Abstract

Protein tyrosine phosphatases (PTP) are a large group of enzymes which work together with protein tyrosine kinases to control the tyrosine phosphorylation of proteins, thus playing a major role in cellular signaling. Here, we provide detailed protocols for expression and purification of the catalytic domain of RPTPμ and full length Eya3 as well as the extracellular region of PTPBR7. Methods are described for evaluation of the purity of the recombinant proteins thus obtained. For the purified Eya3 phosphatase we provide protocols for enzyme activity assay using either chromogenic, fluorescent, or peptide substrates. Determination of kinetic parameters by different graphical and computer-based procedures is also described.

Access provided by CONRICYT – Journals CONACYT. Download protocol PDF

Similar content being viewed by others

Key words

- PTP domains

- 6×His and GST tagged recombinant proteins

- Prokaryotic expression

- Eukaryotic expression

- PTP purification

- PTP kinetics

- pNPP

- DiFMUP

- Phosphopeptide

1 Introduction

Since the discovery of tyrosine phosphorylation in proteins [1, 2] major progress has been made in elucidating its role in cellular signaling. The balance of tyrosine phosphorylation in cell, which is crucial for normal cellular homeostasis and disease, is a result of opposing actions of protein tyrosine kinases (PTKs) and protein tyrosine phosphatases (PTPs) . Although early investigations regarding tyrosine phosphorylation were almost exclusively centered on PTKs, later studies clearly revealed that PTPs play a key role in signal transduction [3].

The superfamily of PTPs has a large number of representatives. Thus, there are 107 PTP genes in human genome [4]. They can be classified into four subfamilies based on their amino acid sequences and functional characteristics. Class I, the major group of PTPs , shares the conserved (H/V)C(X)5R(S/T) sequence called “PTP signature motif .” This sequence contains the active-site cysteine which plays the essential role of nucleophile in the catalytic mechanism of dephosphorylation . There are two subclasses in Class I PTPs : the subclass of classical, phospho-tyrosine-specific PTPs and the subclass of dual-specific phosphatases which recognize and dephosphorylate not only phospho-tyrosine but also phospho-serine/phospho-threonine. Class II contains the low molecular weight or acid phosphatases which act on tyrosine phosphorylated proteins as well as on some natural and synthetic aryl- and acyl-phosphates. Members of Class III contain also an essential, active-site cysteine and include several cell-cycle regulatory phosphatases. Class IV diverges from the other classes as its members do not share the PTP signature motif and do not use cysteine as a nucleophile in catalytic mechanism. Instead, they use a nucleophilic aspartic acid residue in a metal ion-dependent catalytic mechanism.

The structural architecture of PTPs is frequently multimodular due to the presence of various functional domains. Thus, the receptor-like PTP (RPTPs) group of classical PTPs contains in the extracellular region domains like: CAH (carbonic anhydrase-like), MAM (meprin/A5/μ), Ig (Immunoglobulin-like), or Fn (fibronectin type III-like). The intracellular region of RPTPs contains a membrane-proximal catalytic domain and, in case of some representatives, also a membrane-distal domain which is either inactive or has residual catalytic activity. The non-transmembrane group of classical PTPs contains, besides the catalytic domain, various noncatalytic domains like: HD (histidine domain), Pro (Proline-rich), SH2 (Src-homology 2), Sec14 (Sec14/cellular retinaldehyde-binding protein-like), KIM (kinase-interaction motif), FERM (4.1 protein/ezrin/radixin/moesin), or PDZ (PSD95/Dlg1/zo-1) [5].

Although PTPs have been studied since decades, there are still numerous unknowns concerning their molecular characteristics which need in-depth investigations. For example, novel crystal structures of PTPs are expected to be obtained. Despite the relatively high number of crystal structures of PTP catalytic domains so far reported, there are very few structures of extracellular regions of RPTPs , full-length non-receptor-like PTPs , or complexes between PTPs and their protein ligands (including phospho-tyrosine -containing protein substrates). On the other hand protein crystallization as other experimental approach requires reasonable amounts of pure, active protein preparations. Another example of research area which needs purified protein and which can lead to finding novel molecular characteristics of PTPs is substrate specificity studies. Indeed, identification of factors that determine substrate specificity, identification of novel substrates, and characterization of PTPs interaction with their physiological substrates are major research targets for many representatives of PTPs superfamily.

Here, we provide robust expression, purification, and kinetic analysis protocols for catalytic domains of an RPTP from Class I, subclass R2A (human RPTPμ or PTPRM), a full-length PTP from Class IV (human Eya3), and the extracellular region of an RPTP from Class I, subclass R7 (mouse PTPBR7 or PTPRR). The protocols described here contain specific experimental details for the mentioned PTPs . However, the protocols can be easily extended to other similar PTP representatives.

2 Materials

All mentioned chemicals should be of reagent grade. All solutions should be prepared in ultrapure water (deionized water purified to attain a resistivity of 18 MΩ at 25 °C) and filtered through a 45 μm filter. Solutions are stored at room temperature unless indicated.

2.1 PTP Domains Expression

2.1.1 Prokaryotic Expression of PTP Domains (Exemplified by Expressions of hEya3 and hRPTPμD1)

-

1.

Prokaryotic expression vectors (see Note 1 ).

-

2.

Chemically competent E. coli strains (see Note 2 ).

-

3.

Liquid Luria-Bertani (LB) medium: add 10 g Bacto-Tryptone, 5 g Bacto-Yeast extract, and 10 g NaCl to 900 mL of ultrapure water. Adjust pH to 7.0 with NaOH and bring to a final volume of 1 L. Autoclave 20 min at 121 °C.

-

4.

Ampicillin (Amp) stock solution: make 100 mg/mL solution in ultrapure water, filter sterilize using a 0.22 μm filter, and aliquot to an appropriate volume. Make aliquots and store at −20 °C. Use it at a final concentration of 100 μg/mL in LB medium.

-

5.

LB agar plates with Amp (see Note 3 ).

-

6.

Isopropyl-thio-β-d-galactopyranoside (IPTG), stock solution: prepare a 500 mM solution and filter sterilize. Make 1 mL aliquots and store at −20 °C, in the dark.

-

7.

Block heater.

-

8.

Shaker incubator.

-

9.

Spectrophotometer.

2.1.2 Eukaryotic Expression of PTP Domains (Exemplified by Expression of the Extracellular Region of PTPBR7–Ecto-PTPBR7)

-

1.

Eukaryotic expression vector pHLsec-Ecto-PTPBR7, containing the gene encoding for the extracellular region of PTPBR7 fused with a 6×His-tag (see Note 4 ).

-

2.

Mammalian HEK293T (ATCC CRL-3216) and 293S (ATCC® CRL-3022) cell lines.

-

3.

The complete growth media used Dulbecco’s Modified Eagle’s Medium (DMEM) high glucose with Glutamax supplemented with 1× non-essential amino acids (NEAA) and 10 % fetal bovine serum (FBS).

-

4.

Plasmid DNA purification kit.

-

5.

Transfection reagent: polyethylenimine (PEI). Make an aqueous stock solution of 1 mg/mL PEI, adjust to pH 7 with HCl, filter sterilize and make aliquots and store at –20°C (see Note 5 ).

-

6.

Expanded surface polystyrene roller bottles of 2125 cm2.

-

7.

Phosphate -buffered saline 1× (PBS-1×): 1.8 mM KH2PO4, 10 mM Na2HPO4, 137 mM NaCl, and 2.7 mM KCl, pH 7.4.

-

8.

0.05 % Trypsin-EDTA.

-

9.

Sterile serological pipettes (2, 5, 10, 25 mL).

-

10.

Sterile cell culture plastics.

-

11.

Rotating incubator (37 °C, 5 % CO2).

2.2 Recombinant Protein Purification

2.2.1 Affinity Chromatography on Glutathione-Sepharose

For hRPTPμ D1 catalytic domain (hRPTPμD1):

-

1.

Glutathione-Sepharose 4B.

-

2.

GST -LyB buffer (lysis buffer): 137 mM NaCl, 4.3 mM Na2HPO4, 1.47 mM KH2PO4, 2.7 mM KCl, pH 7.4, 1 % Triton X-100, 4 mM DTT, 1 mM PMSF, and protease inhibitor cocktail EDTA-free.

-

3.

GST -WB buffer (washing buffer): 137 mM NaCl, 4.3 mM Na2HPO4, 1.47 mM KH2PO4, 2.7 mM KCl, pH 7.4, 1 % Triton X-100, 4 mM DTT, and 1 mM PMSF.

-

4.

GST -EB buffer (elution buffer): 50 mM Tris–HCl pH 8.0, and 10 mM reduced glutathione.

-

5.

Conical centrifuge tubes.

-

6.

Amicon Ultra-4 centrifugal filter unit with 50 kDa Nominal Molecular Weight Limit (NMWL).

-

7.

0.2 μm membrane filters.

-

8.

Eppendorf tubes.

-

9.

Cooling centrifuge.

-

10.

French press.

2.2.2 Affinity Chromatography on Ni-Sepharose

For hEya3:

-

1.

HisTrap HP—5 mL immobilized metal ion affinity chromatography (IMAC) columns (GE Healthcare).

-

2.

Lysis buffer (LyB): 50 mM Tris–HCl pH 7.4, 350 mM NaCl, 20 mM imidazole, 2 mM DTT, 2 mM MgCl2, 0.1 % Triton X-10, and 1× protease inhibitor cocktails or 1 mM PMSF (see Note 6 ).

-

3.

Binding buffer for affinity purification (BBAP): 50 mM Tris–HCl pH 7.4, 350 mM NaCl, 20 mM imidazole, 2 mM DTT, 2 mM MgCl2, and 0.1 % Triton X-10 (see Note 6 ).

-

4.

Elution buffer for affinity purification (EBAP): 50 mM Tris–HCl pH 7.4, 350 mM NaCl, 500 mM imidazole, 2 mM DTT, 2 mM MgCl2, and 0.1 % Triton X-100 (see Note 6 ).

-

5.

Amicon Ultra-4 and -15 Centrifugal filter Units with 50 kDa NMWL.

-

6.

0.2 μm membrane filters.

-

7.

Probe Sonicator.

For Ecto-PTPBR7:

-

1.

Ni-Sepharose High Performance.

-

2.

Sepharose washing buffer 1: 10 mM Tris–HCl, 150 mM NaCl, and 2 mM imidazole pH 8.0.

-

3.

Sepharose washing buffer 2: 10 mM Tris–HCl, 150 mM NaCl, and 5 mM imidazole pH 8.0.

-

4.

Elution buffer: 10 mM Tris–HCl, 150 mM NaCl, and 250 mM imidazole pH 8.0.

-

5.

0.2 μm membrane filters.

-

6.

Centricon Plus-70 Centrifugal filter unit with 10 kDa NMWL.

-

7.

Empty columns for collecting the Ni-Sepharose beads.

-

8.

Endo-H enzyme.

-

9.

PNGase F enzyme (NEB).

2.2.3 Anion Exchange Chromatography

For hEya3:

-

1.

MonoQ 5/50GL strong anion exchange column.

-

2.

Binding buffer for anion exchange (BBAE): 50 mM Tris–HCl pH 7.4, 50 mM NaCl, 2 mM DTT, and 2 mM MgCl2 (see Note 6 ).

-

3.

Elution buffer for anion exchange (EBAE): 50 mM Tris–HCl pH 7.4, 1 M NaCl, 2 mM DTT, and 2 mM MgCl2 (see Note 6 ).

2.2.4 Size Exclusion Chromatography

For hEya3, hRPTPμD1 and Ecto-PTPBR7 :

-

1.

Superdex 75 10/300 GL prepacked, high-resolution, size exclusion chromatography column.

-

2.

20 % ethanol (see Note 6 ).

-

3.

Fraction collecting tubes.

-

4.

Gel filtration buffers (GFB) (see Note 6 ).

-

GFB for hEya3: 50 mM Tris–HCl pH 7.4, 100 mM NaCl, 2 mM DTT, 2 mM MgCl2.

-

GFB for hRPTPμD1: 50 mM Tris–HCl pH 7.5, 150 mM NaCl, 10 % glycerol, 4 mM DTT, and 0.5 mM PMSF.

-

GFB for Ecto-PTPBR7 : 10 mM HEPES pH 7.5, and 150 mM NaCl.

-

2.3 Analysis of Purified Proteins by SDS-PAGE and Western Blotting

-

1.

Solutions for SDS-PAGE gels (see Note 7 ):

-

4× running gel buffer: 1.5 M Tris–HCl pH 8.8.

-

4× stacking gel buffer: 0.5 M Tris–HCl pH 6.8.

-

30 % acrylamide/bis-acrylamide solution (37.5:1).

-

10 % sodium dodecyl sulfate solution (SDS).

-

10 % ammonium persulfate (APS) solution.

-

N,N,N′,N′-tetramethyl-ethylenediamine (TEMED).

-

-

2.

5× SDS-PAGE running buffer pH 8.3: 125 mM Tris Base, 960 mM glycine, and 0.5 % SDS. The pH should be around 8.3 without adjusting. Dilute 1:5 with ultrapure water, before usage.

-

3.

5× SDS-PAGE reducing loading buffer (5× RLB): 60 mM Tris–HCl pH 6.8, 2 % SDS, 0.01 % bromophenol blue, 10 % glycerol, and 100 mM β-mercaptoethanol. Store at −20 °C in small aliquots.

-

4.

Coomassie blue staining solution: 2.4 g/L Coomassie blue, 0.5 L ethanol, 0.48 L acetic acid, 0.12 L distilled water.

-

5.

Destaining solution: 20 % acetic acid in ultrapure water.

-

6.

10× Transfer buffer: 250 mM Tris Base, and 1.9 M glycine. The pH should be around 8.3 without adjusting. Store at 4 °C. Before use, dilute 1:10 with ultrapure water plus 10 % methanol or ethanol (see Note 8 ).

-

7.

TBS-T buffer: 20 mM Tris–HCl pH 7.5, 150 mM NaCl, and 0.1 % Tween-20.

-

8.

Blocking buffer: 5 % non-fat skim milk in TBS-T.

-

9.

Methanol (100 %) or ethanol (96–100 %) for activation of PVDF membrane (see Note 8 ).

-

10.

Polyvinylidene fluoride (PVDF) membrane, 45 μm pore size.

-

11.

Primary antibody polyclonal rabbit anti-GST .

-

12.

PentaHis monoclonal primary antibody.

-

13.

Secondary antibodies: anti-rabbit and anti-mouse conjugated with HRP.

-

14.

Chemiluminescence (ECL) detection kit.

-

15.

X-ray films.

-

16.

Plastic box.

-

17.

Molecular weight markers for SDS-PAGE and Western blotting .

-

18.

Mini-Protean protein electrophoresis system.

-

19.

Semidry transfer system.

2.4 Mass Spectrometric Analysis

-

1.

Purified recombinant 6×His-hEya3 protein.

-

2.

Bradford assay kit.

-

3.

Water LC-MS CHROMASOLV®.

-

4.

Eppendorf tubes.

-

5.

Nitrile gloves.

-

6.

Protein denaturation buffer: 8 M urea solution in 50 mM Tris–HCl pH 8, freshly prepared.

-

7.

Protein reduction buffer: 200 mM DTT solution in 50 mM (NH4)2CO3 (LC-MS grade) freshly prepared with LC-MS CHROMASOLV® water.

-

8.

Protein alkylation buffer: 200 mM iodoacetamide solution in 50 mM (NH4)2CO3, freshly prepared with LC-MS CHROMASOLV® water.

-

9.

rLysC, Mass Spec Grade.

-

10.

Chymotrypsin, Sequencing Grade.

-

11.

Pierce™ C18 Tips 100 μL.

-

12.

Sample treatment solution: 2.5 % trifluoroacetic acid (TFA) in water.

-

13.

Elution solution: 0.1 % formic acid (FA, LC-MS Grade) in 70 % acetonitrile (ACN, LC-MS Grade), up to 100 μL per sample.

-

14.

SpeedVac®, for removing the solvent from peptide solution obtained after desalting procedure.

-

15.

Nano-liquid chromatography (nLC) vials.

-

16.

Resuspension buffer and mobile phase A for nLC: 0.1 % FA in 2 % ACN:water.

-

17.

Mobile phase B for nLC: 0.1 % FA in ACN. nLC coupled with a hybrid LTQ-Orbitrap mass spectrometer. The chromatographic system should be composed of a desalting C18 trap column connected with an analytical C18 column for peptide separation.

-

18.

Proteome Discoverer v1.4 program, containing SEQUEST or Sequest HT algorithms, or v1.3, containing SEQUEST.

2.5 Tyrosine Phosphatase Assays

-

1.

Bradford assay kit.

-

2.

pNPP (para-nitrophenyl phosphate) as a chromogenic PTP substrate.

-

100 mM pNPP stock solution (see Note 9 ).

-

10 mM pNP in ethanol (for standard curve).

-

10× Assay buffer: 200 mM HEPES pH 7, 1500 mM NaCl, and 100 mM MgCl2.

-

Disposable cuvettes.

-

-

3.

DiFMUP (6,8-difluoro-4-methylumbelliferyl phosphate) as a fluorescent PTP substrate.

-

10 mM DiFMUP in DMSO, store at −20 °C in single-use aliquots.

-

Assay buffer: 20 mM MES pH 6.5, 100 mM NaCl, 10 mM MgCl2 and 5 mM DTT.

-

Black 96-well plates, flat bottom, nontreated.

-

-

4.

Phospho-H2AX as a peptide substrate for hEya3 PTP.

-

H2AX-pY142 peptide sequence: Acetyl-CPSGGKKATQASQE(pY)-NH2.

-

10× Assay buffer: 200 mM MES pH 6.5, 1 M NaCl, 100 mM MgCl2, and 50 mM DTT (see Note 10 ).

-

2 mM H2AX-pY142 phosphopeptide : dissolve 2.5 mg of peptide in 100 μL of 50 % DMSO and 650 μL of 50 mM Tris-Cl pH 7.6, 150 mM NaCl (see Note 11 ).

-

Clear 96-well plates, flat bottom, nontreated.

-

BIOMOL Green reagent for phosphate detection (Enzo Life Sciences).

-

3 Methods

3.1 D1 Domain of Human Receptor Protein Tyrosine Phosphatase μ (hRPTPμD1)

3.1.1 Prokaryotic Expression of hRPTPμD1

-

1.

Transform DH5α competent cells with pGEX-KT-hRPTPμD1 prokaryotic expression vector (see Note 1 ). Thaw a 50 μL aliquot of DH5α competent cells on ice. Add 1 μL (~100–200 ng DNA) of the vector and incubate ~10 min on ice. Heat shock the cells for 1 min at 42 °C and put them quickly on ice for 2 min. Spread the cell suspension on a LB agar plate supplemented with Amp using a sterile spreader. Incubate overnight at 37 °C (see Note 12 ).

-

2.

Prepare a starter culture, pick a single colony of the transformed DH5α to inoculate 40 mL of LB medium with 100 μg/mL Amp (LB-Amp). Incubate the bacterial inoculum at 37 °C overnight with shaking (see Note 13 ).

-

3.

Next morning, centrifuge the starter culture 5 min at 5000 × g at room temperature, resuspend the pellet into 10 mL fresh LB medium, and add into 990 mL LB-Amp. In our lab, we typically use cultures of 2 L for prokaryotic expression of hRPTPμD1 (see Note 14 ).

-

4.

Incubate the culture with shaking at 37 °C until the optical density of the culture at 600 nm (OD600 nm) (measured with a spectrophotometer/colorimeter covering the visible region of the spectrum) reaches 0.3 (see Note 15 ). This typically takes about 3 h.

-

5.

Shift the culture temperature to 25 °C and continue the culture growth, until OD600 nm is between 0.6 and 0.7 (see Note 16 ).

-

6.

Induce protein expression by adding IPTG stock solution to 0.1 mM final concentration. Keep shaking overnight at 25 °C. Before induction, take a “before induction sample” (BI) by collecting the cells from 1 mL culture. Store the sample at −20 °C.

-

7.

After about 16–18 h of expression, harvest the cells by centrifugation at 7000 × g for 10 min, at 4 °C, and use the cells directly for protein purification or store the cells at −80 °C until processing.

3.1.2 Purification of hRPTPμD1

-

1.

Thaw the bacterial pellet on ice.

-

2.

Resuspend the pellet in GST -Ly buffer (~35 mL for a cell pellet collected from 1 L bacterial culture) and homogenize thoroughly using a glass douncer (see Note 17 ).

-

3.

Pass the homogenized suspension through a French press four times (pressure: 1000 psi) to disrupt the membrane of the bacterial cells (see Note 18 ). Take now the “whole lysate” sample (WL), collecting a small volume (~20–30 μL) of cell suspension for SDS-PAGE.

Centrifuge the lysate at 20,000 × g, for 20 min at 4 °C. Take the “soluble protein” sample (S) by collecting a small volume (~20–30 μL) of supernatant for SDS-PAGE. Next, discard the pellet and submit the supernatant to the first purification step.

-

4.

Affinity chromatography on Glutathione-Sepharose:

-

Prepare the Glutathione-Sepharose resin: gently shake the bottle of Glutathione-Sepharose to resuspend the resin and pick up 700 μL slurry. Cut off with a scissors about 1 mm of the pipet tip and use this tip to pipette the slurry. Equilibrate the beads by washing with at least 3 volumes of GST-WB buffer for three times. Between washes, spin down the beads 3 min, 1000 × g, at 4 °C.

-

Put the supernatant resulted after cell lysis in a 50 mL falcon tube. Add ~700 μL Glutathione-Sepharose resin (50 % slurry equilibrated with GST-WB buffer) and incubate 1 h at 4 °C, on a tube rotator.

-

Spin down the resin by centrifugation 3 min at 1000 × g and transfer it into a 2 mL Eppendorf tube. Take the “flow through” (FT) sample by collecting a small volume (20–30 μL) from the supernatant, after protein adsorption on the resin.

-

Wash the resin three to five times, 10 min each, at 4 °C, with 1.5 mL GST-WB. Centrifuge the resin 3 min at 1000 × g. Take a small volume of beads (10 μL) for SDS-PAGE, using a cut-off pipet tip. This sample is “protein adsorbed on the beads” (denoted “B”).

-

Elute the resin with GST-EB buffer four times (~1 mL GST-EB to 350 μL beads). For each elution incubate 5 min at 4 °C rotating the tube on a tube rotator. Take a small volume (20–30 μL) of each eluted fraction for SDS-PAGE.

-

Analyze the collected elution fractions (E1–E4) together with the previous samples: BI, WL, S, B and FT by 10 % SDS-PAGE (Fig. 1a).

Fig. 1 Analysis of expression and purification of hRPTPμD1. (a) SDS-PAGE analysis of the expression and purification by affinity chromatography of RPTPμD1, N-terminally fused with GST . Gel was stained with Coomassie: BI bacterial cells before induction of the protein expression with IPTG, WL whole lysate, S soluble proteins, B protein adsorbed on Glutathione-Sepharose beads, E1–E4 eluted protein, FT flow through, M low molecular weight marker. (b)RPTPμD1 elution profile after size exclusion chromatography (left) and SDS-PAGE analysis of the peak fractions (right): CP protein purified by affinity chromatography and concentrated on Amicon Ultra 50-K, 8–12 fractions of purified protein. Gel was stained with Coomassie. (c) Immunoblotting detection of the purifiedGlutathione S-transferase (GST) GST-RPTPμD1, detected with anti-GST antibody. All electrophoretic separations of proteins were performed in 10 % SDS-PAGE gels

-

Put together the eluted fractions containing the purified protein, add 10 % glycerol, and resuspend gently (without making foam) (see Note 19 ). Store the protein at −80 °C until the next purification step.

-

-

5.

Size exclusion chromatography:

-

Start the FPLC-ÄKTA system (see Note 20 ).

-

Connect the Superdex 75 10/300 GL column to the system (see Note 21 ).

-

Wash the column with at least one column volume (25 mL) of ultrapure degassed water, to remove the column storage solution (20 % ethanol) and then equilibrate it with at least one column volume (25 mL) of GFB buffer (flow rate of 0.8 mL/min).

-

Thaw the protein purified by affinity chromatography from −80 °C, and centrifuge at 20,000 × g for at least 15 min, at 4 °C (to remove the precipitated protein). Collect the supernatant carefully.

-

Concentrate the supernatant to ~250 μL volume by centrifugation on Amicon Ultra-4 centrifugal filter unit with 50 kDa NMWL at 5000 × g, 4 °C.

-

Inject the prepared sample into the column using a suitable loop.

-

Wash the column with at least 1 volume GFB (flow rate of 0.8 mL/min) and collect fractions of 1 mL volume.

-

After protein separation wash the column with 50 mL water (flow rate of 0.8 mL/min) and then with 30 mL of 20 % ethanol (see Note 26 ). Detach the column from the ÄKTA system and keep it at 4 °C (see Note 21).

-

Analyze the collected fractions by 10 % SDS-PAGE (Fig. 1b).

-

Put together the fractions containing the pure protein, add 10 % glycerol, and mix gently (to avoid foaming).

-

Determine the total protein concentration by Bradford method (or any other method used in your lab).

-

Make aliquots of volumes adequate for your next assays and store aliquots at −80 °C (see Note 22 ).

-

3.1.3 Analysis of the Expression and Purification of hRPTP μD1 by SDS-PAGE

-

1.

Prepare 10 % SDS-PAGE gels using your lab protocol.

-

2.

Prepare SDS samples: mix the samples taken after each step of protein expression and purification with 5× RLB, boil the samples for 5 min at 100 °C, then centrifuge at 13,000 × g for 1 min at room temperature. Prepare the molecular marker as specified by the manufacturer.

-

3.

Prepare the electrophoresis system according to the manufacturer’s instructions.

-

4.

Load 10 μL of each prepared sample on gel. Do not forget to load the molecular weight marker on the gel.

-

5.

Run gels about 40 min at 35 mA/gel. When the blue line is out of the gel, stop the device and place the gels into a clean plastic box with lid, suitable for microwave device.

-

6.

Coomassie blue staining of gels: add solution to fully cover the gels (the volume depends on the box size), place the box in a microwave device for 30–60 s then incubate for 3 min on a rocker (see Note 23 ).

-

7.

Destaining of the gels: wash gels with plenty of distilled water and cover gels with destaining solution, place the box again in a microwave for 30–60 s and let on a rocker for 5 min. Repeat the destaining steps until the protein bands become visible (usually is enough three to four times).

-

8.

Analyze the gels. Collect the fractions containing the protein of interest (the molecular weight of RPTPμD1 is 68.6 kDa).

3.1.4 Detection of hRPTPμ by Western Blotting

-

1.

Run the SDS samples on a 10 % SDS-PAGE gel (use the same procedure like in Subheading 3.1.3, steps 1–5).

-

2.

Prepare the PVDF membrane (see Note 24 ).

-

3.

Transfer the proteins from the gel on a PVDF membrane for 1 h at 80 mA/gel, using a semidry transfer system.

-

4.

Take the membrane from the transfer system, remove the excess membrane by cutting its margins with a scissors and lay the membrane into a plastic box.

-

5.

Add blocking buffer to cover the PVDF membrane and incubate for 1 h at room temperature or overnight at 4 °C, on a rocker.

-

6.

Cover the membrane with the primary antibody, anti-GST in blocking buffer and incubate for 1 h at room temperature.

-

7.

Rinse the membrane with 10–20 mL TBS-T, three times for 10 min at room temperature, to remove the unbound primary antibody.

-

8.

Cover the membrane with the appropriate secondary antibody and incubate for 1 h at room temperature.

-

9.

Rinse the membrane with 10–20 mL TBS-T, three times for 10 min at room temperature, to remove the excess of secondary antibody.

-

10.

Incubate the membrane with mixed ECL kit solutions according to the manufacturer’s instructions.

-

11.

Expose the membrane to a X-ray film. The time of exposure depends on the protein concentration, antibodies affinity, and ECL kit sensitivity (Fig. 1c).

3.2 Human Eya3 (hEya3) Tyrosine Phosphatase

3.2.1 Prokaryotic Expression of hEya3 Tyrosine Phosphatase

-

1.

Introduce the pHAT2-hEya3 plasmid carrying the hEya3 gene into BL21(DE3)RIL cells by heat-shock transformation (see Note 12 ). Proceed like in Subheading 3.1.1, step 1.

-

2.

Pick one colony from the plate and inoculate 20 mL of LB-Amp and incubate it at 37 °C overnight (see Note 13 ).

-

3.

Centrifuge the 20 mL overnight culture in a sterile falcon tube at 5000 × g for 10 min, remove the supernatant and resuspend the pellet in fresh 30 mL of LB-Amp, and finally add to 1 L LB-Amp (see Note 14 ). Incubate the culture at 30 °C under shaking at 120 rpm until OD600 nm is about 0.7–0.9 (see Note 15 ). Add IPTG to a final concentration of 0.3 mM, and return the flask to the incubator (keep the same parameters) for 16–18 h. Take the “before induction” sample as in Subheading 3.1.1, step 6 (Fig. 2a).

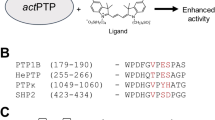

Fig. 2 Analysis of expression and purification of hEya3 phosphatase. (a) SDS-PAGE analysis of the expression of recombinant hEya3 phosphatase: M low molecular weight protein marker, BI before induction, WL whole lysate, S soluble proteins. (b) Affinity chromatography elution profile of hEya3 phosphatase (left) and SDS-PAGE analysis of peak fractions visualized on a 10 % SDS-PAGE (right). M low molecular weight protein marker, 8–14 eluted fractions containing Eya3 phosphatase. (c) Anion exchange chromatography elution profile of hEya3 phosphatase (left) and SDS-PAGE analysis of peak fractions visualized on a 10 % SDS-PAGE (right). M low molecular weight protein marker, 9–13 eluted fractions containing Eya3 phosphatase. (d) Gel filtration elution profile of hEya3 phosphatase (right) and SDS-PAGE analysis of peak fractions visualized on a 10 % SDS-PAGE (left). M low molecular weight protein marker, 62–68 eluted fractions containing Eya3 phosphatase. All gels were stained with Coomassie. (e) Example of sequence coverage of hEya3 (Q99504) obtained after sequential digestion with rLysC and Chymotrypsin and analysis by Collision-induced dissociation (CID). Underlined are the identified hEya3 peptides

-

4.

Next day, centrifuge the culture at 7000 × g for 10 min. Then, either proceed to protein purification or store the pellet at −80 °C.

3.2.2 Purification of hEya3

-

1.

Cell lysis: thaw on ice the cellular pellet and resuspend it in 25 mL LyB buffer (see Note 17 ). Disrupt the cells by sonication for 10–15 times, 10 s each at 70 % power with a Bandelin Sonicator (for efficient cell lysis split the resuspended pellet in three tubes, with about 10 mL of culture, and perform sonication for each of them). Take the “whole lysate” sample like in Subheading 3.1.2, step 3 (Fig. 2a). After sonication, centrifuge the cell lysate for 25 min at 20,000 × g and 4 °C. Keep the supernatant which contains the 6×His-tagged hEya3 phosphatase and discard, as appropriate, the cellular pellet. Take “soluble protein” sample, like in Subheading 3.1.2, step 3 (Fig. 2a). hEya3 phosphatase is further purified by a three-step purification protocol using a FPLC-ÄKTA system (steps 2–4).

-

2.

Affinity chromatography:

-

Prepare the HisTrap HP column for purification: connect the column to the system (see Notes 20 and 21 ).

-

Wash the column with 25 mL water to remove the 20 % ethanol storage solution; wash the column with 25 mL EBAP and finally equilibrate it on BBAP buffer (flow rate of 5 mL/min).

-

Inject the supernatant on the column, using a 50 mL SuperLoop (flow rate of 5 mL/min) (see Note 25 ).

-

Wash column with BBAP until the absorbance 280 nm (A 280 nm) reaches the baseline (flow rate of 5 mL/min).

-

Elute the 6×His-tagged hEya3 protein with EBAP buffer in gradient. Set the gradient to reach 50 % of EBAP buffer in 40 min (flow rate 1 mL/min). Collect 1 mL fractions.

-

Prepare the column for storage: set the gradient to reach 100 % of EBAP buffer and run five column volumes (25 mL) to clean the column. Next, wash with 25 mL water and then with 25 mL of 20 % ethanol.

-

All peak fractions are analyzed by SDS-PAGE, and those corresponding to the protein of interest are saved for further purification steps and stored with 10 % glycerol at −80 °C (Fig. 2b).

-

-

3.

Anion exchange chromatography:

-

Prepare the MonoQ 5/50 GL column: connect the column to the system (see Notes 20 and 21 ); use 5 mL water to remove the 20 % ethanol storage solution; wash the column with 5 mL EBAE and finally equilibrate it on BBAE buffer (flow rate of 1 mL/min).

-

Thaw on ice the protein saved from the previous purification step (step 2), centrifuge at 4 °C and 20,000 × g for 30 min. Carefully, take the supernatant and exchange protein buffer to BBAE buffer using Amicon Ultra-15 Centrifugal filter Units. Collect the sample from the Amicon filter unit into an Eppendorf tube and centrifuge it at 4 °C and 20,000 × g for 10 min. Inject the supernatant into the column using an appropriate size loop (flow rate of 1 mL/min) (see Note 25 ).

-

Wash unbound proteins until A 280 nm reached baseline with BBAE.

-

Elute hEya3 phosphatase in gradient of EBAE. Set the gradient to reach 50 % of EBAP buffer in 40 min (flow rate 1 mL/min). Collect 1 mL fractions.

-

Prepare the column for storage: set the gradient to reach 100 % of EBAE buffer and run for 5 mL. Next, wash with 5 mL water and then with 5 mL of 20 % ethanol and store it at 4 °C (see Note 26 ).

-

All peak fractions are analyzed by SDS-PAGE. Fractions corresponding to the protein of interest are saved for further purification steps and stored with 10 % glycerol at −80 °C (Fig. 2c).

-

-

4.

Size exclusion chromatography:

-

Prepare Superdex 75 10/300 GL column: connect the column to the system (see Notes 20 and 21 ).

-

Thaw on ice the protein fraction stored at −80 °C (from step 3), then centrifuge at 4 °C and 20,000 × g for 30 min. Carefully, take the supernatant and concentrate it to at least 250–300 μL using Amicon Ultra-4 Centrifugal filter Units with 50 kDa cutoff.

-

Collect the supernatant into an Eppendorf tube and centrifuge it at 4 °C and 20,000 × g for 10 min. Inject the supernatant onto the column using a 500 μL loop (flow rate of 0.8 mL/min) (see Note 25 ).

-

Run at least one column volume on GFB and collect 1 mL fractions.

-

Proceed like in Subheading 3.1.2, step 5.

-

Analyze all peak fractions by SDS-PAGE. All fractions containing the pure hEya3 protein are mixed together and aliquoted in 100 μL fractions (single-use aliquots). Proteins are stored with 10 % glycerol at −80 °C until are used in further experiments (Fig. 2d).

-

3.2.3 Analysis of the Expression and Purification of hEya3 by SDS-PAGE

-

1.

Prepare the 10 % SDS-PAGE gels using your lab protocol.

-

2.

SDS sample preparation: mix 10 μL from each fraction with 10 μL of 5× RLB, boil for 5 min at 100 °C. Centrifuge samples for 1 min to 13,000 × g.

-

3.

Prepare the electrophoresis system, load the samples in the gel and run the gel.

-

4.

Stain and then destain the gels to visualize the protein bands (see Subheading 3.1.3, steps 6 and 7).

-

5.

Analyze the gels and collect the fractions which contain the highest quantity of pure hEya3 protein.

3.2.4 Mass Spectrometric Identification of hEya3 Using Bottom-Up Approach

-

1.

Preparation of the protein for in-solution digestion: thaw an aliquot of hEya3 on ice. Centrifuge it for 20–25 min, at 4 °C and 20,000 × g. Carefully transfer the protein solution in a new Eppendorf tube. Measure the protein concentration using the Bradford assay kit. Take a volume corresponding to 2 μg of hEya3 and transfer it into a new Eppendorf tube.

-

2.

In-solution digestion:

-

Denaturation: add 8 M urea in 50 mM Tris–HCl pH 8 so the final concentration of urea in sample volume is 4 M.

-

Reduction : add protein reduction buffer until you reach a final concentration of 10 mM DTT in the sample volume. Incubate for 45–60 min at room temperature with moderate shaking. Do not heat the sample.

-

Alkylation: add protein alkylation buffer until the final concentration of 55 mM iodoacetamide has been reached in the sample volume. Incubate in the dark for 45–60 min at room temperature with moderate shaking.

-

Inactivation of the alkylating agent: add the same volume as the volume of iodoacetamide solution, from the protein reduction buffer. Incubate for 45–60 min at room temperature with moderate shaking.

-

Protein digestion with rLysC: add rLys-C Mass Spec Grade (10 ng/μL), to a final protease: protein ratio of 1:30 (w/w) and incubate sample for 16–18 h at 37 °C (see Notes 27 and 28 ).

-

Digestion with Chymotrypsin: add Chymotrypsin Sequencing Grade (10 ng/μL) to a final protease: protein ratio of 1:20 and incubate the sample for 16–18 h at 25 °C (see Note 29 ).

-

Stop the reaction by adding 2.5 % TFA solution in sample, so that the final concentration in sample volume is 0.5 % TFA; keep the sample on ice until desalting; avoid repeated freezing (−20 °C) and thawing of the peptide sample.

-

-

3.

Desalting procedure:

-

Adjust sample to 0.5 %TFA (with Sample treatment solution).

-

Desalting was performed according to the manufacturer’s instructions (Thermo Scientific™ Pierce™ C18 Tips 100 μL bed) (also see Note 30).

-

Eluting the sample: slowly aspirate 50 μL of 0.1 % FA in 70 % ACN and dispense in a new Eppendorf tube. Repeat once and reunite the eluates.

-

Dry the eluate in a SpeedVac® to dryness.

-

Keep the resulted sample at −20 °C until LC-MS/MS analysis.

-

-

4.

LC-MS/MS analysis:

-

Resuspend the dried peptides in 20 μL of 0.1 % FA in 2 % ACN.

-

Transfer the solution obtained into a nLC vial or well plate (depending on the nLC type).

-

Set the parameters for the LC-MS/MS analysis (see Note 31 ).

-

-

5.

Protein identification

-

Search the spectrum files acquired over the entire run with Proteome Discoverer v1.4, using SEQUEST or Sequest HT as algorithms, or v1.4, using SEQUEST (see Note 32 ).

-

Set the following parameters in SEQUEST or Sequest HT: database UniProtKB/Swiss-Prot; enzymes used: rLysC (full), chymotrypsin (full), each with maximum two missed cleavages; precursor mass tolerance of 10 ppm; fragment mass tolerance of 0.6 Da; methionine oxidation as dynamic modification and carbamidomethylation on cysteine set as static modification.

-

Perform a decoy database (with reversed sequences) search using a target false discovery rate (FDR) of 0.1 % to eliminate the false positive results from the search (see Note 33 ).

-

The protein sequence obtained is displayed in Fig. 2e.

-

3.2.5 hEya3 Tyrosine Phosphatase Assays

-

1.

Enzyme preparation: thaw an aliquot of hEya3 phosphatase on ice and then centrifuge at 4 °C and 20,000 × g for 20–25 min and carefully transfer the protein solution to a new Eppendorf tube. Determine the protein concentration using Bradford assay kit.

-

2.

Phosphatase assay using pNPP as substrate:

-

Open the spectrophotometer and set the temperature controller at 37 °C.

-

Prepare 100 mM pNPP stock (see Note 34 ) and 5× pNPP assays buffer (see Note 35 ), keep both on ice. In a disposable cuvette pipette 40 μL of 5× pNPP assay buffer, X μL of 100 mM pNPP (see Note 36 ) and MilliQ water to the 195 μL final volume. Prepare also a cuvette for blank (use instead of enzyme solution the same amount of enzyme storage buffer). Incubate the reaction mixtures for 5 min in spectrophotometer (allow to reach 37 °C). Set up the “Kinetics” program on the spectrophotometer. Measure the blank. Add 5 μL of hEya3 enzyme solution (0.122 mg/mL), mix well, and begin measuring the reaction immediately, for 5 min. Make sure the ΔA 405 vs. time stays linear. The spectrophotometer will display a slope, but it may be incorrect if the rate is not constant! Note the slope in your lab book. Follow the same procedure for all concentrations of pNPP. The initial rate values ΔA 405/min (calculated from the linear portion of the progress curves) are converted into concentration of product per min (mM−1 min−1) using the molar extinction coefficient of the reaction product pNP. Next, the values are plotted against the corresponding substrate concentrations and the steady-state constants K m and k cat can be obtained using different methods (see Subheading 3.2.6).

-

Determine the molar extinction coefficient for pNP (the product formed), which depends on both assay buffer and equipment used. Prepare different concentrations of pNP, ranging from 0 to 0.1 mM in the same assay buffer and read the absorbance at A 405. Plot the values obtained vs. the concentrations of pNP used .

-

-

3.

Phosphatase assay using DiFMUP as substrate:

-

Open the microplate reader and set the temperature controller to 25 °C. Create a kinetic measurement protocol, setting the parameters: filters Ex/Em 360/460, Gain 1955 (depends on the instrument used), 70 reading cycles (10s per cycle, ten flashes per well per cycle), and set to shake plate 5 s before reading.

-

Prepare 1 mM DiFMUP in assay buffer (see Note 37 ), keep it on ice.

-

The reactions are done in a 96-well black microplate. For each substrate concentration use three wells, one for the blank and two for enzyme reactions. Pipette X μL DiFMUP (depending on the substrate concentration made), then add assay buffer to 97.5 μL. Incubate the plate in microplate reader for 5 min to reach 25 °C, take out the plate and add 2.5 μL of hEya3 phosphatase (0.122 mg/mL) (see Note 38 ). Insert the plate and run the kinetic protocol immediately (see Note 39 ). Initial velocity values measured in fluorescence per minute (RFU/min) are converted into concentration of product per minute (μM/min) using the extinction coefficient calculated for DiFMU.

-

The extinction coefficient for DiFMU is calculated using known amounts of DiFMUP and DiFMU (Fig. 3a) (see Note 40 ). Plot the fluorescence intensity versus μM of DiFMU and the steady-state constants K m and k cat can be obtained using different methods (see Subheading 3.2.6).

Fig. 3 Determination of the kinetic parameters of hEya3 phosphatase assay using DIFMUP as substrate. (a) Standard series of DiFMU/DiFMUP solutions used for DiFMU Standard Calibration Curve. (b) DiFMU Standard Calibration Curve. (c) Michaelis-Menten plot for DiFMUP as substrate for hEya3 phosphatase. Various concentrations of DiFMUP (0–400 μM) were incubated with purified hEya3 phosphatase and substrate conversion monitored in kinetic mode using 360 nm excitation and 460 nm emission. Initial velocities (v 0) for each substrate concentration were determined and were plotted against the concentration of substrate and V max and K m were calculated using Michaelis-Menten equation in GraphPad Prism. (d) Kinetic analysis of recombinant hEya3 phosphatase on DiFMUP as substrate using Lineweaver Burk plot. (e) Kinetic analysis of recombinant hEya3 phosphatase on DiFMUP as substrate using Eadie-Hofstee plot. (f) Kinetic analysis of recombinant hEya3 phosphatase on DiFMUP as substrate using Hanes-Woolf plot

-

-

4.

Phosphatase assay using H2AX-pY142 phosphopeptide : the phosphate released in the reaction was measured using BIOMOL Green (see Note 41 ).

-

Open the absorbance reading mode of the microplate reader and set wavelength at 620 nm. Choose to read absorbance with 1 cm path length correction.

-

Prepare 1 mM peptide stock in assay buffer. Pipette different volumes of peptide, from 0 to 400 μM, in a 96-well black plate, add 5 μL of 10× assay buffer and MilliQ water to the final volume of 30 μL. Incubate plate for 5 min at 37 °C, then add 20 μL of hEya3 enzyme (the enzyme was diluted in the reaction buffer to 0.034 mg/mL) and further incubate plate at the same temperature. After 40 min add 100 μL BIOMOL Green and reactions are further incubated 30 min at room temperature. Finally, read the absorbance at 620 nm.

-

Prepare a standard curve using the phosphate standard supplied with the BIOMOL Green kit according to the manufacturer instructions.

-

The steady-state constants K m and k cat can be obtained using different methods (see Subheading 3.2.5).

-

3.2.6 Determination of Kinetic Parameters of hEya3 Phosphatase

Exemplification of kinetic parameters determination on a set of data collected from DiFMUP phosphatase assay.

-

1.

Plot the standard curve: the fluorescence intensity (RFU at Ex360/Em460) of standard series of DiFMU/DiFMUP solutions is measured and the calibration curve is generated by plotting concentration (μM) of the standard series vs. RFU (Fig. 3b). Standard curve fits the linear equation: y = mx in which y = fluorescence intensity (RFU), x = concentration, and the slope is the extinction coefficient for DiFMU.

-

2.

For each substrate concentration record the product formed over time, subtract the blank (reaction containing only DiFMUP , no enzyme), and determine the initial slope of RFU time-dependence curve (RFU/min). Divide the RFU/min to the extinction coefficient of DiFMU (in our case 36,810 RFU/μM) thus obtaining the initial reaction rates v 0 (μM of product/min). Divide to 60 to convert μM/min to μM/s (Table 1). For each substrate concentration perform reactions in duplicate. Duplicate values are mentioned in Table 1.

Table 1 Data collected when DiFMUP is used as substrate for hEya3 phosphatase. Values of the slope of RFU time-dependence curve and of the corresponding initial rates for two replicates are mentioned -

3.

Graphical procedures for estimation of kinetic parameters (K m, and k cat ). All graphs were created using GraphPad Prism software:

-

Nonlinear regression procedures based on initial rate dependence (v 0) on substrate concentration [S] (Fig. 3c) (see Note 42 ).

-

Lineweaver Burk representation (Fig. 3d): 1/v 0 versus 1/[S]

-

Eadie-Hofstee representation (Fig. 3e): v 0 versus v 0/[S]

-

Hanes-Woolf representation (Fig. 3f): [S]/v 0 versus [S]

-

All four types of representation give roughly similar results, but nonlinear regression procedure is preferred because no data transformation is required.

3.3 Extracellular Domain of PTPBR7 (Ecto-PTPBR7)

3.3.1 Cell Culture

-

1.

We usually use HEK293T and HEK293S-GnTI- cells that are easy to transfect, produce a high amount of recombinant protein, and are economically efficient. The HEK293S-GnTI−cells [6] are deficient in N-Acetylglucosaminyltransferase I and consequently do not produce complex N-linked glycans.

-

2.

Cells grown in 175 cm2 flasks were used to seed the roller bottles.

-

3.

Remove the medium from one flask of 175 cm2 with a 25 mL serological sterile pipette, in a way that no medium remains in the flask and the cells are not disturbed.

-

4.

Wash two times with 10 mL of PBS, remove the PBS and discard it (see Note 43 ).

-

5.

Add 5 mL Trypsin/EDTA to the cells and incubate for maximum 5 min at room temperature.

-

6.

Dislodge the cells by tapping the flask gently.

-

7.

Add 21 mL of complete medium (DMEM with Glutamax, NEAA, 10 % FCS).

-

8.

Pour 200 mL of complete medium into a fresh roller bottle, using the measure on the side of the roller bottle to estimate the amount.

-

9.

Tap the 175-cm2 flask several times so that no cell clumps are present in the solution and transfer all the cells to the roller bottle. Place the roller bottle into the rolling incubator at 0.8 rpm at 37 °C for 3–4 days for the cells to reach about 90 % confluence.

3.3.2 Large-Scale Transfection

-

1.

For a successful transfection a high-quality plasmid DNA, without endotoxins, is necessary. Plasmid DNA is purified from a bacterial culture grown overnight, initially transformed with pHLsec-Ecto-PTPBR7 vector.

-

2.

Large-scale cultures for protein production are performed in expanded surface polystyrene roller bottles.

-

3.

Transfection cocktail: 0.5 mg of Endotoxin-free plasmid DNA is required/2125 cm2 roller bottle.

-

4.

Add 80 μL of chloroform to 1 mL of plasmid DNA and vortex (to remove the contaminants).

-

5.

Centrifuge for 10 min at 13,000 × g and take off the DNA leaving behind the chloroform.

-

6.

For each roller bottle add 0.5 mg of chloroform treated plasmid DNA into 50 mL serum-free media in a separate tube and mix well.

-

7.

Add 0.75 mL of PEI (1 mg/mL) to the serum-free media with plasmid DNA, mix well and incubate at room temperature for about 15 min for the complex to be formed. The resulting mixture is termed “transfection cocktail.”

-

8.

After 3 days of culture, remove by pouring the medium from the roller bottles.

-

9.

Add 200 mL of serum-reduced medium (DMEM with Glutamax, NEAA, 2 % FBS) into each roller bottle.

-

10.

Add into each roller bottle, in this order, 0.25 mL of kifunensine (inhibitor of the mannosidase I enzyme), 5 mL of HEPES 1 M, and 50 mL of transfection cocktail.

-

11.

Place the roller bottle back in the incubator at 37 °C at 0.8 rpm for 3–4 days (this is dependent on the state of the cells, if they start to detach, it is time to collect the media).

-

12.

4 days post-transfection collect the conditioned medium in which secreted protein of interest is present and purify it in order to obtain pure protein.

-

13.

The collected medium is centrifuged at 3500 × g for 10 min at 4 °C to separate the detached cells from the media, and then filtered using 0.2 μm membrane filters to remove the leftover debris.

-

14.

This medium is diluted threefold with ice-cold PBS and adjusted to pH 8 by adding 1 M Tris buffer pH 8.0.

3.3.3 Protein Purification

-

1.

Immobilized metal ion affinity chromatography (IMAC):

-

Nickel-coated chelating Sepharose beads, previously washed and equilibrated with PBS, are added to the filtered conditioned medium (from Subheading 3.3.2, steps 13 and 14).

-

The protein is allowed to bind to the beads by incubating in an orbital shaker at 120 rpm at 16 °C for about 90 min.

-

The suspension of beads and conditioned medium is loaded into an empty column.

-

The beads are washed with 50 mL Sepharose washing buffer 1, followed by a second wash with 50 mL of Sepharose washing buffer 2 in order to remove nonspecific proteins that are bound to the beads.

-

The protein is eluted in 15 mL of Elution buffer, and the eluted samples are analyzed by 12 % SDS-PAGE and fractions containing the protein of interest (Fig. 4a) are collected for further purification (step 2).

Fig. 4 Analysis of expression and purification of PTPBR7 . (a) SDS-PAGE analysis of the samples of IMAC purification of PTPBR7 . Me conditioned medium, MD medium after dilution, W1 wash1, W2 wash2, M marker, E1 elution1, E2 elution2, E3 elution3, E4 elution4, B beads after elution. (b) Gel filtration elution profile of ecto PTPBR7 (left) and peak fractions of gel filtration profile of ecto PTPBR7 visualized on a 12 % SDS-PAGE (right). (c) Western Blot analysis of deglycosylation of purified PTPBR7 by PNGase. M marker, UN PNGase untreated, T PNGase treated

-

Proteins samples pooled after IMAC are partially deglycosylated with endo-H enzyme, before the next round of purification. The protein samples are diluted twofold with PBS and 50 μL (1.2 mg/mL) of endo-H enzyme is added to it and incubated overnight at room temperature.

-

-

2.

Size exclusion chromatography:

-

Prepare Superdex 75 10/300 GL column: connect the column to the system (see Notes 20 and 21 ).

-

The samples containing the protein of interest are pooled and concentrated to 250 μL using membrane filter Centricon Plus-70 Centrifugal filter unit 10-kDa, according to manufacturer’s instructions.

-

Inject the concentrated protein and collect the fractions (0.8 mL/min) (proceed as in Subheading 3.1.2, step 5).

-

Analyze the fractions by 12 % SDS-PAGE.

-

The PTPBR7 purified protein showed multiple lower bands to the expected molecular weight of 24 kDa (theoretical MW of nonglycosylated protein) (Fig. 4b, right). The N-glycosylation prediction site NetNGlyc server predicted only one glycosylation site. Deglycosylation with PNGase F was done to see if all the bands collapsed to lesser number of bands post-deglycosylation.

3.3.4 Deglycosylation of Protein

-

1.

Purified protein sample was denatured with glycoprotein denaturing buffer at 100 °C for 10 min. This was then mixed with reaction G7 buffer (50 mM sodium phosphate pH 7.5), 1 % NP40 and PNGase F and incubated at 37 °C for 1 h. Both G7 buffer and NP40 are provided with the commercial PNGase F preparation. Samples were analyzed by western blot (semidry transfer on PVDF membrane, PentaHis monoclonal primary antibody, followed by the appropriate secondary antibody).

The Western blot showed a small shift in all bands, but the bands did not collapse into a single band. Therefore, it can be speculated that PTPBR7 is somehow susceptible to proteolytic cleavage during the large-scale production of the protein (Fig. 4c).

4 Notes

-

1.

We used the following vectors: (a) pHAT2-hEya3—containing 6×His-tagged human Eyes absent 3 (hEya3) gene; and (b) pGEX-KT-hRPTPμD1—containing the gene fragment encoding for the D1 catalytic domain (residues 818–1190) of human receptor-like protein tyrosine phosphatase μ (RPTPμ) tagged with glutathione S-transferase (GST) .

-

2.

We used calcium competent cells: (a) BL21(DE3)RIL strain for 6×His-hEya3; and (b) DH5α for GST-hRPTPμD1 protein expression. Competent bacteria cells can be either prepared in the lab or purchased from a biotech company.

-

3.

To prepare LB plates weigh 15 g agar (Bacto) and add to 1 L with LB. Autoclave 20 min at 120 °C. Then, allow medium to cool or cool it with cold water until bottle can be held in hands without burning, then add 1 mL Amp stock solution (100 mg/mL), mix by gentle swirling, and put ~20 mL into each sterile Petri dish (100 mm diameter). Hold plates at room temperature until agar solidifies, then invert them to avoid condensation on lid of plates and store at 4 °C until usage (no more than 1 month).

-

4.

pHLSec, kindly provided by R. Aricescu, is a mammalian expression vector designed to obtain a high yield of secreted protein [7].

-

5.

PEI is extremely viscous liquid which cannot be pipetted. To prepare the PEI solution first tare an empty flask, put some PEI with a spatula into the empty flask and weigh the flask again. Add the calculated volume of water to reach the indicated concentration of PEI solution. Stir it until completely dissolved.

-

6.

All buffers for FPLC-purification must be degassed 10 min using an ultrasonic bath and cooled at 4 °C before usage.

-

7.

Running gel and stacking gel buffers can be kept at 4 °C not longer than about 3 month. Ammonium persulfate solution can be either freshly prepared or can be frozen in single-use aliquots at −20 °C.

-

8.

You can change methanol with ethanol (96–100 %), to avoid methanol toxicity. Using ethanol for activation of PVDF membrane and for preparation of transfer buffer we obtained similar results as in the case of methanol.

-

9.

It is very important to make this stock solution in cold distilled water; otherwise it is very quickly hydrolyzed to pNP. We currently use 40 mg tablets of Phosphatase substrate from Sigma-Aldrich.

-

10.

It is very important to keep this buffer phosphate -free; therefore, we usually prepare it in sterile plastic tubes.

-

11.

Add 50 % DMSO in water over the phosphopeptide , allow 5 min to dissolve, then add TBS buffer.

-

12.

Manipulate the competent cells in sterile area, either in a bacterial hood or close to a flame. Using this short heat-shock transformation protocol we obtain enough colonies on plate to be further used in protein expression.

-

13.

Do not keep the culture more than 16 h at 37 °C.

-

14.

A dilution of 1:50–1:100 of the overnight starter culture into fresh LB-Amp medium is optimal for bacterial growth. The volume of the culture flask should be at least three times higher than the volume of the media. For example, in a 5 L flask add no more than 1.5–1.6 L medium.

-

15.

To measure the OD600 nm we use disposable plastic cuvettes and a standard spectrophotometer/colorimeter. We read OD600 nm of 1 mL of culture with LB medium as a background blank.

-

16.

The culture must be cooled at 25 °C prior to IPTG addition in order to obtain a good yield of soluble protein.

-

17.

It is important to homogenize well the bacterial pellet in lysis buffer; otherwise the disruption of the bacterial cells will not be efficient.

-

18.

Lysis is complete when the cloudy cell suspension becomes translucent.

-

19.

It is important to add glycerol to the protein samples before freezing to preserve protein stability.

-

20.

Before connecting any column to the ÄKTA system it is very important to check whether all parameters are within column specifications; otherwise the column may be damaged.

-

21.

Connecting and detaching of the column has to be performed at a low flow rate (0.5 mL/min).

-

22.

Make aliquots sufficiently small so that they should not be freeze-thaw cycled more than three times. Repeated freezing and thawing can cause protein inactivation. We typically make aliquots of 250–300 μL.

-

23.

Coomassie staining solution can be reused several times.

-

24.

Activate the PVDF membrane by soaking into methanol or ethanol for 2 min at room temperature. Then equilibrate the membrane in 1× Transfer buffer.

-

25.

For the first 2 ml of supernatant passing through the column use a reduced flow rate (0.25 mL/min) and then increase it gradually to 5 mL/min.

-

26.

Running on ethanol usually increases the back pressure of the column, so for this final step decrease flow rate to 0.5 mL/min.

-

27.

Check the pH of the solution before performing the digestion. The pH should be between 7 and 9 for the protease to have maximum enzyme activity.

-

28.

After incubation with rLysC keep the sample at 4 °C, until incubation with chymotrypsin.

-

29.

Before digestion with chymotrypsin, dilute the sample with 50 mM Tris–HCl pH 8 so that the final concentration of urea is less than 1 M and the DTT concentration is less than 10 mM in sample volume.

-

30.

Set pipettor to 100 μL then secure the pipette tip tightly to the end of the pipettor for optimum sample aspiration. Do not introduce air through the membrane at any time during the procedure.

-

31.

For our instrument we set the following parameters: LC method—40 min linear gradient of 2–30 % mobile phase B; LTQ-Orbitrap method, Scan Event details: initial survey MS scan between 300 and 1800 m/z at a resolution of 60,000 at m/z 400 (in the Orbitrap), followed by a data-dependent analysis of the five most intense peaks from the survey scan with +2, +3, and +4 charge using CID (Collision-Induced Dissociation) fragmentation method. Make at least two technical replicates from one sample (two consecutive runs).

-

32.

Separately search each run (technical replicate) to reveal protein identification.

-

33.

Assign a positive identification of a protein when there are at least two unique peptides with high confidence (99 %) present in the sample.

-

34.

100 mM pNPP stock can be stored at −20 °C in single-use aliquots.

-

35.

All assay buffers are stored at −20 °C in 10 mL aliquots. 5× pNPP assay buffer is prepared fresh from 10× assay buffer and is supplemented with 25 mM DTT.

-

36.

pNPP final concentration in the assay varies from 0.5 to 30 mM.

-

37.

DiFMUP solution is very sensitive to light, so either use a black Eppendorf tube or cover one with tinfoil. Make up fresh daily.

-

38.

First add enzyme storage buffer in blank well and then add enzyme in reaction wells.

-

39.

Do not forget to subtract the values corresponding to the blank wells from those corresponding to the reaction wells.

-

40.

For the standard curve of DiFMU, prepare 100 μM solution of both DiFMUP and DiFMU in assay buffer. We usually prepare 400 μL of each standard point in a tube, then split in three wells.

-

41.

For this phosphatase assay method it is very important to check all reaction components, including enzyme solution, for phosphate contaminants. Pipette the maximum amount of each component of reaction; add MilliQ water to 50 and 100 μL of BIOMOL Green. Read the absorbance at 620 nm and compare with blank, which contains 50 μL water. Free phosphate present on labware and in reagent solutions will greatly increase the background absorbance of the assay.

-

42.

To determine the k cat parameter the value obtained for V max has to be divided to the enzyme concentration used in assay.

-

43.

To keep the cells in the flask, washing should be performed by adding PBS on the opposite side of the flask without disturbing the cells.

References

Eckhart W, Hutchinson MA, Hunter T (1979) An activity phosphorylating tyrosine in polyoma T antigen immunoprecipitates. Cell 18:925–933

Ushiro H, Cohen S (1980) Identification of phosphotyrosine as a product of epidermal growth factor-activated protein kinase in A-431 cell membranes. J Biol Chem 255:8363–8365

Tonks NK (2013) Protein tyrosine phosphatases—from housekeeping enzymes to master regulators of signal transduction. FEBS J 280:346–378

Alonso A, Sasin J, Bottini N et al (2004) Protein tyrosine phosphatases in the human genome. Cell 117:699–711

Lee H (2015) Mining the function of protein tyrosine phosphatases in health and disease. Semin Cell Dev Biol 37:66–72

Reeves PJ, Callewaert N, Contreras R, Khorana HG (2002) Structure and function in rhodopsin: high-level expression of rhodopsin with restricted and homogeneous N-glycosylation by a tetracycline-inducible N-acetylglucosaminyltransferase I-negative HEK293S stable mammalian cell line. Proc Natl Acad Sci U S A 99:13419–13424

Aricescu AR, Lu W, Jones EY (2006) A time- and cost-efficient system for high-level protein production in mammalian cells. Acta Crystallogr D Biol Crystallogr 62:1243–1250

Acknowledgments

This work was financially supported by the Romanian National Council for Higher Education Research (PN-II-ID-PCE-2011-3-0743, PN-II-PT-PCCA-2011-79/2012 (THERION) and PN-II-ID-PCCE-2011-2-0024), Programme Human Resources Development (POSDRU/89/1.5/S/60746) (SES, MM and GP), “CERO—Career profile: Romanian Researcher” project (POSDRU/159/1.5/S/135760) cofinanced by the European Social Fund for Sectoral Operational Programme Human Resources Development 2007–2013 (AEI), The European Commission (project P-CUBE-227764) (MM, GP) and in part by European Research Community Funds to PTPNET (MRTN-CT-2006-035830) (S.E.S. and S.T.M.).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media New York

About this protocol

Cite this protocol

Mentel, M., Badea, R.A., Necula - Petrareanu, G., Mallikarjuna, S.T., Ionescu, A.E., Szedlacsek, S.E. (2016). Expression, Purification, and Kinetic Analysis of PTP Domains. In: Pulido, R. (eds) Protein Tyrosine Phosphatases. Methods in Molecular Biology, vol 1447. Humana Press, New York, NY. https://doi.org/10.1007/978-1-4939-3746-2_3

Download citation

DOI: https://doi.org/10.1007/978-1-4939-3746-2_3

Published:

Publisher Name: Humana Press, New York, NY

Print ISBN: 978-1-4939-3744-8

Online ISBN: 978-1-4939-3746-2

eBook Packages: Springer Protocols