Abstract

High pressure processing is an alternative to thermal treatment for the production of safe meat and meat products which retains quality and freshness. Due to its effectiveness and acceptability by consumers, a considerable number of meat companies worldwide apply this technology to extend the shelf life of a wide variety of meat products without using chemical additives. Research studies have shown that the inhibitory effect of HPP on microorganisms depends on both the cycle parameters (especially pressure intensity and holding time) and the physicochemical characteristics of the meat product. While low water activity decreases the inhibitory effect of HPP, acidity and the combination of HPP with other factors such as natural preservatives enhance it. In addition to the inactivation of microorganisms, HPP can also affect the appearance, flavor, and texture of meat products. The extent and importance of these changes ultimately determine the commercial suitability of HPP for use on food products.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

High pressure processing (HPP) facilitates the improvement of the microbial safety of meat and meat products (Cheftel 1995; Cheftel and Culioli 1997; Hugas et al. 2002). Also known as cold pasteurization , HPP is often presented as the main alternative, with good consumer acceptability (Baron et al. 1999; Nielsen et al. 2009), to thermal pasteurization of meat products. The main objectives in industrial HPP are to destroy the pathogenic and spoilage microorganisms and to extend shelf life, while maintaining the characteristics and the quality of meat and meat products almost intact (Balasubramaniam et al. 2008). In some cases, as in dry-cured meat products, HPP is the only feasible pasteurization process which has minimal effects on appearance, flavor, texture, and nutritional value (Hugas et al. 2002). Nonetheless, different effects of HPP on meat and meat products, other than microbial inactivation, have been studied and described by many authors, as reported in numerous reviews (Cheftel and Culioli 1997; Dumoulin and Hayashi 1998; San Martín et al. 2002; Suzuki et al. 2006; Rastogi et al. 2007; Norton and Sun 2008; Sun and Holley 2010; Zhou et al. 2010).

2 Microbiological Aspects

2.1 High Pressure and Hurdle Technology

Hurdle effect refers to the concept of controlling the growth of spoilage or pathogenic microorganisms by combining in series, or parallel, a number of intrinsic and/or extrinsic factors which individually would not be adequate. In the food industry, this has led to the application of hurdle technology, where the survival of microorganisms is greatly decreased when they are confronted with multiple antimicrobial factors such as temperature, water activity (a w), pH, and redox potential (Leistner and Gorris 1995). With the aim of reducing the extent of processing and due to demand for lightly processed or fresh-like products , new hurdles such as high pressure processing and combinations of hurdles are applied to obtain safe value-added food products.

A great number of studies have shown that HPP improves the safety of raw meat and various other kinds of meat products (Table 26.1 ); the success of this technology is confirmed by the fact that pressurized meat products are commercially available in the USA, Europe, and Japan (Table 26.2 ). However, it has also been shown that the intrinsic properties of the meat products used highly influence the effectiveness of this technology. While high inactivation rates have been demonstrated in raw and cooked meat products, a baroprotective effect has been observed in dry-cured meats. As shown in Table 26.3 , inactivation of L. monocytogenes after high-pressure (HP) treatments at a similar level is higher in cooked ham than in some other dry-cured meat products (dry-cured ham and fermented sausages). In contrast, during refrigerated storage, the recovery and growth of survivors is prevented or delayed by the presence of hurdles such as low a w, acidity, or bacteriocins (Leistner and Gorris 1995; Aymerich et al. 2005; Jofré et al. 2010).

Currently, HP treatments of up to 600 MPa are being successfully applied in the food industry. The availability of equipment able to reach pressures higher than 600 MPa is limited; therefore, research performed at those ultra-high-pressure levels is scarce. The application of 200–900 MPa treatments to L. monocytogenes, Salmonella, and S. aureus grown overnight in models of cooked and dry-cured ham showed that treatments ≥600 MPa decreased L. monocytogenes and Salmonella to levels below the detection limit (10 CFU/g), while S. aureus could be detected even after a treatment of 5 min at 900 MPa (16–18 °C) in some of the replicates (Jofré et al. 2008a). Again, dry-cured ham exerted a baroprotective effect, which could be related with stress cross-protection and interaction among hurdles (Scheyhing et al. 2004; Sagarzazu et al. 2010), and control (absence of hurdles) showed the highest recovery rates. Accordingly, even after treatments at 900 MPa, composition of the food product determines both the immediate effect of pressurization and the ability of the resulting sublethally injured cells to recover. Apart from increasing pressure intensity, inactivation can be enhanced by combination with other factors such as antimicrobials, temperature, etc .

2.2 Fresh Meat Products

Muscle tissue of healthy animals is considered to be essentially sterile. However, animals harbor large numbers of various microorganisms on body surfaces that are exposed to the environment, e.g., skin, hooves, and mucosal membranes of digestive and respiratory tracts (Paulsen and Smulders 2003) which can contaminate muscle tissues during slaughtering. Thus, hygiene is the primary factor for controlling initial microbial contamination of fresh meat surfaces, meat being a rich medium, and therefore encouraging the growth of mesophile and psychrophile microorganisms during storage and distribution.

High pressure is a decontamination method that has been described as increasing the quality and safety of fresh meat by inactivating both spoilage and pathogenic microorganisms . Since the 1990s, several studies have been performed on different types of raw meat products, and a wide variety of microorganisms, especially bacteria (pathogens and spoilers), have been shown to be significantly inactivated. In ground beef, a highly perishable derivate of fresh meat, Carlez et al. (1993) observed that pressurization above 200, 280, and 400 MPa for 20 min completely eliminated Pseudomonas fluorescens, Citrobacter freundii, and L. innocua, respectively. The highest inactivation was observed at low (4 °C) and markedly at high (50 °C) holding time temperatures. When studying the evolution of the bacteria during storage, the same authors found that microbial growth was delayed from 2 to 6 days after 200–300 MPa at 20 °C. After treatment at 400–450 MPa Pseudomonas sp., Lactobacillus sp., and coliforms were completely inactivated after HPP, but recovered after storage at 3 °C in air. When storage was performed under vacuum, only Pseudomonas recovered (after 9 days) (Carlez et al. 1994). O'Brien and Marshall (1996) also demonstrated an extension of the shelf life of raw ground chicken. Treatments at 408, 616, and 888 MPa (maximal temperatures during holding time ranged from 14.4 to 28.4 °C) showed estimated microbial spoilage times of 27 days, 70 days, and >98 days, respectively .

E. coli O157:H7 is of major concern to the meat industry. Despite improvements in farming and slaughterhouses, beef products remain a common source of outbreaks of E. coli O157:H7 in ground meat, mainly beef (Black et al. 2010). Microbiological studies performed to date have shown that HPP has potential as an additional hurdle for ensuring the safety of ground beef. Gola et al. (2000) showed immediate reductions up to 5 log units by pressure treatments up to 700 MPa at 15 °C in raw minced meat. In ground beef, Morales et al. (2008) compared inactivation by single and multiple-cycle treatments of 400 MPa at 12 °C and demonstrated higher lethality for the latter for the same total length of treatment. For example, to achieve a reduction of 4.4 log CFU/g, a single cycle of 20 min or four 1 min cycles was necessary. More recently, Black et al. (2010) compared the effect of pressurization at 400 MPa for 10 min at −5 or 20 °C and storage at the same temperatures in ground beef. They concluded that the highest reductions in the levels of E. coli O157:H7 (3 log CFU/g) were achieved after pressurization at 20 °C followed by storage at −20 °C (an additional 1.5 log reduction). The authors also observed sublethal injury of the surviving cells , which were inhibited by low pH, bile salts, and mild cooking, plus an impairment of toxin production.

The HPP approach has proved to be successful in ensuring the safety of other fresh products apart from raw meat such as pork slurries (Shigehisa et al. 1991), raw smoked pork loin (Karlowski et al. 2002), and duck liver (Cruz et al. 2003). In pork slurries, Shigehisa et al. (1991) showed that Gram-positive bacteria were more HPP resistant (treatments of 10 min at 25 °C) than Gram-negative, concretely, Campylobacter jejuni, P. aeruginosa, Salmonella typhimurium, and Yersinia enterocolitica which were inactivated at pressures higher than 300 MPa; Escherichia coli, Saccharomyces cerevisiae, and Candida utilis at pressures higher than 400 MPa; and Micrococcus luteus, Staphylococcus aureus, and Streptococcus faecalis at 600 MPa. B. cereus spores were less than 1 log CFU/g inactivated at 600 MPa. In marinated beef loin, treatment at 600 MPa for 6 min at 16 °C (experimental process parameters estimated to be the maximum industrially acceptable according to cost and the available industrial equipment) decreased levels of total aerobics, psychrotrophs, LAB, enterobacteria, yeasts, and E. coli to levels below detection limit (1 or 2 log CFU/g). These low levels lasted for 120 days of storage at 4 °C in vacuum packaging. Pressurization also eliminated the presence of Salmonella and Listeria monocytogenes which were found in several of the beef loin samples (Garriga et al. 2004). In a subsequent study, the same authors artificially contaminated marinated beef loin with ca. 3.5 log CFU/g of food-borne pathogens L. monocytogenes, Salmonella enterica, S. aureus, Y. enterocolitica, and C. jejuni, spoilage lactic acid bacteria (LAB), Escherichia coli, and yeast Debaryomyces hansenii. Pressurization at 600 MPa kept the levels of all studied microorganisms, except for LAB, below detection limit for 120 days of storage at 4 °C under vacuum (Jofré et al. 2009b). An increase in shelf life after HPP was also found in raw smoked pork loin treated at 600 MPa for 10 min (Karlowski et al. 2002) and duck liver treated at 550 MPa for 20 min at 55 °C (Cruz et al. 2003).

The combination of HPP with other hurdles for microbial growth such as natural antimicrobials has not been widely studied in raw meat. Yuste et al. (2000a) evaluated the combined effect of HPP with nisin or lysozyme on aerobic mesophile and psychrotroph populations of mechanically recovered poultry meat and observed enhanced inactivation when nisin and HPP were combined. In contrast, no synergism was observed between HPP and lysozyme .

2.3 Cooked Products

Pasteurization destroys vegetative spoilage organisms and food-borne pathogens. Therefore, microbiota of cooked products is mainly represented by microorganisms resulting from recontamination (Thippareddi et al. 2009). According to hurdle technology, perishability of cooked meat products will depend on their physicochemical characteristics, i.e., the number of obstacles to microbial growth they contain.

Cooked ham is a highly perishable product due to its high a w, pH close to neutrality, and the absence of competing microbiota. Once sold, sliced post-processing contamination is the greatest hazard. However, research has shown that HPP is a useful technology for inactivating food-borne pathogens and extending the shelf life of cooked ham and cooked meat products in general. Indeed, the first pressurized meat product commercialized in the world was sliced cooked ham, which was launched by the Spanish enterprise Espuña in 1998.

The effectiveness of HPP has been widely studied in sliced cooked ham. Karlowski et al. (2002) showed that application of treatments of 300–400 MPa for 10 min did not extend the shelf life of the product; 500 MPa produced a decrease in levels of total bacterial count, psychrophilic bacteria, acidophilic bacteria and Enterococci; but application of 600 MPa for 10 min was necessary to reduce the number of all investigated microorganisms by 5–6 log units and extend shelf life to 6–8 weeks. Treatment at 600 MPa for 6 min at 16 °C also demonstrated the ability to avoid growth of yeasts and enterobacteria which can potentially produce off-flavors and delay the growth of LAB as spoilage microorganisms at 4 °C (Garriga et al. 2004). Another study showed that pressurization also reduces safety risks associated with Salmonella spp. and L. monocytogenes . Treatment of sliced ham at 400 MPa for 10 min at 17 °C did not completely eliminate L. monocytogenes nor Salmonella spiked at 2.5 log CFU/g, but decreased their levels to <1 log CFU/g. During subsequent storage at 1 °C, both pathogens were inhibited. In contrast, at 6 °C, L. monocytogenes increased to 6 log CFU/g after 84 days (Aymerich et al. 2005). In a similar experiment performed at a higher pressure level (600 MPa for 5 min at 10 °C), both refrigeration temperatures inhibited the growth of pathogens, which remained absent in 25 g of product for 90 days of storage. Conversely, baroresistant S. aureus only diminished 0.9 log units after 5 min at 600 MPa, although the growth of the pathogen was prevented by refrigerated storage (Jofré et al 2008a). In another study at 600 MPa (for 6 min at 31 °C during holding time), a poor decrease of S. aureus but complete inactivation of L. monocytogenes, Salmonella, C. jejuni, and Y. enterocolitica was reported in cooked ham (Jofré et al. 2009b).

Combined application of HPP and natural antimicrobials such as bacteriocins from LAB and lactate salts has been shown to be very useful for increasing the safe shelf life of sliced cooked ham. Aymerich et al. (2005) showed that treatment of 10 min at 400 MPa (17 °C) reduced counts of L. monocytogenes from 2.7 log CFU/g to 0.7, 0.3, and 1.3 log CFU/g in the control, nisin (800 AU/g), and 1.8 % potassium lactate (3 % Purasal® P/Hi Pure 60, Purac Biochem) batches, respectively. During subsequent storage, the presence of nisin inhibited recovery of L. monocytogenes for 42 days, while lactate inhibited the pathogen during the entire storage time (84 days at 6 °C). When bacteriocins and lactate were applied through active packaging (interleavers) in slices of cooked ham inoculated with 4.5 log CFU/g of L. monocytogenes and submitted to the same HP treatment, the highest reductions (4 log units) and the lowest counts (<1.51 log CFU/g) after 3 months of storage at 6 °C were found in batches containing bacteriocins (i.e., 200 AU/cm2 of nisin, 200 and 2000 AU/cm2 of sakacin, and 200 and 2000 AU/cm2 of enterocins A and B). In contrast, application of lactate through active packaging was not effective and only moderately reduced L. monocytogenes counts, which reached levels of 6.5 log CFU/g at the end of storage (Jofré et al. 2007). In contrast to L. monocytogenes, Salmonella was completely eliminated (from 25 g of ham) by pressurization with nisin-containing interleavers (Jofré et al. 2008b). In another kind of active packaging, alginate films containing enterocins A and B, the efficiency of combining both technologies was also demonstrated using different storage temperatures. While at 1 °C the application of a HP treatment of 10 min at 400 MPa and 17 °C was enough to maintain levels of L. monocytogenes < 1.5 log CFU/g, the application of active alginate films was necessary to maintain those levels when storage was performed at 6 °C and after a cold chain break of 24 h at 20 °C (Marcos et al. 2008a). At 600 MPa, the combination of HPP with 800 AU/g of nisin, 1.8 % lactate, and nisin + lactate was more effective in the control of Salmonella and L. monocytogenes inoculated at 4 log CFU/g than at 400 MPa. After pressurization (600 MPa, 5 min, 10 °C), levels of both pathogens decreased to <1 log CFU/g and were kept at this level for 3 months at both 1 and 6 °C. However, the proportion of samples with the absence of the pathogen in 25 g of product was higher for L. monocytogenes (97.6 % of the samples) than for Salmonella (88.7 %) and even higher for control and nisin-containing ham batches than lactate. Both HPP and combined treatments were much less effective against S. aureus, although additional reduction was observed in the presence of nisin (Jofré et al 2008d). Due to the inability of S. aureus to grow at refrigeration temperatures together with the fact that at least 105 CFU/g is required to produce enough toxin to elicit symptoms (Food and Drug Administration 2003), S. aureus would not be a major concern if food products were properly refrigerated. In another cooked product, Vienna sausages, the application of HPP treatment at 600 MPa for 5 min at 28 °C applied alone resulted in only a modest decrease in the number of positive samples for L. monocytogenes 48 h after treatment. Enhanced inactivation was observed by the combination of HPP with 300 ppm of tert-butylhydroquinone (TBHQ) or 100 ppm of TBHQ plus 100 IU/g of nisin, which eliminated the pathogen from all samples (Chung et al. 2005). Thus, the combination of HPP at 600 MPa combined with antimicrobials appears to be an effective way of obtaining value-added cooked meat products with safe long-term storage life.

Pressurization has also been shown to improve the shelf life and/or safety of other meat products. Blood sausages are traditional cooked meat products popular in many parts of the world. High-pressure treatment of morcilla de Burgos, a popular Spanish blood sausage made with onion, rice, animal fat, blood, and different spices, was studied with the aim of extending shelf life, which under refrigeration and vacuum packaging is around 14–21 days. Diez et al. (2008a) showed that the application of HPP treatments of 300, 500, and 600 MPa for 10 min at 15 °C reduced enterobacteria and pseudomonads to levels below their LOD. In contrast, LAB, typical spoilage microbiota under vacuum, were only slightly reduced. After treatment at 600 MPa for 10 min at 15 °C, counts of LAB decreased 1.3 log CFU/g and shelf life was extended by 15 days (Diez et al. 2009a). This shelf-life extension was related to a reduction of bacterial populations and changes in the prevalence of LAB during storage, mainly W. viridescens and L. mesenteroides, the most intensive spoilage microorganisms in morcilla (Diez et al. 2008b, 2009a). In contrast to what occurs with L. monocytogenes in cooked ham, the combination of pressurization at 600 MPa with potassium and sodium lactate (3 % Purasal™ Lite S/6) in morcilla de Burgos did not enhance the quality of the product (spoilage reduction) when compared with HPP treatment applied alone. In vacuum-packaged cooked poultry meat, W. viridescens was found to be the dominant microorganism and no obvious signs of spoilage were observed even when counts were >7 log CFU/g. Due to its high-pressure resistance (<1 log reduction after 2 min at 600 MPa and 18 °C) and ability to inhibit Gram-positive and Gram-negative pathogens , W. viridescens could be used to extend the shelf life and microbiological safety of the product (Patterson et al. 2010).

Predictive microbiology offers various tools in the form of mathematical models that can be useful to determine inactivation or growth of microorganisms in foods. Slongo et al. (2009) developed a model of the growth of LAB during storage of vacuum-packaged sliced cooked ham processed by HPP applying Gompertz and logistic models. The main factor influencing the growth of LAB and, consequently, shelf life of the product was pressure intensity. The highest inhibition was found after application of the most severe treatment (400 MPa, 15 min, and 27 °C), which extended product shelf life (LAB levels at 107 CFU/g) from 19 days in non-pressurized slices to 85 days.

2.4 Dry-Cured Meat Products

Traditionally ripened meat products can be made from chopped meat (fermented sausages) or from whole pieces of meat (dry-cured ham) and have been produced since ancient times to extend the longevity of meat. In fermented sausages, stability i s due to acidulation caused by the production of lactic acid and a w reduction caused by the addition of salts (curing by NaCl, nitrite, and/or nitrate) and drying. In dry-cured ham, the amount of NaCl is higher than in sausages and the main hurdle to microbial growth is low a w. However, traditional manufacturing practices cannot assure the elimination of meat-borne pathogens; the application of high pressure processing appears to be a nonthermal processing technology that improves the safety of such products without affecting sensory quality.

2.4.1 Fermented Sausages

Fermentation is a widely used preservation method in which microorganisms change the sensory and functional properties of meat products. Fermented sausages often have a long shelf life, but traditional manufacturing practices cannot assure the elimination of meat-borne pathogens such as S. aureus, L. monocytogenes, Salmonella, and verotoxigenic E. coli from the final product, especially in low-acid and semidry sausages.

Porto-Fett et al. (2010) demonstrated the effectiveness of HPP applied after fermentation and drying to inactivate L. monocytogenes, E. coli O157:H7, and Salmonella spp. (inoculated at 7 log CFU/g of batter) in four types of Genoa salami differing in casing diameter (65 and 105 mm) and a w produced with trichinae-infected pork. After fermentation the pH of the salamis decreased to 4.6–4.8 and pathogen levels decreased, but were not eliminated from any of the salamis. The lowest levels were for Salmonella (around 2.2 log CFU/g) and the highest for L. monocytogenes (6 log CFU/g in 105 mm diameter casings). Pressurization at 483 MPa for 12 min and 600 MPa for 5 min at 20 °C completely eliminated Salmonella and E. coli O157:H7, while L. monocytogenes reductions ranged from 2 to 6 log units depending on the type of salami. During subsequent storage of 28 days at 4 °C, Salmonella remained absent in all replicates and E. coli O157:H7 in the majority of the replicates. L. monocytogenes only was completely eliminated when treated for 5 min at 600 MPa from the salami with the lowest pH (4.7). However, HPP proved to be useful as a post-process intervention to meet performance standards and/or compliance guidelines for the three pathogens and appeared as an alternative method to heating, curing, or freezing to eliminate Trichinella spiralis. The effect of HPP at 600 MPa for 3, 6, and 9 min (at ambient temperature) on the inactivation of E. coli O157:H7 was also tested in two types of salami: Hungarian (pork meat, pH 4.8, and a w 0.927) and All Beef, less acid (pH 6.3) and with higher a w (0.968). HPP reduced E. coli levels on both salamis by more than 4 log CFU/g. During storage at 15 °C, the numbers of E. coli O157 increased on All Beef salami, but remained static on the Hungarian salami, which had a restrictive pH and a w ( Gill and Ramaswamy 2008).

In slightly fermented sausages, typically produced in Mediterranean countries and characterized by a relatively high pH, microorganisms contaminating raw materials (pathogens and aminogenic bacteria) might not be totally inhibited during the manufacturing process and can compromise the safety and stability of the final product. The application of HPP before fermentation was an additional hurdle to control Salmonella but had a negative effect on L. monocytogenes due to inactivation of endogenous LAB and consequent delay in pH drop (Marcos et al. 2005). In contrast, pressurization after ripening produced better results at both sensory and microbiological levels . However, treatments of 400 MPa (for 10 min at 17 °C) applied alone were not enough to completely eliminate L. monocytogenes, and the combination of HPP with the use of starter cultures was necessary to eliminate L. monocytogenes and Salmonella, to control enterobacteria and Enterococci, and to reduce the content of biogenic amines in the final product (Garriga et al. 2005; Marcos et al. 2007). The combination of HPP with bacteriocins (enterocins A and B and enterocin AS48) also proved to be useful in reducing L. monocytogenes and Salmonella spiked at 3 log CFU/g to levels ≤ 1 log CFU/g during storage under refrigeration but especially during storage at room temperature where decrease of a w was higher. These hurdles could not decrease the levels of S. aureus, a baroresistant and low a w-tolerant bacterium (Jofré et al. 2009a; Ananou et al. 2010). Given the capacity of certain pathogenic bacteria to survive in low-acid fermented sausages, selection of high-quality raw materials and good manufacturing practices are crucial.

2.4.2 Dry-Cured Ham

Whole-muscle dry-cured meat products , such as dry-cured ham, have pH values close to neutrality, and low a w is the main hurdle for the growth of spoilage and pathogenic microorganisms. In dry-cured ham, the inhibitory effect of HPP has been shown to vary depending on a w of the product. Morales et al. (2006) compared inactivation of L. monocytogenes in Iberian and Serrano ham by treatment at 450 MPa for 10 min at 12 °C and observed higher inactivation in Iberian ham (a w = 0.904 and 1.5 log unit decrease) than in Serrano ham (a w = 0.880 and 1.16 log decrease). The authors attributed these differences to the higher concentration of NaCl and lower fat content of Serrano ham. Another study demonstrated that after treatment at 600 MPa for 6 min at 16 °C (31 °C during holding time), sensory freshness of sliced dry-cured ham was maintained due to reduction of aerobic bacteria from 4.8 to 2.1 log CFU/g and diminution of psychrotrophs, LAB, and yeasts to levels below plate detection limit. During 120 days of storage at 4 °C, populations maintained similar levels (Garriga et al. 2004). Furthermore, when dry-cured ham was spiked with a wide range of pathogenic and spoilage microorganisms (i.e., L. monocytogenes, Salmonella, S. aureus, Y. enterocolitica, C. jejuni, LAB, E. coli, and D. hansenii) and treated at 600 MPa for 6 min at 31 °C during holding time, all microorganisms decreased to below the limit of detection (3–4 log unit reduction) with the exception of S. aureus and LAB, which decreased only 0.5 and 1.6 log CFU/g, respectively. During 120 days of storage at 4 °C, both pressurized and non-pressurized microorganisms remained at the same level (Jofré et al. 2009b). Recently, modeling of HPP inactivation of L. monocytogenes in dry-cured ham has shown that pressure time and intensity, but not temperature (in the range of 2.3–24.4 °C), influence inactivation of the pathogen. According to the validated model, treatment of 807 MPa for 5 min would be necessary to attain the 6D reduction recommended by the US Government for RTE products. However, given the inability of L. monocytogenes to grow in dry-cured ham, in addition to the assumed levels of post-processing contamination of 10 CFU/g, Hoz et al. (2008) proposed a 2.39D process to meet the US zero tolerance policy , which requires, according to the model proposed, treatment of 613 MPa for 5 min (Bover-Cid et al. 2011).

As shown for other meat products, combination of HPP with bacteriocins increases the inhibitory effect of HPP in dry-cured ham. Application of sakacin K, enterocins A and B, and especially nisin together with HPP treatment of 600 MPa for 5 min at 15 °C eliminated Salmonella and L. monocytogenes spiked at 3.5 log CFU/g and decreased S. aureus to <1 log CFU/g in the batch containing nisin. During storage at temperature of abuse (15 °C), none of the pathogens recovered (Jofré et al. 2008c).

In conclusion, from a microbiology point of view, the main goal of HPP in the food industry is to ensure absence or low levels of pathogens and spoilage microorganisms in foods at the time of consumption. In meat products, HPP appears to be a promising technology which is already used by companies and accepted by consumers. Intrinsic and extrinsic factors associated with each meat product result in high- and low-risk products and determine levels of microbial inactivation by HPP and growth during storage. Thus, research efforts are needed to generate realistic data and to determine which combinations would be more effective to ensure destruction of food-borne pathogens in a wide variety of optimal quality meat products . At the same time, development of cost competitive industrial equipment able to reach pressure intensities higher than 600 MPa is necessary .

3 HPP Effects on Color, Texture, and Other Quality Characteristics

3.1 Raw Meat

In the last 15 years, the HPP effect on the color of raw minced beef, pork, and poultry meat and whole muscles has been studied by many authors. The main reason for this interest is because the most frequent visible effect of HPP on raw meat is a dramatic color change , i.e., meat discoloration, due to protein denaturation caused by the pressure increase necessary to reach microbial inactivation (i.e., >400 MPa). Many studies have focused on the HPP effect on meat color as the main aim of their investigation (Carlez et al. 1995; Goutefongea et al. 1995; Jung et al. 2003), but also in many other studies the effect on color was complementary information to their main objective, i.e., effect on pathogenic and/or spoilage microorganisms and shelf-life extension , among others. In any case, most studies agree on reporting lightness *) increase with increasing pressure, whereas yellowness (b *) either increases or is not affected, and redness (a *) is the more variable and dependent on experimental design (i.e., meat species, minced or whole muscle, and HPP conditions).

3.1.1 Minced Meat Color

Minced beef from semimembranosus muscle subjected to HPP (200–500 MPa, 10 min, 10 °C) showed paler color at pressures above 200 MPa. Lightness (L *) values increased from 200 to 350 MPa, whereas redness (a *) values decreased with increasing pressure, and yellowness (b *) did not change significantly. The pH of minced meat increased with HPP from 5.55 to 5.78 (Carlez et al. 1995). Discoloration of HPP red meat is caused both by a whitening effect, probably related to globin denaturation, that would occur between 200 and 350 MPa (causing an increase in L * values and turning the red color of beef into a paler pink), and by a loss of red color between 400 and 500 MPa (causing a decrease in a * values and turning the pale pink color into a pale gray-brown) which could be attributed to the oxidation of ferrous myoglobin into ferric metmyoglobin (Carlez et al. 1995). Frozen ground beef (−15 °C) submitted to high-pressure thawing (210 MPa, 30 min, and 280 MPa, 25 min, room temperature) showed higher lightness (L *) and lower redness (a *) at 280 MPa than at 210 MPa or samples thawed in a cooler at 3 °C (Zhao et al. 1998). Fresh minced pork (m. gluteus superficialis) and beef (m. semimembranosus) meat showed brownish-grayish color after HPP (600 MPa, 30 min, 20 °C), which was consistent with significantly higher L *, a *, and b * values and oxymyoglobin oxidation to metmyoglobin (Goutefongea et al. 1995). Ground beef lean meat subjected to HPP (400 MPa, 1–20 min single cycles and multiple cycles of up to 3 × 5 min, 12 °C) showed higher lightness (L *) and yellowness (b *) values, in the exterior of beef patties, with increasing treatment length and number of cycles. Similarly, color measurements of the inner part of beef patties showed higher lightness but lower redness (a *) (Morales et al. 2008). Pressurization above 300 MPa (HPP: 200–800 MPa, 20 min, 20 °C) caused oxymyoglobin denaturation (ferric form) in post-rigor minced pork and pH increase from 5.90 to 6.06 (measured in muscle suspension) as a result of protein denaturation (Cheah and Ledward 1996). Pork loin slurries subjected to HPP (100–600 MPa, 10 min, 25 °C) showed discoloration with increasing pressure. Higher lightness (L *) and lower redness (a *) were observed above 300 MPa, whereas yellowness (b *) increased above 400 MPa (Shigehisa et al. 1991). Minced chicken thighs (HPP:500 MPa, 60 min, −10, +5, 20, and 50 °C) showed a cooked appearance (lightness increase and redness decrease) at all temperatures tested (Beltran et al. 2004). Thawed minced chicken breast mixed with spices (HPP:300, 600, and 800 MPa, 10 min, initial T = 5 °C and reaching max. T = 22.6, 40.2, and 49.7 °C, respectively) showed increased light ness and reduced redness with increasing pressure, irrespective of use of spices (Mariutti et al. 2008).

3.1.2 Whole Muscle Color

In beef biceps femoris muscle (2.5 × 2.5 × 3.0 cm samples), instrumental color parameters (L *, a *, and b *) increased significantly after HPP (520 MPa, 260 s, 10 °C) at 2 days post-mortem. However, color differences after cooking between HPP and unprocessed samples were reduced to less than one third (Jung et al. 2000). Redness (a *) values of beef biceps femoris muscle (2.5 × 2.5 × 2.5 cm samples) (HPP: 50–600 MPa, 20–300 s, 10 ± 3 °C) increased up to 350 MPa, but above this pressure started to decrease. Metmyoglobin content followed redness evolution with increasing pressure, but conversely, i.e., metmyoglobin content decreased with increasing pressure up to 300 MPa approximately and then increased up to 600 MPa. Total color difference between HPP and unprocessed meat increased significantly with increasing pressure. In concordance with these results, reflectance spectra showed that HPP meat had higher lightness than the control. However, reflectance spectra of raw HPP samples were very similar to those of the cooked control, suggesting that HPP could induce myoglobin modifications similar to cooking. Furthermore, no color differences between cooked control and raw pressurized samples after cooking were observed. Color evolution up to 4 days of storage showed higher redness in HPP meat at 130 MPa (10 °C; 260 s) than in control samples, whereas meat at 520 MPa showed lower values. In contrast, after 7 days of storage, meat at both 130 and 520 MPa showed lower redness than the control. Evolution of redness (a *) during storage was well correlated with metmyoglobin content (Jung et al. 2003). Beef semitendinosus muscle steaks subjected to HPP (100–500 MPa, 5 min, 15 ± 3 °C) showed significant lightness (L *) increase with increasing pressure above 200 MPa and up to 500 MPa. Redness (a *) decreased at 500 MPa, whereas yellowness (b *) increased above 300 MPa (Kim et al. 2007). Raw beef longissimus dorsi samples (cylinders: 2.5 cm Ø × 6.0 cm length) showed increased lightness (L *) and yellowness (b *) and reduced redness (a *) values after HPP (650 MPa, 10 min, 20 °C) with respect to the control. In contrast, HPP (650 MPa, 10 min, −35 °C) of raw beef frozen at −30 °C did not affect L * and b * parameters measured after thawing, but a * values were lower than the control. Despite the redness reduction observed, freezing would apparently protect beef meat against negative color changes, i.e., lightness increase, caused by HPP (Fernández et al. 2007). Beef longissimus dorsi muscle (2.5 × 2.5 × 3 cm samples) subjected to HPP (200–600 MPa, 20 min, 10–30 °C) showed lightness (L *) increase in all pressure × temperature combinations tested. Yellowness (b *) increased only at 400 and 600 MPa, whereas redness (a *) was not affected. However, when comparing HPP, independently from process temperature, redness reduction was observed at 600 MPa, which could be related to ferric metmyoglobin formation. The highest lightness values were observed at 400 MPa, followed by 600 MPa. Meat at 400 and 600 MPa showed the highest yellowness and total color increase values. The temperature effect, independently of pressure level, lightness, and total color increase , showed the highest values at 30 °C (Marcos et al. 2010). Beef pectoralis profundus steaks showed a higher lightness (HPP:200–400 MPa, 20 min, 20 and 40 °C) in all processes except for the mildest one at 200 MPa and 20 °C. Temperature effect, independently of pressure level, showed the highest lightness and the lowest yellowness values at 40 °C (McArdle et al. 2010). Fresh beef (m. semitendinosus) and pork (m. longissimus dorsi) submitted to HPP (200 MPa, 2.5 h, −20 °C, plus 0.5 h at 30 °C before depressurization) and pressure shift freezing (200 MPa, 2.5 h, −20 °C) showed higher lightness, redness (only in beef), and yellowness than raw samples, after overnight thawing at 20 °C, in both treatments (Fernández-Martín et al. 2000). Fresh pork loin (post-rigor) submitted to HPP (414 MPa, 9 min at 2 °C and 13 min at 25 °C) showed higher lightness (L *) and yellowness (b *) than control samples, but no redness (a *) differences. These color differences continued during storage at 4 °C up to 33 days. However, these color differences disappeared after cooking (Ananth et al. 1998). Fresh pork rib portions (cylinders: 5 cm Ø × 16 cm length) submitted to pressure shift freezing (100, 150 and 200 MPa, 3 MPa s−1, −11, −16.5, and −21.5 °C, respectively) showed increase in lightness, yellowness, and total color difference with increasing pressure, after thawing at room temperature (20 °C) (Zhu et al. 2004). Pork meat (cylinders, 3.2 cm Ø × 2.8 cm length; HPP, 600 MPa, 10 min, ambient T) showed higher lightness (L *) and yellowness (b *) and lower redness (a *) than control samples (Wackerbarth et al. 2009). Different meat species (pork, m. longissimus dorsi, turkey and chicken, m. pectoralis superficialis) showed clear color change after HPP (100–600 MPa, 1 min, 10 °C) with increasing lightness (L *) above 300 MPa (above 200 MPa in chicken) (Tintchev et al. 2010). Chicken breast fillets subjected to HPP (300–600 MPa, 5 min, 15 ± 3 °C) showed higher L *, a *, and b * values with increasing pressure. However, redness reduction was observed at 600 MPa, though it was still higher than the control (Kruk et al. 2011). In another study, chicken breast fillets submitted to HPP (400 MPa, 1–20 min single cycles and multiple cycles of up to 10 min overall, 5 °C) showed higher L *, a *, and b * values in all treatments (Del Olmo et al. 2010).

3.1.3 Texture and Other Quality Characteristics

During HPP (isostatic compression ), although no shear forces are produced, some texture changes occur as a result of the increasing pressure effect on the structure and functionality of proteins (Cheftel and Culioli 1997). Quality changes in post-rigor meat and muscle protein gelation, i.e., texture changes induced by pressurization, have been studied by different authors at both nonthermal denaturing temperatures (before reaching 30–35 °C) and in heating under pressure (thermal denaturing conditions >40 °C) (Jiménez-Colmenero 2002). Generally, HPP at non-denaturing temperatures has been reported to increase cooking loss and texture parameters such as TPA hardness and Warner-Bratzler shear force In contrast, heating under pressure (HPP) seems to decrease texture characteristics like shear force and hardness. In addition, some studies with seemingly contradictory results could probably be explained by different effects, often opposite, resulting from different combinations of pressure, temperature, and other HPP parameters.

In a nonthermal denaturing study, frozen ground beef (−15 °C) submitted to high-pressure thawing (280 MPa, 25 min, room temperature) showed higher cooking loss than conventional thawing, although no differences in penetration force were observed (Zhao et al. 1998). Ground beef lean meat subjected to HPP (400 MPa, 1–20 min single cycles and multiple cycles of up to 3 × 5 min, 12 °C) showed higher Kramer shear force and energy values than the control (Morales et al. 2008). Fresh pork loin showed no differences in moisture content, water-holding capacity, or instrumental texture (peak load) between HPP (414 MPa, 9 min at 2 °C and 13 min at 25 °C) and control samples (Ananth et al. 1998). Fresh pork (m. longissimus dorsi) and beef (m. semitendinosus) submitted to pressure shift freezing (200 MPa, 2.5 h, −20 °C) showed higher drip loss (centrifugal method) than HPP meat (200 MPa, 2.5 h, −20 °C plus 0.5 h at 30 °C before depressurization) and raw meat (Fernández-Martín et al. 2000). Beef biceps femoris (BF) and longissimus dorsi (LD) muscles (HPP:520 MPa, 260 s, 10 °C) showed higher Warner-Bratzler shear force (toughness increase) and cooking loss values than the control meat during aging (2–17 days post-mortem). HPP appeared to delay natural tenderization (i.e., shear force decrease) in both BF and LD muscles (Jung et al. 2000). Fresh pork rib portions submitted to pressure shift freezing (100–200 MPa, 3 MPa s−1, −11 to −21.5 °C) were tougher, i.e., showing higher Warner-Bratzler shear force values, than unprocessed meat (Zhu et al. 2004). Similarly, beef semitendinosus muscle steaks (HPP:100–500 MPa, 5 min, 15 ± 3 °C) showed an increase in Warner-Bratzler shear force and TPA (texture profile analysis) hardness at 500 MPa. However, a decrease in these two parameters was observed at 300 MPa. Cooking loss values increased with increasing pressure and stabilized at 300 MPa, whereas water-holding capacity decreased at 200 MPa and remained stable. The pH values (measured in muscle suspension) increased with increasing pressure above 200 MPa (Kim et al. 2007). Raw HPP beef longissimus dorsi (650 MPa, 10 min, 20 °C) showed higher expressible moisture (centrifugal method) than unprocessed meat. In contrast, air-blast frozen-HPP raw beef (650 MPa, 10 min, –35 °C) showed lower expressible moisture than raw HPP beef, indicating a freezing protective effect against HPP protein denaturation (Fernández et al. 2007). Water-holding capacity (WHC ) of beef longissimus dorsi muscle (measured as expressible moisture with a centrifugal method) decreased with increasing pressure at 400 and 600 MPa, irrespective of the process temperature (HPP:200–600 MPa, 20 min, 10–30 °C) (Marcos et al. 2010). Beef pectoralis profundus HPP steaks (200–400 MPa, 20 min, 20 and 40 °C) showed the highest cooking loss at 400 MPa and 20 °C, whereas no differences were observed at 40 °C. HPP at 300 and 400 MPa increased cooking loss and pH values irrespective of process temperature (McArdle et al. 2010). Chicken breast fillets subjected to HPP (400 MPa, 1–20 min single cycles and multiple cycles of up to 10 min overall, 5 °C) showed higher shear force values in single-cycle HPP for 10 min with increasing number of 1 min cycles (Kramer cell) and in single-cycle HPP for 15 min and in 2× 1 min (Warner-Bratzler cell). However, instrumental texture parameters in the most severe multiple-cycle HPP were similar to controls (Del Olmo et al. 2010). HPP chicken breast fillets (300–600 MPa, 5 min, 15 ± 3 °C) showed higher cooking loss and TPA hardness and chewiness at 450 and 600 MPa than unprocessed meat or at 300 MPa (Kruk et al. 2011).

In a study combining nonthermal denaturing temperatures and heating under pressure, beef longissimus dorsi muscle (HPP:200–800 MPa, 20 min, 20–70 °C) showed pH increase (between 0.06 and 0.19 units) with increasing pressure, irrespective of the temperature applied. Concerning texture, instrumental hardness (TPA) increased with increasing pressure (HPP at 20 °C) up to 400 MPa and then decreased slightly up to 800 MPa, but was still above the control values. Similar behavior was observed for HPP at 40 °C, although hardness continued to increase slightly up to 800 MPa. In contrast, HPP at both 60 and 70 °C led to hardness decrease at 200 MPa, but above this pressure hardness increased again. In general, all other TPA parameters (chewiness, cohesiveness, springiness, etc.) increased with increasing pressure at both 20 and 40 °C (Ma and Ledward 2004). Beef longissimus muscle at different aging times (1–16 days) cooked after HPP (samples pre-heated at 45 °C for 45 min before HPP: 150 MPa, 30 min, 60 °C) showed lower shear force (Warner-Bratzler) than cooked control samples. In HPP samples, shear force was very low and did not vary much throughout the aging period. In contrast, control samples showed higher values, the highest being 1 and 8 days of aging. HPP cooking loss was quite similar throughout the aging period and higher than that of the control at aging days 1 and 3 (Bertram et al. 2004). Post-rigor chicken (pectoralis fundus muscle, samples: 3 × 2.5 × 6 cm) submitted to HPP (200–800 MPa, 30 min, 20–70 °C) showed increase in TPA hardness with increasing pressure from 20 to 50 °C. The highest increase was observed between 200 and 400 MPa from 20 to 50 °C. In contrast, from 60 to 70 °C hardness increased at 200 MPa and subsequently decreased between 200 and 400 MPa, where it stabilized (Zamri et al. 2006). Post-rigor beef neck muscle (sternomandibularis; samples: 15 × 3.5 × 3.5) submitted to HPP (200 MPa, 20 min, 60 °C) showed higher pH values and lower Warner-Bratzler peak force than the raw control (Sikes et al. 2010).

With regard to sensory characteristics of meat, only a few studies have been focused on the HPP effect on flavor. Suzuki et al. (1994) studied the effects of HPP (100–400 MPa, 5 min, 2 °C) on flavor-related components in beef shoulder lean meat, concluding that HPP caused similar flavor changes to those caused during meat conditioning. Similarly, Schindler et al. (2010) studied aroma development in HPP beef sirloin and chicken breast meat (400 and 600 MPa, 15 min, 5 °C) and reported no significant changes when compared with raw and cooked meat.

3.2 Cooked and Raw Salted Meat Products

In general, HPP effect on muscle proteins and minced meat products depends on the combination of pressure, temperature, time, and product type (Jiménez-Colmenero 2002). Many studies of minced meat products have reported HPP effects on color: lightness (L *) increase with increasing pressure and, to a lesser extent, a decrease in redness (a *) and affecting yellowness (Jiménez-Colmenero et al. 1997; Carballo et al. 2000; Sikes et al. 2009). Furthermore, HPP at non-denaturing temperatures has been reported to improve texture in low-salt minced meat products by improving protein gelation and thus increasing the water-holding capacity (Iwasaki et al. 2006; Sikes et al. 2009). In contrast, heating under pressure (HPP with thermal denaturation) produces less protein denaturation than thermal treatment alone, and the resulting gel structures have improved water-holding capacity, although texture characteristics like hardness, cohesiveness, and chewiness are decreased, i.e., producing weaker gels (Jiménez-Colmenero et al. 1998b; Carballo et al. 2000; Fernández-Martín et al. 2002; Jiménez-Colmenero 2002). A compilation of studies carried out over the last 15 years on the HPP effects on the quality characteristics of processed minced meat products, i.e., sausage batters, patties, gels, and emulsions from different meat species in combination with other effects, is presented in Table 26.4 .

Cured minced beef meat (100–200 mg/kg sodium nitrite, 10 g/kg NaCl, vacuum-packaged and stored overnight at 5 °C to allow nitrosomyoglobin formation) showed higher lightness (L *) values with increasing pressure (HPP:350–500 MPa; 10 min; 10 °C) but no differences in redness (a *) and yellowness (b *). In cured meat products, nitrosomyoglobin resists the HPP-induced oxidation into ferric form. However, the HPP-induced “whitening” effect (protein denaturation) is not prevented (Carlez et al. 1995). In another study, raw sausage batter with and without NaCl and nitrites subjected to HPP (600 MPa, 20 min, room temperature) showed visual discoloration, higher lightness (L *), and lower redness (a *) than the control samples. Furthermore, discoloration was higher in HPP batters without nitrites than in HPP batters with nitrites. HPP reduced batter softness, especially in batters with salt (Farkas et al. 2002).

3.2.1 Ready-to-Eat Meat Products

Frankfurter-type sausages , elaborated with different percentages of mechanically recovered poultry meat and minced pork meat and submitted to HPP (500 MPa, 30 min, 50–75 °C), showed higher lightness (L *), yellowness (b *), and cohesiveness (TPA) and lower hardness and springiness than cooked sausages (30 min, 75 °C) (Yuste et al. 1999). Raw minced beef (HPP:150 and 300 MPa; 5 min; 20 °C) was used for the elaboration of frankfurters with reduced salt content (1.5 % and 2.5 % NaCl). Frankfurters with HPP beef at 150 MPa showed lower cooking loss values than controls, whereas emulsion stability (% expressible fluid) was similar to controls. In contrast, frankfurters with HPP beef at 300 MPa showed the lowest emulsion stability, i.e., higher expressible fluid. No HPP effect on color was observed. In general, HPP frankfurters were more juicy but with lower overall texture and acceptability scores than the controls. Salt-reduced frankfurters (1.5 %) with 300 MPa treated beef had less smoky and spicy flavor values. Instrumental texture parameters (TPA) decreased at 300 MPa in comparison with controls and 150 MPa, irrespective of salt level. Furthermore, HPP (300 MPa) salt-reduced frankfurters had lower TPA hardness and chewiness, i.e., better texture attributes than the controls (Crehan et al. 2000). In another study, frankfurter-type cooked sausages (made with poultry and pork meat) submitted to HPP (500 MPa, 5 and 15 min, 65 °C) showed higher total color difference values than cooked sausages with conventional heat pasteurization or non-pasteurized cooked sausages (although no differences in L * a * b * values were observed). HPP sausages showed higher TPA cohesiveness and lower hardness (less firmness) and weight loss than cooked sausages. According to sensory analysis results, HPP sausages were preferred because of their better appearance (with less gelatin on the surface due to lower formation of exudates), a stronger and more pleasant taste, and better texture, i.e., more juicy, less grainy, and more uniformly consistent (Mor-Mur and Yuste 2003). Raw sausages formulated to obtain low-acid fermented sausages (fuet and chorizo) were subjected to HPP (300 MPa, 10 min, 17 °C) 1 day after stuffing (i.e., prior to pH decrease and dehydration typical of the ripening stage). Visual discoloration was observed after HPP in both types of sausages. The instrumental color measurements showed a lightness (L *) increase, but no changes in redness (a *) were observed due to the protective effect of nitrification against HPP, i.e., nitrosomyoglobin formation. Yellowness (b *) decreased in HPP fuet but not in chorizo, probably due to the chorizo formulation which includes paprika and cayenne pepper (Marcos et al. 2005). Ostrich-meat yor (Thai sausage) heated under pressure (HPP:300–700 MPa, 40 and 60 min, 40 and 60 °C) showed higher lightness (L *) and yellowness (b *) and lower redness (a *) with increasing pressure and temperature. The amount of released plus expressible water of HPP sausages decreased with increasing pressure and temperature, indicating an increase in cooking yield. Furthermore, gel strength and elasticity of HPP sausages increased gradually with increasing pressure and temperature (Supavititpatana and Apichartsrangkoon 2007). In another study, ostrich-meat yor submitted to HPP (200–600 MPa; 40 and 60 min, 40 and 50 °C) showed that increasing pressure, temperature, and holding time increased water-holding capacity and solid-like behavior, indicating a stronger gel structure. Sensory analysis (hedonic) comparing yors processed at 600 MPa at 50 °C for 60 min (completely denatured protein) with yors elaborated using a conventional steaming process showed that texture, color, juiciness, and acceptability of HPP yors were higher than results for the steamed sausages. However, no flavor differences were observed (Chattong and Apichartsrangkoon 2009). Prepacked, sliced, refrigerated , ready-to-eat (RTE) commercial meat products like low-fat pastrami (a cooked, cured, whole beef muscle product), Strasburg beef (a cooked, cured, comminuted beef product), export sausage (a cooked, cured, comminuted beef product), and Cajun beef (a cooked, uncured, whole beef muscle encrusted with spices) were evaluated during shelf life after HPP (600 MPa, 3 min; 20 °C). HPP did not affect pH or water activity (a w) of RTE products. Consumer acceptability evaluation during shelf life showed no differences between HPP and unprocessed RTE meats (Hayman et al. 2004). Cooked ham (cured and cooked at 68 °C) showed no color changes after HPP (600 MPa; 30 min; 20 °C). In contrast, HPP raw-cured (salted) minced pork and beef meats showed higher lightness (L *) than unprocessed meat. Furthermore, HPP raw-cured beef also showed higher redness (a *) and yellowness (b *) values than the control, whereas raw-cured pork was not affected (Goutefongea et al. 1995). Vacuum-packaged, sliced cooked ham submitted to HPP (200 and 400 MPa; 5 and 20 min; 7 °C) showed no pH or purge loss (liquid loss) differences when compared with controls during chilled storage at 2 °C (López-Caballero et al. 1999). In another study with sliced cooked ham (HPP:300 MPa, 15 min, 5–50 °C), no color changes were observed between HPP ham and control (López-Caballero et al. (2002)). HPP raw smoked pork loin (500 MPa, 10 and 30 min) showed higher lightness values than controls, whereas in HPP cooked pork ham (300–500 MPa, 10 and 30 min) lightness decreased slightly, but visual color and sensory characteristics were not affected (Karlowski et al. 2002). Cooked pork ham (with low or high salt and sodium nitrite contents) submitted to HPP (600 MPa, 10 min, 20 °C) showed higher weight loss during storage than the controls. HPP did not affect color, instrumental texture, (penetration force) or sensory characteristics of ham (Pietrzak et al. 2007).

3.2.2 Raw Salted Meat Products

HPP has also been used in marinated or salted raw meat studies . Marinated sliced beef loin (1 % NaCl and without nitrites) subjected to HPP (600 MPa, 6 min, 16 °C) showed visual color modifications, i.e., grayish color, whereas HPP in sliced cooked ham helped to prevent off-odors, ropiness, and color changes, thereby contributing to the maintenance of sensory freshness for at least 60 days (Garriga et al. 2004). Salted raw beef (m. longissimus dorsi; 1 % NaCl) air-blast frozen and with subsequent HPP (650 MPa, 10 min, −35 °C) showed lower expressible moisture than HPP salted raw beef (650 MPa; 10 min; 20 °C) and unprocessed salted raw beef. With regard to color, HPP salted raw beef showed higher lightness (L *) and yellowness (b *) than air-blast-frozen-HPP and unprocessed salted raw beef. These results indicate a protective effect of freezing against HPP protein denaturation. Concerning redness, both HPP and air-blast HPP samples showed lower values than the control (Fernández et al. 2007). Turkey breast cubes (2 × 2 × 2 cm cut from thawed muscle) vacuum-packaged, immersed in a NaCl solution (50 g/l), and submitted to HPP (50–300 MPa, pressure holding time = 0.1 s, 25 ± 1 °C) showed higher moisture and NaCl contents with increasing pressure up to 150 MPa. In contrast, moisture and NaCl contents decreased between 200 and 300 MPa, probably due to a decrease in protein solubility. HPP reduced salting time and enhanced moisture content in comparison with salting at atmospheric pressure. HPP with increasing holding time (50–300 MPa, 1–15 min, 25 ± 1 °C) increased NaCl content and decreased moisture content, although these were higher than those in unprocessed samples. TPA hardness and chewiness were lowest at 150 MPa (pressure holding time = 0.1 s), but their values increased at higher pressures. Furthermore, HPP at 100–150 MPa and 15 min holding time also showed the lowest hardness and chewiness values. In general, HPP at 15 min holding time showed higher hardness, cohesiveness, and chewiness than at 0.1 s, at all the pressures tested. The authors concluded that pressure treatment resulted in a tenfold increase in NaCl diffusion coefficient in turkey meat in comparison to salting at ambient pressures (Villacís et al. 2008).

3.2.3 Pressure-Assisted Thermal Sterilization

HPP can also be used for food sterilization , although its industrial application is not yet available. Lau and Turek (2007) studied the quality differences between low-acid foods sterilized by HPP and retorting. Fresh chicken breasts sprinkled with barbecue spice rub, grilled for 30 s, and vacuum-packaged were equilibrated, first in a 40 °C water bath for 15 min and subsequently pre-heated in a 90 °C hot water bath until reaching an internal temperature of 80 °C. After heating, the chicken breasts were subjected to HPP by means of a two-pulse process (690 MPa, 90s pressure come-up time and 1 min holding time; 106 ºC maximum temperature attained during pressurization) with pressure release between the two consecutive pulses. The sensory evaluation results showed that HPP chicken “retained the flavor of a fresh roast chicken” and was moist and tender in contrast with the retorted chicken that had a “flavor similar to stewed or canned chicken” and was fibrous, tender, and soft. Furthermore, HPP chicken showed a muscle structure that was more intact than retorted chicken, which had lost muscle integrity and “tended to ‘fall apart’ parallel to the grain.” However, the instrumental texture test (single blade shear) showed no differences between HPP and retorted chicken. With regard to color evaluation, HPP chicken was lighter (higher L *) and yellower (higher b *) than retorted chicken .

3.3 Dry-Cured Meat Products

Conventional thermal pasteurization is not a good option for application to dry-cured meat products due to the dramatic color and texture changes these products undergo when heated. Alternatively, HPP allows the submission of dry-cured meat products to cold pasteurization with minimal changes in product quality (Hugas et al. 2002). Therefore, HPP meets the needs of industry for greater microbiological safety and longer shelf life of sliced meat products. As evidence of its effectiveness and good consumer acceptability (Baron et al. 1999; Nielsen et al. 2009), several food companies throughout the world are currently using HPP on an industrial scale to cold pasteurize meat products (see Table 26.2) (Balasubramaniam et al. 2008) and, particularly, sliced ready-to-eat meat products, including a wide range of dry-cured meat products such as low-acid and acid fermented sausages and dry-cured ham and loin (Hyperbaric 2006; Avure 2009).

3.3.1 Fermented Sausages

Low-acid cured fermented sausages (Catalan fuet and Spanish chorizo, pH > 5.3) after 28 days of ripening (water activity, 0.854–0.878) were subjected to HPP (400 MPa, 10 min, 17 °C). HPP low-acid fermented sausages showed no instrumental color changes, although a slight decrease in color intensity was observed by the trained sensory panel in HPP chorizo. The texture profile analysis (TPA) showed higher cohesiveness, chewiness, and springiness in both HPP fuet and chorizo. However, no sensory texture differences were observed in the sensory analysis by trained panelists (Marcos et al. 2007). Sliced cured fermented sausages (Spanish salchichón, pH = 5.1–5.2 and a w = 0.827–0.853) at the end of the ripening process were subjected to HPP (500 MPa; pressure come-up time, approx 4 min; pressure holding time, 5 min; decompression time, instantaneous, 18 °C). HPP fermented sausages showed no instrumental color differences and no changes in sensory attributes in comparison with the controls throughout the storage period (from 1 day to 210 days). However, by the end of the storage period, both HPP and control samples showed lower scores in sensory analysis (Rubio et al. 2007a). In the aforementioned studies, the authors suggest that the ripening process leads to color stabilization due to transformation of my oglobin into nitrosylmyoglobin and nitrosyl-haemochrome, as described previously (Carlez et al. 1995; Cheftel and Culioli 1997).

3.3.2 Dry-Cured Ham and Other Dry-Cured Muscles

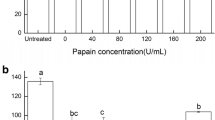

Many recent studies have dealt with HPP effects, not only on dry-cured whole-muscle products such as pork dry-cured ham and loin but also dry-cured beef muscles (cecina). In a study with vacuum-packaged pieces of Parma ham (elaborated without nitrites and ripened for 14 and 18 months) subjected to HPP (600 MPa, 9 min), pressurized hams showed a lightness (L *) and yellowness (b *) increase and a redness (a *) decrease in both HPP 14– and 18–month ripened hams, although redness decrease was lower in HPP 18-month hams. Instrumental color measurements were in concordance with the visual color evaluation, since lower visual color intensity was observed in HPP hams, with differences being more marked in 14 month hams. With regard to sensory evaluation, HPP hams showed higher salty taste, fibrousness on chewing, and consistency (described as resistance to compression) than unprocessed hams. However, HPP differences were lower in hams aged for 18 months in comparison with those aged for 14 months. Longer-ripened hams (18 months) undergo higher dehydration and, presumably, have higher pigment stability and are therefore less exposed to HPP changes because of the protective effect of the lower moisture content on color and sensory characteristics (Tanzi et al. 2004). Parma ham elaboration does not include the use of nitrites, which increase myoglobin stabilization by means of nitrosomyoglobin formation, as reported by Carlez et al. (1995), and this could explain the redness decrease induced by HPP. In another study, sliced dry-cured ham (elaborated with nitrites and with an average moisture content of 50.2 % in the final product) subjected to HPP (600 MPa, 6 min, 16 °C) showed no visual color differences and maintained sensory freshness for up to 120 days (Garriga et al. 2004). Iberian dry-cured ham (samples 4 × 3 × 0.3 cm) submitted to HPP (200–800 MPa, 15 min, 20 °C) showed a lightness (L *) decrease with HPP, although at 600–800 MPa L * values increased back to unprocessed samples. Redness (a *) decreased with pressure increase up to 600 MPa, whereas at 800 MPa a * values increased again above 400 MPa values (Andrés et al. 2004). In a similar study, slices of Iberian dry-cured ham submitted to HPP (200 and 400 MPa, 15 min, 20 °C) showed a lightness (L *) increase, especially at 400 MPa and a redness (a *) decrease (Andrés et al. 2006). Sliced Iberian and Serrano dry-cured hams subjected to HPP (450 MPa, 10 min, 12 °C) did not show color differences except for yellowness (b *) in HPP Iberian ham, which was higher than before HPP. No detrimental effect of HPP was observed as to the sensory characteristics (score preference of visual appearance, flavor, and texture) of either Iberian or Serrano ham (Morales et al. 2006). The effect of HPP (400 MPa and 600 MPa, 10 min, 10 °C) on the sensory properties of commercial dry-cured hams with texture problems, i.e., defective texture such as pastiness and excessive softness, was evaluated by Serra et al. (2006) in vacuum-packaged slices (1.5 mm thick) alternately assigned to either control or HPP. The flavor attributes of HPP dry-cured hams with defective texture were not affected, except for the BF saltiness, which increased at 600 MPa (scores control vs HPP, 2.9 vs 4.0). However, HPP reduced adhesiveness and pastiness and increased hardness and fibrousness in both biceps femoris (Fig. 26.1a) and semimembranosus (Fig. 26.1 b) muscles. These results show that HPP can be used to improve the sensory texture of pasty and excessively soft dry-cured hams by reducing sensory pastiness and increasing hardness. Furthermore, HPP increase in fibrousness does not affect dry-cured ham texture negatively (Serra et al. 2006).

Results of sensory analysis of (a) biceps femoris and (b) semimembranosus muscles from commercial dry-cured hams with defective texture, i.e., pastiness and excessive softness (– Control; · · · 400 MPa; - - - 600 MPa). Least squares means with a common letter are not significantly different (P > 0.05)

The effect of HPP (400 MPa, 6 min, 11 °C and 600 MPa, 12–35 min, 20 °C) on whole frozen hams at two early stages of the dry-cured ham process (green hams and at the end of the resting stage) was studied by Serra et al. (2007b). HPP at the green ham stage increased lightness (L *) of the biceps femoris muscle (BF) in the final product (i.e., dry-cured ham) both at 400 MPa and 600 MPa. Similarly, visual color intensity was lower (higher discoloration) with increasing pressure. At the end of the resting stage, HPP effect on the color of dry-cured ham was limited to 600 MPa. In general, HPP did not much affect the sensory attributes of dry-cured ham. Nonetheless, at the green ham stage HPP at 600 MPa decreased sensory crumbliness of BF muscle, whereas at the end of the resting stage, HPP at 600 MPa decreased crumbliness and increased fibrousness in both BF and semimembranosus muscles of the final dry-cured ham (Serra et al. 2007a). In a study with a slightly different dry-cured ham type, transglutaminase restructured dry-cured hams (boned hams with reduced salt content and potassium lactate; final product, 60–65 % moisture content) subjected to HPP (600 MPa, 6 min, 10 °C) showed a pH increase (0.2–0.3 units) and a water-holding capacity decrease (centrifugal method). The instrumental color of the biceps femoris (BF) muscle was affected by HPP, showing an increase in lightness (L *), redness (a *), and yellowness (b *) in comparison with unprocessed samples. Similarly, HPP also affected the slice appearance by increasing brightness and iridescence and decreasing color homogeneity. Pressurization affected both sensory and instrumental (tensile test) texture attributes. HPP increased sensory hardness, gumminess, and fibrousness, whereas adhesiveness and pastiness incidence and its intensity decreased. The tensile test results showed that the apparent Young’s modulus (high values indicate lower elasticity) and the breaking stress increased with HPP. Regarding sensory flavor, HPP increased saltiness perception, sweetness, and umami flavors (Fulladosa et al. 2009). Sliced biceps femoris muscle from dry-cured Iberian ham and dry-cured Iberian loin submitted to HPP (200 and 300 MPa, 15 and 30 min, <14 °C) showed no effect on color lightness (L *) and yellowness (b *). In contrast, redness (a *) decreased in dry-cured ham with increasing pressure, as it did in HPP dry-cured loin with respect to unprocessed loin, although no a * differences were observed between the different pressure levels (Cava et al. 2009). Iberian dry-cured ham biceps femoris muscle (vacuum-packaged slices and pieces) subjected to HPP (600 MPa, 6 min, 12 °C) showed no color changes in lightness (L *) or yellowness (b *), although redness (a *) decreased slightly and the lean appearance was less bright. Concerning sensory attributes, HPP samples were harder, chewier, and less juicy and showed higher saltiness, bitterness, cured, and overall flavor scores than unprocessed samples (Fuentes et al. 2010). Commercial dry-cured hams (5 cm thick slices) of two different salt levels submitted to HPP (500 MPa, 7 min, 7 °C) showed higher pink color appearance (i.e., visual lightness), sweetness, saltiness, hardness, and stringiness (fibrousness) and lower crumbliness than unprocessed samples, irrespective of the salt content (Guerrero et al. 2010). Commercial vacuum-packaged sliced dry-cured pork loin subjected to HPP (300–400 MPa, 10 min, 20 °C) showed a lightness (L *) increase and a redness (a *) decrease above 300 MPa, which were observed throughout the storage time (Campus et al. 2008). Vacuum-packaged pieces of pork longissimus muscle, salted either with NaCl or KCl, without nitrites and dried at different moisture contents, were submitted to HPP (600 MPa, 6 min, 12 °C). Irrespective of the salting treatment, HPP increased lightness (L *) and sensory fibrousness at moisture contents above 50 %, as shown in Figs. 26.2 and 26.3 , respectively. However, in the driest samples (below 50 % moisture content), no differences were observed between HPP and unprocessed loins. The visual color appearance was lighter in HPP samples in agreement with the L * increase. Furthermore, visual redness was lower in HPP, although no differences were observed for either a * or b * (Serra et al. 2009). Dry-cured beef Cecina de León (a salted, smoked, and dried traditional product from northwestern Spain) was subjected to HPP (500 MPa, 5 min, 18 °C) in vacuum-packaged cuts (4–5 cm) and slices (1.5 mm). HPP did not affect Cecina de León instrumental color (L *, a *, and b *), texture (TPA), or sensory attributes (Rubio et al. 2007b).

As a general conclusion, HPP of dry-cured meat products increases lightness (L *), decreases redness (a *), and affects both sensory texture and flavor by increasing fibrousness, hardness, and saltiness. However, it is worth mentioning that in most cases these changes fall within the intrinsic product variability range and, therefore, changes are not to be seen as negative, but as slight product modifications. Furthermore, the extent of most HPP changes in dry-cured meat products is determined by the moisture content of the product, i.e., the moister the product, the bigger the HPP changes expected.

References

Ananou S, Garriga M, Jofré A, Aymerich T, Gálvez A, Maqueda M, Martínez-Bueno M, Valdivia E (2010) Combined effect of enterocin AS-48 and high hydrostatic pressure to control food-borne pathogens inoculated in low acid fermented sausages. Meat Sci 84:594–600

Ananth V, Dickson JS, Olson DG, Murano EA (1998) Shelf life extension, safety, and quality of fresh pork loin treated with high hydrostatic pressure. J Food Prot 61:1649–1656

Andrés AI, Cava R, Ventanas J, Thovar V, Ruiz J (2004) Sensory characteristics of Iberian ham: Influence of salt content and processing conditions. Meat Sci 68:45–51

Andrés AI, Adamsen CE, Møller JKS, Ruiz J, Skibsted LH (2006) High-pressure treatment of dry-cured Iberian ham. Effect on colour and oxidative stability during chill storage packed in modified atmosphere. Eur Food Res Technol 222:486–491

Ashie INA, Lanier TC (1999) High pressure effects on gelation of surimi and turkey breast muscle enhanced by microbial transglutaminase. J Food Sci 64:704–708

Avure (2009). High pressure processing meat products. Available at http://www.avure.com/archive/documents/Food-products/meat-application-brief--letter-email-version.pdf. Accessed 18 Aug 2010

Aymerich MT, Jofré A, Garriga M, Hugas M (2005) Inhibition of Listeria monocytogenes and Salmonella by natural antimicrobials and high hydrostatic pressure in sliced cooked ham. J Food Prot 68:173–177

Aymerich T, Rubio R, Martín B, Bover-Cid S, Garriga M (2009) Assessment of safe enterococci as bioprotective cultures in fermented sausages combined with high pressure processing. In: Second safe consortium international congress on food safety, Girona. España

Ayo J, Carballo J, Solas MT, Jiménez-Colmenero F (2005) High pressure processing of meat batters with added walnuts. Int J Food Sci Technol 40:47–54

Balasubramaniam VM, Farkas D, Turek E (2008) Preserving foods through high-pressure processing. Food Technol 62:32–38

Baron A, Bayer O, Butz P, Geisel B, Gupta B, Oltersdorf U, Tauscher B (1999) Consumer perception of high pressure processing: a three country survey. In: European conference on emerging food science and technology, Tampere, Finland

Beltran E, Pla R, Capellas M, Yuste J, Mor-Mur M (2004) Lipid oxidation and colour in pressure- and heat-treated minced chicken thighs. J Sci Food Agric 84:1285–1289

Bertram HC, Whittaker AK, Shorthose WR, Andersen HJ, Karlsson AH (2004) Water characteristics in cooked beef as influenced by ageing and high-pressure treatment—an NMR micro imaging study. Meat Sci 66:301–306

Black EP, Hirneisen KA, Hoover DG, Kniel KE (2010) Fate of Escherichia coli O157:H7 in ground beef following high-pressure processing and freezing. J Appl Microbiol 108:1352–1360

Bover-Cid S, Belletti N, Garriga M, Aymerich T (2011) Model for Listeria monocytogenes inactivation on dry-cured ham by high hydrostatic pressure processing. Food Microbiol 28:804–809

Campus M, Flores M, Martinez A, Toldrá F (2008) Effect of high pressure treatment on colour, microbial and chemical characteristics of dry cured loin. Meat Sci 80:1174–1181

Carballo J, Fernández P, Carrascosa AV, Solas MT, Colmenero FJ (1997) Characteristics of low- and high-fat beef patties: effect of high hydrostatic pressure. J Food Prot 60:48–53

Carballo J, Cofrades S, Solas MT, Jiménez-Colmenero F (2000) High pressure/thermal treatment of meat batters prepared from freeze-thawed pork. Meat Sci 54:357–364

Carlez A, Rosec JP, Richard N, Cheftel JC (1993) High pressure inactivation of Citrobacter freundii, Pseudomonas fluorescens and Listeria innocua in inoculated minced beef muscle. Lebensm Wiss Technol 26:357–363

Carlez A, Rosec JP, Richard N, Cheftel JC (1994) Bacterial growth during chilled storage of pressure-treated minced meat. Lebensm Wiss Technol 27:48–54

Carlez A, Veciana-Nogués MT, Cheftel JC (1995) Changes in colour and myoglobin of minced meat due to high pressure processing. Lebensm Wiss Technol 28:528–538

Cava R, Ladero L, González S, Carrasco A, Ramírez MR (2009) Effect of pressure and holding time on colour, protein and lipid oxidation of sliced dry-cured Iberian ham and loin during refrigerated storage. Innov Food Sci Emerg Technol 10:76–81

Chattong U, Apichartsrangkoon A, Bell AE (2007) Effects of hydrocolloid addition and high pressure processing on the rheological properties and microstructure of a commercial ostrich meat product “Yor” (Thai sausage). Meat Sci 76:548–554

Chattong U, Apichartsrangkoon A (2009) Dynamic viscoelastic characterisation of ostrich-meat yor (Thai sausage) following pressure, temperature and holding time regimes. Meat Sci 81:426–432

Cheah PB, Ledward DA (1996) High pressure effects on lipid oxidation in minced pork. Meat Sci 43:123–134

Cheftel JC (1995) High-pressure, microbial inactivation and food preservation. Food Sci Technol Int 1:75–90

Cheftel JC, Culioli J (1997) Effects of high pressure on meat: a review. Meat Sci 46:211–236

Chen C, Wang R, Sun G, Fang H, Ma D, Yi S (2010) Effects of high pressure level and holding time on properties of duck muscle gels containing 1% curdlan. Innov Food Sci Emerg Technol 11:538–542

Chung YK, Vurma M, Turek EJ, Chism GW, Yousef AE (2005) Inactivation of barotolerant Listeria monocytogenes in sausage by combination of high-pressure processing and food-grade additives. J Food Prot 68:744–750

Cofrades S, Bañon S, Carballo J, Jiménez-Colmenero F (2003) Role of cathepsin D activity in gelation of chicken meat heated under pressure. Food Chem 80:241–247

Crehan CM, Troy DJ, Buckley DJ (2000) Effects of salt level and high hydrostatic pressure processing on frankfurters formulated with 1.5 and 2.5% salt. Meat Sci 55:123–130

Cruz C, Moueffak AE, Antoine M, Montury M, Demazeau G, Largeteau A, Roy B, Zuber F (2003) Preservation of fatty duck liver by high pressure treatment. Int J Food Sci Technol 38:267–272

Del Olmo A, Morales P, Ávila M, Calzada J, Nuñez M (2010) Effect of single-cycle and multiple-cycle high-pressure treatments on the colour and texture of chicken breast fillets. Innov Food Sci Emerg Technol 11:441–444

Diez AM, Santos EM, Jaime I, Rovira J (2008a) Application of organic acid salts and high-pressure treatments to improve the preservation of blood sausage. Food Microbiol 25:154–161

Diez AM, Urso R, Rantsiou K, Jaime I, Rovira J, Cocolin L (2008b) Spoilage of blood sausages morcilla de Burgos treated with high hydrostatic pressure. Int J Food Microbiol 123:246–253

Diez AM, Jaime I, Rovira J (2009a) The influence of different preservation methods on spoilage bacteria populations inoculated in morcilla de Burgos during anaerobic cold storage. Int J Food Microbiol 132:91–99

Diez AM, Santos EM, Jaime I, Rovira J (2009b) Effectiveness of combined preservation methods to extend the shelf life of Morcilla de Burgos. Meat Sci 81:171–177

Dumoulin M, Hayashi R (1998) High pressure, a unique tool for food texturization. Food Sci Technol Int (Tokyo) 4:99–113

Farkas J, Hajós G, Szerdahelyi E, Andrassy E, Krommer J, Meszaros L (2002) Protein changes in high pressure pasteurized raw sausage batter. In: Proceedings 48th international congress of meat science and technology, Rome, Italy

Fernández-Martín F, Fernández P, Carballo J, Jiménez-Colmenero F (1997) Pressure/heat combinations on pork meat batters: protein thermal behavior and product rheological properties. J Agric Food Chem 45:4440–4445

Fernández-Martín F, Otero L, Solas M, Sanz P (2000) Protein denaturation and structural damage during high-pressure-shift freezing of porcine and bovine muscle. J Food Sci 65:1002–1008

Fernández-Martín F, Cofrades S, Carballo J, Jiménez-Colmenero F (2002) Salt and phosphate effects on the gelling process of pressure/heat treated pork batters. Meat Sci 61:15–23

Fernández P, Cofrades S, Solas M, Carballo J, Jiménez-Colmenero F (1998) High pressure-cooking of chicken meat batters with starch, egg white, and iota carrageenan. J Food Sci 63:267–271

Fernández PP, Sanz PD, Molina-García AD, Otero L, Guignon B, Vaudagna SR (2007) Conventional freezing plus high pressure-low temperature treatment: physical properties, microbial quality and storage stability of beef meat. Meat Sci 77:616–625

Food and Drug Administration (2003) Foodborne pathogenic microorganisms and natural toxins handbook (Bad Bug Book). Accessible at: http://www.fda.gov/Food/FoodSafety/FoodborneIllness/FoodborneIllnessFoodbornePathogensNaturalToxins/BadBugBook/default.htm

Fuentes V, Ventanas J, Morcuende D, Estévez M, Ventanas S (2010) Lipid and protein oxidation and sensory properties of vacuum-packaged dry-cured ham subjected to high hydrostatic pressure. Meat Sci 85:506–514

Fulladosa E, Serra X, Gou P, Arnau J (2009) Effects of potassium lactate and high pressure on transglutaminase restructured dry-cured hams with reduced salt content. Meat Sci 82:213–218

Garriga M, Grèbol N, Aymerich MT, Monfort JM, Hugas M (2004) Microbial inactivation after high-pressure processing at 600 MPa in commercial meat products over its shelf life. Innov Food Sci Emerg Technol 5:451–457

Garriga M, Marcos B, Martín B, Veciana-Nogués MT, Bover-Cid S, Hugas M, Aymerich MT (2005) Starter cultures and high pressure processing to improve the hygiene and safety of slightly fermented sausages. J Food Prot 68:2341–2348

Gill AO, Ramaswamy HS (2008) Application of high pressure processing to kill Escherichia coli O157 in ready-to-eat meats. J Food Prot 71:2182–2189