Abstract

Processes that occur in porous media such as drying, vapor-induced puffing and rehydration take place in a dynamic environment constrained by initial porosity and/or changes in porosity as the process proceeds. In the literature, modeling of porosity is performed using fundamental concepts (Datta 2007) or empirical correlations (Mayor and Sereno 2004; Saguy et al. 2005).

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Porous Medium

- Capillary Pressure

- Moisture Diffusion

- Pore Structure Parameter

- Weibull Distribution Function

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Processes that occur in porous media such as drying, vapor-induced puffing and rehydration take place in a dynamic environment constrained by initial porosity and/or changes in porosity as the process proceeds. In the literature, modeling of porosity is performed using fundamental concepts (Datta 2007) or empirical correlations (Mayor and Sereno 2004; Saguy et al. 2005).

Fundamental mathematical models require in depth understanding of the process that requires evaluation of physical properties and quantification of their complex inter-relationships. Since it will not be possible to quantify all these complexities, the accuracy of the fundamental models are constrained with the assumptions made. Thus, fundamental models are not one-to-one representations of the reality; they only signify rational perceptions.

Empirical models are developed by curve fitting to the experimental data. Process variables are selected and the response variables are measured. Uncertainties are taken into consideration by means of a statistically designed experimental plan. The empirical correlation found as a result of this experimental plan has no physical meaning, and it is specific to the particular material, particular geometry and configuration of the equipment, and also the constraints of the equipment related with the boundary conditions (Khalloufi et al. 2009).

Mathematical modeling is a cognitive field that offers practical solutions to complex problems. Thus, fundamental and empirical models are also not as black and white, but there are grey areas in which fundamental concepts are applied and the constants of the fundamental model are evaluated from statistically designed experiments. One such model is the diffusion model.

4.1 The Continuum Model (Diffusion Model)

The diffusion model is a combination of fundamental and empirical approaches. The pore space is treated as continuum consistent with the macroscopic scale appearance in which all microscopic effects are lumped into an effective diffusivity. Effective diffusivity is described in terms of Fick’s 2nd law of diffusion:

where \( \varphi \) is moisture (kg/m3) or energy \( \left( {\rho C_{p} T,{\text{ W/m}}^{ 3} } \right) \), t is the time (s), D eff is the effective moisture (m2/s), or thermal diffusivity (m2/s), which can be expressed by:

in which ε is the porosity of the material (dimensionless), \( D \) is the actual diffusivity in the pores (m2/s) and \( \tau \) is the tortuosity factor (dimensionless). Tortuosity is a correction factor that lengthens the diffusive path accounting for the fact that the pores do not follow straight line paths. This results in a reduction in local diffusion fluxes. The main drawback of the diffusion model is: it assumes that the process is mainly diffusion controlled, and the tortuosity correction may not be able to provide an explanation on other mechanisms involved.

The model ignores the effect of chemical interaction between the solid walls and the fluid phase (moisture or oil). Diffusivities are lumped over the whole porous medium, and thus are independent of local concentrations. However, puffed, baked, extruded, dried, frozen and freeze-dried processed porous solid foods do not exhibit a uniform pore structure, i.e. pore sizes vary within several orders of magnitude (Dogan et al. 2013; Gueven and Hicsasmaz 2011; Kocer et al. 2007; Hicsasmaz et al. 2003; Hicsasmaz and Clayton 1992). This further leads to local variations in cell wall thicknesses (Trater et al. 2005). In addition to that the pore space is formed of three types of pores, namely interconnected pores, dead-end pores and non-interconnected, closed pores (Gueven and Hicsasmaz 2011; Hicsasmaz and Clayton 1992). Therefore, concentrations of transported quantities and their diffusivities are subject to local variations. Initial concentrations are assumed to be uniform within the sample. Instant saturation of the surface is assumed in the case of moisture diffusion, and thus boundary layer resistance is ignored. The geometry is assumed to be a perfect slab, cylinder or sphere. Swelling and shrinkage are not taken into consideration.

4.2 Empirical and Semi-Empirical Models

The most common empirical model used to express moisture diffusion is the Weibull distribution function:

where \( M_{t} \) is the moisture content at time t (kg/kg), \( M_{i} \) is the initial moisture content (kg/kg), t is time (s), and α and β are the model parameters. In the Weibull distribution function, α is the scale parameter and is the reciprocal of the process rate constant, while β determines the shape of the distribution. Weibull model provides information on the kinetics of moisture diffusion (Marabi et al. 2003), but does not provide information on the effects of the pore structure and the transport mechanisms.

4.3 Capillary Models

Experimental studies on porous food matrices suggested that moisture and oil transport in food materials is driven by the capillary pressure (Carbonell et al. 2004) described by Laplace-Young equation:

where \( P_{\text{c}} \) is the capillary pressure (Pa), σ is the surface tension (N/m), θ is the contact angle and D is the capillary diameter (m). The capillary rise, h (m) curve (Aguilera et al. 2004) can be depicted from a force balance known as the Lucas-Washburn equation:

and

in which k is the capillary coefficient (m/√s), μ is the liquid viscosity (Pa-s) and t is time (s). However, discrepancies from the experimental curve were encountered since the porous food was regarded as a bundle of cylindrical straight capillaries with an effective mean diameter. Carbonell et al. (2004) introduced a tortuosity correction factor (\( \tau^{2} \), dimensionless) in which the capillary coefficient was redefined:

4.4 The Pore Network Model

The advantage of the pore network model is: it does not require assumptions and approximations on transport properties such as effective diffusivity or tortuosity. It is a realistic pore structure model that simulates the measured pore structure parameters such as the total pore volume, the non-interconnected pore volume and the pore size distribution. Then, transport problems can further be simulated numerically on the suggested pore network. Conclusions can then be implemented by comparing the simulation results with the experimental data.

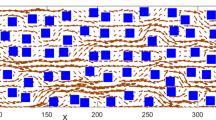

The classical capillary model assumes the porous medium to be formed of pores with an effective mean pore size. The network model accounts for the interconnectivity of pore segments with various sizes within the limitations of a lattice geometry. The simplest network is the one in which capillary segments are connected in descending order, i.e., large pore segments are always followed by progressively smaller ones in the direction of intrusion into the network. This is a 1-D network (Fig. 4.1a) called the straight capillary model. The straight capillary model is used to evaluate pore size distributions from porosimetry data, i.e., mercury intruded pore volume versus capillary pressure.

The corrugated pore concept (Tsetsekou et al. 1991) is an improvement on the straight capillary network. It offers 1-D interconnectivity allowing random distribution of capillary diameters in a parallel bundle of corrugated pores (Fig. 4.1b). This type of network allows integration of neck-and-bulge assemblies into the pore structure. The corrugated pores can be designed as assemblies of cylindrical, triangular, slit or polygonal sections. Segura and Toledo (2005) found that pore shapes used in the model do not affect transport characteristics such as drying curves, relative vapor diffusivity, and relative liquid permeability. Thus, the usual approach is to assume the porous medium to be made up of cylindrical pore segments. A highly interconnected porous sample can be approached as a 1-D network of corrugated pores since penetration of the pore space in any direction will lead to flooding in all directions. The 1-D interconnectivity is capable of simulating the microstructure of materials with porosities ≤ 0.85. The 1-D topology is inadequate in quantitative verification of the non-interconnected pore volume (Gueven and Hicsasmaz 2011).

The network model is referred to as the 2-D network model when 2-D interconnectivity on the lattice plane is considered. When 3-D interconnectivity is considered in a 3-D lattice, then the model is referred to as the 3-D network model. There are two possible ways of building 2- and 3-D network models (Chan and Hughes 1988; Steele and Nieber 1994; Deepak and Bhatia 1994). One way is not to consider junction volumes and the other way is to specify the junction volumes. Specifying the junction volumes is necessary for realistic pore structure simulations of high porosity materials (porosity > 0.85) (Fig. 4.2). Highly expanded foods such as breads and extruded snacks fall into this category. These materials are characterized by high porosity, highly interconnected pore structure together with considerable amount of non-interconnected pores (Fig. 4.1b). However, it is obvious that a network model that represents the porous material realistically requires sensitive measurements of the macroscopic and microscopic pore structure parameters.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2013 Alper Gueven and Zeynep Hicsasmaz

About this chapter

Cite this chapter

Gueven, A., Katnas, Z.H. (2013). Transport in Porous Media. In: Pore Structure in Food. SpringerBriefs in Food, Health, and Nutrition. Springer, New York, NY. https://doi.org/10.1007/978-1-4614-7354-1_4

Download citation

DOI: https://doi.org/10.1007/978-1-4614-7354-1_4

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4614-7353-4

Online ISBN: 978-1-4614-7354-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)