Abstract

Soft materials show numerous advantages compared to rigid ones in exosuit devices. We present the design of a soft wearable elbow assistance device with flexion and extension actuations. Commercially available butyl rubber tubes have been used as a pneumatic actuator. Tubes are enveloped by a lightweight polyester fabric to eliminate a non-homogeneous expansion. The surrounding fabric in turn is mounted on a clothes fabric as zigzag paths. The exosuit is lightweight, shock resistant, simple to manufacture, and low cost. The subjective experiments show a reduction average of 48% in the Rectified & integrated raw electromyography signal of the brachialis muscle during a rhythmic flexion/extension sequence while lifting weights (3 and 5 [kg]). Results indicate a significant assistance with respect to the other existing soft elbow exosuits.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

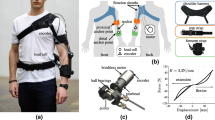

One trend in the wearable robotics research is to develop assistance devices to support human motion. These devises contribute in human’s daily life, e.g., supporting elderlies, rehabilitation, lifting and manipulating heavy objects in the production lines, and other performance augmentation applications. Rigid wearable devices show limitations in terms of the wearing duration, the device weight, and the soft interaction with the human body [1, 2]. In order to be more accepted by human, compact solutions based on lightweight soft materials have been developed recently. With respect to the actuation technique, the soft wearable devices are classed into two main categories: electric [3,4,5,6] and pneumatic [7, 8]. As an example for pneumatic soft wearable devices, Suzumori and colleagues proposed a “Muscle Textile” exosuit that reduces the integrated EMG signal of the brachialis muscle by 33% [7]. A recent work used high strength bubble artificial muscle to assist walking [10], 33% of the required torques were delivered by a group of three actuators. As an example for electric soft wearable devices, the lower body wearable device proposed by Poliero et al. reduced the mechanical energy requirement for walking up to 30% [9]. In this paper, we present a pneumatic elbow assistance device, see Fig. 1. The actuator uses butyl tubes organized in zigzag horizontal patterns for flexion and vertical patterns for extension. Textile is used to envelop the rubber and also to hold the actuators. Section 2 presents the fabrication process. The actuator was tested with a simple flexion/extension sequence. Results are presented in Sect. 3. We finally discuss the contribution in Sect. 4.

The control diagram of the soft exosuit. The device is mounted on the elbow of a human subject while lifting weights. Sensory information for joint bending and flexion/extension air pressure are transferred into the control unit (Raspberry PiTM) via an analog to digital converters. A rectified & integrated EMG signal is measured with MyoWareTM muscle sensor during the experiment. The Raspberry Pi drives a 12[v] air-pump and four solenoids for flexion and extension actuators. A video link about the paper is available in [12].

2 Material and Methods

Figure 2 shows the external and the internal views of the design. The flexion actuator is illustrated in red, the extension actuator in blue. The manufacturing process is detailed in the video link [12]. To distribute the actuator force along the arm and the forearm we attached a clothe fabric into two parts of commercially available shin pads protection. A double side polyester belt (\(5\times 15\) [cm]) hosts two curving sensors (Short Flex/Bend Sensor Adafruit®). The belt protects sensors from damage while keeping the freedom for bending. The sensory belt is mounted to the internal side of the two shin pads to measure the joint angle of the device. We are using two curving sensors aligned in parallel to each other and shifted by 1 [cm] each to the left and right sides of the longitudinal axis, see Fig. 2.

3 Results

The contribution of the actuator in weight lifting tasks is presented through two experimental parts. First, a human subject lifts weight without the assistance (passive), then with assistance (active). We performed this experiment several times and with different weight (3 and 5 [kg]). During the experiment, the EMG raw signal of the brachialis muscle was measured. Figure 3 demonstrates the experiment set-up (top), and the results. The subjective experiments shows a reduction of 52% and 38% in the rectified & integrated raw electromyography signal of the brachialis muscle during a rhythmic extension and 56% and 47% during rhythmic flexion while lifting 3 and 5 [kg] payloads respectively. Experiment data are available on [11]. Middle graphs show the rectified EMG signals, the bending sensors’ readings, and the air pressure for two experiments in lifting 3 [kg] payload with actuation (in blue) and without actuation (in red). The bar graph shows the average of the EMG rectified integral signals over the sets of four experiments with 3 and 5 [kg] payloads in active and passive movements. For each exercise cycle (one flexion and one extension), we calculated the integral of rectified EMG signal based on the reading of banding sensors for the extension and flexion movements. Since the extension and the flexion durations may differ from one cycle to another, we use the mean value of the integral in the comparison. The averages of that mean value over sets of the experiments and its confidence intervals are given in the bar graph.

EMG measurement for active and passive movements. Experiment set-up and the EMG electrodes locations (top). Middle graphs illustrate the rectified EMG, the bending sensors average voltage, and the air pressure for two experiments (passive and active) in lifting 3 [kg] payload. The bar graph shows average values of the mean of the integrated EMG signals for flexion and extension while lifting 3 and 5 [kg] payloads (bottom).

4 Conclusions

We present a soft exosuit for elbow assistance with 1 D.O.F. (flexion/extension). It is made using butyl rubber tubes and textile material. The device produces a range of motion of \(95^\circ \) and support the elbow joint to lift different weights (48% EMG signal reduction). Results show that the assistance provided by the exosuit during the rhythmic extension/flexion movements of the elbow joint is high compared to the existing elbow assistance devices.

References

Wu, K.-Y., Su, Y.-Y., Yu, Y.-L., Lin, K.-Y., Lan, C.-C.: Series elastic actuation of an elbow rehabilitation exoskeleton with axis misalignment adaptation. In: International Conference on Rehabilitation Robotics (2017)

Manna, S.K., Dubey, V.N.: A mechanism for elbow exoskeleton for customised training. In: International Conference on Rehabilitation Robotics (2017)

Chiaradia, D., Xiloyannis, M., Antuvan, C.W., Frisoli, A., Masia, L.: Design and embedded control of a soft elbow exosuit. In: IEEE International Conference on Soft Robotics (2018)

Guo, J., et al.: A soft robotic exo-sheath using fabric EMG sensing for hand rehabilitation and assistance. In: IEEE International Conference on Soft Robotics (2018)

Awad, L.N., et al.: Soft exosuits increase walking speed and distance after stroke. In: International Symposium on Wearable Robotics (2017)

Bae, J., et al.: Exosuit-induced improvements in walking after stroke: comprehensive analysis on gait energetics and biomechanics. In: International Symposium on Wearable Robotics (2017)

Abe, T., Koizummi, S., Nabae, H., Endo, G., Suzumori, K.: Muscle textile to implement soft suit to shift balancing posture of the body. In: IEEE International Conference on Soft Robotics (2018)

Koh, T.H., Cheng, N., Yap, H.K., Yeow, C.H.: Design of a soft robotic elbow sleeve with passive and intent-controlled actuation. Front. Neurosci. 11, 597 (2017)

Poliero, T., et al.: Soft wearable device for lower limb assistance: assessment of an optimized energy efficient actuation prototype. In: IEEE International Conference on Soft Robotics, pp. 559–564 (2018)

Diteesawat, R.S., Helps, T., Taghavi, M., Rossiter, J.: High strength bubble artificial muscles for walking assistance. In: IEEE International Conference on Soft Robotics, pp. 388–393 (2018)

The paper experiments data. https://www.tu-chemnitz.de/informatik/KI/edu/robotik/videos/werob2018data.zip

The paper descriptive video. https://youtu.be/-BOO6PC-9Pc

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Nassour, J., Vaghani, S., Hamker, F.H. (2019). Design of Soft Exosuit for Elbow Assistance Using Butyl Rubber Tubes and Textile. In: Carrozza, M., Micera, S., Pons, J. (eds) Wearable Robotics: Challenges and Trends. WeRob 2018. Biosystems & Biorobotics, vol 22. Springer, Cham. https://doi.org/10.1007/978-3-030-01887-0_81

Download citation

DOI: https://doi.org/10.1007/978-3-030-01887-0_81

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-01886-3

Online ISBN: 978-3-030-01887-0

eBook Packages: EngineeringEngineering (R0)