Abstract

C-Glycosides represent an attractive class of compounds for the medicinal chemist because they are more resistant to enzymatic hydrolysis than O-glycosides and therefore are considered as potential drug candidates. The potential was confirmed by the emergence of a new family of C-glycosides known as the SGLT-2 inhibitors leading to the development of new drugs for the treatment of type 2 diabetes. In this chapter, chemical processes to access new active pharmaceutical ingredients (API) will be described focusing on the key C-glycosylation step.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- C-glycosylation

- Canagliflozin

- Dapagliflozin

- Ertugliflozin

- Ipragliflozin

- Luseogliflozin

- Sotagliflozin

- Tofogliflozin

1 Introduction

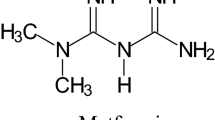

C-Glycosides are ubiquitous natural products of high medicinal significance [1]. In addition to naturally occurring C-glycosides, synthetic C-glycosides are also of interest. Recently, a new type of therapeutic agents belonging to the class of sodium-coupled glucose cotransporter 2 (SGLT-2) inhibitors has received much interest. These new drugs block the body’s capacity to reabsorb glucose via the kidney leading to glucose elimination in the urine and a reduction in blood glucose levels [2]. It represents a new treatment for people suffering from type 2 diabetes (90% of all cases of diabetes). According to the World Health Organization, more than 346 million people have diabetes of which an estimated 3.4 million patients have passed away from the disease [3]. The importance of this new class of drug is emphasized by the marketing approval by the FDA of four SGLT-2 inhibitors since 2012 (Fig. 1): canagliflozin 1a, dapagliflozin 1b, ipragliflozin 1c, and empagliflozin 1d.

Other SGLT-2 inhibitors, which are currently in late phase development, include ertugliflozin 2, tofogliflozin 3, luseogliflozin 4 and sotagliflozin 5 (Fig. 2).

There are basically two strategies to construct the C-aryl glycosides that are depicted in Figs. 1 and 2. The first strategy involves the addition of an organometallic species to a carbonyl derivative followed by a reduction to afford the desired C-glycoside with the correct oxidation state at the anomeric carbon (two-step sequence, classical approach). The second strategy avoids the reduction step and involves a one-step direct substitution reaction at the anomeric carbon by an appropriate nucleophile (new approach).

In this chapter both strategies are discussed and exemplified by the synthesis of these SGLT-2 inhibitors. The most salient features of the process research work leading to optimized processes will also be highlighted. After an introduction on the traditional approach to access C-glycoside starting from the gluconolactone, the medicinal chemistry approaches will be described followed by the efforts and achievements allowing transfer to production plant. In a final section, recent reports describing direct C-glycosylation via arylzinc and arylalane derivatives will be presented.

2 C-Glycoside Synthesis via Nucleophilic Addition to Carbonyl Derivatives

2.1 Addition on Lactone Derivatives

2.1.1 C-Glycoside Stereoselective Synthesis

Although several stereoselective syntheses of β-D-glucopyranosides were developed in the seventies, the first efficient syntheses with high stereoselectivity were reported by Kishi’s group in 1982 ([4], and references cited therein). Three strategies are described in the article (Scheme 1):

-

A.

Substitution of the p-methoxybenzoyl group in position 6 of (6) by allyl(trimethyl)silane in the presence of boron trifluoride gives exclusively the α-product (7) in high yield (80%) and diastereoselectivity (10:1). The stereochemical control is realized by the addition of the nucleophile to the oxonium ion derived from the protected pyranose derivative. The oxonium ion is preferentially attacked on the α-face by nucleophiles.

-

B.

Addition of allyl Grignard or lithium enolate at low temperature on the perbenzylated gluconolactone 8 gives the opposite anomer in 85%. The intermediate lactol 9 is not isolated but directly reduced to the desired product using triethylsilane and boron trifluoride. The diastereoselectivity is also 10:1 in favour of the β-anomer 10 for the Grignard addition. For the lithium enolate, only the β-anomer 11 is observed.

-

C.

Addition of allyl(trimethyl)silane in the presence of boron trifluoride on the benzyl-protected 1,6-anhydroglucose 12 under the same reaction conditions as described for p-methoxybenzoyl gives in this case the α-anomer 13 in 60% yield and diastereoselectivity >10:1.

The good yields and high diastereoselectivities observed render these strategies very attractive for the synthesis of C-glycosides.

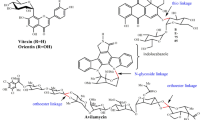

2.1.2 Aryl Addition on Gluconolactone Derivatives

The use of gluconolactone derivatives for the introduction of aryl moieties was demonstrated by Kraus and Molina in 1988 [5] followed by Czernecki and Ville in 1989 [6]. These groups have shown that a variety of aryllithium derivatives are added at low temperature with high selectivities to protected gluconolactone 8. Subsequent reduction of the lactol product 14 with a silane in the presence of a Lewis acid allowed the isolation of β-D-aryl glycosides 15 in high yield (>80%) with very high diastereoisomeric purity. The preferred protecting group is the benzyl since it is compatible with aryllithiums reagents and is easy to remove afterwards. The general approach is depicted in Scheme 2.

Both research groups concluded that only the β-isomer was formed in the reaction.

2.1.3 Use in Discovery (Medicinal Chemistry)

The addition of aryllithiums or Grignard derivatives on protected gluconolactone derivatives was extensively used in medicinal chemistry for hit-to-lead optimization since it allows the introduction of a wide variety of aryl moieties on sugar derivatives in a simple way from readily available starting material.

Medicinal chemists employed the TMS-protected D-gluconolactone for the synthesis of dapagliflozin [7], canagliflozin [8], ertugliflozin [9] and empagliflozin [10].

The benzyl-protected D-gluconolactone was used for the synthesis of ipragliflozin [11] and tofogliflozin [12, 13] and can be extended to the thiogluconolactone 17 as in the case of luseogliflozin 4 (Scheme 3) [14].

The method is very general but it suffers from several drawbacks that need to be addressed for commercial processes:

-

Expensive starting material (for benzyl-protected gluconolactone and thiogluconolactone).

-

Lack of crystalline intermediates at the lactol stage.

-

The intermediate lactol does not always give high diastereoselectivity in the reduction step.

-

The debenzylation can be problematic and not always compatible with the functional groups present on the aryl moiety.

In the next sections we will describe the development work done by the process research groups that led to commercial processes for several marketed SGLT-2 inhibitors while highlighting the most important features.

2.1.4 Diastereoselectivity Improvement

A significant contribution to improve the selectivity of the lactol reduction was reported by the process research group of Deshpande et al. at Bristol–Myers Squibb when developing the manufacturing route for dapagliflozin. They have demonstrated that the reduction of perbenzylated lactol intermediate 20 was not as selective as it was previously reported by Czerniecky and Ville [6]. Actually, the reduction of the perbenzylated lactol with triethylsilane in the presence of trifluoroboron etherate affords a 4:1 β:α isomeric mixture [15]. When the mixture is subjected to atmospheric hydrogenation over Pd/C and subsequently acylated using the Czerniecky conditions, only the β-isomer 23 is obtained. But a careful analysis revealed that the minor component was preferentially lost in the mother liquor during the hydrogenolysis step misleading to completely stereoselective ketal reduction (Scheme 4).

The selectivity of the reduction is influenced by the steric bulk of the silane, and the use of the triisopropylsilane as reducing agent gives the best β:α ratio (>35:1).

2.1.5 Commercial Processes

2.1.5.1 Dapagliflozin

Further process research work was performed at Bristol–Myers Squibb for the development of the commercial manufacturing route of dapagliflozin. The final process incorporates the following improvements [16, 17] (Scheme 5):

-

The use of less polar solvent to perform the aryllithium addition (THF/toluene or THF/heptanes) instead of pure THF leads to higher yield.

-

The use of TMS protecting groups on the gluconolactone to perform the aryllithium addition followed by acidic quench with methanol and isolation of the tetra-acylated ketal 27 (stable and crystalline compound) in a one-pot process.

-

High diastereoselectivity is achieved with triethylsilane/boron trifluoride etherate when acetate is the protecting group. This was not the case when benzyl was the protecting group (sterically hindered and costly silanes were necessary). The acetate group does not stabilize the carbocation, and the delivery of the hydride is made via the α-face to give the β-1-C-aryl glycoside 28.

-

Water is a critical additive for the reduction step of the ketal most probably by forming a stronger Lewis acid with the boron trifluoride. On plant scale 1 mol of water and >2 equiv. of boron trifluoride are required to drive the reduction to completion.

It is worth noting that the Bristol–Myers Squibb strategy relies on the use of two different protecting groups to better control the selectivity of the aryllithium addition and the selective reduction step. This protecting–deprotecting–reprotecting strategy was made financially possible by telescoping the sequence and never isolating any of the intermediates. Moreover, it allows isolating an enantiopure crystalline intermediate at the penultimate stage of the synthesis and achieving an overall yield around 50% starting from the inexpensive and readily available D-gluconolactone. The last step of the synthesis is the deprotection of the acetyl groups followed by the isolation of the dapagliflozin.

2.1.5.2 Empagliflozin

The optimized process developed at Boehringer Ingelheim followed a similar synthetic strategy but contains several different and interesting features [18]:

-

The aromatic iodo moiety 29 was preferred to the cheaper aryl bromo derivative because the aryl addition to the lactone can be done at higher temperature (−20°C to 10°C) and does not require deep cooling.

-

After addition on the TMS-gluconolactone derivative, the in situ produced lactol 30 is converted in a mixture of α/β-furanoketals 31, which is finally transformed into the β-pyranoketal 32 after pH adjustment (Scheme 6).

-

No protecting group is needed for the reduction of the β-glucopyranoside, but the presence of water is detrimental as it generates an undesired furanose impurity 33 leading to compound 34 upon reduction conditions. This problem was circumvented by the use of AlCl3 instead of BF3·Et2O in combination with an azeotropic distillation prior to starting the reduction.

After reduction and a solvent switch to i-PrOAc, the final API is crystallized in 60–70% yield. Empagliflozin is obtained in about 50% overall yield from D-gluconolactone derivative 24. This process was implemented at ton scale and used for the launch of commercial supplies.

2.1.5.3 Canagliflozin (First-Generation Process)

The commercial process for the production of canagliflozin is also based on the addition of an aryl-Grignard derivative on protected D-gluconolactone 36. The Grignard is generated from the iodo aryl 35 using Knochel’s methodology. The interesting point is that the protecting groups used are acetate because it allows isolating a crystalline tetra-acetate intermediate 38 that showed very good purifying capabilities [19] (Scheme 7).

The acetate protecting groups are removed under basic conditions using a solution of sodium methoxide in methanol, and the crude API is recrystallized in i-PrOAc/water to deliver the canagliflozin API.

The overall yield of the synthesis is around 40% from D-gluconolactone. The process is used at ton scale to supply the market demand for canagliflozin.

2.2 Addition to Amide Derivatives

2.2.1 Ertugliflozin

The deliveries of ertugliflozin to support the early clinical phases were based on the classical approach (lactone addition). But it rapidly appears that an alternative synthesis will be required for commercial process: the steric hindrance on C5 which is disubstituted in the case of ertugliflozin derivative 39 leads to elimination product 41 instead of the desired lactol 40 (Scheme 8).

A nice alternative approach developed by the Pfizer process research group is based on the addition of the aryl moiety to an open chain amide. The pyranose ring is reformed in the late stage of the synthetic sequence [20]. The key steps of the synthesis are:

-

Nucleophilic hydroxymethylation of a ketogluconamide intermediate 44

-

Introduction of the aglycone moiety via aryl anion addition on a methylpiperazine amide 47

Based on this methodology, an efficient 12-step synthesis was developed for ertugliflozin starting from tetra-benzyl-D-glucose and including only three isolated intermediates (43, 46, 51). The overall yield of the synthesis is a respectable 30% (Scheme 9).

Synthesis of ertugliflozin “adapted with permission from [20]. Copyright (2014) American Chemical Society”

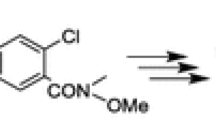

2.2.2 Sotagliflozin

Sotagliflozin is a dual SGLT-1/SGLT-2 inhibitor which is currently under development by Lexicon Pharmaceuticals (phase III). It follows a similar strategy to ertugliflozin, i.e. aryl addition on an acyclic precursor. The synthesis starts from l-xylose 53, and the aryl moiety (same aryl moiety as for dapagliflozin) is introduced on an amide derivative (morpholine amide 54) via Grignard addition. A subsequent transformation leads to the sotagliflozin (Scheme 10) [21].

Sotagliflozin synthesis (following [21])

The overall yield of the synthesis is around 30%.

3 Direct C-Glycosylation

3.1 Introduction to Direct C-Glycosylation

In the previous section, we have presented the traditional methodology employed to access C-glycosides in a 2-step sequence by 1,2-addition of an organometallic species to a Csp2 carbonyl function. Even if this approach is an adequate tool for the medicinal chemist, it is suffering from limitations for the scale-up such as low temperature reactions and sensitive reduction steps. With the growing demand for type 2 diabetes treatment with those new aryl glycosides, a demand for new synthetic methodologies, avoiding oxidation/reduction sequence, is generating an enormous interest. In this approach, the presence of an appropriate leaving group (LG) at the anomeric position of the glycoside moiety 57 should react with an organometallic nucleophile 58. Choice of the protecting groups, solvent composition as well as the presence or not of catalyst should be preciously selected to generate high yield and excellent selectivity (Scheme 11).

In this respect, Gagné has described a transition metal approach allowing Ni-catalysed coupling of organozinc reagents with glycosyl bromides to obtain with good stereoselectivity the aryl derivative (PG=Ac, R=H, β/α ratio of 12:1) [22–24]. Cossy has also demonstrated efficient C-glycosylation with Co(acac)3/TMEDA in the presence of Grignard reagents [25, 26]. However, the high transition metal catalyst loading (e.g. up to 10 mol% for Ni) and the high toxicity of residual salts hamper potential industrial applications of this coupling reaction.

Alternatively to the transition metal-catalysed approach, ionic pathways have been recently developed and applied to access canagliflozin and dapagliflozin.

3.2 Direct C-Glycosylation in the Presence of Diarylzinc and Its Application to Canagliflozin and Dapagliflozin

Lemaire et al. have reported high stereoselective access to C-aryl glycosides 62 in transition-metal-free conditions by treatment of a per-O-pivaloyl-protected glucosyl bromide 61 substrate with diarylzinc 60 [27] and its application to the preparation of canagliflozin and dapagliflozin (Scheme 12).

The coupling step is conducted at 95°C for 3 hours affording the desired C-aryl glycoside derivative 62 in 75% yield with excellent β selectivity (β/α 99/1). Further treatment with sodium methoxide allows removal of the pivaloyl protecting group in almost quantitative yield providing canagliflozin as well as dapagliflozin.

A judicious choice of the solvent mixture of toluene/di-n-butyl ether (DBE) allows a successful coupling step under the needed thermal conditions. In the presence of THF (or similar ethereal solvents), the Zn(II) salts initiate ring opening of the THF and formation of side products by reaction with the bromo glucoside 61. To circumvent this reaction, a combination of toluene with a nonreactive ether like cyclopentyl methyl ether or di-n-butyl ether allows a successful coupling. Nevertheless, in the absence of THF, direct insertion of metallic zinc was more cumbersome for the formation of the diarylzinc species. Therefore, the metalation reaction was carried out using n-BuLi or lithium tri-n-butyl magnesate followed by transmetalation with ZnBr2·LiBr complex in di-n-butyl ether. The use of ZnBr2·LiBr complex in di-n-butyl ether solution allows fast transmetalation step (Scheme 13).

The high diastereoselectivity for this direct C-glycosylation is based on a “substrate control” approach via anomeric oxonium ion participation. The presence of the pivaloyl group under the Lewis acid conditions participates in the formation of the anomeric oxonium ion intermediate 66 (Scheme 14) limiting the access of the nucleophile through the α-face. The aryl adds thereafter from the top face affording the β-C-arylglucoside 62.

To support this proposed mechanism, a series of confirmation experiments was performed (Scheme 15 and 16):

-

Replacement of the glucose derivative 61 by mannose analogue 67 (C2 epimer) delivers the α-C-glycoside 68 corresponding to the addition anti to the pivaloyl group.

-

If the pivaloyl protecting group is replaced by a benzoyl group (starting material 69), product 71 from the direct addition to the carboxium intermediate is obtained in low yield.

3.3 Direct C-Glycosylation in the Presence of Arylalanes and Its Application to Canagliflozin and Dapagliflozin

In the scope of preparation of SGLT-2 inhibitors, Henschke et al. have developed a direct C-glycosylation by stereoselective arylation of hydroxyl-protected 1,6-anhydro-β-D-glucose 72 with arylalanes under thermal conditions to access canagliflozin in 51% overall yield (Scheme 17) [28].

Deprotonation of the hydroxyl-protected 1,6-anhydro-β-D-glucose 72a by treatment with AlMe3 allows the formation of the alkoxydimethylalanes 72b. This intermediate is later arylated in 75% yield using 3 equivalents of diarylalane chloride at 140°C for 15 h. The opening of the anhydroglucose 72 is completely stereoselective for the β-isomer 73, and no trace of the α-derivative is detected. A large excess of the diarylalane chloride is needed because the reaction is sensitive to the steric hindrance of the nucleophile. Reducing the amount of alane derivative to 1.5 equivalents provides only a 16% yield with 80% of unreactive species. After purification by chromatography, canagliflozin 1a is isolated 68% yield after the removal of the tert-butyldiphenylsilyl protection group with fluoride source.

The coupling step is successful in solvents such as toluene, anisole, chlorobenzene, and di-n-butyl ether. In the presence of ethereal solvent, such as THF, the reaction does not work because the arylalane derivative complexes better to the oxygen lone pair of the solvent compared to anhydroglucose derivative.

The formation of the diarylalane chloride 75 for the preparation of canagliflozin 1a was also costly. The aryl bromide 35b was lithiated in a mixture of toluene/di-isopropyl ether with n-BuLi at 0°C and transmetalated with AlCl3 in di-n-butyl ether at 90°C to afford the trisarylalane species 74 as a milky suspension. After dilution in toluene, the di-isopropyl ether was removed by evaporation, and the solution was filtered to remove the lithium chloride (LiCl) and was concentrated further. Extensive examination of the effect of the metal halides has highlighted the negative effect of the chloride anions to inhibit the arylation step. When filtration of the LiCl is omitted, the arylation fails to reach completion. Finally the trisarylalane 74 species was treated with AlCl3 in n-Bu2O to generate in situ the active species diarylalane chloride 75 suitable for the coupling with the 1,6-anhydroglucose 72 deprotonated by Me3Al (Scheme 18).

The proposed mechanism to support the high stereoselectivity is depicted in Scheme 19.

Proposed mechanism “adapted with permission from [28]. Copyright (2015) American Chemical Society”

In parallel to the formation of the desired product, the presence of the enol ether side product 81 was consistently observed. Although the relative ratios of the two differed under different reaction conditions, the relative rates of their formation implied a common intermediate. Therefore, the proposed mechanism is suggested: After complexation of the arylalane species with the C6-O ether linkage (complex 76), the ring is opened to afford the oxonium intermediate 77. This intermediate undergoes either an aryl shift (path a) to furnish the desired C-glycoside 73b via ipso substitution or a deprotonation intramoleculary at the C2 position to afford the glycal intermediate 78 (path b). Further elimination of the dialkylaluminum oxide forms the oxonium 79 followed by ring closing to form back the 1,6-anhydro moiety 80 [28].

In extension to this direct approach, Henschke has developed a modified version starting directly from unprotected 1,6-anhydroglucose 82 and thus avoiding the protection step with the TBDPS (Scheme 20).

The treatment of 1,6-anhydroglucose 82 with 3 equiv. of DIBAL-H allows after addition of the Ar2AlCl 75 the direct formation of canagliflozin 1a in 50% under thermal conditions [29]. Unfortunately, conversion was not complete even with prolonged reaction times.

4 Conclusion

With the growing demand for the treatment of the type 2 diabetes, the aryl C-glycoside derivatives are rapidly becoming the choice treatment. As developed above, the main approach to access this extremely efficacious medicinal agent remains the nucleophilic addition of an organometallic species to per-protected gluconolactone derivatives followed by selective reduction. This path allows the medicinal chemists to access diversity that process chemists further developed even to commercial plant. Nevertheless, more straightforward approaches have been recently reported by direct formation of the key C–C bond either by treatment with organozinc or organoalane reagents. In the particular case of canagliflozin, the direct C-glycosylation in the presence of diarylzinc species has been transferred to commercial plant.

Abbreviations

- Ac:

-

Acetyl

- acac:

-

Acetylacetonate

- API:

-

Active pharmaceutical ingredient

- Ar:

-

Aryl

- Bn:

-

Benzyl

- Bz:

-

Benzoyl

- d:

-

Day(s)

- DBE:

-

Di-n-butyl ether

- DIBAL-H:

-

Diisobutylaluminum hydride

- DMAP:

-

4-(Dimethylamino)pyridine

- DMP:

-

Dess–Martin periodinane

- DMSO:

-

Dimethyl sulfoxide

- equiv:

-

Equivalent(s)

- Et:

-

Ethyl

- Et3SiH:

-

Triethylsilane

- h:

-

Hour(s)

- i-Pr:

-

Isopropyl

- LG:

-

Leaving group

- L-PGA:

-

l-Pyroglutamic acid

- Me:

-

Methyl

- MSA:

-

Methanesulfonic acid

- MTBE:

-

Methyl tert-butyl ether

- n-Bu:

-

Butyl

- n-Hex:

-

n-Hexane

- Nu:

-

Nucleophile

- PG:

-

Protecting group

- Ph:

-

Phenyl

- Piv:

-

Pivaloyl

- PMB:

-

4-Methoxyphenyl

- PNB:

-

4-Nitrobenzoyl

- py:

-

Pyridine

- R:

-

Alkyl

- rt:

-

Room temperature

- s-Bu:

-

sec-Butyl

- TBAF:

-

Tetrabutylammonium fluoride

- TBDPS:

-

tert-Butyldiphenylsilyl

- t-Bu:

-

tert-Butyl

- TEA:

-

Triethylamine

- TFA:

-

Trifluoroacetic acid

- THF:

-

Tetrahydrofuran

- TMEDA:

-

N,N,N',N'-Tetramethyl-1,2-ethylenediamine

- TMS:

-

Trimethylsilyl

- Tol:

-

Toluene, 4-methylphenyl

References

Štambaský J, Hocek M, Kočovský P (2009) C-Nucleosides: Synthetic strategies and biological applications. Chem Rev 129:6729–6764

Isaji M (2007) Sodium-glucose cotransporter inhibitors for diabetes. Curr Opin Invest Drugs 8:285–292

World Health Organization (2011) Diabete: Facts Sheet N0. 312. Geneva. http://www.who.int/mediacenter/factsheets/fs312/en

Lewis M, Cha J, Kishi Y (1982) Highly stereoselective approaches to α- and β-C-glycopyranosides. J Am Chem Soc 104:4976–4978

Kraus G, Molina M (1988) A direct synthesis of C-glycosyl compounds. J Org Chem 53:752–753

Czernecki S, Ville G (1989) C-Glycosides. 7. stereospecific C-glycosylation of aromatic and heterocyclic rings. J Org Chem 54:610–612

Meng W, Ellsworth B, Nirschl A, McCann P, Patel M, Girotra R, Wu G, Sher P, Morrison E, Biller S, Zahler R, Deshpande P, Pullockaran A, Hagan D, Morgan N, Taylor J, Obermeier M, Humphreys W, Khanna A, Discenza L, Robertson J, Wang A, Han S, Wetterau J, Janovitz E, Flint O, Whaley J, Washburn W (2008) Discovery of dapagliflozin: a potent, selective renal sodium-dependent glucose cotransporter 2 (SGLT2) inhibitor for the treatment of type 2 diabetes. J Med Chem 51:1145–1149

Nomura S, Sakamaki S, Hongu M, Kawanishi E, Koga Y, Sakamoto T, Yamamoto Y, Ueta K, Kimata H, Nakayama K, Tsuda-Tsukimoto M (2010) Discovery of canagliflozin, a novel C-glucoside with thiophene ring, as sodium-dependent glucose cotransporter 2 inhibitor for the treatment of type 2 diabetes mellitus. J Med Chem 53:6355–6360

Bernhardson D, Brandt T, Hulford C, Lehner R, Preston B, Price K, Sagal J, St. Pierre M, Thompson P, Thuma B (2014) Development of an early-phase bulk enabling route to sodium-dependent glucose cotransporter 2 inhibitor ertugliflozin. Org Process Res Dev 18:57–65

Eckhardt M, Himmelsbach F, Wang X, Sun X, Zhang L, Tang W, Krishnamurthy D, Senanayake C, Han Z (2006) Processes for preparing of glucopyranosyl-substituted benzyl-benzene derivatives and intermediates therein. WO Pat. Appl. 2006120,208, 7 Sept 2007

Imamura M, Nakanishi K, Suzuki T, Ikegai K, Shiraki R, Ogiyama T, Murakami T, Kurosaki E, Noda A, Kobayashi Y, Yokota M, Koide T, Kosakai K, Ohkura Y, Takeuchi M, Tomiyama H, Ohta M (2012) Discovery of ipragliflozin (ASP1941): a novel C-glucoside with benzothiophene structure as a potent and selective sodium glucose co-transporter 2 (SGLT2) inhibitor for the treatment of type 2 diabetes mellitus. Bioorg Med Chem 20:3263–3279

Ohtake Y, Sato T, Kobayashi T, Nishimoto M, Taka N, Takano K, Yamamoto K, Ohmori M, Yamaguchi M, Takami K, Yeu S, Ahn K, Matsuoka H, Morikawa K, Suzuki M, Hagita H, Ozawa K, Yamaguchi K, Kato M, Ikeda S (2012) Discovery of tofogliflozin, a novel C-arylglucoside with an O-spiroketal ring system, as a highly selective sodium glucose cotransporter 2 (SGLT2) inhibitor for the treatment of type 2 diabetes. J Med Chem 55:7828–7840

Liu Y, Fu T, Ou C, Fan W, Peng G (2013) Improved preparation of (1S,3′R,4′S,5′S,6′R)-5-chloro-6-[(4-(ethylpheny)methyl]-3′,4′,5′,6′-tetrahydro-6′-(hydroxymethyl)-spiro[isobenzofuran-1(3H),2′-[2H]pyran-3′,4′,5′-triol. Chin Chem Lett 24:131–133

Kakinuma H, Oi T, Hashimoto-Tsuchiya Y, Arai M, Kawakita Y, Fukasawa Y, Iida I, Hagima N, Takeuchi H, Chino Y, Asami J, Okumura-Kitajima L, Io F, Yamamoto D, Miyata N, Takahashi T, Uchida S, Yamamoto K (2010) (1S)-1,5-Anhydro-1-[5-(4-ethoxybenzyl)-2-methoxy-4-methylphenyl]1-thio-D-glucitol (TS-071) is a potent, selective sodium-dependent glucose cotransporter 2 (SGLT2) inhibitor for type 2 diabetes treatment. J Med Chem 53:3247–3261

Ellsworth B, Doyle A, Patel M, Caceres-Cortes J, Mend W, Deshpande P, Pullockaran A, Washburn W (2003) C-Arylglucoside synthesis: triisopropyl silane as a selective reagent for the reduction of an anomeric C-phenyl ketal. Tetrahedron Asymmetry 14:3243–3247

Deshpande P, Ellsworth B, Buono F, Pullockaran A, Singh J, Kissick T, Huand M-H, Lobinger H, Denzel T, Mueller R (2007) Remarkable β-selectivity in the synthesis of β-1-C-arylglucosides: stereoselective reduction of acetyl-protected methyl 1-C-arylglucosides without acetoxy-group participation. J Org Chem 72:9746–9749

Ellsworth B, Washburn W, Sher P, Wu G, Meng W (2002) C-Aryl glucoside SGLT2 inhibitors and method. US Pat. Appl. 6,414,126, 2 July 2002

Wang X-J, Zhang L, Byrne D, Nummy L, Weber D, Krishnamurthy D, Yee N, Senanayake C (2014) Efficient synthesis of empagliflozin, an inhibitor of SGLT-2, utilizing an AlCl3-promoted silane reduction of a β-glycopyranoside. Org Lett 16:4090–4093

Filliers W, Broeckx R, Nieste P, Hatsuda M, Yoshinaga M, Yada M (2010) Process for the preparation of compounds useful as inhibitor of SGLT. WO Pat. Appl. 2010043,682, 22 Apr 2010

Bowles P, Brenek J, Caron S, Do N, Drexler M, Duan S, Dubé P, Hansen E, Jones B, Jones K, Ljubicic T, Makowski T, Mustakis J, Nelson J, Olivier M, Peng Z, Perfect H, Place D, Ragan J, Salisbury J, Stanchina C, Vanderplas B, Webster M, Weekly R (2014) Commercial route research and development for SGLT2 inhibitor candidate ertugliflozin. Org Process Res Dev 18:66–81

De Paul S, Perlberg A, Zhao M (2010) Solid forms of (2S,3R,4R,5S,6R)-2-(4-chloro-3-(4-ethoxybenzyl)phenyl)-6-(methylthio)tetrahydro-2H-pyran-3,4,5-triol and methods of their use. WO Pat. Appl. 2010009,197, 21 Jan 2010

Gong H, Andrews RS, Zuccarello JL, Lee SJ, Gagné MR (2009) Sn-Free Ni-catalyzed reductive coupling of glycosyl bromides with activated alkenes. Org Lett 11:879–882

Gong H, Gagné MR (2008) Diastereoselective Ni-catalyzed Negishi cross-coupling approach to saturated, fully oxygenated C-alkyl and C-aryl glycosides. J Am Chem Soc 130:12177–12183

Gong H, Sinisi R, Gagné MR (2007) A room temperature Negishi cross-coupling approach to C-alkyl glycosides. J Am Chem Soc 129:1908–1909

Nicholas L, Angibaud P, Stansfield I, Bonnet P, Meerpoel L, Reymond S, Cossy J (2012) Diastereoselective metal-catalyzed synthesis of C-aryl and C-vinyl glycosides. Angew Chem Int Ed 51:11101–11104

Nicolas L, Izquierdo E, Angibaud P, Stansfield I, Meerpoel L, Reymond S, Cossy J (2013) Cobalt-catalyzed diastereoselective synthesis of C-furanosides. total synthesis of (−)-isoaltholactone. J Org Chem 78:11807–11814

Lemaire S, Houpis IN, Xiao T, Li J, Digard E, Gozlan C, Liu R, Gavryushin A, Diene C, Wang Y, Farina V, Knochel P (2012) Stereoselective C-glycosylation reactions with arylzinc reagents. Org Lett 14:1480–1483

Henschke JP, Wu P-Y, Lin C-W, Chen S-F, Chiang P-C, Hsiao C-N (2105) β-Selective C-arylation of silyl protected 1,6-anhydroglucose with arylalanes: the synthesis of SGLT2 inhibitors. J Org Chem 80:2295–2309

Henschke JP, Lin C-W, Wu P-Y, Tsao W-S, Liao J-H, Chiang P-H (2015) β-Selective C-arylation of diisobutylaluminum hydride modified 1,6-anhydroglucose: synthesis of canagliflozin without recourse to conventional protecting groups. J Org Chem (80):5189–5195

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Lemaire, S., Schils, D. (2015). Development of Efficient Routes to Access C-Glycosides as SGLT-2 Inhibitors for the Treatment of Type 2 Diabetes. In: Časar, Z. (eds) Synthesis of Heterocycles in Contemporary Medicinal Chemistry. Topics in Heterocyclic Chemistry, vol 44. Springer, Cham. https://doi.org/10.1007/7081_2015_166

Download citation

DOI: https://doi.org/10.1007/7081_2015_166

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-39915-7

Online ISBN: 978-3-319-39917-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)