An integrated fuzzy risk assessment for seaport operations. Safety Science, 68, 180–194.

Kenya Ministries of Health and IntraHealth International. (2013). Report of the occupational safety and health risk assessment. Nairobi, Kenya: MsOH.

Liu, H. C., Fan, X. J., Li, P., & Chen, Y. Z. (2014). Evaluating the risk of failure modes with extended MULTIMOORA method under fuzzy environment. Engineering Applications of Artificial Intelligence, 34, 168–177.

Liu, H. C., Liu, L., Liu, N., & Mao, L. X. (2012). Risk evaluation in failure mode and effects analysis with extended VIKOR method under fuzzy environment. Expert Systems with Applications, 39(17), 12926–12934.

Liu, H. C., You, J. X., You, X. Y., & Shan, M. M. (2015). A novel approach for failure mode and effects analysis using combination weighting and fuzzy VIKOR method. Applied Soft Computing, 28, 579–588.

Liu, H. T., & Tsai, Y. L. (2012). A fuzzy risk assessment approach for occupational hazards in the construction industry. Safety Science, 50(4), 1067–1078.

Mahdevari, S., Shahriar, K., & Esfahanipour, A. (2014). Human health and safety risks management in underground coal mines using fuzzy TOPSIS. Science of the Total Environment, 488, 85–99.

Opricovic, S. (1998). Multicriteria optimization of civil engineering systems. Faculty of Civil Engineering, Belgrade, 2(1), 5–21.

Saaty, T. L. (1990). How to make a decision: The analytic hierarchy process. European Journal of Operational Research, 48(1), 9–26.

Tzeng, G., & Huang, J. (2011). Multiple attribute decision making: Methods and applications. Boca Raton, FL: Chapman & Hall/CRC.

Vahdani, B., Salimi, M., & Charkhchian, M. (2015). A new FMEA method by integrating fuzzy belief structure and TOPSIS to improve risk evaluation process. The International Journal of Advanced Manufacturing Technology, 77(1–4), 357–368.

Amalberti, R. (2001). The paradoxes of almost totally safe transportation systems. Safety Science., 37, 109–126.

Lin, P. H. (2001). Safety management and risk modelling in aviation – The challenge of quantifying management influences, PhD thesis, Delft University of Technology.

Xianfeng, L., & Shengguo, H. (2012). Airport safety risk evaluation based on modification of quantitative safety management model. Procedia Engineering., 43, 238–244.

Elgstrand, K., & Vingärd, E. (2013). Occupational safety and health in mining: Anthology on the situation in 16 mining countries. Gotenburg: University of Gothenburg.

Verma, S., & Chaudhri, S. (2014). Integration of fuzzy reasoning approach (FRA) and fuzzy analytic hierarchy process (FAHP) for risk assessment in mining industry. Journal of Industrial Engineering and Management, 7(5), 1347.

Aven, T. (2009). Risk analysis: Assessing uncertainties beyond expected values and probabilities. Chichester: Wiley.

Awasthi, A., & Kannan, G. (2016). Green supplier development program selection using NGT and VIKOR under fuzzy environment. Computers & Industrial Engineering, 91, 100–108.

Badri, A. (2015). The challenge of integrating OHS into industrial project risk management: Proposal of a methodological approach to guide future research (case of mining projects in Quebec, Canada). Minerals, 5(2), 314–334.

Badri, A., Nadeau, S., & Gbodossou, A. (2013). A new practical approach to risk management for underground mining project in Quebec. Journal of Loss Prevention in the Process Industries, 26(6), 1145–1158.

Chen, C. T. (2000). Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets and Systems, 114(1), 1–9.

Donoghue, A. M. (2004). Occupational health hazards in mining: An overview. Occupational Medicine, 54(5), 283–289.

Lang, L., & Fu-Bao, Z. (2010). A comprehensive hazard evaluation system for spontaneous combustion of coal in underground mining. International Journal of Coal Geology, 82(1), 27–36.

Petrović, D. V., Tanasijević, M., Milić, V., Lilić, N., Stojadinović, S., & Svrkota, I. (2014). Risk assessment model of mining equipment failure based on fuzzy logic. Expert Systems with Applications, 41(18), 8157–8164. Samantra, C., Datta, S., & Mahapatra, S. S. (2016). Analysis.

Tixier, J., Dusserre, G., Salvi, O., & Gaston, D. (2002). Review of 62 risk analysis methodologies of industrial plants. Journal of Loss Prevention in the Process Industries, 15(4), 291–303.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Appendix

Appendix

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Ak, M.F. (2019). A Neuro-fuzzy-Based Multi-criteria Risk Evaluation Approach: A Case Study of Underground Mining. In: Al-Turjman, F. (eds) Artificial Intelligence in IoT. Transactions on Computational Science and Computational Intelligence. Springer, Cham. https://doi.org/10.1007/978-3-030-04110-6_9

Download citation

DOI: https://doi.org/10.1007/978-3-030-04110-6_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-04109-0

Online ISBN: 978-3-030-04110-6

eBook Packages: EngineeringEngineering (R0)