Abstract

In recent years, the production of consumer goods has exceeded that of industrial products. This has led to changes in the areas of design and production. The target users of industrial products (in the Business to Business—B2B market) are industries that decide to purchase a product on the basis of its technical features, functions and performance. Differently, the target users of consumer products (in the Business to Consumer—B2C market) are the consumers who choose a product driven by other aspects, besides features and functions, such as the perceived value, the expected benefits, the emotions elicited, as well as features and functions. This has brought a paradigm shift in the design process. And in fact, the design of consumer products is increasingly focusing on the so-called user experience. The designer must not design only the product, but also the user experience in relation to its use. The resulting product should have a high perceived value and generate positive emotions in the consumer. These factors make a successful product on the market. Therefore, the role of the designer is designing the products and the perceptual aspects of their use, that is, designing the user experience and deriving from that the products’ specifications. Consequently to that, the design process has changed in the last years. In fact, the user is now at the center of the design process, named user-centered design. Being the new focus the target users, the evaluation of their interaction with the new designed products is expected to be rigorous and systematic. An efficient approach has proved to be one in which the validation is made up by involving users in the early stages of the product design. Since typically at the level of the concept the product, or a prototype that is comparable with it at the perceptual level, is not available, it is not possible to make a thorough validation of its use with users. However, new methodologies of Virtual Prototyping allow us to simulate multisensory user interaction with product concepts early in the design process. This chapter introduces the use of interactive Virtual Prototyping (iVP) methodology for the design of the user experience with the concept of a new product. Interactive components of new products and their behavior are simulated through functional models, and users can experience them through multisensory Virtual Reality (VR) technologies.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

14.1 Introduction

Product innovation refers to the design and implementation of newly designed products, which are proving successful in the market for their novel aspects, which may concern aesthetics, functionality and usability. Product innovation is based on a first generative phase in which many solutions are proposed in response to an initial market question [1, 2]. A creative approach of the designers and engineers at this stage is crucial in order to identify genuinely new solutions. Obviously, the creative phase is also very exploratory, and the set of solutions identified must then be carefully analyzed in order to discard most of those and preserve the one to implement.

The traditional approach of design is based on the proposition of engineering (technical and quantitative) questions that focus the research of the design solutions on issues relating to the efficiency and effectiveness of the product, in relation to the task it must perform.

A product is designed and produced for its consumers, and this is especially true for consumer products, that is, those goods intended for direct use or consumption by the average consumer. Consumers buy a specific product for several reasons, for example, because of its price or brand. Or for its features, for its specific functionalities, but also for the perceived benefits the product delivers. These aspects are related to the perceived value of a product, which can be defined as the mental estimation a consumer makes of it [3]. When considering consumer products, the consumption experience is the true value of a product for consumers. In this view, the consumers, and all issues related to them like feelings, preferences, emotions, become central in the design of a new product.

Actually, the traditional design approach based on engineering questions is independent of considerations related to the consumer. The questions that the designer must answer concern engineering aspects, such as Does the solution work? Are consumption and cost optimized? Is the product sturdy, durable, etc.? Such questions certainly do not consider the preferences of the user of the product. In fact, questions that can be defined as emotional questions are not typically raised, such as Does the user like the product for what concerns its aesthetics, usability, comfort? Which are the user preferences? Does he prefer solution A or solution B or rather C?

As it is demonstrated that emotional aspects contribute greatly to the success of a product and to the affection of the users for that product or brand at long term, today’s design cannot ignore the study of the emotional aspects, since the early stages of the product concept [4]. The bond of an individual to a product is significantly driven by the emotional-subjective values. Actually, emotion is one of the strongest differentiators in user experience principally because it triggers unconscious attitude and mood in relation to a product [5].

Nowadays, users have clear expectations about a product. For example, they assume that a product works properly and also that they have the possibility of choosing among many comparable alternatives at the moment of purchase. What is becoming evident is the importance that the user (a potential customer before becoming a user) really likes the product, from various perspectives, and chooses it among a set of alternative products offered by competitors. So, it is important to ensure that the product captures the preferences of the user through several features, such as form, finishing, material, meaning and others.

Therefore, generating positive emotions in consumers becomes an essential design issue. In the view of designing a successful product, the designer should now favor the users’ preferences, rather than the product performances. And this is why emotion becomes one of the key requirements of design. As the emotional responses should be predicted already during the conceptual phase, the drivers of the emotions can be intended as tuner for design: an elicited negative emotion can be used to change the product features as long as a positive emotion is yielded.

Engineering questions usually generate answers and solutions that are well analyzed, observable, measurable and quantifiable. Instead, how to understand and consider the implicit and explicit desires and feelings of the individual, how to measure the emotions and how to trigger them when interacting with the product are actually open issues. An additional issue is also about how to test the design solutions, considering the emotional aspects and not just the functional ones. Or indeed, the question to answer is about how to organize the design requirements around the emotions that embody users’ expectations and preferences.

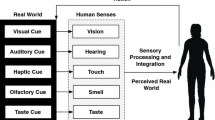

Users learn about products through a direct experience, which happens through an actual interaction with the product. People interact with everyday objects through sensory dimensions, which include vision, touch, hearing, smell and taste. This experience is also important when purchasing a product. Actually, it is also on the basis of the kind of experience one makes that one chooses and buys a product rather than another one.

When considering the interaction between a user and a consumer product, the sense of touch is a fundamental part of our experience. In fact, everyday, we use products and we also use our sense of touch as an integral part of our experience when using these products. It has been demonstrated that the design requirements should also address haptic interaction with products, including the user emotional engagement [6]. Haptic interaction design (HID) is then a topic of major importance deserving study and experimenting [7], as well as sonic interaction design, since touch also works in tight partnership with vision and hearing in many ways [8]. So, it is necessary to consider the user interaction with the product as a multisensory experience.

This chapter first describes the evolution of the design context, where in the last decades we have assisted to an evolution of machines, systems, products and services, and accordingly the changes in the design methodology and paradigms, in the role of designers, and in enabling tools as well. Then, the chapter reasons about the relationship between consumers and products, including perceived value of a product and user interaction with a product. The two subsequent sections present issues about user experience design (UXD) and how iVP can be used for the simulation of the user experience, including two case studies as examples. Finally, the last section presents the conclusions.

14.2 The Evolution of the Design Context

In order to fully understand the present design practice and its evolution trend, it is useful analyzing the evolution of design, also in relation to the kinds of artifacts it addressed. This section presents the evolution of the design context where we analyze the objective and output of the design, the design process, the role of designers and the enabling design methods and tools. These issues are tightly correlated; for in the last decades, the design process has evolved, in accordance with the evolution of the typology and complexity of the artifacts, and new tools have been introduced, and also designers have taken on new roles.

14.2.1 Machines, Systems and Products

Traditionally, the designers’ activity was about creating and designing machines. Machines were intended as devices consisting of fixed and moving parts that modify mechanical energy and transmit it into a more useful form [9]. Therefore, machines were built with the aim of satisfying functions, generally oriented to help humans in doing things usually amplifying their craftsmanship and skill, by decreasing risk, fatigue, etc. In that time, users’ expectation was that the machine operates properly and does not break.

Besides machines, systems have been subjects of study for design teams. Systems are more complex than machines, as they consist of groups of interacting, interrelated elements forming a whole complex. Systems are characterized by being multitechnological and with embedded controls and usually can be made up of mechanical electronic, pneumatic and oleodynamic components. Systems consist of assembly of subsystems, based on varied technologies for operating as a whole. Also for complex systems, the expectations of users are essentially related to technical functions, with an emphasis on reliability, fault tolerance, adaptability, flexibility, etc.

While technical systems can be part of a whole without any relation with humans, and only interact with other technical systems, products are strictly related to their users. A product can be defined as anything that can be offered to customers, which might satisfy a want or a need. The increasing spread of products with respect to systems has been accompanied by the growing importance of the users in relation to the products. Their satisfaction about the product is of primary importance for its success. Besides, designing a product also means designing the market addressed by the product and the accompanying services [10, 11].

In summary, the subject of design includes machines and systems, which have little to do with users, and products, which conversely have a strong relation with their users.

14.2.2 Functions and User Experience

In case of machines or systems, the users’ main interest is focused on issues concerning their functions and technical features. Actually, it is important that the system that works well, does not break, is efficient and performing. Accordingly, the design is primarily aiming at ensuring these characteristics.

But in recent years, the focus has shifted. In fact, innovation in design is also crucial when delivering systems and industrial products more generally. Innovation has to do with the improvement of existing products or with the development of new products, which have new features, new aesthetics, new materials, etc. The technological innovation is accompanied by an additional value, namely the user experience, which is related to the effects that the product’s use have on users.

These effects are particularly important in relation to the first contact that a customer has with a product during the purchasing decision process. Most of the times, the customers choose and buy what they like most. The motivation is often not clearly expressed or expressible and is somehow related to the emotional response, which induces the user to prefer a product to another.

In this changing and evolving context, also the design process has evolved accordingly, as described in the following section.

14.2.3 The Evolution of the Design Process

The design process has followed the evolution of the typology of designed artifacts. At least four types of design processes and approaches can be identified, which are related to the kind of users’ needs (explicit or unspoken) and to the kind of products (incremental or new) (Fig. 14.1). The first are the design questions, and the second are the answers to the design questions, that is, the design solutions.

-

1.

Explicit needs versus incremental products. The design of a product typically answers to a question derived by the analysis of the users’ needs. The design can be very traditional and proposing an incremental development of a product built on previous products, engineering solutions and components. This kind of design process traditionally includes several phases aiming at obtaining a definition of a product that is detailed enough and also optimized for the following manufacturing phase [12]. These phases include conceptual phase and detailed design phase, evaluation phase and redesign and optimization phase. This approach is very typical and somehow conservative and is adopted by several companies developing products based on incremental solutions that answer to present users’ needs.

-

2.

Explicit needs versus radically new products. The design activity can bring to the definition of new products, which answer to questions explicitly posed by a group of target users. In order to make the proposed product a successful one, the design must be a response to an actual user demand. This approach is typical of technology-push paradigm, where the design solutions developed can be intended as answers for the current traditional market or can even open new markets [13]. For example, the PC laptops were new products based on an incremental design that at that time satisfied the present market; instead, video game consoles were new products, creating the very new market of home video games back in the early 1980s.

-

3.

Unspoken needs versus incremental products. The design can also be based on latent and unspoken needs that are somehow described, typically by marketing experts. Traditionally, users’ needs and requirements are collected and identified through surveys that are carried out by companies’ marketing departments. Many studies have shown that user’s needs surveys based on customers’ statements do not express real customer needs [14, 15]. Currently, in order to overcome these problems, some other methods are used. For example, ethnographic methods are used to study the behaviors of a small number of testers when using products. However, some issues still remain, despite attempts to improve survey methods for users’ needs collection. These issues relate to the difficulty in collecting data about “unspoken” customer needs, which could represent the most important input for defining the requirements of new and innovative products. Once the unspoken needs are identified, the designers proceed in the search for possible solutions to the questions posed by the requirements. Since the solutions can be many and varied, the designs require performing careful tests, followed by optimization, in order to converge to the final and optimum solution. Products answering to unspoken needs can be suitable for the present market. An example is that of the electric city cars. Besides, there are products that open new markets. An example is the Roomba vacuum cleaning robot, which is not a totally new product considering its functionality, but has certainly opened a new market in the field of household appliances [16].

-

4.

Unspoken needs versus new products. Finally, a new design can be developed for satisfying unspoken needs. This can lead to the design of completely new products. Given the uncertainty of users’ acceptance, the product has to be developed by holding the users in high regard and often involving them in the validation phases of the design choices. Actually, the level of success is less predictable than in the previous cases, and therefore, a more careful analysis and testing is required. The Segway is an example of an innovative product designed for satisfying unspoken users’ needs, which has been created for a traditional market that is the one of personal mobility [17]. Instead, recent examples of innovative products created for a completely new market are personal 3D printers, which allow us to easily and directly create physical objects from 3D models [18].

14.2.4 People Responsible for the Design Results

Within the evolving context presented so far, also the role of the people responsible for the design process has changed in years (Fig. 14.2). Various skills are required to manage the various phases in the design process.

The roles of the various expertise involved in the design process can be listed as those who

-

define the requirements

-

propose the solutions

-

decide and organize the validation

-

validate the product

-

choose among the various alternatives during the process and are in charge and responsible for the design as a whole

The design of machines was mainly carried out by mechanical engineers who approached the design problems from a functional point of view and often starting from known solutions. With the increasing complexity of machines, the role of designers has become multidisciplinary. Actually, design teams have replaced designers, and the system engineer is the one who designs the architecture of complex systems and who coordinates the design and assembly of subsystems.

The requirements of modern products are not primarily and uniquely related to engineering and technical questions, and the design process does not follow the traditional sequence of mechanical product design, as well as the role and kinds of practitioners involved have changed. In the view of designing products that are successful with users, it is important that designers always keep in mind who the end user of a product will be. Industrial designers have key roles and are sort of product architects, the ones who collaborate with several experts and have a whole vision of the product. They are called to design innovative solutions to real market problems and to define the overall product architecture and are expected to work closely with product and marketing managers, user interaction designers and software engineers to develop new products and to improve existing ones. This new figure of designer is knowledgeable about design (shape, aesthetics, ergonomics) and engineering (function, materials and production).

It is quite typical of the consumer market that marketing people give input to the design process of new products, by defining the initial requirements. Then, those are transformed into other kinds of requirements by the industrial designers, and by the system engineers, and eventually are handled by the mechanical engineers. It appears increasingly strategic that user interface and interaction aspects are considered since the beginning of the design process, for they may influence the design decisions throughout the process, especially for what concerns the way of using a product. For example, an interactive device should be designed differently if the potential user is someone usually working with a computer, than if it is designed for an elderly person, with a limited or no experience with computers. And therefore, today’s designer is also the one who starts designing the users’ experience, also named experience designer.

14.2.5 Design Methods and Tools

The design process has evolved over the years, and its evolution has been partially driven by the progresses of technology. Actually, the design process has changed since when digital tools have been integrated into the overall product life cycle management. At the beginning of the introduction of digital tools into the design process, design tools were used for replicating the production of design deliverables, that is, drawings. Today, digital tools are more intended to integrate and collaborate with the designers so as to expand their joint capabilities used to design and also test the results of the design activity.

Figure 14.3 shows a diagram reporting design methods versus tools. Design methods are classified as function-based and use-based, and design tools as geometry-centered and interaction-centered. Hereafter, we describe in details the evolution of digital methods and tools for product design and testing, including Digital Mock-up, Virtual Prototyping and iVP.

14.2.5.1 Digital Mock-Up: Function-Based: Geometry-Centered

The activities concerning the design of products are supported by various tools, which are mainly based on a geometric representation of the product and aiming at solving engineering and functional problems. Computer-aided design (CAD) tools support the geometrical description of products, including details as dimensions and tolerances.

Digital Mock-Ups (DMU) have been introduced to simulate and test the behavior and the performance of the components of products designed by using CAD tools. DMU are typically geometry-based, where the geometry of the system, subsystems and components is precisely defined [19]. The features describing the product, which are necessary for assessing its behavior and performances, are attached to the geometry. The DMU is therefore a static representation of the product or system, which can be used for simulating the movement of the various parts with the aim of detecting clashes, collisions and interferences, and simulating assembly and disassembly activities.

Various functional models can be derived from the DMU, which can be used for testing specific aspects of a product, for example, structural models, dynamic models. Much of the embodiment and detailed design phases of mechanical design consist of ensuring that the components in the design will not fail mechanically, either through excessive stress or through excessive deformation. Initially, this is done by using simple mathematical models. Then, more elaborate analysis methods are used, such as finite element analysis or computational fluid dynamic analysis.

The results of each test and analysis are used to solve a specific design problem, which does not necessarily mean optimizing the overall design of the product. In fact, the optimization of one aspect made on the basis of the analysis results may impact on other aspects. Therefore, there is a great need for more comprehensive testing methods.

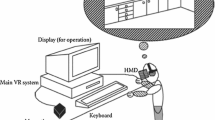

14.2.5.2 Virtual Prototyping: Function-Based: Interaction-Centered

Virtual Prototyping is instead a common practice used to test the design solutions mainly with the aim of evaluating product function performance [20]. Virtual Prototyping consists of a combination of single- or multidomain functional models, which fully represent the physical behavior of a product, and VR technologies, which are used to give realism to the product representation. The geometry of the product can be simplified and is not anyhow the core of the prototyping; on the contrary the functional models are. The functional models can be modified during the testing phase, and the results are evaluated globally, thus providing a comprehensive view of the product.

In addition, VR technologies are used to realistically represent and render the virtual prototypes to users [21]. Most of Virtual Prototyping has been based on the use of visualization technologies, such as stereoscopic displays. In a sense, they are sort of “visual prototypes,” where the realism of the representation is focused on the visualization of the product features. In order to overcome this limitation, recently Virtual Prototyping has integrated haptic technologies for simulating the physical contact and haptic interaction with products [22, 23].

Virtual Prototypes can also be used for testing the product design with end users. In this case, they can be used and operated by users with the aim of testing specific product features. The design configurations that can be tested are actually limited and must be predefined by the design team. So, users can say which configuration they prefer, but they cannot ask and try any other configuration outside those ones.

14.2.5.3 iVP: Use-Based: Interaction-centered

It is reasonable expecting that the design of a product that is typically used interactively by users would start by focusing on the interaction, instead of on the overall product. Therefore, before designing the product, the focus should be put on the design of the user interaction. In this case, the design team should work on the design of the product use, independently from how the product itself will be designed. iVP is aimed at supporting this activity [24]. This capability is particularly important for the validation of the initial conceptual design of such products, as those for the consumer market. In fact, in this case, the prototype is used early in the design phase for simulating the behavior and the interaction of something that is meant to be used by a person.

In conclusion, changes in design over the last decades have brought us to the present situation, where the product design starts, being focused on the design of the user experience. Proposed new methods and tools for the evaluation of user interaction to use early in the concept phase are based on iVP, which gives target users the possibility to try and test early simulations and variants of the user experience with new products.

14.3 Consumer–Product Interaction

It has been previously claimed that in the evolution of the products, of the users’ expectations, and of the design methods, the attention to those who are the users of the products has grown to the point that the design of consumers’ products put the user at the center of the design process. The focus is on the so-called user-centered design, which primarily addresses the user experience with a product during its conceptual design. The following sections address some definitions and issues related to consumer products, perceived value for users and salient attributes of these kinds of products.

14.3.1 Consumer Products and Their Perceived Value

Consumer products can be defined as goods that satisfy personal needs. They can be described as any tangible personal property for direct use or consumption and that are used for personal, family or household purposes.

From a production perspective, consumer products are the final result of manufacturing and are what a consumer will see on the store shelf. Household supplies and furniture, consumer electronics, jewelry, children’s toys, kitchen supplies and automotive accessories are all examples of consumer goods.

Consumer products are typically produced in volumes. Consequent their scales of production, consumer products represent a major global design and manufacturing sector responsible for the production and supply of diverse goods. It can be reasonably said that consumer goods are universally the most competitive and fastest growing market compared with other products purchased only by industry and businesses.

The perceived value of a product is the personal estimation a consumer makes of it. The consumer’s perceived value of a good affects the price that he is willing to pay for it. Generally speaking, consumers are unaware of the true cost of production for the products they buy. Instead, they simply have an internal feeling for how much certain products are worth to them. Thus, in order to obtain successful products and a higher price for their products, producers may pursue marketing strategies to create a higher perceived value for their products [25].

Traditionally, the reasoning about relative perceived value of products has been centered on fundamental concepts as features and functions, and cost. Customers buy products for their features (e.g., a mobile phone with a touch screen) or their specific functionalities (e.g., a mobile phone playing video and music). Similarly, potential customers make purchase decisions considering a product’s price. That is, how much a customer thinks that a product will cost him.

Today, these perceptions may not completely reflect reality. Recently, people tend to buy products for the perceived benefits that they deliver. Features and functions, which are the main focus of product design specifications, are sort of container for delivering the benefits that are desired by customers. A product may meet objective performance criteria, which are typically validated by analytical or physical laboratory tests. But a product is successful only if the customers and consumers recognize that the product actually delivers some benefits. And it is also worth noticing that the perception of the customer about the product is central in the purchasing experience.

Formally, the value of a product may be conceptualized as the relationship between the consumer’s perceived benefits in relation to the costs of receiving these benefits [25]. It is often expressed as the equation: value = benefits/cost. Value is thus subjective, that is, a function of consumers’ estimation.

Today, regarding consumer products, the consumption experience is the true value of a product for consumers. A product purchase can be directed not directly toward a physical product, but rather toward a consumption experience, which consists of both cognitive and emotional activities [26].

Therefore, some of the issues that people consider before placing a value on a product are as follows:

-

Attributes They include characteristics like size and color. For example, one consumer may prefer a pink mobile phone cover to a black one.

-

Functional benefits This is what the consumer expects to gain from the product. It concerns all the advantages a product offers as compared to similar product offerings. For example, a product is easy to use, its design meets the expectations of the customer, it is easily available and it has a long lifetime.

-

Emotionalbenefits This refers to the feelings evoked in customers while and after buying a product. The quality and reputation of the brand as well as the characteristics of the product play an important role in stirring feelings in customers [4]. The feeling can be contentment, angry, excitement, etc. For example, a lady decides to buy a dress according to how it fits on her body and also for the tactile feedback provided by the fabric.

14.3.2 Salient Attributes of Products

Various attributes, named salient attributes, can be associated with products, which can be classified as follows:

-

geometric/shape attributes

-

material attributes

-

functional attributes

-

experience attributes

There are some products mainly containing shape attributes, which are visually salient attributes. These products can be assessed and selected by consumers merely through vision. An example of such product is a vase. When material attributes are part of a product, consumers typically desire to obtain further information using their hands to touch and feel the products, in addition to the visual exploration. A typical example is a dress. Functional attributes are related to what a user can do when using a product and to its performance. For example, some radio stations can be directly connected with our iPod and allow us to listen to our music playlist. Furthermore, there are some attributes of a product, which we name experience attributes, that consumers can only assess through actual use, or direct contact, with the products. These are, for example, taste, fit, softness and also ways of using the product through buttons, touch screens.

People explore everyday objects through sensory dimensions, which include vision, touch, hearing, smell and taste. Different types of salient attributes involve different sensory input in regard to consumption experience. For example, a pan can be experienced through vision and touch (to check its appearance and how much it weighs), a bar of soap through smell (to feel its fragrance). But basically, according to some studies, in most cases, people tend to explore objects through two sensory dimensions: vision and touch [27].

Already during a purchase experience, consumers learn about products through both direct and indirect experience [28]. The most effective is the direct experience, which happens through an actual contact with the product. This means touching, holding, handling, manipulating and using the product. Consequently, a major issue for companies is to identify which types of attributes are dominant, which are important to consider when customers make purchase decisions. Therefore, it is important to be able to check the probability that a product can provide an expected experience before customers are confident in making a purchase decision. In order to be effective and relatively inexpensive, this check should be made at the concept design phase, when it is possible to perform the simulation of a consumption experience for consumers, which is assessed prior to the purchase or actual use of the product.

14.4 User Experience Design

User experience design (UXD) is part of the design of a new product [29]. UXD includes the definition of the interaction components, that is, their shapes, material and layout, and the definition of their behavior to users’ actions. UXD refers to the application of user-centered design practices to generate predictive and desirable designs based on the consideration of users’ experience with a system. The practice includes the definition of the user interface, graphics, and physical and manual interaction performed in close collaboration with target users.

Two very similar products, with the same look and the same functionality, can deliver experiences of different quality that users like differently [30]. Therefore, the user experience, once designed, needs to be tested with users in order to measure its quality and appreciation.

The experience of a person with a product occurs through direct contact and use. For example, the shape and material that constitute an object are relevant, as well as the modality of use and interaction with it. For this reason, a product should be designed keeping in mind and focusing on the direct and physical interaction.

Part of UXD is the haptic interaction design (HID). HID is that phase of product development where one designs the interaction with the product that occurs through touch and manual control [31, 32]. This activity includes the design of the physical interaction components and devices, as well as the design of the modalities for interacting with them, also including the integration with other modalities as vision and sound (also named cross-modal interaction).

The kind of interaction designed depends on the product attributes and on its functionalities and also on the target users of the product. We can design products integrating haptic and touch as a novel interaction modality, which proposes users a new way of doing the usual things. Or we can even design a novel physical interaction that aims at creating new emotional and compelling experiences for the potential future users of the product. The design of haptic interaction devoted to skilled users requires the acquisition of knowledge about the users’ skills and dexterity, about the users’ objectives in using the product, so as to best exploit the ways these users are used to do things and perform manual tasks.

So, the design team must deal with the design of the experience of a person with a product, so as to optimize his enjoyment, satisfaction and positive emotional response. A major issue is how to check if the designed experience is really satisfactory. This issue is actually difficult to address, since it implies that it is necessary to have a properly functioning product that one can use for testing, before the real final product is available. iVP, based on the simulation of products behavior and use, has demonstrated to be effective for this purpose.

14.5 Interactive Virtual Prototyping

This section introduces the concepts related to interactive Virtual Prototyping (iVP), which is proposed as a product concept evaluation methodology for testing the use of products with users, for evaluating the users’ experience and ultimately for compiling the list of specifications for product design [20, 33].

Interactive Virtual Prototypes can be used in two ways:

-

1.

for verifying and validating the behavior of a designed product with people (potential customers and consumers) and also

-

2.

for evaluating variations in interaction experiences and identifying the ones that people (potential customers and consumers) like more.

In the first case, the iVP can be used for testing the design solutions that respond to user’s needs and requirements, and this is typically done when the design is advanced enough. The second one can be used to test proposed novel interactive solutions with users, when the product has not been yet fully decided and designed.

In both cases, for being beneficial, iVPs should be used in a continuous design-validation loop, where a new interactive modality can be designed, soon after tested with users, and modified if necessary. This close loop requires that the iVP can be easily and quickly modified and adapted to meet the user’s preferences.

In order to satisfy all these issues, the iVP should have the following characteristics:

-

Realism and fidelity The iVP should be perceived by the human senses exactly as a real prototype would be, hiding the complexity of the simulation and of the technology at its basis.

-

Multimodality and multisensory interaction The iVP should support the same interaction modalities and stimulate the same sensorial channels, as it happens when humans interact with real products.

-

Real-time feedback The iVP should react to user’s actions in real time (from the users’ perceptual point of view), with no perceivable delays. This requirement impacts also on the complexity of the product and on the behavioral simulation performances.

-

Parametric The iVP should be based on functional models describing the behavior of each component to test. The models should be parametric, so that the behavior can be changed until an optimum is reached.

-

Sharable among different users remotely located Sometimes the testing activities on the same product might be performed in different placed and also in different cultural contexts. Therefore, interactive Virtual Prototypes should be effectively used for this purpose.

14.5.1 iVP Architecture

The architecture of a framework for iVP consists of three main components: the Functional Mock-Up (FMU), consisting of functional models, describing the product behavior and the user interaction model, including a perceptual model for each human sense, which actually implements the user interaction, and the multisensory VR environment for performing and handling the user interaction in a realistic way (Fig. 14.4). The three components are described in the following.

14.5.1.1 Functional Mock-Up

The FMU includes functional models and related functional simulation tools. The FMU is based on the definition of several elements, one for each effect that one wants to simulate. A set of parameters is used to describe the behavior of each element, which is simulated by multiphysics functional simulation tools. All these elements are integrated into a unique and comprehensive model, named the multidomain functional model. As an example, let us consider the FMU built for simulating the door of a refrigerator. In a real refrigerator, there can be several functional elements, each representing an effect: the element simulating the effect of the magnetic attraction of the door when it is closed, the element simulating the effect of the gasket when opening/closing the door, the element related to the sucker-like effect generated by the air contained in the refrigerator, the friction and inertial effects generated when opening/closing the door, etc. These elements are set as parametric, and the parameter values can be changed for setting the final behavior perceived by the user during the interaction, which is performed by the multiphysics simulation tool. FMU is generally a mathematical complex structure, whose computation is time-consuming and typically not running at real time. For this reason, they cannot be used straightforward in interactive applications, and alternative solutions are required for mapping the output of these models into values that can be handled at real time.

14.5.1.2 User Interaction Model

The output of the FMU consists of parameters concerning velocity, acceleration and force related to the simulated effects. These parameters can be mapped into a user interaction model, which consists of a set of parametric perceptual models that define the behavior of the product defined at the user perception level. Each model addresses a sensory channel: visual, sound and haptic. These models, including their parameters, are rendered to the user through appropriate VR technologies (3D displays, stereo glasses, haptic devices, auditory devices, etc.) [21]. While visualization and auditory interaction modalities are output modalities, the haptic interaction modality is of type input/output, which can be activated by users’ actions, and which reacts accordingly by exerting force-feedback. These models are simplification of the FMUs, which can be used to render the effects at real time. For example, the behavior of the refrigerator door previously considered as an example can be simplified as a spring/damper element described by a force–displacement relation. This parametric model, where the displacement values can be changed, can be rendered to the user as a haptic feedback.

14.5.1.3 Multisensory Virtual Reality Environment

The third component consists of a Multisensory Virtual Reality Environment allowing multisensory and multimodal interaction. In the section about the evolution of design tools, it was mentioned that the practice of Virtual Prototyping has been based for years purely on visual representation of products. Actually, iVPs based on the solely visualization of the product are not good for testing the interaction with the product. For example, the study of the use of a door handle is ineffective if performed using a virtual model of the handle. In fact, the user cannot feel the contact with the handle, the mechanical response, etc. Therefore, it is evident that the realistic simulation of the physical contact of the user with the component is important and allows users to feel and evaluate the geometrical shape of the product component, as well as the material properties, as elasticity, rigidity, plasticity, hardness, texture, etc.

For what concerns the physical interaction with the virtual prototype, modern haptic technologies can be used to simulate the physical interaction with a product component [24]. General-purpose haptic devices are not effective for the simulation of the interaction with any object, since they may have limited degrees of freedom, low force-feedback rendering values, or end-effector shapes that do not conform to the component shape [34]. A possible solution to this problem is to develop ad hoc force-feedback systems. Examples are the refrigerator door proposed in [35] and the car door described in [36]. Alternatively, it is possible to use commercial devices where the end effector is replaced or integrated with more appropriate handling tools. This second option, more flexible and general purpose with respect to the first one, has demonstrated to be feasible and effective in various set ups [37]. For example, the end effector of a MOOG HapticMaster device [38] can be replaced with a door handle. An additional benefit is obtained if the handling tool is designed and then produced using a rapid prototyping technique. In fact, it can be easily and relatively quickly re-designed and adapted so as to meet the users’ preferences.

14.5.2 iVP and Users Tests

Interactive Virtual Prototyping is a practice used for validating the user interaction with a product, which has been newly designed and is simulated in its various aspects. The validation is done through tests performed with users’ groups, during which the designed interaction effects are tested and evaluated. If the effects are considered unsatisfactory or unpleasant, they can be modified.

Two modalities can be used for modifying the product behavior and the interaction effects:

-

1.

Change the parameter values of the FMU. As an example, let us consider the development of the iVP of a knob. The FMU includes the dynamic friction model that describes the knob behavior when it is turned. The FMU is translated into an interaction model, consisting of torque values, which determine the behavior of the knob and which are rendered as haptic feedback by means of a haptic device. The user can ask to modify the reaction to turn. This can be done by modifying the dynamic friction model describing the knob behavior. Once modified, the FMU has to be re-mapped into an updated interaction model.

-

2.

Change the parameter values of the user interaction model. One of the benefits of operating at the level of the interaction model is that the modification of the effects can affect only one component, and the new configuration can be evaluated by considering the overall behavior of the product. Referring to the previous example, the knob dynamic friction model is mapped into a haptic parametric model, consisting of torque values. Besides, it can be added a sound parametric model, consisting of a set of clicks sounds, which is defined only at the interaction level. The effect conveyed to the user is both the force returned and the sound clicks played when the user rotates the knob. The user can ask for making the reaction force of the knob stronger, but without changing the quality and kind of the sound clicks. The modification of the haptic behavior can be done easily and directly by changing the torque values in the interaction model, without affecting the sound model and its output. This is feasible since the interaction models for haptic and sound are independent. The FMU has to be changed according to the changes made in the model at the interaction level.

At the end of the test sessions, the FMU includes all the functional parameters to use for designing the product, which the users tested, assessed and validated. The information included in the FMU in terms of functional model and parameter values can be used straightforward by an engineer as specifications for the definition of the CAD model of the product and its subsystems and components.

14.6 Case Study

The design methods based on the use of iVP presented in the previous sections have been applied and tested for the design and evaluation of the experience of use of some consumer products. Two examples have been selected:

-

1.

FMU of a dishwasher

-

2.

Multisensory interaction model of a refrigerator door

14.6.1 FMU of a Dishwasher

The first case study consists of the simulation of the force returned on the user’s hand while opening and closing the door of a dishwasher. The aim of the simulation is to analyze the interaction with the door and identify some new specifications for the re-design of the haptic feedback provided by the interaction with the door of new dishwashers, in accordance with the study results. The case study has been proposed by a company operating in the field of household appliances.

The analysis of the opening effect shows that the haptic feedback is a combination of the initial leaf spring (this is the click effect perceived at the beginning of the opening) and of the inertia of the door. Furthermore, static frictions and compression spring effects complete the overall effect. Traditionally, the door opening/closing force effect is not designed with particular attention to the experiential effects on the users (experience attributes), but it is designed so as to prevent any free movement of the door during its use (functional attributes). For example, when the user opens the door and subsequently releases it, the door does not slam and is gradually braked up. This suggests that the design has focused on the functionality and performance of the product, rather than on the final effect experienced by the users.

On the basis of the door behavioral analysis, it has been defined a model of the door and a simulation of the opening effect. The simulation has been performed using the LMS-AMESim suite [39], which is one-dimensional simulation software tool for multidomain systems. Figure 14.5 illustrates the sketch of the door mechanical system developed using LMS-AMESim where the main parts contributing to the force are highlighted. In particular, it can be seen the contribution of the friction, of the springs and of the leaf spring. Furthermore, the sketch includes a function describing the human force exerted on the door. The one represented is a simulation of the human behavior while opening and closing the door, which is based on the results described in the work by Jain et al. [40], as well as on the results of a set of acquisitions performed on the door of the dishwasher, as described in [41]. Basically, the behavior is represented as a ramp function. Different ramps can be simulated easily through a batch-run simulation, so as to verify the behavior of the door at different accelerations. This is very important in order to understand the efficiency of the door in different opening and closing conditions.

Figure 14.6 graphically shows the results of the behavior of the door obtained by changing the friction constant values.

If we aim at enabling the user to test the behavior of the door through a haptic interface, as, for example, the MOOG HapticMaster [38], we must take into account some important issues. The user’s input that has been treated as a ramp with varying peaks in the simulation described so far is actually varying continuously during the opening action. The door system reacts consequently to the user’s input. In order to return to the user a realistic feedback in dynamic conditions, we should capture the force exerted by the user’s hand continuously and compute the angular position of the door in real time. This is unfeasible at the frequency required by the device to grant a fluid haptic interaction, which is typically of or is higher than 1 kHz.

A way to overcome this limitation consists of simplifying the model that can be tested by the user until real time is obtained. This can be done for example by summing up all the friction contributions so that eventually only one overall friction will be simulated. The same approach can be adopted for springs, dampers, etc. This simplified model is then translated into parametric equations that are rendered through the haptic device. The user can test the force profiles and tune the haptic behavior of the door by asking some modifications that will be translated into parameters of the equations. Finally, the results can be used as input to the LMS-AMESim simulation model, by means of optimization tools.

14.6.2 Multisensory Interaction Model of a Refrigerator Door

This second case study consists of designing the experience of a user interacting with the door of a new refrigerator. For what concerns the functional model, the effect of opening the door has been derived from the analysis of the CAD models and from some measurements performed on a real refrigerator door. Specifically, it has been analyzed the door, its shape, users’ handling and the door physical behavior. Subsequently, it has been simulated the physical handling of the door. The overall effect has been divided into the following steps:

-

initial effect due to the mechanism for keeping the door close;

-

subsequent effect due to inertia and friction of the components;

-

collisions occurring at the end of the stroke;

-

sound made by the moving parts, also depending on the velocity of movement.

The parametric haptic functional model is as such that the effect transmitted to the users is a force returned when they try and open the door. This force is modifiable on user requests until an optimum is obtained. The model of the forces is implemented through a piecewise function, where each subfunction is parametric and can be changed in real time without affecting the other interval subfunctions. The user can ask higher or lower reaction force for each interval; this will be obtained by modifying the parameters. When the test is over, these changes are stored and subsequently mapped into design specifications.

Regarding the haptic device, the initial hypothesis was to use the end effector of a commercially available haptic device for the physical handling simulation. Unfortunately, no haptic device allows us to realistically simulate the shape of any handle. Therefore, it was decided to use an ad hoc physical component for at best representing the interaction experience. This physical component representing the door handling part has been developed using rapid prototyping manufacturing methods. Then, it has been then mounted on the MOOG HapticMaster system [39], which has been used for rendering the forces (Fig. 14.7).

14.7 Conclusion

In products where the user interaction is one of the main features determining their value, the design of user experience gains importance in view of a successful product. In fact, people often buy products on the basis of the first impression they have about their features gathered during the short use and interaction with them occurring at the selling points. Designing the experience with a new product is not an easy task, especially when the product is radically new and proposes very new interaction modalities. Measuring at what extent a product satisfies the users’ needs—spoken or unspoken—is still an open issue.

Therefore, testing the designed experience soon in the product development process becomes crucial for developing a successful product. Actually, testing activities require modalities for presenting the design proposals and variants to the users in a proper and clear way. Prototyping is certainly an effective way for demonstrating a product and its interaction modalities. But if the prototype is physical, it is costly and hardly modifiable. Conversely, the first examples of design experience tests based on interactive virtual prototypes have shown the potentiality and applicability of this very new approach. The effectiveness depends on several factors, including the fidelity of the prototype and of the interaction, the performances, the capability of rendering multimodal and multisensory effects.

In conclusion, on the basis of the initial studies, the use of iVP for designing and testing user experience of consumer products is a course that must be pursued and investigated further. The subject is very interdisciplinary, requiring expertise in many domains as engineering, design, marketing, human factors and neuroscience.

References

Goldenberg J, Mazursky D (2002) Creativity in product innovation. Cambridge University Press, Cambridge

Bordegoni M (2010) Exploitation of designers and customers’ skills and creativity in product design and engineering. In: Fukuda S (ed) Emotional engineering: service development. Springer, London

Sweeney JC, Soutar GN (2001) Consumer perceived value: the development of a multiple item scale. J Retail 77(2):203–220

Akshay RR, Kent B (1989) The effect of price, brand name, and store name on buyers’ perceptions of product quality: an integrative review. Monroe J Mark Res 26(3):351–357

Norman DA (1988) The design of everyday things. Doubleday, New York

Spence C, Gallace A (2011) Multisensory design: reaching out to touch the consumer. Psychol Mark 28(3):267–308

MacLean KE (2009) Putting haptics into the ambience. IEEE Trans Haptics 2(3):123–135

Magnusson C, Szymczak D, Brewster S (eds) (2012) Haptic and audio interaction design. Information systems and applications, incl. internet/web, and HCI. Lecture notes in computer science, vol 7468. Springer, Heidelberg, pp 131–140

Oberg E (2008) Machinery’s handbook. Industrial Press Inc., New York

Sakao T, Lindahl M (eds) (2010) Introduction to product/service-system design. Springer, London

Fukuda S (2012) Customer productivity: a measure for product and process development with customers. In: Proceedings of ASME IDETC/CIE conference

Ulrich KT, Eppinger SD (2004) Product Design and Development. McGraw-Hill, New York

Schumpeter JA (1934) The theory of economic development. Harvard University Press, Cambridge

Wicker AW (1969) Attitudes versus actions: the relationship of verbal and overt behavioral responses to attitude objects. J Soc Issues 25(4):41–78

Loftus E, Wells G (1984) Eyewitness testimony: psychological perspectives. Cambridge University Press, New York

Roomba robot (2012) http//www.irobot.com/. Accessed July 2012

Segway (2012) http://www.segway.com/. Accessed July 2012

The Economist web page (2012) http://www.economist.com/topics/digital-fabrication. Accessed July 2012

Doellner G, Kellner P, Tegel O (2000) DMU digital mock-up and rapid prototyping in automotive product development. J Integr Des Process Sci 4(1):55–66 (IOS Press)

Bordegoni M (2011) Product virtualization: an effective method for the evaluation of concept design of new products. In: Bordegoni M, Rizzi C (eds) Innovation in product design—from CAD to virtual prototyping. Springer, London, pp 117–142

Burdea G, Coiffet P (2003) Virtual reality technology, 2nd edn. Wiley, New Jersey

Burdea GC (2000) Haptic feedback for virtual reality. Int J Des Innov Res 2(1):17–29 (Special issue on Virtual Prototyping)

Biggs SJ, Srinivasan MA (2002) Haptic interfaces. In: Stanney K (ed) Handbook of virtual environments: design, implementation, and applications. Lawrence Earlbaum, Inc., London, pp 93–116

Ferrise F, Bordegoni M, Cugini U (2012) Interactive virtual prototypes for testing the interaction with new products. Comput Aided Des Appl 10(3):515–525

Doyle P (2000) Value-based marketing: marketing strategies for corporate growth and shareholder value. Wiley, Chichester

Lofman B (1991) Elements of experiential consumption: an exploratory study. In: Holman RH, Solomon MR (eds) Advances in consumer research, 18th edn. Association for Consumer Research, Provo, pp 729–773

Klatzky RL, Lederman SJ, Matula D (1993) Haptic exploration in the presence of vision. J Exp Psychol Hum Percept Perform 19(4):726–743

Millar MG, Millar KU (1996) The effects of direct and indirect experience on affective and cognitive responses and the attitude–behavior relation. J Exp Soc Psychol 32(6):561–579

Norman DA (1988) The design of everyday things. Doubleday, New York

Buxton B (2007) Sketching user experiences: getting the design right and the right design. Morgan Kaufmann, Interactive Technologies)

Benyon D, Turner P, Benyon S (2005) Designing interactive systems: people, activities, contexts, technologies. Addison Wesley, Boston

MacLean KE (2008) Haptic interaction design for everyday interfaces. Rev Hum Factors Ergon 4(1):149–194

Burdea GC (2000) Haptic feedback for virtual reality. Int J Des Innov Res 2(1):17–29 (Special issue on Virtual Prototyping)

Hannaford B, Okamura AM (2008) Haptics. In: Siciliano B, Khatib O (eds) Handbook of robotics. Springer, New York

Shin S, Lee I, Lee H, Han G, Hong K, Yim S, Lee J, Park Y, Kang BK, Ryoo HD, Kim DW, Choi S, Chung WK (2012) Haptic simulation of refrigerator door. IEEE haptics symposium (HAPTICS), pp 147–154

Strolz M, Groten R, Peer A, Buss M (2011) Development and evaluation of a device for the haptic rendering of rotatory car doors. Ind Electron IEEE Trans Ind Electron 58(8):3133–3140

Ferrise F, Bordegoni M, Graziosi S (2012) A method for designing users’ experience with industrial products based on a multimodal environment and mixed prototypes. Comput Aided Des Appl 10(3):461–474

MOOG (2012) HapticMaster. http://www.moog.com/products/haptics-robotics/. Accessed July 2012

LMS (2012) http://www.lmsintl.com/. Accessed July 2012

Jain A, Nguyen H, Rath M, Okerman J, Kemp CC (2010) The complex structure of simple devices: a survey of trajectories and forces that open doors and drawers. In: Proceedings of the IEEE RAS/EMBS international conference on biomedical robotics and biomechatronics (BIOROB)

Ferrise F, Ambrogio M, Gatti E, Lizaranzu J, Bordegoni M (2011) Virtualization of Industrial Consumer Products for Haptic Interaction Design. ASME Conf Proc 2011(44328):9–18

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag London

About this chapter

Cite this chapter

Bordegoni, M., Cugini, U., Ferrise, F. (2013). Multisensory User Experience Design of Consumer Products. In: Fukuda, S. (eds) Emotional Engineering vol. 2. Springer, London. https://doi.org/10.1007/978-1-4471-4984-2_14

Download citation

DOI: https://doi.org/10.1007/978-1-4471-4984-2_14

Published:

Publisher Name: Springer, London

Print ISBN: 978-1-4471-4983-5

Online ISBN: 978-1-4471-4984-2

eBook Packages: EngineeringEngineering (R0)