Abstract

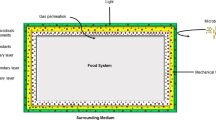

Films and coatings based on edible/biodegradable hydrocolloids have received special attention in the last few years as an alternative to preserve foods with several possibilities: to maintain sensory and nutritional properties or microbial stability, to reduce moisture losses or mechanical damage, to improve food appearance (especially gloss), to add different food ingredients such as color or aroma compounds, to incorporate bioactive compounds such as antimicrobials or antioxidants, and to reduce the use of plastic packaging. Films or coatings must be transparent, flavorless, and odorless and they must have adequate water vapor permeability and selective permeability to gases and volatiles. They must not represent a health risk and be low cost (Krochta and de Mulder-Johnston 1997; Tharanathan 2003).

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Films and coatings based on edible/biodegradable hydrocolloids have received special attention in the last few years as an alternative to preserve foods with several possibilities: to maintain sensory and nutritional properties or microbial stability, to reduce moisture losses or mechanical damage, to improve food appearance (especially gloss), to add different food ingredients such as color or aroma compounds, to incorporate bioactive compounds such as antimicrobials or antioxidants, and to reduce the use of plastic packaging. Films or coatings must be transparent, flavorless, and odorless and they must have adequate water vapor permeability and selective permeability to gases and volatiles. They must not represent a health risk and be low cost (Krochta and de Mulder-Johnston 1997; Tharanathan 2003).

The usual components of films and coatings are hydrocolloids, i.e., polysaccharides or proteins, which show good mechanical properties and good barrier properties to gases (O2 y CO2) or aroma compounds, but poor water vapor barrier properties due to their hydrophilic nature. Plasticizers, such as glycerol or sorbitol (these are the most frequently used), are usually incorporated at a determined ratio, which gives adequate flexibility to the film, decreasing brittleness, but enhancing the poor water vapor barrier properties of hydrocolloids, also due to their hydrophilic nature. The incorporation of hydrophobic compounds, such as lipids, in the film forming formulations allows us to significantly reduce water uptake capacity and water vapor permeability of the films or coatings (Morillon et al. 2002; Srinivasa et al. 2007). In general, lipids show good water vapor barrier properties, but poor ability to form films and, in some cases, they give rise to undesirable properties, such as rancidity development. In some cases, lipid compounds provide the film with additional functional properties, such as antimicrobial or antioxidant capacity, as occurs with some essential oils (Gómez-Estaca et al. 2010; Sánchez-González et al. 2010, 2011).

Surfactants, fatty acids, or different nonpolar, organic compounds have been incorporated to film formulations giving rise to heterogeneous dispersions due to the lack of miscibility with the hydrophilic macromolecules (Fabra et al. 2009a; Jiménez et al. 2010). Thus, composite films were obtained where it is possible to optimize the film properties since they have better water vapor barrier properties (Debeaufort et al. 2000; Elsabee et al. 2008), selective permeability to O2 and CO2 (Alves et al. 2010) or other volatiles (Fabra et al. 2009b; Hambleton et al. 2011), durability, and structural cohesion.

The heterogeneous structure of the composite film forming dispersions also occurs in the dried film which shows a continuous matrix of hydrocolloid and miscible compounds, such as plasticizer, and dispersed particles of different sizes and shapes, depending on the structural properties of the initial dispersion and the film drying conditions (Villalobos et al. 2005). Figure 1 shows the microstructure of some films obtained with sodium caseinate and glycerol where lipids, oleic acid (OA), beeswax (BW), and their mixture, in a ratio of 70:30, were incorporated. The protein-lipid ratio was 1:0.5 in all cases. The lipid dispersed phase can be appreciated, showing clear differences depending on the lipid composition. The heterogeneity of the structure is also reflected in the film surface, as has been observed by the atomic force microscopy (AFM) (Fabra et al. 2009a, c). The different surface topography is the result of the initial lipid particle size in the film forming dispersion and the destabilization phenomenon, which occur during film drying and which imply flocculation, coalescence, and creaming of lipid particles. The more unstable dispersions lead to a greater surface roughness of the films due to the faster progression of destabilization phenomena and, as a result, the lipid migration to the film surface is more intense. Surface roughness has a high impact on the film gloss; the greater the surface roughness, the lower the gloss (Villalobos et al. 2005; Fabra et al. 2009a).

In polar lipids, such as fatty acids, the lipid self-association phenomenon plays an important role in the film microstructure. This phenomenon is determined by molecular interactions in the film forming dispersion and their changes in line with the water evaporation during the film formation. Several authors observed a multilayered structure for saturated fatty acids (lauric, palmitic, and stearic) in sodium caseinate (Fabra et al. 2009c) and hydroxypropyl methylcellulose (Jiménez et al. 2010) films. This was associated with the growth of the molecular aggregations in the bilayer self-association of the lipid molecules during film drying and the final crystallization of fatty acids in the polymer matrix. The length of lipid layers in the matrix was greater for lauric acid and decreased as the fatty acid chain length increased. This indicates that the growth of the molecule aggregates during film drying was more effective when the fatty acid chain was shorter, probably due to its greater molecular mobility. These successive lipid layers in the film matrix greatly contribute to reduce water vapor permeability, thus improving the water barrier properties; the longer the lipid layers, the lower the water vapor permeability (WVP) values. Films containing stearic acid, of a more hydrophobic nature, showed the poorest water barrier properties, which can be explained by these structural effects. These considerations underline the importance of relating the properties of the film forming dispersions with the relevant characteristics of the films. The properties related with the stability of the film forming dispersion such as rheology, particle size distribution, zeta-potential, or contact angle on a determined surface affect the properties related to the film functionality to a great extent.

Optical properties of the films such as gloss and transparency are important, since they have an impact on product appearance and are greatly affected by the degree of the film’s structural heterogeneity (Villalobos et al. 2005; Ozdemir and Floros 2008; Fabra et al. 2009a). Nevertheless, one of the most relevant properties of the films/coatings is the water affinity and water sorption behavior, since equilibrium water content of the film impacts directly on its mass transport properties (water vapor and gas permeability) and mechanical resistance, which are decisive for the film’s practical applications.

Components of the hydrocolloid matrix can interact to a different degree with the polymer chain/groups, giving rise to systems where water relationships can change considerably, as compared with pure hydrocolloid. Some examples of how the compounds incorporated into the polymer matrix can affect water sorption capacity, phase transitions, or molecular mobility are commented on for some protein or polysaccharide matrices.

2 Effect of Film Plasticizers on Film Water Sorption Behavior

Plasticizers, such as glycerol, or sorbitol, are usual components of films they have a great impact on the sorption behavior and water sorption capacity (WSC) of the hydrocolloid films due to their hydrophilic nature. Figure 2a shows the sorption isotherms, at 5 and 20 °C, of films based on soy protein isolate (SPI), both pure and combined with glycerol in a ratio 1:0.3, where the promotion of the WSC of the matrix due to the glycerol addition can be observed at both temperatures. This promotion is particularly intense at high water activity levels, when the solvent effects of water are exhibited for films containing low molecular weight polar solutes, such as glycerol.

Similar behavior can be observed for WSC of sodium caseinate (NaCas) at 25 °C when glycerol is incorporated at the same ratio (Fig. 2b). In all cases, the incorporation of glycerol to hydrocolloid implied the promotion of the hygroscopic nature of the film mainly from water activity (a w) of 0.4 onwards and, as commented above, this can be attributed to the promotion of solvent effects from a determined a w value, when low molecular weight polar solutes are present. This solvent effect allows the system to incorporate a great amount of bonded water without a notable increase of a w. Thus, the high water uptake in sodium caseinate or SPI films containing glycerol from a w = 0.6 did not appear in pure hydrocolloids due to the absence of this kind of polar solutes. The effect on water sorption behavior was observed by Kristo and Biliaderis (2006) to be similar for sodium caseinate and pullulan matrices when these contained sorbitol.

3 Effect of Lipids on Water Sorption Behavior of Hydrocolloid Films

Lipids are also usually added to the film formulation in order to improve water barrier properties. The incorporation of these compounds also changes the WSC of the film. The effect of lipids can be very different, depending on the hydrocolloid-lipid interactions in the matrix. The incorporation of lipids usually reduces water sorption due to the fact that lipids correspond to a fraction of solids with small water uptake capacity, especially for the more hydrophobic compounds. This has been observed for films of sodium caseinate (with 0.3 g of glycerol/g protein) containing oleic acid (OA) and beeswax (BW) mixtures (Fabra et al. 2010). In this case, the amount of water uptake was estimated from the values obtained for the lipid-free film and the mass fraction of the nonlipid solids (caseinate plus glycerol) and predicted values were compared with the experimental ones. The comparison showed that the values agreed quite closely. Nevertheless, for films containing oleic acid experimental values are slightly greater than predicted, which means that a certain amount of water uptake in this case is retained by the lipid. Nevertheless, the opposite behavior was observed for films containing pure BW, where predicted values are lower than the experimental ones, thus indicating that BW seems to inhibit the water sorption capacity of the protein matrix, probably due to the promotion of hydrophobic interactions in the lipid-protein matrix which reduce the active points for water adsorption.

Figure 3 shows the effect of the incorporation of OA to SPI matrices containing glycerol (0.3 g/g protein) on water sorption behavior at 5 and 20 °C. A different effect of lipid can be observed at each temperature for different lipid-protein ratios (0.25 and 0.5 g/g protein). For the highest ratio, OA promotes water adsorption at both 5 and 20 °C, which indicates that a greater amount of water sorption active groups are exhibited in the matrix when OA interacts with the SPI chains. Nevertheless, when the OA-protein ratio decreased to 0.25 g lipid/g protein, a clear decrease in the water sorption capacity was observed when film was equilibrated at 20 °C. This seems to indicate that changes in molecular interactions are induced by the temperature increase, which affects the number of water sorption active points.

Figure 4 shows the sorption behavior of SPI-glycerol films, at 5 and 20 °C, when BW was incorporated at two different ratios, 0.25 and 0.5 g lipid/g protein. Very similar behavior can be observed in both cases where WSC of the matrix decreased because of the addition of BW.

By only considering the contribution of the nonlipid fraction, the predicted moisture content values of lipid-containing SPI films were compared with the experimental values (as shown in Fig. 5). For OA at 5 °C, points were observed to deviate greatly from the diagonal, as expected from the previously mentioned promotion of WSC, clearly showing the increase in the number of active points in the matrix due to the OA-SPI interactions. At this temperature, no different behavior was observed between the films containing a different ratio of OA. Nevertheless, at 20 °C, only the films with the greatest OA ratio showed a greater WSC than SPI-Gly films, whereas a slightly negative deviation was observed for films with the lowest OA ratio, similar to that provoked by BW. This suggests that only a part of the OA molecules contributes to the enhancement of the hygroscopic character of the polymer network, depending on the temperature. This interactive OA amount was exceeded by the lowest lipid ratio at 5 °C, but this ratio was not high enough at 20 °C. It seems that there are not enough lipids to provoke a similar effect to that observed at 5 °C in the protein network when the lipid-protein ratio decreases and hydrophobic interactions are promoted in line with the temperature increase. No notable deviations from the diagonal were observed for films containing BW at either temperature, thus indicating that this component is in a separate phase, hardly interacting with the polymer network.

The effect of the incorporation of other organic compounds, such as ethanol extract of propolis (EEP), on the WSC of hydroxypropyl methylcellulose (HPMC) films has been described for films equilibrated at 5 and 25 °C and 55 or 75 % relative humidity (RH) (Pastor et al. 2010). A decrease in the equilibrium water content of the film when the content of EEP in the film increased was observed for all of the equilibration conditions. Nevertheless, it is remarkable that when moisture content was referred to the HPMC basis (g water/g HPMC), no significant change in water content was detected until there was nearly 10 % of EEP in the film. However, a significant and similar decrease was obtained for the two greatest EEP ratios (0.167 and 0.231 g/g dried film) in the films. This reduction was greater for samples equilibrated at low RH conditions (about 80 and 60 % reduction at 5 and 25 °C, respectively) than for those equilibrated at high RH (about 10 % at both temperatures). These results seem to indicate that whereas at low propolis contents the interactions with the EEP compounds seem not to affect the sorption behavior notably, at the highest propolis contents, these compounds notably modify the water-film relationships, thus reducing the ability of the polymer chains to bond water molecules. This fact coincides with notable differences observed in the behavior of the most highly EEP concentrated (1.0 and 1.5 %, wt) film forming dispersions which points to the bonding of HPMC chains to the EEP components, thus limiting their capacity for water interactions. The degree of the polymer bonding was greater at low moisture contents in the films and seems to reduce in line with the water gain in the matrix. In this sense, it is remarkable that the temperature effect on water sorption, which is related to the sorption enthalpy, was very similar for all samples containing different ratios of EEP at high water contents (when samples were equilibrated at about 75 % RH). Nevertheless, it is greatly reduced at low water contents (when samples were equilibrated at 56 % RH) for the highest ratios of propolis in the films. This indicates a great decrease of the water sorption enthalpy in these samples, which points to the promotion of the hydrophobicity of the matrix, associated with the above-mentioned bonding of HPMC to the propolis compounds, which blocks the HPMC active points.

4 Effect of Film Components on Phase Transitions

Component interactions in the hydrocolloid films may affect phase transitions, particularly glass transition temperature (Tg) of the polymer, which can induce changes in the barrier and mechanical properties at a determined temperature. The difference between the product temperature and Tg determines the rate at which diffusion-dependent processes, such as mass transport, occur in the system (Roos 1995) and so it has a great incidence on film barrier properties. Phase transition analysis by DSC in NaCas films containing lipids (OA and BW) was carried out in order to know how the protein-lipid interactions affect the film properties (Fabra et al. 2010). In this sense, glass transition of the hydrocolloid matrices and lipid melting endotherm were characterized as a function of the sample water activity (a w). Table 1 shows the values of Tg (midpoint) obtained for pure sodium caseinate, sodium caseinate-glycerol film (1:0.3 ratio), and sodium caseinate-glycerol-OA film (1:0.3:0.5 ratios) as a function of the sample a w. For samples containing BW, Tg was not obtained because of the fact that the melting endotherm of BW extends over a wide temperature range, overlapping the glass transition of the amorphous matrix. The expected decrease of Tg when sample a w decreases can be observed for all samples, as corresponds to the plasticizing effect of water, which implies a reduction in the mean molecular weight in the system and the corresponding increase in the molecular mobility of the amorphous solid.

It is remarkable that the presence of glycerol implies a marked decrease in the Tg values with respect to the values obtained for caseinate at the same a w, mainly at low a w values. This is coherent with the plasticizing role of glycerol, decreasing the mean molecular weight in the system and affecting molecular mobility and mechanical behavior of the material. The plasticizing effect of water in this case is very mild, since the Tg decrease with a w is very small. This indicates that the glycerol interactions in the matrix inhibit the effect of water and no subsequent, significant plasticization effect was induced. In the completely dried film, 0.3 g of glycerol/g of protein allows the Tg to reach a value in the order of that obtained in the pure caseinate film at a w = 0.675.

The observed behavior indicates that water plasticization effect is more effective in caseinate than in the caseinate-glycerol system, which has also been observed for caseinate and pullulan matrices containing sorbitol as plasticizer (Kristo and Biliaderis 2006) and for gluten matrices when fructose, glucose, and sucrose are incorporated (Kalichevsky et al. 1992). The main factor responsible for this behavior could be the great water bonding capacity of glycerol and other polyol plasticizers that limits the water interactions with the polymer chains and determines the final distribution of water in the system.

In the samples containing OA, no significant effect of this component on Tg values was observed below a w = 0.43, which seems to indicate that OA is in a separate phase and no notable interactions with the caseinate matrix take place. However, a different tendency was observed from this a w value onwards, where Tg in the samples containing OA showed a more decreasing tendency with a w. This behavior indicates that the plasticizing effect of water on the caseinate-glycerol system was promoted in the presence of OA from intermediate a w values onwards, where the molecular mobility has reached a critical level. Interactions of OA in the caseinate matrix could limit the protein chain aggregations to some extent, provoking this effect.

When the Gordon and Taylor equation was fitted to the Tg-water content relationship for the different samples, the above-mentioned glycerol and OA effects on Tg were reflected in significant changes in both Tgas and k parameters (Fabra et al. 2010). The k value is a measure of the water plasticization effect, which is very small in samples containing glycerol (k = 0.12), as compared with pure caseinate (k = 1.56), and slightly increases when OA is incorporated in the matrix (k = 0.68), in agreement with the promotion of the water plasticization effect caused by OA. The Tg values of the anhydrous solids (Tgs) were 109, 58, and 63 °C, respectively, for caseinate, caseinate-glycerol, and caseinate-glycerol-OA films.

The protein-lipid interactions may also affect lipid phase transitions, melting temperature range, and enthalpy. Fabra et al. (2010) analyzed lipid phase transition in the sodium caseinate films containing OA and BW, equilibrated at different a w values, in order to obtain complementary information about their interactions in the film matrix. No significant differences were observed between pure BW melting characteristics (initial melting temperature: 31.3 (±2.4) °C, final melting temperature: 88.3 (±2.8) °C, peak temperature: 69.4 (±1.2) °C, and melting enthalpy 159 (±9) J/g) and those obtained for BW in films equilibrated at different a w. The initial and final temperatures of the endotherm were 29 and 84 °C respectively, peak temperature was 66.4 (±0.5) °C, and melting enthalpy was 155 (±6) J/g BW, without significant differences associated with the equilibrium a w (Fig. 6). This seems to indicate that no notable interactions were developed between protein and wax, which behave as if they were in separate phases. Nevertheless, significant differences were observed among OA melting endotherms of the pure compound and OA films equilibrated at different a w values. Pure OA behaves in a similar way to that described by other authors (Cedeño et al. 2001), with a solid-solid transition (Tr1) at about −50 °C (ΔH = 5.0 J/g) and a solid-liquid transition (Tr2) at about 5 °C (ΔH = 75.5 J/g), showing a broad melting endotherm. The obtained values for the melting enthalpy (Tr2) appear in Fig. 6, as a function of the equilibrium a w value, where a significant reduction was observed in line with the a w increase. So, in film samples, OA crystallization was inhibited to quite an extent, as deduced from the melting enthalpy reduction, and this inhibition increases in line with the increase in sample a w, despite the fact that the associated increase in molecular mobility usually promotes crystallization rates. These results are in agreement with that previously commented on with respect to the OA interactions in the caseinate matrix, which seem to be promoted when a w increases. These interactions lead to the bonding of OA molecules which then are not able to crystallize. So, a part of OA seems to be linked to the caseinate molecules and when the water content increases in the sample, these bonds weaken the polymeric cross-linking in the matrix, making it softer (lower Tg values). This has a great impact on the film’s mechanical and barrier properties due to the influence of molecular mobility on both rheological properties and diffusional processes. In fact, films containing OA showed a marked decrease in both elastic module (EM) and tensile at break (TS) and a sharp increase in elongation at break (E), enhanced by the increase in a w, as compared with the lipid-free caseinate films (Fabra et al. 2010). It is remarkable that the film with OA did not break under the mechanical test conditions when a w is 0.75. However, when BW was the lipid present, the film was more fragile and broke at much lower deformation levels, showing the effect of the matrix discontinuities and the fact that the solid dispersed phase was less deformable (Fabra et al. 2010).

5 Final Remarks

The results commented on reflect the impact of water and lipid-protein interactions on film functionality. Lipids are usually incorporated to modify film barrier properties which are essential to define their application. In this sense, in the composite films obtained through emulsification of components, the development of compound interactions, such as in the case of the OA-caseinate or OA-SPI systems, gives rise to particular functional properties of the film that are not expected in films formed with the lipid dispersed in a separate phase. These aspects are very important in the developing of emulsified polymer films, since two kinds of fillers can be found: inactive or active. Whereas the former only gives rise to discontinuities in the polymer continuous matrix, the latter greatly modifies the properties of this matrix, by changing the cross-linking behavior of the polymer chains, which leads to more marked differences in the film behavior. Physical properties of heterogeneous systems are much more affected by the characteristics of the continuous phase than those of the dispersed phase. So, when active fillers are incorporated in the matrix, the product can behave very differently than when the matrix is not filled. Phase transition analysis as a function of water activity is a good approach to identify the degree of polymer-filler interactions, which in turn are usually affected by water content, and so to predict the final effect of the filler on the film equilibrated at different relative humidities.

Abbreviations

- AFM:

-

Atomic force microscopy

- a w :

-

Water activity

- BW:

-

Beeswax

- E :

-

Elongation at break

- EEP:

-

Ethanol extract of propolis

- EM:

-

Elastic module

- HPMC:

-

Hydroxypropyl methylcellulose

- NaCas:

-

Sodium caseinate

- OA:

-

Oleic acid

- SPI:

-

Soy protein isolate

- Tg:

-

Glass transition temperature

- Tr1:

-

Solid-solid transition

- Tr2:

-

Solid-liquid transition

- TS:

-

Tensile at break

- WSC:

-

Water sorption capacity

- WVP:

-

Water vapor permeability

References

Alves VD, Costa N, Colehoso IM (2010) Barrier properties of biodegradable composite films based on kappa-carrageenan/pectin blends and mica flakes. Carbohydr Polym 79:269–276

Cedeño FO, Prieto MM, Espina A, García JR (2001) Measurements of temperature and melting heat of some pure fatty acids and their binary and ternary mixtures by differential scanning calorimetry. Thermochim Acta 369:39–50

Debeaufort F, Quezada-Gallo JA, Delporte B, Voilley A (2000) Lipid hydrophobicity and physical state effects on the properties of bilayer edible films. J Membr Sci 180:47–55

Elsabee MZ, Abdou ES, Nagy KSA, Eweis M (2008) Surface modification of polypropylene films by chitosan and chitosan/pectin multilayer. Carbohydr Polym 71:187–195

Fabra MJ, Talens P, Chiralt A (2009a) Microstructure and optical properties of sodium caseinate films containing oleic acid–beeswax mixtures. Food Hydrocoll 23:676–683

Fabra MJ, Hambleton A, Talens P, Debeaufort F, Chiralt A, Voilley A (2009b) Influence of interactions on water and aroma permeabilities of ι-carrageenan–oleic acid–beeswax films used for flavour encapsulation. Carbohydr Polym 76:325–332

Fabra MJ, Jiménez A, Atarés L, Talens P, Chiralt A (2009c) Effect of fatty acids and beeswax addition on properties of sodium caseinate dispersions and films. Biomacromolecules 10:1500–1507

Fabra MJ, Talens P, Chiralt A (2010) Water sorption isotherms and phase transitions of sodium caseinate–lipid films as affected by lipid interactions. Food Hydrocoll 24:384–391

Gómez-Estaca J, López de Lacey A, López-Caballero ME, Gómez-Guillén MC, Montero P (2010) Biodegradable gelatin–chitosan films incorporated with essential oils as antimicrobial agents for fish preservation. Food Microbiol 27:889–896

Hambleton A, Voilley A, Debeaufort F (2011) Transport parameters for aroma compounds through i-carrageenan and sodium alginate-based edible films. Food Hydrocoll 25:1128–1133

Jiménez A, Fabra MJ, Talens P, Chiralt A (2010) Effect of lipid self-association on the microstructure and physical properties of hydroxypropyl-methylcellulose edible films containing fatty acids. Carbohydr Polym 82:585–593

Kalichevsky MT, Jaroskiewicz EM, Blanshard JMV (1992) Glass transition of gluten. 1. Gluten and gluten–sugar mixtures. Int J Biol Macromol 14:257–266

Kristo E, Biliaderis CG (2006) Water sorption and thermo-mechanical properties of water/sorbitol-plasticized composite biopolymer films: caseinate-pullulan bilayers and blends. Food Hydrocoll 20:1057–1071

Krochta JM, de Mulder-Johnston C (1997) Edible and biodegradable polymer films: challenges and opportunities. Food Technol 51:61–74

Morillon V, Debeaufort F, Blond G, Capelle M, Voilley A (2002) Factors affecting the moisture permeability of lipid-based edible films: a review. Crit Rev Food Sci Nutr 42:67–89

Ozdemir M, Floros JD (2008) Optimization of edible whey protein films containing preservatives for mechanical and optical properties. J Food Eng 84:116–123

Pastor C, Sánchez-González L, Cháfer M, Chiralt A, González-Martínez C (2010) Physical and antifungal properties of hydroxypropyl-methylcellulose based films containing propolis as affected by moisture content. Carbohydr Polym 82:1174–1183

Roos YH (1995) Phase transitions in food. Academic, San Diego, CA, 360 p

Sánchez-González L, González-Martínez C, Chiralt A, Cháfer M (2010) Physical and antimicrobial properties of chitosan-tea tree essential oil composite films. J Food Eng 98:443–452

Sánchez-González L, Cháfer M, Hernández M, Chiralt A, González-Martínez C (2011) Antimicrobial activity of polysaccharide films containing essential oils. Food Control 22:1302–1310

Srinivasa PC, Ramesh MN, Tharanathan RN (2007) Effect of plasticizers and fatty acids on mechanical and permeability characteristics of chitosan films. Food Hydrocoll 21:1113–1122

Tharanathan RN (2003) Biodegradable films and composite coatings: past, present and future. Trends Food Sci Technol 14:71–78

Villalobos R, Chanona J, Hernández P, Gutiérrez G, Chiralt A (2005) Gloss and transparency of hydroxypropyl-methylcellulose films containing surfactants as affected by their microstructure. Food Hydrocoll 19:53–61

Acknowledgment

The authors acknowledge the financial support from Spanish Ministerio de Educación y Ciencia throughout the project AGL2007-01009 and AGL2010-20694.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer Science+Business Media New York

About this chapter

Cite this chapter

Chiralt, A., Talens, P., Monedero, F.M., Fabra, M.J. (2015). Effect of Different Components of Edible/Biodegradable Composite Films on Water Relationships in the Polymer Matrix. In: Gutiérrez-López, G., Alamilla-Beltrán, L., del Pilar Buera, M., Welti-Chanes, J., Parada-Arias, E., Barbosa-Cánovas, G. (eds) Water Stress in Biological, Chemical, Pharmaceutical and Food Systems. Food Engineering Series. Springer, New York, NY. https://doi.org/10.1007/978-1-4939-2578-0_8

Download citation

DOI: https://doi.org/10.1007/978-1-4939-2578-0_8

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4939-2577-3

Online ISBN: 978-1-4939-2578-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)