Abstract

Physics-based models provide increased understanding and predictive capabilities that can increase efficiency in food product, process, and equipment design; they also improve quality and safety. However, certain key food-specific developments are needed to enable widespread use of simulation technology in the food sector. First and foremost is the need to develop concise modeling frameworks (formulating various food-processing situations in mathematical models) for various classes of processes, as opposed to a custom model for each process, as mostly exists today. Deformable porous media with multiphase transport can provide such a framework, as will be discussed through examples of various processes that have been modeled by many researchers. The next critical piece is to have easy access to the properties that needed to be model. State-of-property prediction, starting from simple correlations and proceeding to multiscale modeling and thermodynamics-based and molecular dynamics, as is being pursued by researchers around the world, will be shared. Prediction beyond process to quality and safety is the third topic, where various approaches to modeling quality in a diffusion-reaction modeling framework will be presented. For safety, a practical approach that groups various food products, and thus provides an avenue to simulate safety for a large number of situations, will be shared. Finally, efforts to integrate modeling components into a novel, user-friendly software for increased use of modeling will be described.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Introduction: Overview of Modeling Frameworks

Food materials, processes, and equipment cover a very large set of scenarios. Modeling of food processes has also been approached in a number of ways, from completely empirical to completely physics-based approaches. The question is whether we can develop a few general frameworks for modeling food processes that can effectively handle a large number of practical situations and be easily implemented (preferably in a commercial software) for widespread use of computer-aided food process engineering. In other words, what is a methodical and the most effective approach to modeling a process?

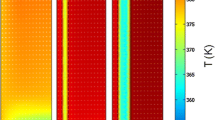

Over the years, the author’s research group has modeled temperature and moisture transport in microwave heating, baking, deep frying, puffing, and meat cooking (Halder et al. 2011b). These processes cover a range of physics in addition to simple conduction and diffusion processes, for example, bread baking pressure generation inside the dough due to both evaporation and gas from fermentation, and large volume changes due to the ensuing pressures. Meat cooking involves significant moisture loss, which results in large volume changes and transport of water, while the driving force for transport of water is swelling pressure (instead of capillary pressure). In deep frying, strong evaporation inside the food matrix leads to pressure-driven flow, while oil pickup is an additional transport process of interest. Likewise, microwave heating entails enhanced pressure-driven transport of moisture from the interior to the surface. It appears that the same general framework of multiphase transport in deformable/swellable porous media with rapid evaporation is at work in this spectrum of processes. A survey of most of the existing models in the food literature shows that of the fundamental physics-based approaches, this framework is broad, flexible in accommodating many different processes, and easier to understand and implement in commercial software. By looking at additional processes, such as transport plus deformation plus reaction kinetics, an investigation was undertaken into how this same framework could include other processes and thus indeed be a general framework. Also investigated were the auxiliary relationships (e.g., evaporation) that would be needed for such frameworks. Finally, the frameworks were extended to quality and safety prediction.

Frameworks

The frameworks that can be used to model an arbitrary food process are summarized here. As shown in Fig. 22.1, first, all formulations are divided into three major categories – continuum formulation, porous media formulation, and deformable porous media formulation. Each of these may be called a framework. The typical continuum formulation (Framework F1) will not be discussed here, nor will the large pore formulation (Framework F2), which has been discussed elsewhere (Datta 2007). Here, we elaborate more on the small pore formulation and, especially, how to handle deformation. Thus, Fig. 22.2 shows a schematic of various possibilities for dealing with mass transport, heat transport, and deformation (Frameworks F3 and F4).

Framework F1: Single-phase and Multiphase Continuum Equations

The most common set of transport equations is for single-phase transport equations, as shown in any standard textbook on transport processes. Examples of processes that can be modeled using single-phase and multiphase continuum equations are shown in Table 22.1.

Framework F2: Large Pores: Multiphase Transport with Navier–Stokes Equivalent of Darcy Equation

An example of a problem formulation in large pores is the cooling of stacked bulk produce such as potatoes, chicory roots, and pears. The Navier-Stokes (N–S) analog of the Darcy equation, together with species transport and energy equations, is used in these studies. It is discussed elsewhere (Datta 2007) in more detail.

Summary Framework F3: Multiphase, Rigid Porous Media Continuum Equations

An enormous range of food processes can be viewed as involving the transport of heat and mass through porous media. Examples include drying, frying, microwave heating, meat roasting, puffing, and rehydration of solids. Most solid food materials can be treated as hygroscopic and capillary-porous. A porous media formulation homogenizes the real porous material and treats it as a continuum where the pore-scale information is no longer available. Since this framework can cover a large range of situations and be simplified to various levels, the general set of equations is presented first, followed by various adaptations, which are the simplified versions.

In the most general version (for rigid porous media), individual phases of water, vapor, air, and energy are tracked using their conservation equations:

Here

is the flux of water due to gas pressure, the moisture dependence of capillarity, and the temperature dependence of capillarity, respectively. Similarly, flux of vapor is given by

due to gradients in gas pressure and vapor pressure (decomposed into three separate effects representing the last three terms – binary diffusion, driven by liquid concentration and by temperature) (Dhall and Datta 2011). There is no distinct flow equation because Darcy’s law used in water, vapor, and air transport equations is a replacement for the fluid flow or momentum equation. To complete the system, we need an additional equation. This additional information provides the rate of evaporation and can be formulated in one of two ways (Halder et al. 2011b):

Equation 22.7 is the equilibrium relation for material relating the vapor pressure to moisture and temperature. Equation 22.8 is a nonequilibrium formulation that approaches Eq. 22.7 for large values of K. A number of food processes (e.g., drying, baking, frying, microwave heating) have been modeled by several researchers using mostly Eq. 22.7, but some have used Eq. 22.8.

Framework F3.1 Small Pores: Effective Diffusivity of Combined “Moisture” Phase

The liquid water and water vapor phases in the previous section can be combined into an effective “moisture” phase with the following equations that perhaps have been the most common formulations used in food:

Here the pressure gradient inside the food is ignored and the transport of liquid or vapor due to the temperature gradient is also ignored. The diffusivity, \(D_{c_{w}}\), is due to liquid and vapor diffusion from the gradient in the water content, \(D_{c_{w}} = D_{w,c_{w}} + D_{v,c_{w}}\), which includes the capillary-pressure dependence on the moisture content in \(D_{w,c_{w}}\) and vapor-pressure dependence on the moisture content in \(D_{v,c_{w}}\). Note that the rate of evaporation, \(\dot{I}\), is not required if temperature is not a concern. If temperatures are required, Eq. 22.4 for energy will have convective terms contributed by the water and vapor.

Framework F3.2 Small Pores: Transport of Liquid Phase Only

Evaporation is considered only from the surface and ignores evaporation inside the domain. This can happen for intensive surface heating of a very wet material. The energy equation will have a convective term due to water only. Transport of water will be given by

The liquid diffusivity, \(D_{w,c_{w}}\), includes parameters for Darcy flow and those relating pressure to concentration. For meat cooking (Dhall and Datta 2011), for example, the liquid diffusivity includes parameters related to Darcy flow and those relating swelling pressure to water concentration (van der Sman 2007a). Additional temperature-related terms can also be present on the right-hand side (Dhall and Datta 2011).

Framework F3.3 Small Pores: Transport of Vapor Phase Only

This is a special case when very little liquid moisture is present, as near the end of a drying process. Transport is dominated by that of vapor:

Since little liquid is present, the transport of liquid can be ignored, which then leads to the equation for \(\dot{I} = -\partial c_{w}/\partial t\), which can be substituted into the energy equation.

Framework F4: Multiphase, Deformable Porous Media Continuum Equations

A deforming (shrinking/swelling) porous medium is essentially handled by treating all the fluxes discussed earlier for a rigid porous medium as being relative to the solid skeleton and combining this with a velocity of the solid skeleton that comes from the deformation obtained from a solid mechanical analysis. Since the solid has a finite velocity, \(\vec{v}_{s,G}\), the mass flux of a species, i, with respect to a stationary observer, \(\vec{n}_{i,G}\), (used in Eqs. 22.14–22.17) can be written as the sum of the flux with respect to solid and that due to the movement of the solid with respect to the stationary observer:

The movement of the solid, in turn, is obtained from a stress–strain analysis. If \(\bar{\boldsymbol{ \sigma }}^{\prime}\) is the effective stress on the solid skeleton, then for an unsaturated material where the capillary pressure is dominant, and the swelling pressure and gravity can be ignored, \(\bar{\boldsymbol{ \sigma }}^{\prime}\) can be written in terms of fluid pressures as

where the first term on the right-hand side is the gas pressure gradient (due to the evaporation of water or to gas release, as with carbon dioxide in baking) and p c in the second term on the right-hand side is the capillary pressure that would be a function of the temperature and moisture content of the food material. In this equation, S w is the water saturation. Kelvin’s law can be used to estimate p c from water activity. In situations where a swelling pressure is present, as in meat cooking, the right-hand side of the preceding equation has different terms, and an example of such details can be found in (Dhall and Datta 2011; van der Sman 2007a). A general form of such pressures is discussed in Datta (2012). Food material can be treated as elastic or viscoelastic, and the corresponding stress–strain relationship can be used with the appropriate solid momentum equation.

The transport equations in Framework F3 are generalized for this situation, using Eq. 22.12, as

Here the air equation is replaced by a gas (vapor plus air) equation (Eq. 22.16), which is an equivalent form.

Advantages of Modeling Framework (F3 or F4)

Frameworks F3 and F4 described earlier are physics-based and mechanistic and use standard conservation laws and poromechanics formulations. The transport model is a departure from the effective diffusivity-based models often seen in the food process modeling literature. There are very few empirical factors in the preceding formulations. Food material aspects, such as a glassy or rubbery state, are included by having material properties that vary with the state of the material. A significant aspect of the formulations is that since they are based on standard forms of the equations, they are readily implementable in standard commercial software. Such an ability to be implemented should enable the food process modeling community to significantly reduce the time and effort needed in building a process model, bringing the full utility of modeling as a tool to design and optimization.

Challenges

Several challenges must be faced in the large-scale use of the modeling framework discussed earlier; these challenges are not insurmountable, but they would demand continuous improvement in the coming years. Such challenges can involve (1) obtaining the required properties, (2) obtaining appropriate driving forces, (3) obtaining the appropriate boundary conditions, (4) meeting computational challenges, (5) making sure all relevant phenomena are adequately included, and (6) validating the models.

One of the bottlenecks in the large-scale use of the preceding framework is the lack of material properties. Since food material changes in temperature and composition during processing, the material must possess properties as a function of temperature and composition. Such exhaustive data will never be available from direct experimentation; predictive models are needed for properties, as compiled in Gulati and Datta (2012). Such prediction can come from thermodynamics, a soft-matter approach, effective medium theory, and homogenization, in addition to empirical correlations obtained directly from experiment. Significant work is being done with respect to a soft-matter approach, which has been successful in modeling moisture sorption and phase transitions in mixtures of water, polysaccharides, and proteins (van der Sman 2012; van der Sman and Meinders 2011) and computing the water-holding capacity of meat proteins (van der Sman 2007a,b, 2012). Another promising approach is to obtain properties through homogenization. This is also a multiscale approach (Nicolai et al. 2012) in which a detailed microstructure is obtained and the microscale problem is solved using a framework similar to that described here. The results are then homogenized to obtain macroscale properties. As the equipment and related software to obtain a complete three-dimensional microstructure and its analysis become readily available, this approach to obtaining macroscale properties is quite likely to become an important one.

The liquid pressure, p w , in Eq. 22.13 is the driving force for liquid transport – it is part of the closure relations needed to solve the governing transport equations. In general, liquid pressure is composed of gas pressure (from evaporation or gas generation, as in bread baking), capillary pressure (in unsaturated materials), swelling pressure (arising from osmotic, elastic, and ionic components), and gravity. This is discussed in detail in Datta (2012). Difficulties arise in deciding which of these pressures are significant in a given situation and, for some of the pressures, in obtaining their numerical values.

Obtaining boundary conditions on a porous media surface can be a challenge, at least in some situations. For example, in frying, the surface heat and mass transfer coefficients vary with time in a complex manner that is difficult to determine even experimentally. In some situations, as in microwave heating of a food (porous medium) with surrounding air, the heat transfer coefficient was obtained by formulating the porous medium and its surrounding as a conjugate problem (Halder and Datta 2012).

There can be a number of numerical challenges. When one of the phases disappears (e.g., a pore is completely saturated with liquid so the gas phase becomes zero), a numerical workaround is needed. For example, the disappearing phase can be set to not drop below some very small amount (so the overall computation is not significantly affected). In some software, implementation of Darcy’s law is straightforward, whereas in other software, Navier–Stokes equations need to be solved for each fluid phase, leading to a significant increase in computing time.

Although the framework is general enough and includes transport, solid mechanics, and their coupling, it is not clear whether the phenomenon of Case II diffusion can be captured in the framework. Based on the competing theories used to explain Case II diffusion (Bargmann et al. 2011), which are not unlike the framework presented here, whether Case II diffusion is included in the framework is far from obvious. Of course, a very important question in this context has to do with the product-process combination for which Case II diffusion is relevant (and must be included), which has also not been adequately answered. Planning is under way to compare the results from the framework presented here with those from a theory (Pawan 2011) that includes Case II diffusion more explicitly.

Detailed porous media models generate information on many different physical variables, including, for example, temperature, moisture, pressure, porosity development, and evaporation zones. Both the spatial and temporal variations of these quantities are available. While experimental verifications are possible, with reasonable effort, for temperatures at one physical location (using a thermocouple), spatial variation on an outside surface (using an infrared camera), loss of total moisture with time (from simple weight measurements), total change in volume with time (using a volume displacement method), and other predictions from the model can be quite difficult to verify. For example, spatial temperature and moisture profiles with time are possible (Rakesh et al. 2010) using magnetic resonance imaging (MRI), but this is hardly a routine process and the experimental work can be more time and resource consuming than the model. It would be very difficult to verify, for example, the spatial variation of the evaporation rate. Thus, comprehensive validation of these models will be difficult for years to come.

Framework for Quality Modeling

Once the process modeling framework is developed, quality and safety models can be related to the process models in a somewhat straightforward way as long as the relationship between quality parameters and temperature/moisture/composition or their histories are available. Although there are missing areas, such relationships for the kinetics of quality changes are available in a number of important areas (van Boekel 2009). A framework for the eventual prediction of quality from temperature and moisture is shown in Fig. 22.3a. We consider an effective quality attribute (e.g., texture, color) as a composite of a local (i.e., at a spatial location) quality attribute, obtained either by following relevant chemical reactions and transport or by following measured local properties. The local quality attribute, in turn, is predicted from the local temperature and composition available from the process models. The process and quality prediction models are thus coupled, closing the gap between process prediction and quality prediction for complex food processes. An application of this framework to the modeling of texture in the deep frying of potatoes is illustrated in Fig. 22.3b (Thussu and Datta 2012). Here the temperature and moisture variations from the process model are combined with the relationship of Young’s modulus to the moisture obtained from thin sections of potatoes dried to various moisture contents to obtain a profile of Young’s modulus throughout the cross section of the fried potatoes. Using this varying Young’s modulus, a small deformation mechanical analysis is performed to obtain the effective Young’s modulus of the entire cross section of the fried potato that correlates with texture.

Framework for Safety Modeling

In a very analogous way, the safety prediction framework will couple microbiological (or chemical) kinetics to temperature, moisture, and composition information obtained from the process model. The main issues in building such a framework include the selection of predictive models, associations of various food types with pathogens (as determined from outbreak histories), and variability in data from different experiments (Halder et al. 2010). More than 1,000 data sets from the published literature were analyzed and grouped by microorganism and food type. The final grouping of data consisted of the 8 most prevalent pathogens for 14 different food groups, covering all of the foods (more than 7,000) listed in the USDA National Nutrient Database. The primary advantage in obtaining group-specific kinetic data is that it confers the ability to extend microbiological growth and death simulation to a large array of product and process possibilities while still being reasonably accurate. This integration has been included in a software to be made publicly available (Halder et al. 2011a).

Conclusions

A deformable porous media framework can effectively model a large number of complex food processes. Such a generalized framework that is also easily implementable in existing software can go a long way toward enabling computer-aided food process engineering. Simplifications are possible in this framework, which resembles commonly used formulations but, starting from the most general equations, makes it easier to see the assumptions that are involved in the simplified formulations. A synthesis is provided for frameworks for modeling the largest collection of food processes. A framework for process models can be included in an overall diffusion-reaction framework to predict quality and safety.

References

Bargmann S, McBride AT, Steinmann P (2011) Models of solvent penetration in glassy polymers with an emphasis on case II diffusion. A comparative review. Appl Mech Rev 64(1). doi:10.1115/1.4003955

Datta AK (2007) Porous media approaches to studying simultaneous heat and mass transfer in food processes. I: problem formulations. J Food Eng 80:80–95

Dhall A, Datta AK (2011) Transport in deformable food materials: a poromechanics approach. Chem Eng Sci 66(24):6482–6497

Datta AK, van der Sman R, Gulati T, Warning A (2012) Soft matter approaches as enablers for food macroscale simulation. Faraday Discuss 158:435–459

Gulati T, Datta AK (2013) Enabling computer-aided food process engineering: property estimation equations for transport phenomena-based models. J Food Eng 116:483–504

Halder A, Datta AK (2012) Surface heat and mass transfer coefficients for multiphase porous media transport models with rapid evaporation. Food Bioprod Process 90(c3):475–490

Halder A, Black DG, Davidson PM, Datta AK (2010) Development of associations and kinetic models for microbiological data to be used in comprehensive food safety prediction software. J Food Sci 75(6):R107–R120

Halder A, Dhall A, Datta AK, Black DG, Davidson PM, Li J, Zivanovic S (2011a) User-friendly general-purpose predictive software package for food safety. J Food Eng 104:173–185

Halder A, Dhall A, Datta AK (2011b) Modeling transport in porous media with phase change: applications to food processing. J Heat Transf Trans Am Soc Mech Eng 133(3):031010-1–031010-13

Ho QT, Carmeliet J, Datta AK, Defraeye T, Delele MA, Herremans E, Opara L, Ramon H, Tijskens E, van der Sman R, Van Liedekerke P, Verboven P, Nicolai BM (2013) Multiscale modeling in food engineering. J Food Eng 114(3):279–291

Nicolai BM, Datta AK, Defraeye T, Delele MA, Ho QT, Opara L, Ramon H, Tijskens E, van der Sman R, Liedekerke PV, Verboven P (2012) Multiscale modeling in food engineering. J Food Eng (To be submitted)

Pawan ST (2011) Hybrid mixture theory based moisture transport and stress development in corn kernels during drying: coupled fluid transport and stress equations. J Food Eng 105(4):663–670

Rakesh V, Seo Y, Datta AK, McCarthy KL, McCarthy MJ (2010) Heat transfer during microwave combination heating: computational modeling and MRI experiments. Am Inst Chem Eng J 56(9):2468–2478

Thussu S, Datta AK (2012) Texture prediction during deep frying: a mechanistic approach. J Food Eng 108:111–121

van Boekel MAJS (2009) Kinetic modeling of reactions in foods. CRC/Francis & Taylor, Boca Raton, FL

van der Sman RGM (2007a) Soft condensed matter perspective on moisture transport in cooking meat. AIChE J 53(11):2986–2995

van der Sman RGM (2007b) Moisture transport during cooking of meat: an analysis based on Flory-Rehner theory. Meat Sci 76:730–738

van der Sman RGM (2012) Thermodynamics of meat proteins. Food Hydrocoll 27:529–535

van der Sman RGM, Meinders MBJ (2011) Prediction of the state diagram of starch water mixtures using the Flory–Huggins free volume theory. Soft Matter 7(2):429–442

Acknowledgements

This project was partially supported by National Research Initiative Grant 2008-35503-18657 from the U.S. Department of Agriculture Cooperative State Research, Education, and Extension Service Competitive Grants program.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer Science+Business Media New York

About this chapter

Cite this chapter

Datta, A., Dhall, A. (2013). Modeling Food Process, Quality and Safety: Frameworks and Challenges. In: Yanniotis, S., Taoukis, P., Stoforos, N., Karathanos, V. (eds) Advances in Food Process Engineering Research and Applications. Food Engineering Series. Springer, Boston, MA. https://doi.org/10.1007/978-1-4614-7906-2_22

Download citation

DOI: https://doi.org/10.1007/978-1-4614-7906-2_22

Published:

Publisher Name: Springer, Boston, MA

Print ISBN: 978-1-4614-7905-5

Online ISBN: 978-1-4614-7906-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)