Abstract

Applications for new pharmaceuticals in the USA are reviewed by the FDA’s Center for Drug Evaluation and Research (FDA/CDER), which evaluates the safety and efficacy of both drug substances and drug products. The degree of innovation and variety in the drug products containing nanomaterials is broad, and the FDA has conceptual and analytical frameworks to capture consistently the risks introduced by new therapeutic approaches. When reviewing drug product applications the Agency considers the entire product, from the data demonstrating clinical efficacy to the chemistry, production, storage, and delivery method(s). These last four areas are collectively evaluated as the quality attributes of a drug, and FDA determined that these have particular importance for drug products containing nanomaterials. The relevant quality attributes are discussed in detail in this chapter following a brief overview of nanomaterials within products designed to treat cancer and a description of the regulatory structure in which applications for cancer therapeutics are reviewed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Nanomaterials

- United States Food and Drug Administration

- Center for Drug Evaluation and Research

- Drug product quality

- Drug products

- Active pharmaceutical ingredient

- Liposome

- Nanocrystals

- Critical quality attributes

- IND

- NDA

- ANDA

- Nanotechnology in cancer therapeutics

- Doxil®

- DaunoXome®

- Generic drugs

- 505b(1)

- 505b(2)

- 505(j)

- BLA

- Fast track designation

- Breakthrough therapy designation

- Accelerated approval

- Priority review designation

- Drug products containing nanomaterials

- Drug substance

1 Introduction

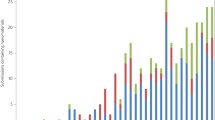

The inclusion of nanomaterials in drug products has increased in recent years, and the United States (US) Food and Drug Administration (FDA or the Agency)Footnote 1 has received several hundred applications from companies seeking to move these products to market [1]. These products and applications are often complex, and the ways this technology is used are myriad [1]. Among all of these nanotechnology-related submissions, the most commonly stated indication is for treatment of cancer. As described in previous chapters, nanomaterials may improve cancer treatments due to enhanced drug dissolution, drug distribution, and targeted delivery mechanisms (passive/active), which can significantly improve drug accumulation at the cancer site while reducing adverse effects [2,3,4]. Reflecting both the promise of these materials and the high-risk tolerance for novel treatments among clinicians and cancer patients [5, 6], FDA saw an 8% increase in submissions for cancer therapeutics containing nanomaterials between 2011 and 2016 [7].

Applications for new pharmaceuticals in the USA are reviewed by the FDA’s Center for Drug Evaluation and Research (FDA/CDER), which evaluates the safety and efficacy of both drug substancesFootnote 2 and drug products.Footnote 3 The degree of innovation and variety in the drug products containing nanomaterials is broad, and FDA has developed conceptual and analytical frameworks to capture consistently the risks introduced by new therapeutic approaches. When reviewing drug product applications, the Agency considers the entire product, from the data demonstrating clinical efficacy to the chemistry, production, storage, and delivery method(s). These last four areas are collectively evaluated as the quality attributes of a drug, and FDA determined that these have particular importance for drug products containing nanomaterials. The relevant quality attributes are discussed in detail in this chapter following a brief overview of the mechanisms of action of nanomaterials within products designed to treat cancer and a description of the regulatory structure in which applications for cancer therapeutics are reviewed.

1.1 Nanomaterials in Anticancer Drug Substances and Products

The Centers for Disease Control and Prevention notes that cancer is at present the second most common cause of death in the USA [8], and as a class of diseases, it is a focus of government-funded research initiatives [9] . The progression of the disease and its potential for causing loss of life make it a good target for the development of innovative drug substances (and drug products) [5, 6]. However, many anticancer drug substances suffer from poor water solubility and toxicity issues [10], which reduce the overall efficacy and safety of the compounds.

Using nanomaterials within the drug product is one potential method for resolving these issues because a material’s physicochemical properties can change with particle size. For example, by reducing the particle size of a drug substance to the nanoscale, the effective surface area can be increased severalfold to modify surface-related characteristics such as apparent rate of dissolution [11, 12]. Alternatively, the properties of nanoscale drug carriers can be “borrowed” to improve the bioavailability of a less-soluble or less-tolerated drug substance by facilitating longer circulation in vivo and targeted delivery (passive/active) [3, 13]. Thus, nanomaterials are used by drug developers to significantly improve drug accumulation at the cancer site while reducing adverse effects seen in the use of conventional formulations [2, 4, 14].

1.1.1 Nanotechnology-Based Platform Technologies

Several nanotechnology-based platform technologies such as liposomes, nanoparticles, micelles, and drug conjugates have been developed to take advantage of the properties of nanomaterials to deliver drug substances to cancerous tissue. They have been applied to support the reformulation of approved cancer drugs as well as to deliver new medicines (Tables 12.1 and 12.3) in order to reduce the size of tumors or related cancer events without damaging healthy tissues. These materials take a number of forms and may be lipidic, metallic, polymeric, or proteinic in nature. They can be used to facilitate drug solubilization and enzymatic stability and/or enhance cellular uptake via either complexation or covalent conjugation with the drug.

In many cases, these materials are tailored to target the tissues passively (e.g., DaunoXome®, Taxotere®, Marqibo®, Genexol, Doxil® [see Box 12.1]) or actively (e.g., Tf-LPN-G3139, MCC-465) by taking advantage of the particular characteristics of a tumor’s microenvironment (i.e., the enhanced permeability and retention effect) or the surface binding features of cancerous cells [13, 15,16,17,18,19,20,21,22,23,24,25].

Box 12.1 Doxil®: Passive Targeting of Tumors with Liposomes

Adriamycin®, a doxorubicin hydrochloride injection, was approved in 1993 for treatment of various types of cancer. Even though it was an effective anticancer therapy, Adriamycin® caused severe cardiotoxicity, among other side effects. To overcome this issue, a PEGylated liposomal formulation of doxorubicin hydrochloride (Doxil®) was developed by Janssen Pharmaceuticals (FDA approved in 1995). Doxil® was designed to be able to passively target to tumor regions, thereby minimizing cardiotoxicity effect [26].

Emerging approaches for nanotechnology-based cancer treatment include the use of two anticancer drugs incorporated into a single product (e.g., ALN-VSP, CPX-351, and CPX-1) and the use of a two-stage system requiring the use of external stimuli to activate the product. The second category of drugs, using so-called “SMART” delivery systems, are designed to become active upon exposure to heat, ultrasound, radiofrequency, or some other energy-based trigger. The product may then change state (e.g., Thermodox®Footnote 4) or enable the particle to directly affect the cell by, for example, locally increasing the temperature within a cell to modify permeability or to cause direct damage to the cell (e.g., Auroshell, NanoTherm™) [13, 27,28,29].Footnote 5

2 Regulatory Guidance for Drug Products Containing Nanomaterials

The drug application review process at the FDA is the same irrespective of whether the product involves the use of nanotechnology, and the Agency has not adopted a regulatory definition of nanotechnology [30]. However, to help industry identify the use of nanotechnology in their products, the Agency has issued a final guidance document on whether FDA-regulated products involve the use of nanotechnology [31]. Guidance documents are a mechanism by which the Agency communicates to industry and to the public, and they represent FDA’s current thinking on a topic. They do not create or confer any rights for or on any person and do not operate to bind FDA or the public [32]. Per the nanotechnology guidance [31], FDA and sponsors may evaluate submitted applications for a drug product to determine:

-

1.

Whether a material or end product is engineered to have at least one external dimension, or an internal or surface structure, in the nanoscale range (approximately 1 nm to 100 nm).

-

2.

Whether a material or end product is engineered to exhibit properties or phenomena, including physical or chemical properties or biological effects that are attributable to its dimension(s), even if these dimensions fall outside the nanoscale range, up to one micrometer (1000 nm).

In addition to the overarching nanotechnology guidance, there are several drug product-specific guidances (e.g., product-specific bioequivalenceFootnote 6 guidances) and guidances for classes of products (e.g., liposome guidance) (Table 12.2). For nanoparticle technology, an example of product-specific guidance is the bioequivalence guidance on lanreotide acetate [33] (a polymer-based depot injection [34]). As the FDA receives more applications related to active targeting and other (advanced) nanotechnologies as discussed above, additional relevant guidance(s) may be drafted to help streamline the application submission and review process. It should be noted that a comprehensive review of the submission for drug products containing nanomaterials was conducted by FDA. Within the review, it was noted that approval rates for drug products containing nanomaterials were comparable to both small molecule and biologics [7].

2.1 The Application Review Process

Figure 12.1 depicts the drug development process and steps where drug applications are submitted to the FDA by a sponsor (usually the manufacturer or potential marketer). Once a drug application is received by FDA/CDER (see Box 12.2), it is assigned to the appropriate division for review based on the product’s indication (for new drugs) or its dosage form (for generic drugsFootnote 7) .

Box 12.2 The Role of CDER within FDA

Within the FDA, the Office of Medical Products and Tobacco houses the Center for Drug Evaluation and Research (CDER). The mission of CDER is “to protect and promote public health by helping to ensure that human drugs are safe and effective for their intended use, that they meet established quality standards, and that they are available to patients.” This is in part achieved by overseeing research, development, manufacturing, premarketing, and post-marketing activities pertaining to drugs (prescription, generic, and over the counter) [35]. As per the US FDA, a “drug” may be defined as “a substance recognized by an official pharmacopoeia or formulary; a substance intended for use in the diagnosis, cure, mitigation, treatment, or prevention of disease; a substance (other than food) intended to affect the structure or any function of the body; a substance intended for use as a component of a medicine but not a device or a component, part or accessory of a device; biological products are included within this definition and are generally covered by the same laws and regulations, but differences exist regarding their manufacturing processes (chemical process versus biological process)” [36].

For new drugs (containing new drug substances), after successful preclinical testing in animals, studies are conducted by (or via) the sponsor to determine whether the product is safe for initial use in human subjects and if the testing in human would demonstrate benefits that outweigh the potential risks and that the product will not expose humans to unreasonable risks when used in early phases of clinical trials. A sponsorFootnote 8 submits an Investigational New Drug (IND) application to the US FDA prior to initiating drug testing in humans. Besides this type, there are other types of INDs, as discussed below [37]:

-

An investigator IND is submitted by a physician who both initiates and conducts an investigation and, under whose immediate direction, the investigational drug is administered or dispensed. A physician might submit a research IND to propose studying an unapproved drug or an approved product for a new indication or in a new patient population.

-

Emergency use IND allows the FDA to authorize use of an experimental drug in an emergency situation that does not allow time for submission of an IND in accordance with the Code of Federal Regulations 21CFR 312 (Sec. 312.23 or Sec. 312.20). It is also used for patients who do not meet the criteria of an existing study protocol or if an approved study protocol does not exist.

-

Treatment IND is submitted for experimental drugs showing promise in clinical testing for serious or immediately life-threatening conditions, while the final clinical work is conducted and the FDA review takes place.

An IND application typically includes information on investigator, manufacturing, data from animal pharmacology and toxicology studies, and clinical study protocols [37, 38]. Once an IND is submitted, the sponsor has to wait for 30 calendar days before clinical trials can be initiated. Meanwhile, FDA reviews the IND for safety in order to assure that human subjects are not exposed to unreasonable risk. Once an IND is approved, Phase I clinical trials can be initiated on a small population of healthy subjects with the goal to determine dose tolerability and obvious side effects. For example, a silencing RNA (anti-EphA2)-based liposomal formulation (siRNA-EphA2-DOPC) has recently received FDA’s approval for initiation of a Phase I clinical trial [39].

If the results of the Phase I trial demonstrate safety in healthy subjects, the drug can be tested in a larger population through Phase II and III clinical trials (see Fig. 12.1) with an objective to evaluate drug safety, efficacy, and toxicity in diseased patients [40].

If the results from clinical studies (end of Phase II or early Phase III) indicate that the benefits from drug efficacy outweigh the risk from drug toxicity(ies), a sponsor may submit a New Drug Application (NDA) to the FDA [40]. As per Section 505 of the Food, Drugs and Cosmetic Act, there are three types of new drug applications:

-

505(b)(1): This application is used for approval of a new drug (for clinical use) whose active ingredient has not been approved previously. The application contains full reports of investigations of safety and effectiveness [41].

-

505(b)(2): This application is used for approval of a new drug that relies, at least in part, on data not developed by the applicant. The application contains full reports of investigations of safety and effectiveness but where at least some of the information required for approval comes from studies not conducted by or for the applicant and for which the applicant has not obtained a right of reference [42]. Typically 505(b)(2) applications include change in dosage form, strength, or route of administration compared to an approved product or substitution of an active ingredient in an approved combination product [43]. 505(b)(2) applications are often used for products containing nanomaterials, especially products where the nanomaterial is used as a carrier for an already approved drug substance. For example, Taxol®, approved in 1998, uses paclitaxel as the active ingredient [44]. Another product, Abraxane®, contains paclitaxel bound to albumin (new formulation of paclitaxel). Abraxane® was approved by the US FDA in 2005 under section 505(b)(2) regulatory pathway [45].

-

505(b)(1) and 505(b)(2) applications require IND and NDA applications to be submitted to the FDA for review. Whereas regulatory requirements for IND applications have been discussed earlier in this chapter, the NDA is expected to include chemistry, manufacturing, and control (CMC) information on drug substance and drug product, bioavailability data, analytical data, labeling, and packaging information, for each of the dosage forms, the sponsor intends to commercialize and any additional toxicological study reports that were not included in the IND application [46]. Detailed requirements for 505(b)(1) and 505(b)(2) applications are described at 21 code of Federal Regulations (CFR) 314.50. Additional requirements for certain 505(b)(2) applications are described at 21 CFR 314.54 as well as in the FDA draft guidance on applications covered under section 505(b)(2) [43].

Biologics License Application (BLA) :

This is a new drug application for biological products. Biological products are approved for marketing under the provisions of the Public Health Service (PHS) Act. This application is a submission, similar to an NDA, containing information on the manufacturing processes, chemistry, pharmacology, clinical pharmacology, and the medical effects of a biologic product [47]. For review, BLA applications are assigned to CDER or the Center of Biologics Evaluation and Research (CBER) depending on the nature of the biological product. Jurisdiction of CDER and CBER pertaining to BLAs is outlined in the cited reference [48].

505(j) (generics):

A new drug, during its development and a few years post-approval, is often protected under a patent in order to give the sponsor the time to exclusively sell the drug to recover development costs. Once the patent expires, other companies can apply to the FDA to sell generic versions of the drug product by filing an Abbreviated New Drug Application (ANDA) with the FDA also known as 505(j) application [49, 50]. This application contains information to show that the proposed product is identical in active ingredient, dosage form, strength, route of administration, labeling, quality, performance characteristics, and intended use, among other things, to a previously approved product. This application is called abbreviated since an ANDA is generally not required to include nonclinical (animal) and clinical (human) data to establish safety and effectiveness. Instead, generic applicants scientifically demonstrate that their product is bioequivalent (i.e., performs in the same manner as the innovator drug) [50].

In all cases, FDA encourages timely, transparent, and effective communication with sponsors before and during the drug development process. This may result in more efficient and robust development programs considering that through FDA-sponsor communications, the key issues can be addressed in the early stages of drug development. This may also help FDA achieve its goal of early availability of safe, effective, and high-quality medicines to the American public. Sponsors can request meetings with FDA during drug development especially critical milestone meetings: pre-IND, end of Phase I, end of Phase II, and pre-NDA/BLA meetings (Fig. 12.1). More details on FDA-sponsor communication can be found in the FDA draft guidance on best practices for communication between IND sponsors and FDA during drug development [51].

Once a drug (new or generic) approaches the approval stage, the FDA requires the submission of additional information on the drug to ensure its continuous safety and efficacy for the period the drug is on the market. These are called Phase IV requirements (submitted pre-approval) and Phase IV commitments (usually submitted post-approval). As an example, post-marketing studies/clinical trials to demonstrate safety and efficacy of a drug approved under the accelerated approval requirement are a Phase IV requirement.

2.2 Review of Quality Attributes

“A CQA is a physical, chemical, biological, or microbiological property or characteristic that should be within an appropriate limit, range, or distribution to ensure the desired product quality. CQAs are generally associated with the drug substance, excipients, intermediates (in-process materials), and drug product”.Guidance for Industry: Q8(R2) Pharmaceutical Development, 2009. http://www.fda.gov/downloads/drugs/guidances/ucm073507.pdf

Clinical trials allow for an evaluation of the safety and efficacy of a new drug substance and product in humans. However, before a medication can be used in patients, quality of the product must also be ensured (e.g., the medicine can be manufactured reproducibly, and the doses produced are equivalent to each other irrespective of batch number or lot number). The evaluation of the process of developing a drug product, manufacturing process, stability protocols, etc. is also known as the quality review. In fact, the quality review is one of the major regulatory considerations for drug products containing nanomaterials, as per the risk assessment performed by the Agency (CDER) in the year 2013 [52].

Drug products containing nanomaterials can vary in their complexity. The more complex the product (containing nanomaterials or not), the more challenging it can be to demonstrate control of the manufacturing and the production of high-quality drugs with reliable batch-to-batch reproducibility. To facilitate the development of these complex products, the FDA often develops guidance for reviewers and for industry that specifically addresses manufacturing and characterization challenges. For example, from the experience reviewing applications for liposomal drug products, the Agency drafted a guidance on liposomal drug products that provides information to liposomal product manufacturers regarding development, manufacturing, pharmacokinetic aspects, and labeling of liposomal drug products [53]. From a quality perspective, the guidance points toward the importance of identification and characterization of critical physical, chemical, biological, and microbiological properties that may influence finished product quality or performance [54]. These properties are often called the critical quality attributes (CQAs) of the product. Some examples of CQAs for liposomal products are lamellarity, internal volume, lipid-phase transition temperature, free and encapsulated drug proportions, lipid degradation products, zeta potential, particle size, and drug release kinetics [53, 55].

From the Agency’s experience reviewing applications involving the use of nanotechnology across all platforms, certain quality issues were observed to be recurrent and are summarized as below.

Inadequate identification of CQAs:

For product robustness and reproducibility, CQAs during formulation and manufacturing processes are identified and suitably controlled. For products using nanomaterials, particle size is often found to be a CQA as particle size distribution has been demonstrated to impact biodistribution, rate of drug release/dissolution, etc. Other examples of common CQAs for drug products containing nanomaterials include zeta potential and drug loading efficiency (for nanomaterials functioning as drug carriers). By definition, CQAs are product dependent. However, some CQAs can span across a product class. For example, lipid-phase transition temperature, which may influence drug loading, release, and overall stability, is a CQA specific to liposomes and not applicable to other (non-lipid) nanotechnology platforms such as dendrimers and iron colloids. By evaluating the applications submitted to FDA for drug products containing nanomaterials, CQAs for products often include (but are not limited to) the following:

-

Size.

-

Size distribution.

-

Nanomaterial composition (e.g., lipids for liposomes).

-

Crystal structure.

-

Morphology/three-dimensional structure.

-

API to nanomaterial ratio.

-

State of API (e.g., encapsulated, bound, etc.)

-

Surface functionalization and state of the surface.

-

Ligands (if any).

-

Zeta potential or surface charge.

-

In vitro release rates (in vitro release studies under multiple conditions, including in biorelevant medium, which can be indicative of the physicochemical stability of the formulation [56]).

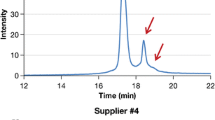

Inappropriate method and/or method validation:

As with any drug product, the analytical methods used for characterization of CQAs is demonstrated to be fit for purpose (e.g., measures what it is supposed to in an accurate and reproducible fashion). Selection and validation of methods to characterize drug products containing nanomaterials may be challenging due to the complexity of the product and because the methods used for characterization of CQAs may not be as familiar for complex products as those used for small molecule drug products. Often these products require the use or development of novel techniques and methods to characterize these products. “Traditional” methods and novel methods should both be used within their capabilities. For example, both dynamic light scattering and static light scattering can be used to determine particle size. However, the useful size range, the way the data are interpreted and analyzed, and other factors differ between the two techniques. In general, the analytical method is validated for sensitivity, accuracy, precision, robustness, and the ability to discriminate between acceptable and unacceptable batches. The use of an additional, orthogonal analytical technique to characterize the materials can often be beneficial to complete a data set prior to submission.

Lack of appropriate control strategies:

Suitable controls are employed during product development to ensure that the CQAs are within an appropriate limit, range, or distribution in order to ensure the desired product quality. This may be achieved by including a CQA in either drug product release or in in-process specifications.

2.3 Special Regulatory Provision for Cancer Products

For therapies that address an unmet medical need in the treatment of a serious condition such as cancer, the FDA allows sponsors to request a faster review process through four FDA programs: fast track designation , breakthrough therapy designation , accelerated approval , and priority review designation [57]. Applications accepted into these expedited programs undergo an accelerated review (i.e., the review is completed faster, but with the same degree of scrutiny), thereby facilitating early availability of new therapies to the patients as soon as it can be determined that their benefits outweigh the risks. Expedited availability of new cancer therapies is crucial, especially in cases where there are no satisfactory alternative (existing) therapies. For a new cancer therapy, sponsors may apply for fast track and breakthrough therapy designations early in the development, for priority review designation during BLA or NDA submission, and for accelerated approval designation during BLA or NDA review. For example, fast track designation was granted to CRLX-101, a nanoparticle-drug conjugate currently under development (Phase I/II) by Cerulean Pharma for the treatment of platinum-resistant ovarian carcinoma and fallopian tube or primary peritoneal cancer [58]. Breakthrough therapy designation was granted by the FDA to CPX-351 or Vyxeos™ (by Celator Pharmaceuticals) for the treatment of acute myeloid leukemia based on the encouraging results from a Phase III clinical trial [59]. Accelerated approval that is granted based on a surrogate end point (since actual end point takes a long time to measure) was granted to Doxil® (liposomal doxorubicin) in 1995 for the treatment of Kaposi’s sarcoma [60]. A priority review designation can abbreviate the review time from 10 months to 6 months and was assigned to Onivyde® (liposomal irinotecan) developed by Merrimack Pharmaceuticals for the treatment of advanced pancreatic cancer [61]. These modified time lines and approaches to review are designed to increase the number of novel therapeutics available to patients, which is in accord with FDA’s mission to promote and protect the public health.

3 Future Perspective

At this time, the Agency anticipates continued interest in the development of products utilizing a variety of nanotechnology platforms, some familiar and some novel. In particular, it is likely that there will be an expansion of nanotechnology in cancer therapeutics designed to improve passive and active (triggered) targeting capabilities. Several products in clinical trials (Table 12.3) involve the use of multifunctional nanocarriers (PEGylated nano-sized particles for tumor targeting with or without an active targeting moiety) in the hope to achieve better efficacy and safety compared to the existing therapies. Industry is also investigating the use of nanotechnology-based delivery platforms for the delivery of anticancer drugs of biological origin (e.g., nucleic acids, peptides), potentially increasing the overall complexity of the products. These technologies could also be applied to therapeutics designed to target multiple tissues or active sites.

When faced with these new approaches, FDA has multiple options for response. For any new product drawing upon a novel platform or technology, the existing guidances apply as appropriate. In cases where new functionality or CQAs become relevant, these would be handled on a case-by-case basis, potentially resulting in the development of a product-specific guidance that could be extended to encompass a class of products at a later date. FDA can also draw upon related technologies. For example, the Agency has experience in reviewing monoclonal antibodies that can deliver a toxin or radioactive isotope in a targeted fashion. Targeted biologics have several parallels to drug products containing nanomaterials, and parallels may be drawn between the product classes. Such similarities have been reviewed previously [92].

In some cases, the new product or technology may require the sponsor to develop an innovative manufacturing process. To facilitate development and review of new manufacturing systems or processes, the FDA has created the Emerging Technology Program, which enables sponsors to discuss the process with Agency experts prior to a regulatory submission. These discussions are designed to identify potential concerns for the sponsor and to increase awareness of the new approach within FDA before the review process occurs to the benefit of both organizations.

As these technologies mature, FDA also anticipates that more generic versions of the products will appear as well. This is important to consider because complex formulations and manufacturing processes can impact the development of generic versions of drug products, and a lack of generic versions of medications can result in higher patient costs as well as a higher risk for drug shortages. The impact of nanotechnology on the generic drug process has been extensively reviewed [62].

4 Conclusion

It is anticipated that drug products will become more complicated in order to meet unmet medical needs. Such complexity spans all indications and routes of administration and includes both drug products containing nanomaterials and those taking advantage of other technologies. With increased incorporation of nanomaterials in cancer therapeutics, both industry and regulatory authorities alike should strive for product understanding that involves adequate characterization of the nanomaterial, understanding of its intended use and application, and how it relates to the product quality , patient safety , and efficacy. By utilizing this framework, patients may gain access to new cancer medications.

Disclaimer

The findings and conclusions in this article have not been formally disseminated by the Food and Drug Administration and should not be construed to represent any Agency determination or policy. The mention of commercial products, their sources, or their use in connection with material reported herein is not to be construed as either an actual or implied endorsement of such products by the Department of Health and Human Services.

Notes

- 1.

The US Food and Drug Administration is a government agency responsible for (1) protecting the public health by assuring the safety, effectiveness, quality, and security of human and veterinary drugs, vaccines, and other biological products and medical devices; (2) ensuring safety and security of most of our nation’s food supply, all cosmetics, dietary supplements, and products that give off radiation; (3) regulating tobacco products; and (4) advancing the public health by supporting innovations that facilitate more effective, safer, and affordable medicines [1]. In the USA, all companies wishing to sell or market a new pharmaceutical must first submit an application for review to the FDA.

- 2.

“an active ingredient that is intended to furnish pharmacological activity or other direct effect in the diagnosis, cure, mitigation, treatment, or prevention of disease or to affect the structure or any function of the human body, but does not include intermediates use in the synthesis of such ingredient” 21 CFR 314.3.

- 3.

“a finished dosage form, for example, tablet, capsule, or solution, that contains a drug substance, generally, but not necessarily, in association with one or more other ingredients” 21 CFR 314.3.

- 4.

Thermodox® is a thermally sensitive liposomal doxorubicin formulation developed by Celsion Corporation (http://celsion.com/thermodox/). When targeted to the tumor site and exposed to temperature of 40 °C–45 °C (via radiofrequency thermal ablation, high-intensity focused ultrasound, etc.), the heat-sensitive liposomes release the encapsulated doxorubicin into and around the targeted tumor.

- 5.

Many of these products are considered “combination products” and would be handled by the FDA Office of Combination Products, http://www.fda.gov/AboutFDA/CentersOffices/OfficeofMedicalProductsandTobacco/OfficeofScienceandHealthCoordination/ucm2018184.htm.

- 6.

“Bioequivalence is defined as the absence of a significant difference in the rate and extent to which the active ingredient or active moiety in pharmaceutical equivalents or pharmaceutical alternatives becomes available at the site of drug action when administered at the same molar dose under similar conditions in an appropriately designed study” (Code of Federal Regulations 21CFR 320.1).

- 7.

As per the US FDA, “a generic drug is a medication created to be the same as an existing approved brand-name drug in dosage form, safety, strength, route of administration, quality, and performance characteristics.”

- 8.

“Sponsor is a person who takes responsibility for and initiates a clinical investigation. A sponsor could be an individual, government agency, pharmaceutical company, academic institute, private or other organization.” Code of Federal Regulations 21CFR 312.3. For example, Janssen Products, LP is the sponsor for “Doxil .”

References

NANOTECHNOLOGY MARKET- Nanotechnology Markets in Healthcare & Medicine (2014) Drug Development & Delivery. http://www.drug-dev.com/Main/Back-Issues/NANOTECHNOLOGY-MARKET-Nanotechnology-Markets-in-He-803.aspx. Accessed 20 Jun 2016

Chidambaram, M., Manavalan, R., Kathiresan, K.: Nanotherapeutics to overcome conventional cancer chemotherapy limitations. J. Pharm. Pharm. Sci. 14(1), 67–77 (2011)

Suzuki, R., Omata, D., Oda, Y., Unga, J., Negishi, Y., Maruyama, K.: Cancer therapy with nanotechnology-based drug delivery systems: applications and challenges of liposome technologies for advanced cancer therapy. Nanomater. Pharmacol. 457–482 (2016)

Thakor, A.S., Gambhir, S.S.: Nanooncology: the future of cancer diagnosis and therapy. CA Cancer J. Clin. 63(6), 395–418 (2013)

Blanco, E., Hsiao, A., Mann, A.P., Landry, M.G., Meric-Bernstam, F., Ferrari, M.: Nanomedicine in cancer therapy: innovative trends and prospects. Cancer Sci. 102(7), 1247–1252 (2011). https://doi.org/10.1111/j.1349-7006.2011.01941.x

Sumer, B., Gao, J.: Theranostic nanomedicine for cancer. Nanomedicine (Lond.). 3(2), 137–140 (2008). https://doi.org/10.2217/17435889.3.2.137

D’Mello, S.R., Cruz, C.N., Chen, M.-L., Kapoor, M., Lee, S.L., Tyner, K.M.: The evolving landscape of drug products containing nanomaterials in the United States. Nat. Nano. 12, 523–529 (2017)

Statistics for Different Kinds of Cancer. Centers for Disease Control and Prevention. http://www.cdc.gov/cancer/dcpc/data/types.htm. Accessed 03 Jun 2016

National Cancer Institure. Cancer Moonshot. https://www.cancer.gov/research/key-initiatives/moonshot-cancer-initiative. Accessed 10 Jul 2016

Gewirtz, D.A., Bristol, M.L., Yalowich, J.C.: Toxicity issues in cancer drug development. Curr. Opin. Investig Drugs. 11(6), 612–614 (2010)

Liversidge, G.G., Cundy, K.C.: Particle size reduction for improvement of oral bioavailability of hydrophobic drugs: I. Absolute oral bioavailability of nanocrystalline danazol in beagle dogs. Int. J. Pharm. 125(1), 91–97 (1995). https://doi.org/10.1016/0378-5173(95)00122-Y

Jinno, J.-i., Kamada, N., Miyake, M., Yamada, K., Mukai, T., Odomi, M., Toguchi, H., Liversidge, G.G., Higaki, K., Kimura, T.: Effect of particle size reduction on dissolution and oral absorption of a poorly water-soluble drug, cilostazol, in beagle dogs. J. Control Release. 111(1–2), 56–64 (2006). https://doi.org/10.1016/j.jconrel.2005.11.013

Pillai, G.: Nanomedicines for cancer therapy: an update of FDA approved and those under various stages of development. SOJ Pharm. Pharm. Sci. 1(2), 13 (2014)

Peer, D., Karp, J.M., Hong, S., Farokhzad, O.C., Margalit, R., Langer, R.: Nanocarriers as an emerging platform for cancer therapy. Nat. Nano. 2(12), 751–760 (2007)

Brown, J.M., Giaccia, A.J.: The unique physiology of solid tumors: opportunities (and problems) for cancer therapy. Cancer Res. 58(7), 1408–1416 (1998)

Hobbs, S.K., Monsky, W.L., Yuan, F., Roberts, W.G., Griffith, L., Torchilin, V.P., Jain, R.K.: Regulation of transport pathways in tumor vessels: role of tumor type and microenvironment. Proc. Natl. Acad. Sci. U. S. A. 95(8), 4607–4612 (1998)

Maeda, H.: The enhanced permeability and retention (EPR) effect in tumor vasculature: the key role of tumor-selective macromolecular drug targeting. Adv. Enzym. Regul. 41(1), 189–207 (2001). https://doi.org/10.1016/S0065-2571(00)00013-3

Maeda, H., Nakamura, H., Fang, J.: The EPR effect for macromolecular drug delivery to solid tumors: improvement of tumor uptake, lowering of systemic toxicity, and distinct tumor imaging in vivo. Adv. Drug Deliv. Rev. 65(1), 71–79 (2013). https://doi.org/10.1016/j.addr.2012.10.002

Weissig, V., Pettinger, T.K., Murdock, N.: Nanopharmaceuticals (part 1): products on the market. Int. J. Nanomedicine. 9, 4357–4373 (2014). https://doi.org/10.2147/IJN.S46900

Yuan, Y., Zhang, L., Cao, H., Yang, Y., Zheng, Y., X-j, Y.: A polyethylenimine-containing and transferrin-conjugated lipid nanoparticle system for antisense oligonucleotide delivery to AML. Biomed. Res. Int. 2016, 8 (2016). https://doi.org/10.1155/2016/1287128

Hamaguchi, T., Matsumura, Y., Nakanishi, Y., Muro, K., Yamada, Y., Shimada, Y., Shirao, K., Niki, H., Hosokawa, S., Tagawa, T., Kakizoe, T.: Antitumor effect of MCC-465, pegylated liposomal doxorubicin tagged with newly developed monoclonal antibody GAH, in colorectal cancer xenografts. Cancer Sci. 95(7), 608–613 (2004). https://doi.org/10.1111/j.1349-7006.2004.tb02495.x

Clinical Trials Worldwide. www.clinicaltrials.gov. Accessed 12 Aug 2016

Davis, M.E., Chen, Z., Shin, D.M.: Nanoparticle therapeutics: an emerging treatment modality for cancer. Nat. Rev. Drug Discov. 7(9), 771–782 (2008)

Thanki, K., Kushwah, V., Jain, S.: Recent advances in tumor targeting approaches. In: Targeted Drug Delivery: Concepts and Design, pp. 41–112. Springer, Cham (2015)

Byrne, J.D., Betancourt, T., Brannon-Peppas, L.: Active targeting schemes for nanoparticle systems in cancer therapeutics. Adv. Drug Deliv. Rev. 60(15), 1615–1626 (2008). https://doi.org/10.1016/j.addr.2008.08.005

Rahman, A.M., Yusuf, S.W., Ewer, M.S.: Anthracycline-induced cardiotoxicity and the cardiac-sparing effect of liposomal formulation. Int. J. Nanomedicine. 2(4), 567–583 (2007)

Morton, J.G., Day, E.S., Halas, N.J., West, J.L.: Nanoshells for photothermal cancer therapy. In: Grobmyer, S.R., Moudgil, B.M. (eds.) Cancer Nanotech: Methods and Protocols, pp. 101–117. Humana Press, Totowa, NJ (2010). https://doi.org/10.1007/978-1-60761-609-2_7

Stern, J.M., Stanfield, J., Kabbani, W., Hsieh, J.-T., Cadeddu, J.A.: Selective prostate cancer thermal ablation with laser activated gold nanoshells. J. Urol. 179(2), 748–753 (2008). https://doi.org/10.1016/j.juro.2007.09.018

First patient treated with MagForce's NanoTherm therapy for recurrent glioblastoma (2011) News Medical. http://www.news-medical.net/news/20111011/First-patient-treated-with-MagForces-NanoTherm-therapy-for-recurrent-glioblastoma.aspx. Accessed 23 Jun 2016

Hamburg, M.A.: Science and regulation. FDA's approach to regulation of products of nanotechnology. Science. 336(6079), 299–300 (2012). https://doi.org/10.1126/science.1205441

Guidance for Industry: Considering whether an FDA-regulated product involves the application of nanotechnology (2014) U.S. Food and Drug Administration. http://www.fda.gov/downloads/RegulatoryInformation/Guidances/UCM401695.pdf

Guidances (Drugs). U.S. Food and Drug Administration. http://www.fda.gov/Drugs/%20GuidanceComplianceRegulatoryInformation/Guidances/default.htm. Accessed 04 May 2016

Draft Guidance on Lanreotide Acetate (2014). U.S. Food and Drug Administration http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM406278.pdf. Accessed 03 Jul 2016

D'Souza, S.S., DeLuca, P.P.: Methods to assess in vitro drug release from injectable polymeric particulate systems. Pharm. Res. 23(3), 460–474 (2006). https://doi.org/10.1007/s11095-005-9397-8

FDA Center for Drug Evaluation and Research (CDER) Strategic Plan 2013–2017. U.S. Food and Drug Administration. http://www.fda.gov/downloads/AboutFDA/CentersOffices/OfficeofMedicalProductsandTobacco/CDER/UCM376545.pdf. Accessed 10 May 2016

Drugs@FDA Glossary of Terms, U.S. Food and Drug Administration. http://www.fda.gov/Drugs/InformationOnDrugs/ucm079436.htm#D. Accessed 20 Jun 2016

Investigational New Drug (IND) Application, U.S. Food and Drug Administration. http://www.fda.gov/Drugs/DevelopmentApprovalProcess/HowDrugsareDevelopedandApproved/ApprovalApplications/InvestigationalNewDrugINDApplication/default.htm. Accessed 05 July 2016

Maeda, H.: Macromolecular therapeutics in cancer treatment: the EPR effect and beyond. J. Control. Release. 164(2), 138–144 (2012). https://doi.org/10.1016/j.jconrel.2012.04.038

Ozcan, G., Ozpolat, B., Coleman, R.L., Sood, A.K., Lopez-Berestein, G.: Preclinical and clinical development of siRNA-based therapeutics. Adv. Drug Deliv. Rev. 87, 108–119 (2015). https://doi.org/10.1016/j.addr.2015.01.007

The Drug Development Process, Step 3: Clinical Research, U.S. Food and Drug Administration. http://www.fda.gov/ForPatients/Approvals/Drugs/ucm405622.htm. Accessed 08 Aug 2016

NDA 505(b)(1) of the FD&C Act, U.S. Food and Drug Administration. http://www.fda.gov/ucm/groups/fdagov-public/@fdagov-drugs-gen/documents/document/ucm245363.pdf Accessed 17 Aug 2016

What is 505(b)(2)? Camargo Pharmaceutical Services (2016): The Global 505(b)(2) Experts. http://camargopharma.com/what-is-505b2/. Accessed 07 July 2016

Draft Guidance for Industry: Applications Covered by Section 505(b)(2) (1999) U.S. Food and Drug Administration. http://www.fda.gov/downloads/Drugs/.../Guidances/ucm079345.pdf

NDA 20–2062/S-064 approval package for Taxol Injection, Center for Drug Evaluation and Research, U.S. Food and Drug Administration. http://www.accessdata.fda.gov/drugsatfda_docs/nda/98/20262s024_Taxol_appltr.pdf. Accesssed 23 July 2016

Abraxane paclitaxel protein-bound particles for injectable suspension, Oncologic Drugs Advisory Committee Meeting, Sept 7, 2006, Abraxis Bioscience. http://www.fda.gov/ohrms/dockets/ac/06/briefing/2006-4235B2-01-01AbraxisBioscience-background.pdf. Accessed 14 Sept 2016

New Drug Application (NDA), U.S. Food and Drug Administration. http://www.fda.gov/Drugs/DevelopmentApprovalProcess/HowDrugsareDevelopedandApproved/ApprovalApplications/NewDrugApplicationNDA/default.htm. Accessed 17 July 2016

Drugs@FDA Glossary of Terms, U.S. Food and Drug Administration. http://www.fda.gov/Drugs/InformationOnDrugs/ucm079436.htm#B. Accessed 17 May 2016

Transfer of therapeutic biological products to the Center for Drug Evaluation and Research (2003) U.S. Food and Drug Administration. http://www.fda.gov/CombinationProducts/JurisdictionalInformation/ucm136265.htm. Accessed 30 Jul 2016

Guidance for Industry ANDA Submissions — Content and Format of Abbreviated New Drug Applications (2014) U.S. Food and Drug Administration. http://www.fda.gov/downloads/drugs/guidancecomplianceregulatoryinformation/guidances/ucm400630.pdf

Abbreviated New Drug Application (ANDA): Generics, U.S. Food and Drug Administration. http://www.fda.gov/Drugs/DevelopmentApprovalProcess/HowDrugsareDevelopedandApproved/ApprovalApplications/AbbreviatedNewDrugApplicationANDAGenerics/default.htm. Accessed 09 Sept 2016

Draft Guidance on best practices for communication between IND sponsors and FDA during drug development guidance for industry and review staff (2015) U.S. Food and Drug Administration. http://www.fda.gov/downloads/drugs/guidancecomplianceregulatoryinformation/guidances/ucm475586.pdf

Cruz, C.N., Tyner, K.M., Velazquez, L., Hyams, K.C., Jacobs, A., Shaw, A.B., Jiang, W., Lionberger, R., Hinderling, P., Kong, Y., Brown, P.C., Ghosh, T., Strasinger, C., Suarez-Sharp, S., Henry, D., Van Uitert, M., Sadrieh, N., Morefield, E.: CDER risk assessment exercise to evaluate potential risks from the use of nanomaterials in drug products. AAPS J. 15(3), 623–628 (2013). https://doi.org/10.1208/s12248-013-9466-6

Gudiance for Industry: Liposome Drug Products. Chemistry, Manufacturing, and Controls; Human Pharmacokinetics and Bioavailability; and Labeling Documentation. (2018) U.S. Food and Drug Administration. https://www.fda.gov/downloads/drugs/guidances/ucm070570.pdf

Pharmaceutical Development Q8(R2) (2009). International Conference on Harmonisation. http://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q8_R1/Step4/Q8_R2_Guideline.pdf. Accessed 04 Jun 2016

Guidance for Industry: Changes to an approved NDA or ANDA (2004) U.S. Food and Drug Administration. http://www.fda.gov/downloads/drugs/guidancecomplianceregulatoryinformation/guidances/ucm077097.pdf

Tyner, K.M., Zou, P., Yang, X., Zhang, H., Cruz, C.N., Lee, S.L.: Product quality for nanomaterials: current U.s. experience and perspective. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 7(5), 640–654 (2015). https://doi.org/10.1002/wnan.1338

Guidance for Industry: Expedited Programs for Serious Conditions – Drugs and Biologics (2014) U.S. Food and Drug Administration. http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM358301.pdf

Cerulean Receives FDA Fast Track Designation for CRLX101 for the Treatment of Platinum-Resistant Ovarian Cancer (2016) Business Wire- A Berkshire Hathaway company. http://www.businesswire.com/news/home/20160719005765/en/Cerulean-Receives-FDA-Fast-Track-Designation-CRLX101. Accessed 12 Aug 2016

Lancet, J.E., Uy, G.L., Cortes, J.E., Newell, L.F., Lin, T.L., Ritchie, E.K., Stuart, R.K., Strickland, S.A., Hogge, D., Solomon, S.R., Stone, R.M., Bixby, D.L., Kolitz, J.E., Schiller, G.J., Wieduwilt, M.J., Ryan, D.H., Hoering, A., Chiarella, M., Louie, A.C., Medeiros, B.C., Lee, H.: Final results of a phase III randomized trial of CPX-351 versus 7+3 in older patients with newly diagnosed high risk (secondary) AML. J. Clin. Oncol. 34. (suppl; abstr 7000, 7000 (2016)

Johnson, J.R., Ning, Y.-M., Farrell, A., Justice, R., Keegan, P., Pazdur, R.: Accelerated approval of oncology products: the Food and Drug Administration experience. J. Natl. Cancer Inst. 103(8), 636–644 (2011). https://doi.org/10.1093/jnci/djr062

FDA approves Onivyde for advanced pancreatic cancer (2015) American Cancer Society, Inc. http://www.cancer.org/cancer/news/news/fda-approves-onivyde-for-advanced-pancreatic-cancer. Accessed 14 Jan 2016

Zheng, N., Sun, D.D., Zou, P., Jiang, W.: Scientific and regulatory considerations for generic complex drug products containing Nanomaterials. AAPS J. 19, 619 (2017). https://doi.org/10.1208/s12248-017-0044-1

Search for FDA Guidance Documents, U.S. Food and Drug Administration. http://www.fda.gov/RegulatoryInformation/Guidances/. Accessed 10 Oct 2016

New Drug Development and Review Process, U.S. Food and Drug Administration. http://www.fda.gov/Drugs/DevelopmentApprovalProcess/SmallBusinessAssistance/ucm053131.htm. Accessed 13 Aug 2016

CTI BioPharma announces independent DMC recommendation to continue GOG-0212 Phase 3 study of OPAXIO™ as maintenance therapy in ovarian cancer, an NRG Oncology/GOG Study (2015) CTI BioPharma Corp. http://www.prnewswire.com/news-releases/cti-biopharma-announces-independent-dmc-recommendation-to-continue-gog-0212-phase-3-study-of-opaxio-as-maintenance-therapy-in-ovarian-cancer-an-nrg-oncologygog-study-300029565.html. Accessed 02 Aug 2016

BIND Therapeutics presents positive Phase 2 results highlighting potential of BIND-014 as novel anti-cancer treatment at Q3W dosing schedule for patients with non-small cell lung cancer at 26th EORTC-NCI-AACR Annual Symposium (2014) Business Wire- A Berkshire Hathaway company. http://www.businesswire.com/news/home/20141119005136/en/BIND-Therapeutics-Presents-Positive-Phase-2-Results. Accessed 01 Aug 2016 (2014)

Awada, A., Bondarenko, I.N., Bonneterre, J., Nowara, E., Ferrero, J.M., Bakshi, A.V., Wilke, C., Piccart, M.: A randomized controlled phase II trial of a novel composition of paclitaxel embedded into neutral and cationic lipids targeting tumor endothelial cells in advanced triple-negative breast cancer (TNBC). Ann. Oncol. 25(4), 824–831 (2014). https://doi.org/10.1093/annonc/mdu025

Batist, G., Gelmon, K.A., Chi, K.N., Miller, W.H., Chia, S.K.L., Mayer, L.D., Swenson, C.E., Janoff, A.S., Louie, A.C.: Safety, pharmacokinetics, and efficacy of CPX-1 liposome injection in patients with advanced solid tumors. Clin. Cancer Res. 15(2), 692–700 (2009). https://doi.org/10.1158/1078-0432.ccr-08-0515

Boorjian, S.A., Milowsky, M.I., Kaplan, J., Albert, M., Cobham, M.V., Coll, D.M., Mongan, N.P., Shelton, G., Petrylak, D., Gudas, L.J., Nanus, D.M.: Phase 1/2 clinical trial of interferon α2b and weekly liposome-encapsulated all-trans retinoic acid in patients with advanced renal cell carcinoma. J. Immunother. 30(6), 655–662 (2007). https://doi.org/10.1097/CJI.0b013e31805449a8

Butts, C.A., Socinski, M.A., Mitchell, P., Thatcher, N., Havel, L., Krzakowski, M.J., Nawrocki, S., Ciuleanu, T.-E., Bosquee, L., Perez, J.M.T., Spira, A.I., Tremblay, L., Nyman, J., Ramlau, R., Helwig, C., Falk, M.H., Shepherd, F.A.: A phase III study of L-BLP25 cancer immunotherapy for unresectable stage III non-small cell lung cancer. J. Clin. Oncol. 31, (2013). suppl; abstr 7500

Calvo, E., Hoch, U., Maslyar, D.J., Tolcher, A.W.: Dose-escalation phase I study of NKTR-105, a novel pegylated form of docetaxel. J. Clin. Oncol. 28(15 Suppl), (2010). abstr TPS160

Gad, S.C., Sharp, K.L., Montgomery, C., Payne, J.D., Goodrich, G.P.: Evaluation of the toxicity of intravenous delivery of auroshell particles (gold–silica nanoshells). Int. J. Toxicol. 31(6), 584–594 (2012)

Gonzalez-Angulo, A.M., Meric-Bernstam, F., Chawla, S., Falchook, G., Hong, D., Akcakanat, A., Chen, H., Naing, A., Fu, S., Wheler, J., Moulder, S., Helgason, T., Li, S., Elias, I., Desai, N., Kurzrock, R.: Weekly nab-rapamycin in patients with advanced nonhematologic malignancies: final results of a phase 1 trial. Clin. Cancer Res. 19(19), 5474–5484 (2013). https://doi.org/10.1158/1078-0432.CCR-12-3110

Hong, D.S., Kang, Y.-K., Brenner, A.J., Sachdev, J.C., Ejadi, S., Borad, M.J., Kim, T.-Y., Lim, H.Y., Park, K., Becerra, C., Bader, A.G., Stoudemire, J., Smith, S., Kim, S., Beg, M.S.: MRX34, a liposomal miR-34 mimic, in patients with advanced solid tumors: final dose-escalation results from a first-in-human phase I trial of microRNA therapy. J. Clin. Oncol. 34 .(suppl; abstr 2508, 2508 (2016)

Kim, D.-W., Kim, S.-Y., Kim, H.-K., Kim, S.-W., Shin, S., Kim, J., Park, K., Lee, M., Heo, D.: Multicenter phase II trial of Genexol-PM, a novel Cremophor-free, polymeric micelle formulation of paclitaxel, with cisplatin in patients with advanced non-small-cell lung cancer. Ann. Oncol. 18(12), 2009–2014 (2007)

Landen, C.N., Chavez-Reyes, A., Bucana, C., Schmandt, R., Deavers, M.T., Lopez-Berestein, G., Sood, A.K.: Therapeutic EphA2 gene targeting in vivo using neutral liposomal small interfering RNA delivery. Cancer Res. 65(15), 6910 (2005)

Libutti, S.K., Paciotti, G.F., Byrnes, A.A., Alexander, H.R., Gannon, W.E., Walker, M., Seidel, G.D., Yuldasheva, N., Tamarkin, L.: Phase I and pharmacokinetic studies of CYT-6091, a novel PEGylated colloidal gold-rhTNF nanomedicine. Clin. Cancer Res. 16(24), 6139–6149 (2010). https://doi.org/10.1158/1078-0432.CCR-10-0978

Nagykalnai, T.: Non-pegylated doxorubicin (Myocet®) as the less cardiotoxic alternative of free doxorubicin. Magy. Onkol. 54(4), 359–367 (2010)

Oerlemans, C., Bult, W., Bos, M., Storm, G., Nijsen, J.F.W., Hennink, W.E.: Polymeric micelles in anticancer therapy: targeting, imaging and triggered release. Pharm. Res. 27(12), 2569–2589 (2010). https://doi.org/10.1007/s11095-010-0233-4

Perez, E.A., Awada, A., O'Shaughnessy, J., Rugo, H.S., Twelves, C., Im, S.-A., Gómez-Pardo, P., Schwartzberg, L.S., Diéras, V., Yardley, D.A., Potter, D.A., Mailliez, A., Moreno-Aspitia, A., Ahn, J.-S., Zhao, C., Hoch, U., Tagliaferri, M., Hannah, A.L., Cortes, J.: Etirinotecan pegol (NKTR-102) versus treatment of physician's choice in women with advanced breast cancer previously treated with an anthracycline, a taxane, and capecitabine (BEACON): a randomised, open-label, multicentre, phase 3 trial. Lancet Oncol. 16(15), 1556–1568 (2015). https://doi.org/10.1016/S1470-2045(15)00332-0

Phan, A., Takimoto, C., Adinin, R., Wood, L., Xiong, H., Matsuno, K., Konno, S., Fujisawa, T., Beeram, M.: Open label phase I study of MBP-426, a novel formulation of oxaliplatin, in patients with advanced or metastatic solid tumors. Mol. Cancer Ther. 6(11 Supplement), C115–C115 (2007)

Schultheis, B., Strumberg, D., Santel, A., Vank, C., Gebhardt, F., Keil, O., Lange, C., Giese, K., Kaufmann, J., Khan, M.: First-in-human phase I study of the liposomal RNA interference therapeutic Atu027 in patients with advanced solid tumors. J. Clin. Oncol. 32(36), 4141–4148 (2014)

Storka, A., Vcelar, B., Klickovic, U., Gouya, G., Weisshaar, S., Aschauer, S., Bolger, G., Helson, L., Wolzt, M.: Safety, tolerability and pharmacokinetics of liposomal curcumin in healthy humans. Int. J. Clin. Pharmacol. Ther. 53(1), 54–65 (2015). https://doi.org/10.5414/CP202076

Tabernero, J., Shapiro, G.I., LoRusso, P.M., Cervantes, A., Schwartz, G.K., Weiss, G.J., Paz-Ares, L., Cho, D.C., Infante, J.R., Alsina, M., Gounder, M.M., Falzone, R., Harrop, J., White, A.C.S., Toudjarska, I., Bumcrot, D., Meyers, R.E., Hinkle, G., Svrzikapa, N., Hutabarat, R.M., Clausen, V.A., Cehelsky, J., Nochur, S.V., Gamba-Vitalo, C., Vaishnaw, A.K., Sah, D.W.Y., Gollob, J.A., Burris, H.A.: First-in-Humans Trial of an RNA interference therapeutic targeting VEGF and KSP in cancer patients with liver involvement. Cancer Discov. 3(4), 406–417 (2013). https://doi.org/10.1158/2159-8290.cd-12-0429

Wetzler, M., Thomas, D.A., Wang, E.S., Shepard, R., Ford, L.A., Heffner, T.L., Parekh, S., Andreeff, M., O'Brien, S., Kantarjian, H.M.: Phase I/II trial of nanomolecular liposomal annamycin in adult patients with relapsed/refractory acute lymphoblastic leukemia. Clin. Lymphoma Myeloma Leuk. 13(4), 430–434 (2013). https://doi.org/10.1016/j.clml.2013.03.015

Yarmolenko, P.S., Zhao, Y., Landon, C., Spasojevic, I., Yuan, F., Needham, D., Viglianti, B.L., Dewhirst, M.W.: Comparative effects of thermosensitive doxorubicin-containing liposomes and hyperthermia in human and murine tumours. Int. J. Hyperth. 26(5), 485–498 (2010). https://doi.org/10.3109/02656731003789284

Young, C., Schluep, T., Hwang, J., Eliasof, S.: CRLX101 (formerly IT-101)–a novel nanopharmaceutical of camptothecin in clinical development. Curr. Bioact. Compd. 7(1), 8–14 (2011). https://doi.org/10.2174/157340711795163866

Zhang, J.A., Anyarambhatla, G., Ma, L., Ugwu, S., Xuan, T., Sardone, T., Ahmad, I.: Development and characterization of a novel Cremophor® EL free liposome-based paclitaxel (LEP-ETU) formulation. Eur. J. Pharm. Biopharm. 59(1), 177–187 (2005). https://doi.org/10.1016/j.ejpb.2004.06.009

Ahmad, A., Sheikh, S., Taran, R., Srivastav, S.P., Prasad, K., Rajappa, S.J., Kumar, V., Gopichand, M., Paithankar, M., Sharma, M., Rane, R.C., Ahmad, I.: Therapeutic efficacy of a novel nanosomal docetaxel lipid suspension compared with taxotere in locally advanced or metastatic breast cancer patients. Clin. Breast Cancer. 14(3), 177–181 (2014). https://doi.org/10.1016/j.clbc.2013.09.011

Senzer, N., Nemunaitis, J., Nemunaitis, D., Bedell, C., Edelman, G., Barve, M., Nunan, R., Pirollo, K.F., Rait, A., Chang, E.H.: Phase I study of a systemically delivered p53 nanoparticle in advanced solid tumors. Mol. Ther. 21(5), 1096–1103 (2013). https://doi.org/10.1038/mt.2013.32

Stathopoulos, G.P., Boulikas, T.: Lipoplatin formulation review article. J. Drug. Deliv. 2012, 1 (2012). https://doi.org/10.1155/2012/581363

Sapsford, K.E., Lauritsen, K., Tyner, K.M.: Current perspectives on the US Food and Drug Administration’s regulatory framework for intelligent drug delivery systems. Ther. Deliv. 3(12), 1383–1394 (2012). https://doi.org/10.4155/tde.12.119

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 This is a U.S. government work and not under copyright protection in the U.S.; foreign copyright protection may apply

About this chapter

Cite this chapter

Kapoor, M., Hughes, K., Tyner, K.M. (2019). Regulatory Considerations for Cancer Drug Products Containing Nanomaterials. In: Rai, P., Morris, S.A. (eds) Nanotheranostics for Cancer Applications. Bioanalysis, vol 5. Springer, Cham. https://doi.org/10.1007/978-3-030-01775-0_12

Download citation

DOI: https://doi.org/10.1007/978-3-030-01775-0_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-01773-6

Online ISBN: 978-3-030-01775-0

eBook Packages: EngineeringEngineering (R0)