Abstract

In contrast to planktonic cultures of the human fungal pathogen Candida albicans, C. albicans biofilms can contain a persister subpopulation that is tolerant to high concentrations of currently used antifungals. In this chapter, the method to determine the persister fraction in a C. albicans biofilm treated with an antifungal compound is described. To this end, a mature biofilm is developed and subsequently treated with a concentration series of the antifungal compound of interest. Upon incubation, the fraction of surviving biofilm cells is determined by plating and plotted versus the used concentrations of the antifungal compound. If a persister subpopulation in the biofilm is present, the dose-dependent killing of the biofilm cells results in a biphasic killing pattern.

Access provided by CONRICYT – Journals CONACYT. Download protocol PDF

Similar content being viewed by others

Keywords

1 Introduction

Persisters are subpopulations of cells that are transiently tolerant to multiple drugs [1]. Biofilms of the human fungal pathogen C. albicans contain a small fraction of persisters that are completely tolerant to currently used antifungals [2]. Interestingly, attachment rather than biofilm formation itself seems to initiate persister formation. Upon reinoculation of the surviving cells, a similar fraction of persisters is formed in the biofilm, suggesting that these cells are phenotypic variants of the wild type rather than mutants. Remarkably, so far no persister fraction has been detected in C. albicans planktonic cultures [2, 3]. This is in contrast to bacteria, which produce persisters in both planktonic and biofilm populations. Periodic application of antimicrobial agents in patients selects for C. albicans strains with increased persister levels, indicating the clinical relevance of persisters [4]. However, not all C. albicans strains have a biofilm persister fraction [3]. Whereas molecular insights into C. albicans persistence are scarce, the occurrence of miconazole-tolerant persisters in C. albicans biofilms has been linked to the ROS (reactive oxygen species) detoxifying activity of different superoxide dismutases (Sod), as a sod4Dsod5D biofilm contains threefold less miconazole-tolerant persisters compared to a biofilm formed by the wild type. In addition, Sod inhibitors can be used to reduce the fraction of miconazole-tolerant persisters [5]. A persister fraction is also present in biofilms of other Candida species, such as C. krusei and C. parapsilosis [3]. As persisters might be the main reason of recalcitrance of chronic infectious diseases to antimicrobial therapy [6], insights into the molecular basis of persistence in C. albicans biofilms can certainly contribute to the rational design of antibiofilm agents that also target the persister fraction.

Here, the protocol to determine the fraction of C. albicans persister cells in mature biofilms upon treatment with an antifungal compound is described. This protocol is based on protocols of LaFleur and coworkers [2, 4] and Bink and coworkers [5] and consists of three consecutive steps: development of a mature biofilm, treatment of the mature biofilm with an antifungal compound, and quantification of the surviving biofilm cells.

2 Materials

-

1.

Yeast-extract Peptone Dextrose (YPD) liquid medium: 10 g yeast extract, 20 g peptone, 20 g glucose, 1 L distilled water. Dissolve 10 g yeast extract powder and 20 g peptone in 950 mL distilled water. Prepare a 40 % glucose stock solution (w/v) in distilled water in a separate bottle (see Note 1 ). Sterilize both liquids. After autoclaving, add 50 mL of 40 % glucose to 950 mL YP medium to obtain YPD liquid medium. YPD liquid medium can be stored at room temperature.

-

2.

Phosphate-buffered saline (PBS): 8 g NaCl, 0.291 g KCl, 1.44 g Na2HPO4, 0.24 g KH2PO4, 1 L distilled water. Stir the solution until all salts are completely dissolved. Adjust the pH to pH 7.4. PBS can be stored at room temperature.

-

3.

Roswell Park Memorial Institute (RPMI) 1640 medium: 10.4 g RPMI 1640, 34.52 g 3-[N-morpholino] propanesulfonic acid (MOPS), 1 L distilled water, pH 7.0. RPMI 1640 medium with l-glutamine and without sodium bicarbonate was purchased from Sigma-Aldrich. Dissolve 10.4 g RPMI 1640 in 900 mL distilled water and add 34.52 g 3-[N-morpholino] propanesulfonic acid (MOPS). Stir until dissolved. Afterwards, adjust the pH to 7.0 using 1 M NaOH. Add additional distilled water to obtain a final volume of 1 L. Sterilize immediately by filtration using a membrane with a porosity of 0.22 μm. Do not sterilize by autoclaving. Store RPMI 1640 at 4 °C in the dark.

-

4.

Yeast-extract Peptone Dextrose (YPD) solid medium: 10 g yeast extract, 20 g peptone, 20 g glucose, 15 g agar, 1 L distilled water. Dissolve 10 g yeast extract powder, 20 g peptone and 15 g agar in 950 mL distilled water. Prepare a 40 % glucose stock solution (w/v) in distilled water in a separate bottle (see Note 1 ). Sterilize both liquids by autoclaving. After sterilization, add 50 mL of 40 % glucose to 950 mL YP medium to obtain YPD agar medium. YPD plates can be stored for several weeks at 4 °C if evaporation is prevented.

-

5.

Round-bottomed polystyrene 96-well microtiter plates.

-

6.

Flat-bottomed polystyrene 96-well microtiter plates.

-

7.

Sterilized glass beads (4 mm diameter).

3 Methods

3.1 Development of a Mature Biofilm

-

1.

Inoculate one colony of C. albicans overnight in a test tube containing 3–5 mL YPD liquid medium at 30 °C in shaking conditions (133 g) (see Note 2 ).

-

2.

Centrifuge 1 mL of the overnight culture (845 g in a microfuge, 3 min) and wash twice using 1 mL PBS. Measure the OD (at 600 nm) of the washed overnight culture.

-

3.

Dilute the optical density of the washed overnight culture to 0.1 (approximately 1.106 cells/mL) in RPMI 1640.

-

4.

Add 100 μL of the diluted culture to wells of a round-bottomed microtiter plate (see Note 3 ). Cover the microtiter plate with the lid.

-

5.

Incubate for 1 h at 37 °C in static conditions (adhesion phase).

-

6.

Rinse the wells: dispose the inoculated RPMI 1640 medium to remove non-adherent cells. Wash the wells by gently adding 100 μL PBS/well (see Note 4 ).

-

7.

Remove PBS and add 100 μL fresh RPMI 1640 medium to each well (see Note 4 ). Cover the microtiter plate with the lid.

-

8.

Incubate the microtiter plate for 24 h at 37 °C under static conditions to allow development of a mature biofilm.

3.2 Treatment of the Mature Biofilm with an Antifungal Compound

-

1.

Make twofold serial dilutions of the antifungal compound in RPMI 1640 in a flat-bottomed microtiter plate (see Note 5 ). To this end, first a twofold dilution series of the antifungal compound should be prepared at 100 times final strength in the appropriate solvent, for example in 100 % dimethyl sulfoxide (DMSO). Afterwards, dilute this dilution series tenfold in RMPI 1640. As such these working concentrations are ten times more concentrated (resulting in a 10 % solvent background) than the desired final concentration series (in 1 % solvent background). Note that in some cases, more diluted solvent backgrounds are necessary—the solvent itself should not affect the biofilm cells. If so, the above concentration series should be adapted.

-

2.

Rinse the wells of the biofilm microtiter plate: remove the RPMI 1640 medium and gently add 100 μL PBS to each well. Remove the PBS (see Note 4 ).

-

3.

Add 90 μL of fresh RPMI 1640 and 10 μL of the working concentrations of the antifungal compound (see Subheading 3.2, step 1) to the wells. This results in the desired final concentrations of the antifungal compound and a 1 % background concentration of the solvent. Use the 1 % background concentration of the solvent as negative control.

-

4.

Incubate the biofilms for 24 h at 37 °C under static conditions.

3.3 Quantification of the Surviving Biofilm Cells

-

1.

Wash the wells gently with 100 μL PBS (see Note 4 ).

-

2.

Add 100 μL PBS to each well and resuspend biofilms by scraping and pipetting up and down vigorously.

-

3.

Check visually if biofilms are completely resuspended (see Note 6 ).

-

4.

Tape the lid carefully to the microtiter plate using parafilm and sonicate for 10 min (see Note 7 ).

-

5.

Make tenfold dilution series in PBS: add 180 μL PBS to each well of a new flat-bottomed microtiter plate. Subsequently, transfer 20 μL of the resuspended biofilm or previous dilution to the next well and mix well before transferring 20 μL to the following well. Continue until the required dilution is reached (see Note 8 ).

-

6.

Plate 100 μL of each dilution on YPD agar plates. Use sterilized glass beads to spread the liquid uniformly over the entire plate.

-

7.

Incubate YPD agar plates for 48 h at 30 °C.

-

8.

Count the colony forming units for each treatment.

-

9.

Determine the percentage survival relatively to the control treatment.

-

10.

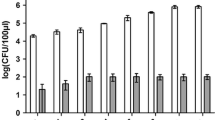

Plot the percentage survival versus the used antifungal concentrations (Fig. 1). If persisters are present, the dose-dependent killing will result in a biphasic killing pattern. Whereas the majority of cells are killed at low concentrations of the antifungal, a persister fraction is present when a certain percentage of the cells remains unaffected by treatment with increasing concentrations of the antifungal, resulting in a distinct plateau of surviving persistors (Fig. 1).

4 Notes

-

1.

Glucose stock solution has to be prepared in a separate bottle to prevent caramelization of the YPD medium during autoclaving.

-

2.

Refresh your plate containing C. albicans colonies at least every 2 weeks, using a C. albicans stock stored at −80 °C.

-

3.

Avoid growing biofilms in the outer wells of the microtiter plate as these wells are more susceptible to evaporation, which can affect your results. Instead, fill these wells with 100 μL PBS to prevent evaporation in the inner wells.

-

4.

Carefully rinse the wells to avoid disruption of the adhered cells or biofilm: place tips to the sides of the wells and avoid touching the bottom of the wells. Keep the microtiter plates in an angle to remove or add the liquid. Liquid should be removed and added very slowly.

-

5.

Use concentrated stock solutions of your antifungal compounds such that the solvent background of your dilution series in RPMI 1640 is not affecting biofilm cells. For example, if the compound is dissolved in dimethyl sulfoxide (DMSO), the final DMSO background in RPMI 1640 should be maximally 2 % but preferably 1 % or lower to prevent toxic side-effects. In the protocol, 100 times concentrated stock solutions are used as an example, resulting in a solvent background of 1 %.

-

6.

In particular, parts of the biofilm at the sides of the wells are more difficult to resuspend. Therefore, scrape and pipette up and down until the complete biofilm is resuspended and no remains of biofilms can be visually detected.

-

7.

Check that the bottom of the microtiter plate is in contact with the water.

-

8.

Before transferring 20 μL of the dilution to the next well, make sure that your dilutions are very well mixed by pipetting up and down thoroughly. Upon growth on YPD agar plates, the accuracy of the different dilutions can be verified as each subsequent dilution should result in an approximately tenfold reduced number of colonies.

References

Fauvart M, De Groote VN, Michiels J (2011) Role of persister cells in chronic infections: clinical relevance and perspectives on anti-persister therapies. J Med Microbiol 60:699–709

LaFleur MD, Kumamoto CA, Lewis K (2006) Candida albicans biofilms produce antifungal-tolerant persister cells. Antimicrob Agents Chemother 50:3839–3846

Al-Dhaheri RS, Douglas LJ (2008) Absence of amphotericin B-tolerant persister cells in biofilms of some Candida species. Antimicrob Agents Chemother 52:1884–1887

LaFleur MD, Qi Q, Lewis K (2010) Patients with long-term oral carriage harbor high-persister mutants of Candida albicans. Antimicrob Agents Chemother 54:39–44

Bink A, Vandenbosch D, Coenye T et al (2011) Superoxide dismutases are involved in Candida albicans biofilm persistence against miconazole. Antimicrob Agents Chemother 55:4033–4037

Lewis K (2012) Persister cells: molecular mechanisms related to antibiotic tolerance. In: Handb. Exp. Pharmacol. Springer, Heidelberg, Berlin, pp 121–133

Acknowledgements

The research leading to these results has received funding from the European Commission’s Seventh Framework Programme (FP7/2007-2013) under the grant agreement COATIM (project n° 278425).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media New York

About this protocol

Cite this protocol

De Brucker, K., De Cremer, K., Cammue, B.P.A., Thevissen, K. (2016). Protocol for Determination of the Persister Subpopulation in Candida Albicans Biofilms. In: Michiels, J., Fauvart, M. (eds) Bacterial Persistence. Methods in Molecular Biology, vol 1333. Humana Press, New York, NY. https://doi.org/10.1007/978-1-4939-2854-5_6

Download citation

DOI: https://doi.org/10.1007/978-1-4939-2854-5_6

Publisher Name: Humana Press, New York, NY

Print ISBN: 978-1-4939-2853-8

Online ISBN: 978-1-4939-2854-5

eBook Packages: Springer Protocols