Abstract

Quartz crystal microbalance (QCM) is a well-known analytical technique that enables sensitive and accurate measurement and characterization of materials adsorbed on a crystal’s surface. QCM has been demonstrated to be highly reliable to measure and characterize the mass of deposited samples, in both gas and liquid phases. In addition, the technique offers real-time monitoring, as well as low operation costs. These features make QCM suitable for a wide range of applications, from mass sensing for biosensors to the study of biomolecules, nanoparticles, and functionalized surface interactions. Hence, QCM has been exploited for the optimization of nanoparticles, thin films, and drugs’ formulations, for the development of their manufacturing process and as a versatile and easy-to-use tool for quality control. This chapter, therefore, firstly summarizes and critically reviews the latest fundamental and applied research studies on the implementations of QCM and QCM-D (QCM with dissipation factor) for the characterization of particles, films, and their interactions both with surfaces and the environment. Then research studies on the use of QCM in the pharmaceutical industry for the optimization of drugs’ formulations and for quality-control post manufacturing are also presented and discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

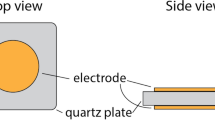

The quartz crystal microbalance (QCM) is a measurement technique that enables highly sensitive characterization of deposited samples both in gas and in liquid and has found wide applications in surface sciences and biotechnology [1,2,3]. QCM is a label-free and acoustic sensor, based on the piezoelectric effect discovered by the Curies in the late nineteenth century. Piezoelectricity states that the application of a voltage to materials with specific symmetry properties in their crystal lattice (piezoelectric) results in mechanical deformation (oscillation) [1]. If the frequency of the applied voltage matches the crystal’s resonance frequency (or its multiples, which are called overtones), a wave is generated inside the crystal. Depending on the cut of the crystal, different kinds of oscillations may arise. AT-cut crystals, used in QCM, vibrate in a thickness-shear mode, where the wave of oscillation travels through the body of the crystal. This implies that the frequency of oscillation is affected by the crystal’s thickness and by the presence of adsorbates on the crystal surface. In the most common measurement configurations, at each overtone, both the resonance frequency of oscillation, f, as well as the dissipation of the oscillation (D) can be measured. As the overtone number increases, the penetration depth (δ) of the oscillation wave from the crystal into the adsorbed layer and into the bulk fluid decreases and the specific value can be calculated. For example, in aqueous solutions, for a 5 MHz resonating AT-cut quartz crystal, δ is 240–250 nm at the fundamental resonant frequency, f0, and it is 68 nm at the 13th overtone [2]. Changes to f and D signals (Δf and ΔD) may occur due to adsorption, desorption, physical changes (e.g., swelling or shrinking), and structural reconfiguration events occurring on the quartz crystal surface [3, 4]. Both for QCM and especially for QCM-D, several models have been proposed to establish a relationship between the frequency and the dissipation changes and either the mass of the material adsorbed or the adsorbate viscoelastic properties, especially when measurements are done in the presence of fluids. Among the several models that have been proposed, the Sauerbrey model (Eq. 1) [5], which envisages direct proportionality between the Δf and the mass adsorbed on the sensor is the most common, for measurements done in gas phase and when the adsorbed material is flat, rigid, and firmly attached to the quartz crystal.

where Δm is the mass adsorbed on the crystal surface, C is the sensitivity constant, n is overtone, and Δf is the change in the sensor frequency.

Several models have been proposed to relate the change in frequency and the phenomenon taking place on the crystal surface in the presence of a rigid and firmly attached adsorbate, when this is exposed to liquids. One of the earliest models (dating from the late 1940) is expressed in Eq. 2.

where n is overtone, ηl and ρl are the liquid viscosity and density, respectively, and ωF is the angular fundamental resonance frequency.

Equation 2 is typically attributed to Kanazawa and Gordon [6]; it states that the decrease in frequency and the increase in dissipation are both proportional to the square root of the product of the liquid’s viscosity and density. Since QCM is sensitive to the properties of the bulk liquid, a reference measurement in the same liquid is often necessary for separating bulk liquid contribution from the film properties. Other viscoelastic models (e.g., Voigt or Kelvin-Voigt models, Eq. 3) [5, 7] have been proposed for when the material is not rigidly adsorbed on the crystal, but consists of a soft layer.

In these models, frequency and dissipation are functions of the deposited material’s thickness (dm), its density (ρm), its viscosity (ηm), and its shear modulus (μm), as well as the density (ρl) and viscosity (ηl) of the bulk contacting liquid (or gas) [2].

Such models allow to relate the Δf and ΔD signals to specific characteristic of the material adsorbed (e.g., hydrodynamic diameter of nanoparticles), as well as understanding phenomena such as swelling, fouling, sorption, and ion exchange [2]. Such features have seen the use of QCM and particularly QCM-D, for a variety of applications from the optimization of drugs’ formulations [8, 9] and the development of their manufacturing systems [10], to the use of QCM as a tool for quality control during or post drugs’ production [11]. Therefore, this chapter firstly will critically review the most recent fundamental studies on the use of QCM or QCM-D to characterize nanomaterial (e.g., nanoparticles), nanofilms, and biomolecules attached on piezoelectric crystals. Then applications of QCM and QCM-D for drug development and quality control in the pharmaceutical industry will also be reviewed and discussed.

2 QCM and QCM-D as a Tool for the Characterization of Nanomaterials

The information on nanomaterials (e.g., biomolecules, metal nanoparticles, bacteria, viruses, etc.), their adsorption kinetics, and their adhesives' contact strength to a particular surface are essential in many scientific fields including analytical sciences, medicine, biology, and catalysis. Therefore, several research groups have focused on how QCM and especially QCM-D signals can be exploited to extract important information of the nanomaterials adsorbed on the crystal surface. In many studies, QCM and QCM-D signals (Δf and ΔD) have been analyzed using several numerical and simulation tools to establish relationships between the signal shifts and the characteristic of the adsorbate. For example, for measurements done in liquid, the Δf recorded is not only proportional to the mass of the adsorbed layer, but also to the characteristics of the hydrodynamically coupled fluid. The relationship between the QCM signal and the characteristic of the adsorbed layer depends on whether this is homogenous or heterogenous. For homogenous and rigid layers, the Sauerbrey or the Kanazawa and Gordon models (Eqs. 1 and 2, respectively), where there is a proportionality between the sensor frequency (f) and the mass of the adsorbate, can be applied for measurements done in gas and in liquids [1, 6].

Heterogenous layers (i.e., a layer of discrete particles) are more difficult to simulate. Several models have been proposed; one of the most common, the Voigt or the Kelvin-Voigt viscoelastic models relates the measured dissipation factor (D), shown in (Eq. 3), with changes on the deposited material and the environment (air/liquid). The relationship between the material adsorbed and the environment can become very complex. For example, in a dense layer of particles, the QCM signal does not only depend on the mass of the nanomaterial and on the hydrodynamic interaction of the particles with the surrounding liquid, but also on the hydrodynamic interactions among the particles themselves (e.g., the sensing of the disturbances generated in the fluid by neighboring particles), making the system difficult to simulate and described numerically. The particle-particle hydrodynamic interactions disappear for sparsely packed layers simplifying the system drastically. Therefore, Gillissen and colleagues have simulated numerically the hydrodynamic behavior of a sparse layer of spherical nanoparticles rigidly attached to the QCM sensor [12]. The simulation enabled the generation of a model, which from the QCM-D signal, permitted the evaluation of the nanoparticles' size in the range of δ/a < 3, where δ is the sensor’s penetration depth and a is the particle's radius. The model allowed them to estimate the size of globular proteins, viruses, colloids, and spherical vesicles, with therefore applications to a wide range of bioparticles. In another work, the group used the model to quantitatively measure the deformation of adsorbed particles (a layer of fluid-like and gel-like liposomes of 34 nm radius) at low surface coverage [13]. Similarly, Adamczyk and co-workers [14] have developed a theoretical model that enabled them to interpret the adsorption kinetics of nano- and micro-size particles on rough surfaces from the Δf and ΔD signals. The model accounted not only for rigidly attached nanoparticles, but also for lightly adsorbed materials. In addition, it evidenced the importance of the roughness and the homogeneity of the QCM sensors surface on the adhesion strength of both micro- and nanoparticles. In many cases, for example on medical implants, the adhesion of biomolecules such as osteoblast cells needs to be promoted to achieve a successful implant integration. In other cases, for example to reduce the spread of viruses and bacteria, metal/glass/plastic surfaces are modified to minimize the adhesion of the biomolecules. Therefore, the model showed the potential to estimate the attachment of different size nanoparticles to various surfaces or surface treatments, enabling to find conditions either to promote or prevent attachment.

Similarly, Van der Western and colleagues [15] have used a window-equipped QCM-D for the high-throughput analysis to estimate the averaged viscoelasticity of the bond between colloids and several surfaces by measuring simultaneously up to 106 colloidal particles. The group assumed that when colloidal particles are sparsely adsorbed on a sensor surface, they act as individual, coupled resonators, whose schematic representation is presented in Fig. 1a. Such individual resonators will impact the resonance frequency shift (Δf) measured, as well as the dissipation energy (ΔD). The development of the coupled resonator model has greatly widened the applications of QCM-D, which were previously confined to molecular mass adsorption. The group also indicated that whereas bond viscoelasticity of individual particles of the same kind often shows large variations, QCM-D identifies a well-defined zero-value in sensor resonance frequency shift (Δfs), when particle and sensor resonance frequencies match (fs equals to fp), Fig. 1b. These zero crossing frequencies are only observed when the adhering particles oscillate at frequencies within the window of the sensor fundamental resonance frequency and its overtones, which for a 5 MHz QCM, ranges from 5 MHz to 65 MHz (see dashed rectangles in Fig. 1b). The asymptotic shift from a negative to a positive Δf takes place when fp equals fs and is accompanied by a maximum in ΔD. This coupled-resonator model was finally able to explain the positive Δf signals often reported in literature following the adsorption of materials on the crystal surface.

Schematic diagram of the coupled resonator model. (a) Particle with mass, mp adhering to a sensor surface through a viscoelastic bond comprised of a spring with a spring constant (k), and with a drag coefficient (ξ), yielding a particle resonance frequency fp. (b), (c), and (d) Theoretical shifts in the sensor resonance frequency (Δfs) and dissipation changes (ΔD) for particles adhering with different adhesive bond stiffnesses to a QCM-D sensor. Particle resonance frequency fp increases with the adhesive bond stiffness, and the frequency of zero-crossing (fs = fp) can only be observed within what is referred to as “the window of observable QCM-D frequencies”, indicated by the dashed rectangles. Illustration adapted from [15]

Using the coupled resonator model, the group was able to relate the Δf and ΔD to the bond viscoelasticity using the Kelvin-Voight equation as reported below in Eq. 4.

where Δf (Hz) is the shift in QCM-D resonance frequency, ΔD is the change in dissipation, fF is the fundamental resonance frequency of the sensor (5 MHz), fs is the QCM-D sensor surface resonance frequency, mp is the particle mass (kg), ωs is the sensor resonance angular frequency (ωs = 2 π fs), ωp is the particle resonance angular frequency (ωp = 2 π fp), Zq is the acoustic impedance of an AT-cut quartz crystal (8.8 × 106 kg m−2 s−1), Np is the number of adhering particles per unit sensor area (m2), and γ equals ξ/mp with ξ being the drag coefficient, indicative of the viscous component of the bond [16].

Using the developed model, the group analyzed QCM-D data to calculate the elasticity (the spring constant) and viscosity (the drag coefficient) of biotic (S. Salivarius HB7) and abiotic (silica particles with 0.5 μm radius) particles adhering to different sensor surfaces (e.g., silica crystal, biotinylated crystal surface, hydrophobic Au, hydrophobic and hydrophilic self-assembled monolayers). Knowledge of the elasticity and viscosity of the bond through which colloidal particles adhere to a surface can help to understand better the mechanisms of particle adhesion. This would aid the development of new strategies to detach or prevent the attachment of several harmful particles such as viruses and bacteria.

In another example, where QCM was used to study colloidal particles, the device was utilized to monitor the evaporation of colloidal suspensions of alumina nanoparticles on a sensor surface [17]. Both the concentration of the colloidal suspension and the size of the particles were varied for the study. The group was able to record QCM data that enabled them to distinguish the several stages of evaporation. Furthermore, they developed a mathematical model allowing to perform a quantitative analysis. They concluded that for diluted solution the frequency shifts were indeed representative of the mass of particles adsorbed on the crystal, but in the presence of concentrated solutions the bond stiffness of the resulting layers and interparticle interactions were the dominating factors for the frequency shifts. These were then made accountable for the positive frequency shifts seen at complete evaporation (Fig. 2). They concluded that the signals observed with smaller particles were mainly due to bond stiffness generated by Van der Waals interactions, while for bigger particles, a capillary or sandcastle effect was considered responsible for the signals, highlighting the importance of relating the frequency shift to the appropriate phenomenon.

Frequency shift during complete drying of 1 μm alumina colloid suspension droplets with varying solid concentration. Representative microscope images taken after the water was evaporated show the residual alumina topography at each concentration. Reproduced with permission from [17]

When studying the adsorption and binding kinetics of materials on an oscillating sensor surface, care needs to be taken about the oscillating amplitude used. In 2005 Höök’s group studied the effect of the sensor shear amplitude (from 1 to 10 V) on the adsorption of several types of material: (i) lipid vesicles to a SiO2 surface; (ii) streptavidin to a biotin-modified substrate; (iii) neutroavidin- (or single stranded DNA) polystyrene bead (200 nm) to a biotin (or DNA) modified surface [18, 19]. The results show that the most used amplitude (1 V) does not affect the binding of any of the nanomaterials tested (with Mw between 10 kDa and 200 kDa). However, an effect of the oscillation amplitude was found on the binding of polystyrene nanoparticles (>200 kDa); particularly, it was observed that particle’s saturation binding decreased with increments of the oscillation amplitude. To explain this effect, Höök and colleagues considered that the oscillation amplitude has its maximum in the center of the crystal and decays to zero at the crystal’s edges. Hence, they explained the effect by proposing a critical oscillation amplitude, Ac, above which there is no binding, but below which the binding is not influenced. The group also stated that for a specific Ac value, there is a critical radius, rc, within which the binding is completely suppressed, but beyond which the binding is not influenced. If the oscillation amplitude is high enough the particle binding can be totally disrupted. Experimentally, for both types of polystyrene immobilization mechanisms studied (via DNA hybridization or biotin-avidin binding) no effect in the saturation binding was observed with oscillation amplitude up to ~5 nm, but a significant decrease was seen for oscillation above ~10 nm. The similarity of the behavior for the different immobilization mechanisms implies that the effect was due to the size of the nanoparticles rather than to the substrate-nanoparticles bond strength and numbers. Therefore, the effect of the shear sensor amplitude on the crystal’s adsorption needs to be considered when using QCM when measuring particles larger than 100–200 nm.

3 QCM and QCM-D as a Tool for the Characterization of Polymeric Films

Thin, porous films are used in numerous scientific fields and for a wide variety of applications, from energy storage [20] to sensing [21, 22]. In the last two decades, QCM and especially QCM-D have been used for the characterization of such films. The technique has been utilized as a tool to follow the formation of films [23,24,25,26] as well as to study the performance of the resulting viscoelastic layers in different environments [5, 27].

Thin polymeric films can be considered soft coatings, which remain rigidly attached to a crystal surface and are characterized by reduced values of their bulk complex shear moduli. Quantification of the complex shear modulus can be carried out using the changes in frequency and dissipation factor over multiple overtones measured experimentally and fitted using suitable viscoelastic models [28]. Such viscoelastic coatings are characterized by both frequency and dissipation factor changes dependent on the overtone order, n. The mass change occurring in viscoelastic films cannot be estimated by the Sauerbrey’s equation (Eq. 1), but this becomes an input parameter in more complex equations. Such equations have a high number of viscoelastic parameters that are influenced by the nature of the coating and the liquid in contact with it. Therefore, by following the changes in frequency and dissipation factors many phenomena occurring in the viscoelastic layers can be explained and monitored.

One of the most common methods to create thin polymeric films on a surface is the layer-by-layer (LbL) deposition. With these techniques, layers of polyelectrolytes with opposite charges can be deposited efficiently to obtain layers used for a variety of applications including drug delivery [29,30,31], sensing [32], and energy (e.g., for organic solar cells [33, 34]). A schematic representation of the LbL deposition process starting from a positively charged surface is depicted in Fig. 3.

Diagram of the LBL film-deposition process, based on the alternating exposure of a charged substrate to solutions of positively and negatively charged polyelectrolytes. A rinsing step (usually in water) is included between the two previously described adsorption processes, to remove excess as well as to prevent cross-contamination of the polyelectrolyte solutions. Illustration adapted from [35]

QCM and especially QCM-D has been used extensively to characterize and understand the behavior of such films when subjected to different conditions and environments.

Lutkenhaus and colleagues [25] stated that to exploit LbL layers properly, characterizing their thermal properties and estimating the layers’ glass transition temperatures (Tg) are critical, as the performance of the films would depend strongly on whether they are rubbery or glassy. In addition, the films’ Tg values and the presence of several Tgs can be correlated to the films’ composition and internal structure. Therefore, the group have used QCM-D to follow the formation of poly(allylamine hydrochloride)/poly(acrylic acid) (PAH/PAA) assembled at different pH values (pH 3.5, 5.0, and 9.0) [25] and the formation of poly(diallyldimethylammonium chloride)/poly(styrene sulphonate) (PDADMA/PSS) assembled from solution with varied anionic concentrations (i.e., 0.25–1.25 M NaCl) [26]. The thermal properties of the resulting LbL layers (70–300 nm) were then evaluated by estimating the Tg values using a thermally controlled QCM-D. They compared the results with those examined by modulated differential scanning calorimetry (DSC) of the same LbL produced in “bulk” (1–1.5 μm). In both studies, QCM-D signals agreed with the DSC and seemed suitable to characterize thermal properties and enable estimating Tg values and how these were affected by film formation and composition. Figure 4 shows an example of one of the results obtained. Specifically, while Fig. 4a depicts the ΔF and the ΔD (13th overtones) raw signals recorded while increasing temperature for a PEI/(PDADMA/PSS)7 LbL film assembled from 1.0 M NaCl, Fig. 3b shows the same two QCM-D signals obtained for a bare crystal also immersed in 1.0 M NaCl. As the viscosity and density of the solution in contact with the crystal is affected by the temperature, so is the signal of a bare electrode. Therefore, for easier identification of the LbL film Tg, the changes in frequency and dissipation of the bare crystal were subtracted from the frequency and dissipation changes of the LbL assemblies, resulting in Fig. 3c, d, where the Tg values for films prepared in different concentration of NaCl can be clearly seen, especially in the ΔD plots.

Temperature dependence of ΔF and ΔD for the 13th overtone of (a) a LbL film assembled from 1.0 M NaCl and (b) a bare crystal in 1.0 M NaCl. Temperature dependence of corrected ΔF (c) and ΔD (d) for PEI/(PDADMA/PSS)7 LbL films assembled from 0, 0.5, and 1.0 M NaCl. Reproduced with permission from [26]

It is well known that solutions with different electrolytes, ionic strengths, and concentrations have a strong influence on the formation of LbL layers [35,36,37,38], but their effect of the films post-formation is less explored. Nevertheless, it has already been proposed that specific electrolytes with different ionic strength can have several effects such as shrinking and swelling on the LbL layers post-formation [39]. QCM-D has been demonstrated to be an efficient tool to study and investigate the effect of several electrolytes and their strength on the LbL films. For example, again the Lutkenhaus group exposed LbL films of PDADMA/PSS, prepared using 0.5 M NaCl, to several electrolytes such as NaCl, KCl, NaBr, and KBr [23]; the last one has been reported to have a strong effect on the swelling of the LbL layers [40]. The same films in free-standing forms were also analyzed for comparison by 1H NMR and neutron activation analysis. The QCM-D results showed that salts containing Br− had a more pronounced swelling effect on the films than salts containing Cl−. In addition, using the QCM-D, the group was able to follow in detail how various concentration ranges of KBr affected the PDADMA/PSS differently. This allowed them to hypothesize not only the forces behind the changes (i.e., electrostatic repulsion), but were able to observe salt annealing at the highest electrolyte concentration tested.

LbL films made of biocompatible electrolytes such as chitosan, alginate, hyaluronic acid, dextran, heparin, etc., have been explored for regenerative medicine, tissue engineering, and drug delivery thanks to their ease of preparation and the ability to tune their physical properties, such as size, composition, porosity, surface functionalization, and colloidal stability [41]. Borge and colleagues [42] have explored hybrid supramolecular multi-layered biomaterials, comprising high-molecular-weight biopolymers (i.e., alginate) and oppositely charged low-molecular-weight peptide amphiphiles (PAs), through LbL assembly. The process of LbL formation was followed by QCM-D, which was able to reveal that alginate and PAs could be successfully combined to achieve stable supramolecular systems that are promising for biomedical applications. Similarly, Sergeeva and co-workers [43] used QCM-D to study the formation of several LbL films made of charged natural and synthetic polyelectrolytes. The QCM-D signals observed during LbL deposition were analyzed qualitatively to estimate the viscoelastic properties of the films and their interactions with serum components. The group also investigated how the composition of the LbL films was able to influence cells adhesion (fibroblasts) and proliferation, permitting to select the best multilayers for cell cultures. The results underlined that cell adhesion is a highly complex process governed by several surface’s features including: (i) functionality, (ii) morphology, (iii) affinity for serum components, and (iv) changes in surface properties generated by adsorbing biomolecules. Of the many LbL-films tested, the group observed that poly(4-styrenesulfonate)/poly(allyl amine) multilayers were best suited for attachment of fibroblast cultures.

QCM-D has also been used to characterize drug attachment and release to and from LbL films in the presence of several stimuli, allowing to tune the LbL composition until the desired kinetics was achieved. Aykut and colleagues [44] have used QCM-D to study the drug loading/release of LbL films made of PDADMA/PSS and PDADMA/PAA. The composition of the films as well as the pH and ionic strength were changed to achieve maximum drug loading and the desired release kinetics [44]. Figure 5 shows the QCM-D signal of the loading and desorption at different pHs (pH 6.3, pH 2.0, and pH 11) of the drug IBF-Na on the LbL film (PDADMA5.5/PSS5.5)10. In Fig. 5, the film was exposed to the drug in step 1 and an increase in signal, confirming attachment of IBF-Na to the LbL film, was obtained. In step 2, a pure water wash (pH 6.3) was applied to remove the loaded drug, demonstrated by the decrease in signal. In step 3, IBF-Na was loaded again, and a smaller increase than in step 1 was observed, with the difference corresponding to 7 ng/cm2. This indicates that the water wash in step 2, in addition to removing the drug, might have removed loosely bound polyelectrolytes from the LbL film. In step 4, a solution with pH 2 was passed on the IBF-Na-loaded LbL film, and the sharp decrease in signal showed that this solution was able to desorb not only the entire amount of drug, but also 11% of the LbL film. The subsequent loading step (5) showed a much higher adsorption of drug as compared to step 1 and 2, revealing morphological/structural changes in the LbL layer generated by the exposure to the strongly acidic solution in step 4. In step 6, a solution with pH 11 was used to trigger the release, but only 27.5% of the drug was desorbed, while 72.5% remained attached, most likely through electrostatic and hydrophobic interactions present between IBF-Na and the LbL film in basic conditions. The group followed the drug attachment and release also by analyzing the solutions by UV-Vis spectroscopy. Both analytical techniques gave consistent results demonstrating that the QCM-D is a powerful tool to study and characterize materials for drug delivery.

An example of QCM-D graph for IBF-Na loading/desorption to/from (PDADMA5.5/PSS5.5)10. (ΔM/A is the change of mass per unit area). Reproduced with permission from [44]

Lipid nanoparticles (LNPs) are another promising type of nanomaterial for drug delivery, in particular for intracellular delivery, as their cellular uptake can be modulated by changing their composition. Usually, one optimizes the composition to achieve the desired uptake and performance by a combination of time-consuming in vitro and in vivo studies. QCM-D has shown to be a quick tool to study the interactions between several LNPs and serum proteins permitting to identify those with the best chance to have high uptake by the cells. In this way, only the most promising LPN candidates would be selected to progress to in vitro and in vivo studies saving time and resources [9]. Sebastiani and co-workers used two approaches to screen for the best LPN candidates. In the first approach, QCM crystals were functionalized with antibodies against a target protein fundamental for maximum cells uptake, enabling to identify which LNPs possessed such protein in their corona. In the second approach the crystals were functionalized with LNPs via polyethylene glycol to study the interactions of the lipid nanoparticles with serum proteins. These two experimental approaches enabled the group to predict the composition of LNPs protein corona and therefore to estimate the nanoparticles chance to approach and cross the cell membranes.

4 QCM and QCM-D to Study Molecule-Surface Interactions and Molecule-Molecule Interactions

In the last 10–15 years QCM and QCM-D have demonstrated to be powerful tools to study interactions among biomolecules and/or chemicals as well as interactions between biomolecules (or chemicals) and surfaces.

The chemistry used to immobilize receptors on sensor surfaces as well as to reduce non-specific interactions caused by the complex composition of clinical and environmental samples is paramount for the development of specific and selective diagnostic devices. Among the several chemicals available, polyethylene glycol (PEG) is one of the most promising for both immobilizing a receptor and minimizing the binding of non-targeted chemicals contained in a sample. Du and co-workers [45] used QCM-D to study the combination of a long-chain PEG (PEG24) and a short-chain PEG (PEG4) for sensing applications. While PEG24 was used to achieve optimal immobilization of the antibodies for binding with the antigen, PEG4 was used to fill the unoccupied sensor’s surface providing an anti-fouling layer capable to minimize binding of other proteins and chemicals present in complex biological fluids such as plasma. The use of QCM-D allowed to visualize how changing the ratios between the two PEGs on the sensor surface influenced the behavior of the resulting sensors in terms of both sensitivity and specificity permitting to identify the ratio leading to the best performance.

The use of QCM-D to optimize surface chemistries has been used not only to develop biosensors, but also in the field of tissue engineering and regenerative medicine. For these, surfaces are usually covered with a layer of functional proteins and growth factors. Many chemistries have been developed to covalently attach proteins and other biomolecules to surfaces in a chemo- and regioselective fashion. For example, peptide or imine bonds can be formed upon reaction of N-hydroxysuccinimide or aldehyde functionalities (attached to the sensor surface), with the carboxylic groups present in proteins. An alternative approach to immobilize proteins and growth factors on a surface is using supramolecular chemistry, enabling mild and reversible protein attachment [46]. Goor and co-workers [47] have used QCM-D as well as fluorescence spectroscopy to monitor the binding of proteins to a combination of a hydrogen bonding motif, 2-ureido-4-pyrimidinon (UPy), with a Cucurbit[8]uril (Q8)-based macrocyclic host–guest assembly. Whereas UPy was directly attached on the crystal surface, Q8 and the protein solution were incubated with the crystal in subsequent steps. In agreement with fluorescence spectroscopy, QCM-D data displayed successful ternary complex formation on the crystal surface, with a small mass increase observed upon incubation of Q8 and a large mass increase observed after subsequent incubation of the protein. Following a washing step, a decrease on the mass adsorbed was observed, which demonstrated the reversible nature of the supramolecular host–guest system. In contrast to fluorescence spectroscopy, QCM-D was able to reveal the presence of nonspecific binding of Q8 to the sensor surface, highlighting the need of additional surface-blocking steps. This demonstrated the advantage of using QCM over fluorescence spectroscopy to optimize the surface chemistry for tissue engineering.

To obtain a more in-depth understanding of protein-surface interactions, QCM-D together with protein assay tests were used to study the controlled and competing surface adsorption of several functional proteins. This enabled to have a model of a multifunctional platform, useful for guiding biological activities [48]. For the study, a hydrophobic chemical (polychloro-para-xylylene) was first attached on the sensor surface. Then, the adsorption of morphogenetic protein 2 (BMP-2) and fibronectin both individually and in combination was characterized by QCM-D. When the two proteins were adsorbed together, several ratios were tested and the proteins’ actual distribution in the resulting layers were characterized by QCM-D using anti-BMP-2 and anti-fibronectin antibody. Specific binding of the antibody to its corresponding protein enabled to estimate the amount of each protein attached on the surface when different ratios were used in the immobilization solution (Fig. 6). Then, the multifaceted and synergistic biological activities of the adsorbed BMP-2 and fibronectin were examined by culturing porcine adipose stem cells (pADSCs) on the modified sensors’ surfaces. Finally, protein assays were then carried out at several time intervals (e.g., 24 and 72 h) on the resulting cell cultures to evaluate the osteogenesis activity of BMP-2 and the cell proliferation activity of fibronectin (two biological activities highly desired when growing new tissues). The results confirmed that there was indeed a synergic effect of the two proteins as a high degree of both osteogenesis and proliferation activity on the cell cultures was observed on sensors’ surfaces containing both BMP-2 and fibronectin. On the other hand, cells grown on surfaces with only one protein immobilized evidenced either a high degree of osteogenesis or proliferation and a very low degree of the other activity. The study also evidenced how the two biological activities could be modulated by controlling the adsorption conditions (proteins ratios) utilized at the immobilization step, which could be followed and characterized by the QCM-D data.

QCM dynamic analysis of the binding affinity to specific antibodies: (a) anti-BMP-2 and (b) anti-fibronectin. Modified surfaces containing a previously adsorbed BMP-2 and fibronectin mixture with combinations of various ratios, including 1:0, 10:1, 1:1, 1:10, and 0:1, were used as the surfaces for binding affinity characterization. Reproduced with permission from [48]

In another example, QCM-D was used to monitor the production and to characterize supported lipid bilayers (SLB): a mimic of the lipid bilayer that constitutes the backbone of cell membranes. Thanks to its amphiphilic properties, the lipid bilayer acts as a protective layer isolating the inside of the cells from the external environment and thus regulates what enters and exits the cells. SBL are a widely accepted model to mimic cell membranes and, therefore, to study many critical biomacromolecular interactions. In fact, SLBs are extremely versatile as they can be functionalized with different functional groups mimicking those found in cell membranes; furthermore, they can incorporate membrane-associated proteins (transmembrane and peripheral). QCM-D has proven to be a powerful tool to study the formation of SLBs as well as their real-time dynamic interactions with biomolecules [49,50,51,52]. For instance, the technique was used to monitor the generation of SLB by surface-mediated vesicle fusion on several different hydrophilic surfaces such as oxides of silicon, gold, and titanium (all rich in hydroxyl groups) [49]. Figure 7a illustrates an example of the QCM signals (Δf in blue and ΔD in red) recorded during the formation of the SLB. In the study, an amphipathic α-helical (AH) peptide was used to form the SLB, as it can interact strongly with lipid vesicles absorbed on hydrophilic surfaces, causing their rapture [53]. Figure 7a clearly shows the addition, at around 10 min of the AH-peptide and its swelling effect on the absorbed intact vesicle, demonstrated by a sharp decrease of the Δf signal and a mirrored sharp increase of the ΔD signal. The vesicle’s rupture due to the AH-peptide is then evidenced at around 60 min by the dramatic change in f and D signals, after which the increasing Δf and decreasing ΔD signals are due to the difference in thickness and viscoelastic properties (calculated using both the Sauerbrey and Voigt models) of the resulting SBL layer as compared with the intact vesicle. Figure 7b shows a schematic representation of the structural transformation from an adsorbed, intact vesicle to a SBL. QCM-D was used to assess the viscoelastic properties of the layers during formation under several different conditions and to record in real time the interactions of the resulting layers with the environment. The same group, for example, studied the adsorption of three proteins (C3, C3b, and properdin) on SLB with either positive or negative charges and were able to observe how the uptake in the SLB was dependent on both the charges and protein concentrations [52].

(a) QCM-D signal recorded during SLB formation: a layer of intact vesicle is formed first and this is ruptured following the addition of a specific short chain peptide (AH) leading to SLB formation; (b) a schematic representation of the AH peptide-mediated structural transformation from adsorbed, intact vesicle to a SLB. Reproduced with permission from [49]

It is paramount to understand the interactions between materials, proteins, and cells for developing biomaterials suitable for a wide variety of medical applications such as orthopedic implants, implantable devices, and tissue engineering. QCM-D has shown to be able to provide an insight into such interactions, becoming a useful characterization tool when developing new materials. Kushiro and co-workers [54] aimed to study the effects of chemical functional groups on the attachment of proteins and cells onto orthopedic implants. For that purpose, they used QCM-D to evaluate the binding of fibronectin followed by fibroblasts L929 to surfaces comprising of different self-assembled monolayers (SAMs) and specifically COOH-SAM, NH2-SAM, CH3-SAM, OH-SAM. Using QCM-D, they were able not only to gain information on the viscoelastic properties of the surface-adsorbed fibronectin, but they could visualize the different patterns of ΔF and ΔD observed on the various SAM surfaces during L929 cell adhesion. Following further analyses and comparison, they suggested that the ΔF and ΔD patterns were unique signatures of protein adsorption and cell adhesion behaviors, which could be modulated by the various chemical functional groups introduced on the surfaces using the different SAM. This demonstrated that QCM-D has the potential of becoming a rapid in vitro platform for the dynamic evaluation of protein and cell behaviors on novel biomaterials. A similar study was conducted by Kao and colleagues, who, after generating either positively or negatively charged SAMs, used QCM-D to follow the attachment of NIH3T3 mouse embryonic fibroblasts. The group was able to see a strong effect of charge and therefore of the surface potential of the SAM, not only on the number of cells attached, but also on the way the cells were immobilizing on the surfaces. In fact, whereas a positive surface potential generated an evenly spread and soft cell monolayer, a negative surface potential, in contrast, led to a triple rigid layer of cells, resembling an extracellular matrix [55].

QCM-D has proven a powerful tool to study cells attachment and physical properties of the resulting layer [56]. Tymchenko and colleagues [57] demonstrated that ΔD could not only yield information on the attachment of fibroblasts (NIH3T3) to the crystal surface, but also assess in real time the reversible changes in the viscoelastic properties of the surface-attached cells, induced by the cytoskeleton-perturbing drug cytochalasin D. This demonstrates how QCM-D can be utilized to screen in vitro a selection of drugs and to observe their effect on specific cell lines.

Small amounts of reactive oxygen species (ROS), such as H2O2, are necessary to activate the body’s cellular defense response (oxidative eustress). In contrast, high levels of ROS lead to cellular damage (oxidative distress). The over-exposition of cells to oxidizing agents, such as H2O2, may lead to changes in cellular redox potential and morphology, which in turn affects the cells’ viscoelastic properties. Oxidative stress of cells is usually evaluated by immunological methods such as ELISA and Western Blot. However, these techniques, although informative, are end point and hence unable to follow the morphological changes of the cells in real time. Therefore, Shoaib and Trabrizian [58] explored whether QCM-D could be used to evaluate the degree of oxidative stress on the morphology of cells’ monolayers. Specifically, they have used a pre-osteoblast murine cell line (MC3T3) and studied the effect of various concentrations of H2O2 on the cells’ viscoelastic by following changes of the QCM-D response (ΔD). The QCM-D data showed that when the cells were exposed to level of H2O2 below 25 μM, the morphology changes of the monolayer were reversible (confirmed also by SEM, AFM, and fluorescence microscopy). On the other hand, when the levels of H2O2 were between 50 μM and 10 mM the viscoelastic/morphology changes of the cell monolayers were irreversible, presenting a shrinkage of the cytoskeleton with a decrease in cell density, which was also supported by viability assays. This demonstrated that QCM-D allows to estimate with ease the viscoelastic properties of cells and can be used to investigate cell recovery from oxidative stress, enabling to distinguish between oxidative eustress and distress. The technique could also potentially be used to screen for antioxidants able to reduce cells’ oxidative distress without suppressing oxidative eustress.

5 QCM and QCM-D for Drug Development and Quality Control

As described in the sections above, QCM and QCM-D can be used to understand the interactions between a functionalized crystal surface and particles (or biomolecules or chemicals), which is extremely useful for many different applications. The sensitivity and the ease of use of QCM have let researchers to explore the technique as a tool to either screen new drugs or to aid the quality control of existing drugs in the pharmaceutical industry.

In the last 10–15 years, recombinant antibodies have become a powerful therapeutic option for clinicians to treat a variety of conditions either cancer-related (particularly blood cancer) or non-cancer-related (autoimmune disease, infectious disease, ophthalmic, dermatologic and respiratory disorders) [59]. Every year since 2014, between 6 and 12 new therapeutic antibodies (Ab) have been granted first approval in the USA and in Europe [60]. Therapeutic Ab is usually administered intravenously, but researchers are currently investigating alternative routes of administration that are less invasive allowing patients to self-medicate and become more compliant with treatments. Injecting the respective Ab subcutaneously is one of the modes of administration currently considered. This route requires using small injection volumes, in the order of 1–1.5 mL. In turn, this means that antibody concentrations in the injection dose need to be much higher (150–200 mg mL−1) as compared to intravenous injections [61]. Antibody solutions containing such high concentrations deteriorate by aggregation or precipitation. Therefore, one needs to add excipients to stabilize the Ab solution. Screening and selecting the excipient, complying best with pharmaceutical formulations in vitro, is challenging as solutions with high protein concentrations tend to be highly viscous. Therefore, most common analytical techniques, such as static or dynamic light scattering require to dilute the solutions to obtain meaningful results [62]. On the contrary, Hartl and colleagues [63] have demonstrated that QCM-D can be used as a high-frequency rheology tool to study the changes of highly concentrated solutions of monoclonal Ab in the presence of excipients. For the analysis, the crystal surface, resonating at 5 MHz, was firstly passivated with poly-L-lysine-graft-poly(ethylene glycol) to reduce the adsorption of the proteins on the surface. Then, they measured changes in frequency and dissipation at several overtones. As the solutions display viscoelastic behavior, both Δf and the ΔD (or ΔΓ, where Γ is the shift at half-bandwidth, with ΔD = 2Γ/f) were then fitted into a Maxwell model allowing to obtain information on the shear modulus at relaxation time, τ, and the shear modulus at the inverse relaxation time, G* (at the “cross-over frequency” ωc = 1/τ, where ω is frequency) of the highly concentrated protein solution in contact with the crystal. This enabled the group to understand the effect of the two chosen excipients (histidine and citrate) on the Ab solution and therefore to select the most suitable.

The presence of sub-visible (2–100 μm) protein particles (protein aggregates) and non-protein particles (silicone or air bubbles) is another important parameter that needs monitoring in pre-filled, silicone-coated syringes containing therapeutic proteins. Formation of such particles indicates the deterioration of the liquid contained in the syringe. Therefore, suitable stabilizers need to be identified and added to prolong the shelf-life of the liquid contained in the syringe. Currently, there are not many analytical techniques that permit one to identify suitable stabilizers that are capable to alter or delay the formation of protein and non-protein particles. Zheng and colleagues [8] proposed the use of micro-flow imaging (MFI), a microscopy-based dynamic imaging system, that allows for evaluating particle sizes and their shapes in the micro-range. The group used MFI to study the effect of an anionic surfactant polysorbate (PS-80) on the formation of such micro-range particles. They observed that the presence of PS-80 under stirring strongly delays particle formation. To better understand the surfactant’s effect at the nano-level, the group exploited the “nano” sensitivity of QCM-D. For the study, gold crystals were first coated with silicon oil. These were then equilibrated in a buffer without surfactant and exposed to solutions of therapeutic proteins with and without PS-80, while recording both Δf and ΔD. The Voigt viscoelastic model was applied for the data analysis based on the positive changes seen in dissipation. The modeling involved fitting-simulated frequency changes to the experimental profiles until obtaining a satisfactory fit. The QCM results indicate that PS-80 most likely interacts with the hydrophobic parts of the proteins thus minimizing aggregation. The QCM data also further demonstrated that PS-80 most likely was able to block the leakage of silicone from syringe walls into solution thus reducing the formation of silicone particles and prolonging the shelf-life of the drug.

Regarding the use of QCM in the pharmaceutical industry, a few studies reported in the literature have highlighted the use of QCM to characterize metered-dose inhalers (MDI), which are commonly used to deliver drugs directly to the bronchi and lungs when treating respiratory disorders and chronic conditions, such as asthma. MDI contains a therapeutically active ingredient (drug) together with excipients (e.g., lactose, surfactant, etc.), dissolved or suspended in a propellant in a compact pressurized aerosol dispenser. Particle size is one of the most important factors influencing deposition of the active MDI drugs in the lungs. The size distribution of pharmaceutical aerosols is commonly measured by the Andersen Mark II cascade impactor (a flow system to deliver the inhaler for the analysis). It determines particle sizes based on inertial separation, followed by UV/high-performance liquid chromatography (HPLC) analysis of the deposited particles [64,65,66]. Although efficient, the technique is time consuming and expensive. Therefore, one study [67] has investigated whether a QCM impactor that includes the crystal in the impactor could be used to assess particle sizes in MDI in real time, providing a fast and cheap analysis. Five MDI formulations were studied: three contained high amounts of surfactant, one with a high drug loading, and one with an additional excipient (menthol). Similarly to Andersen impactor, cut-offs in a range of sizes were used in the QCM impactor to enable only specific particles size reaching the crystal for their mass quantitation. The particle distributions in the inhalers, obtained by QCM, were then compared with those achieved measuring the same samples with the Andersen impactor. The results showed that for most measurements the two techniques agreed, demonstrating that QCM have the potential to replace the more expensive and time-consuming analytical device to estimate MDI particles distribution.

In our group, we have also investigated the use of QCM to characterize MDI as well as multi-dose powder inhalers (MDPI). The latter are a similar type of inhaler, which contains and dispenses the therapeutic drug as dry powder rather than as an aerosol. As mentioned above, inertial separation methods [66] as well as laser diffraction analysis are used to determine the particle size of MDI [68]. Similarly, isothermal microcalorimetry, X-ray diffraction, and scanning electron microscopy have been used to determine powder morphology and electrostatic charges in MDPI [69]. However, to date, no analytical tools exist to monitor the quality of materials in both MDI and MDPI during and after manufacturing. Therefore, we explored whether QCM could be used to both optimize the composition during the inhalers’ development and for post-manufacturing quality control [11]. In one case, QCM was used to explore particle-surface and particle-particle macroscale interactions within components typically found in MDPI. For this purpose, some MDPI components (polyvinyl chloride (PVC) and poly acetate) were immobilized on the crystals and others were injected as powder in a gas stream. Figure 8a shows a typical result obtained by exposing a PVC-coated crystal to several injection of the drug fluticasone propionate (FP) powder in an air stream. The results show that although QCM data did not allow to quantify binding among the different components, it was indeed useful to provide qualitative information on the interactions among the several MDPI components, hence, enabling a facile screening of excipients to optimize formulations capable of avoiding drugs’ aggregation and/or coagulation.

In the same study, we also explored whether QCM could be useful as an in-line analytical tool for quality control of MDI post manufacturing [11]. For this, a pressurized system was designed and fabricated, which allowed for dispensing the inhalers in a fluoroalkane (HFA) stream (mimicking the manufacturing set up) and with the QCM crystal sitting in-line (Fig. 9).

Schematic of pressurized gas experimental setup. (A) Injector port. (B) Valve. (C) QCM pressure cell. (D) Release valve. (E) Buffer loop. (F) Valve. (G) Pressure gauge. Reproduced from permission from [11]

Then a selection of different FP MDI pedigrees (slightly different formulations) was tested using the QCM pressurized system, while recording the frequency. An example of the results, depicted in Fig. 8b, shows that QCM was indeed able to distinguish MDI with slightly different formulations, proving that it could be used as an in-line analytical instrument for quality control of MDI during or post manufacturing.

6 Conclusions

The ability of QCM to characterize chemicals, biomolecules, and particles both at the “nano” and “macro” level has made the corresponding techniques a powerful tool not only in diagnostics, but for characterizing materials in several scientific fields, from the medical to the energy sectors. The variety of studies reviewed by this chapter, where QCM has been used to characterize materials (e.g., nanoparticles and thin films) or to understand inter-particles, inter-molecules, and surface-molecule interactions has demonstrated the versatility of the techniques. Nevertheless, whereas it is straightforward to record changes in frequency and dissipation when using QCM, many different mathematical models, whose detailed description was beyond the scope of this chapter, have been presented for the interpretation of the data. This highlights the importance of deeply understanding the physical phenomenon or the material under investigation, before the QCM signals can be used accurately to quantify features or to understand interactions. Despite this, with more mathematical models for QCM data interpretation becoming wildly accepted, the opportunity to manufacture low-cost devices and the ability of the technique to acquire real-time data make QCM a powerful tool in many analytical applications including quality control for in-line manufacturing processes in several industries.

References

Reviakine I, Johannsmann D, Richter RP (2011) Hearing what you cannot see and visualizing what you hear: interpreting quartz crystal microbalance data from solvated interfaces. Anal Chem 83. https://doi.org/10.1021/ac201778h

Easley AD, Ma T, Eneh CI, Yun J, Thakur RM, Lutkenhaus JL (2022) A practical guide to quartz crystal microbalance with dissipation monitoring of thin polymer films. J Polym Sci 60

Rodahl M, Höök F, Krozer A, Brzezinski P, Kasemo B (1995) Quartz crystal microbalance setup for frequency and Q-factor measurements in gaseous and liquid environments. Rev Sci Instrum 66. https://doi.org/10.1063/1.1145396

Rodahl M, Höök F, Fredriksson C, Keller CA, Krozer A, Brzezinski P, Voinova M, Kasemo B (1997) Simultaneous frequency and dissipation factor QCM measurements of biomolecular adsorption and cell adhesion. Faraday Discuss 107. https://doi.org/10.1039/a703137h

Shpigel N, Sigalov S, Malchik F, Levi MD, Girshevitz O, Khalfin RL, Aurbach D (2019) Quantification of porosity in extensively nanoporous thin films in contact with gases and liquids. Nat Commun 10. https://doi.org/10.1038/s41467-019-12277-4

Kanazawa KK, Gordon JG (1985) Frequency of a quartz microbalance in contact with liquid. Anal Chem 57. https://doi.org/10.1021/ac00285a062

Dunér G, Thormann E, Dedinaite A (2013) Quartz crystal microbalance with dissipation (QCM-D) studies of the viscoelastic response from a continuously growing grafted polyelectrolyte layer. J Colloid Interface Sci 408. https://doi.org/10.1016/j.jcis.2013.07.008

Zheng S, Puri A, Li J, Jaiswal A, Adams M (2017) Particle characterization for a protein drug product stored in pre-filled syringes using micro-flow imaging, archimedes, and quartz crystal microbalance with dissipation. AAPS J 19. https://doi.org/10.1208/s12248-016-9983-1

Sebastiani F, Yanez Arteta M, Lindfors L, Cárdenas M (2022) Screening of the binding affinity of serum proteins to lipid nanoparticles in a cell free environment. J Colloid Interface Sci 610. https://doi.org/10.1016/j.jcis.2021.11.117

Migoń D, Wasilewski T, Suchy D (2020) Application of QCM in peptide and protein-based drug product development. Molecules 25

Turner NW, Bloxham M, Piletsky SA, Whitcombe MJ, Chianella I (2017) The use of a quartz crystal microbalance as an analytical tool to monitor particle/surface and particle/particle interactions under dry ambient and pressurized conditions: a study using common inhaler components. Analyst 142. https://doi.org/10.1039/c6an01572g

Gillissen JJJ, Tabaei SR, Jackman JA, Cho NJ (2017) A model derived from hydrodynamic simulations for extracting the size of spherical particles from the quartz crystal microbalance. Analyst 142. https://doi.org/10.1039/c7an00456g

Gillissen JJJ, Jackman JA, Tabaei SR, Yoon BK, Cho NJ (2017) Quartz crystal microbalance model for quantitatively probing the deformation of adsorbed particles at low surface coverage. Anal Chem 89. https://doi.org/10.1021/acs.analchem.7b03179

Adamczyk Z, Sadowska M, Żeliszewska P (2020) Applicability of QCM-D for quantitative measurements of nano- and microparticle deposition kinetics: theoretical modeling and experiments. Anal Chem 92. https://doi.org/10.1021/acs.analchem.0c03115

van der Westen R, van der Mei HC, De Raedt H, Olsson ALJ, Busscher HJ, Sharma PK (2016) Quantification of the viscoelasticity of the bond of biotic and abiotic particles adhering to solid-liquid interfaces using a window-equipped quartz crystal microbalance with dissipation. Colloids Surf B Biointerfaces 148. https://doi.org/10.1016/j.colsurfb.2016.08.062

Van Der Westen R, Sharma PK, De Raedt H, Vermue I, Van Der Mei HC, Busscher HJ (2017) Elastic and viscous bond components in the adhesion of colloidal particles and fibrillated streptococci to QCM-D crystal surfaces with different hydrophobicities using kelvin-Voigt and Maxwell models. Phys Chem Chem Phys 19. https://doi.org/10.1039/c7cp04676f

Zhuang H, Lu P, Lim SP, Lee HP (2008) Study of the evaporation of colloidal suspension droplets with the quartz crystal microbalance. Langmuir 24. https://doi.org/10.1021/la800661g

Edvardsson M, Rodahl M, Kasemo B, Höök F (2005) A dual-frequency QCM-D setup operating at elevated oscillation amplitudes. Anal Chem 77. https://doi.org/10.1021/ac050116j

Edvardsson M, Rodahl M, Höök F (2006) Investigation of binding event perturbations caused by elevated QCM-D oscillation amplitude. Analyst 131. https://doi.org/10.1039/b601800a

Borenstein A, Hanna O, Attias R, Luski S, Brousse T, Aurbach D (2017) Carbon-based composite materials for supercapacitor electrodes. A review. J Mater Chem A Mater:5

Romero Guerra M, Chianella I, Piletska EV, Karim K, Turner APF, Piletsky SA (2009) Development of a piezoelectric sensor for the detection of methamphetamine. Analyst 134. https://doi.org/10.1039/b819351g

D’Aurelio R, Tothill IE, Salbini M, Calò F, Mazzotta E, Malitesta C, Chianella I (2021) A comparison of EIS and QCM NanoMIP-based sensors for morphine. Nanomaterials 11. https://doi.org/10.3390/nano11123360

O’Neal JT, Dai EY, Zhang Y, Clark KB, Wilcox KG, George IM, Ramasamy NE, Enriquez D, Batys P, Sammalkorpi M et al (2018) QCM-D investigation of swelling behavior of layer-by-layer thin films upon exposure to monovalent ions. Langmuir 34. https://doi.org/10.1021/acs.langmuir.7b02836

Antonio JLS, Martins VL, Córdoba de Torresi SI, Torresi RM (2019) QCM-D study of electrochemical synthesis of 3D polypyrrole thin films for negative electrodes in supercapacitors. Electrochim Acta 324. https://doi.org/10.1016/j.electacta.2019.134887

Vidyasagar A, Sung C, Losensky K, Lutkenhaus JL (2012) PH-dependent thermal transitions in hydrated layer-by-layer assemblies containing weak polyelectrolytes. Macromolecules 45. https://doi.org/10.1021/ma3020454

Vidyasagar A, Sung C, Gamble R, Lutkenhaus JL (2012) Thermal transitions in dry and hydrated layer-by-layer assemblies exhibiting linear and exponential growth. ACS Nano 6. https://doi.org/10.1021/nn301526b

Levi MD, Shpigel N, Sigalov S, Dargel V, Daikhin L, Aurbach D (2017) In situ porous structure characterization of electrodes for energy storage and conversion by EQCM-D: a review. Electrochim Acta 232. https://doi.org/10.1016/j.electacta.2017.02.149

Voinova MV, Rodahl M, Jonson M, Kasemo B (1999) Viscoelastic acoustic response of layered polymer films at fluid-solid interfaces: continuum mechanics approach. Phys Scr 59. https://doi.org/10.1238/physica.regular.059a00391

Alkekhia D, Hammond PT, Shukla A (2020) Layer-by-layer biomaterials for drug delivery. Annu Rev Biomed Eng 22

Ariga K, Lvov YM, Kawakami K, Ji Q, Hill JP (2011) Layer-by-layer self-assembled shells for drug delivery. Adv Drug Deliv Rev 63

Zhang X, Liang T, Ma Q (2021) Layer-by-layer assembled nano-drug delivery systems for cancer treatment. Drug Deliv 28. https://doi.org/10.1080/10717544.2021.1905748

Erkmen C, Selcuk O, Unal DN, Kurbanoglu S, Uslu B (2022) Layer-by-layer modification strategies for electrochemical detection of biomarkers. Biosens Bioelectron X 12. https://doi.org/10.1016/j.biosx.2022.100270

Wang Y, Zhan X (2016) Layer-by-layer processed organic solar cells. Adv Energy Mater 6. https://doi.org/10.1002/aenm.201600414

Sun R, Guo J, Sun C, Wang T, Luo Z, Zhang Z, Jiao X, Tang W, Yang C, Li Y et al (2019) A universal layer-by-layer solution-processing approach for efficient non-fullerene organic solar cells. Energ Environ Sci 12. https://doi.org/10.1039/c8ee02560f

Dubas ST, Schlenoff JB (2001) Polyelectrolyte multilayers containing a weak polyacid: construction and deconstruction. Macromolecules 34. https://doi.org/10.1021/ma001720t

Gui Z, Du B, Qian J, An Q, Zhao Q (2011) Construction and deconstruction of multilayer films containing polycarboxybetaine: effect of PH and ionic strength. J Colloid Interface Sci 353. https://doi.org/10.1016/j.jcis.2010.09.026

Schoeler B, Kumaraswamy G, Caruso F (2002) Investigation of the influence of polyelectrolyte charge density on the growth of multilayer thin films prepared by the layer-by-layer technique. Macromolecules 35. https://doi.org/10.1021/ma011349p

Okutan M, Deligöz H (2019) Effect of external salt addition on the structural, morphological and electrochemical properties of flexible PEDOT:PSS based LbL multilayered films. Colloids Surf A Physicochem Eng Asp 580. https://doi.org/10.1016/j.colsurfa.2019.123695

Ghostine RA, Jisr RM, Lehaf A, Schlenoff JB (2013) Roughness and salt annealing in a polyelectrolyte multilayer. Langmuir 29. https://doi.org/10.1021/la401632x

Salomäki M, Kankare J (2008) Specific anion effect in swelling of polyelectrolyte multilayers. Macromolecules 41. https://doi.org/10.1021/ma800315j

Kurapati R, Groth TW, Raichur AM (2019) Recent developments in layer-by-layer technique for drug delivery applications. ACS Appl Bio Mater 2. https://doi.org/10.1021/acsabm.9b00703

Borges J, Sousa MP, Cinar G, Caridade SG, Guler MO, Mano JF (2017) Nanoengineering hybrid supramolecular multilayered biomaterials using polysaccharides and self-assembling peptide amphiphiles. Adv Funct Mater:27. https://doi.org/10.1002/adfm.201605122

Sergeeva YN, Huang T, Felix O, Jung L, Tropel P, Viville S, Decher G (2016) What is really driving cell–surface interactions? Layer-by-layer assembled films may help to answer questions concerning cell attachment and response to biomaterials. Biointerphases 11. https://doi.org/10.1116/1.4943046

Yılmaz Aykut D, Yolaçan Ö, Deligöz H (2020) PH stimuli drug loading/release platforms from LbL single/blend films: QCM-D and in-vitro studies. Colloids Surf A Physicochem Eng Asp 602. https://doi.org/10.1016/j.colsurfa.2020.125113

Du Y, Jin J, Jiang W (2018) A study of polyethylene glycol backfilling for enhancing target recognition using QCM-D and DPI. J Mater Chem B 6. https://doi.org/10.1039/C8TB01526K

Wasserberg D, Cabanas-Danés J, Subramaniam V, Huskens J, Jonkheijm P (2018) Orthogonal supramolecular protein assembly on patterned bifunctional surfaces. Chem Commun 54. https://doi.org/10.1039/c7cc09808a

Goor OJGM, Bosmans RPG, Brunsveld L, Dankers PYW (2017) Cucurbituril-mediated immobilization of fluorescent proteins on supramolecular biomaterials. J Polym Sci A Polym Chem 55. https://doi.org/10.1002/pola.28743

Guan ZY, Huang CW, Huang MC, Wu CY, Liu HY, Ding ST, Chen HY (2017) Controlling multi-function of biomaterials interfaces based on multiple and competing adsorption of functional proteins. Colloids Surf B Biointerfaces 149. https://doi.org/10.1016/j.colsurfb.2016.10.005

Cho NJ, Frank CW, Kasemo B, Höök F (2010) Quartz crystal microbalance with dissipation monitoring of supported lipid bilayers on various substrates. Nat Protoc 5. https://doi.org/10.1038/nprot.2010.65

Cho N-J, Cheong KH, Lee C, Frank CW, Glenn JS (2007) Binding dynamics of hepatitis C virus’ NS5A amphipathic peptide to cell and model membranes. J Virol 81. https://doi.org/10.1128/jvi.02783-06

Yorulmaz S, Jackman JA, Hunziker W, Cho NJ (2015) Supported lipid bilayer platform to test inhibitors of the membrane attack complex: insights into biomacromolecular assembly and regulation. Biomacromolecules 16. https://doi.org/10.1021/acs.biomac.5b01060

Yorulmaz S, Jackman JA, Hunziker W, Cho NJ (2016) Influence of membrane surface charge on adsorption of complement proteins onto supported lipid bilayers. Colloids Surf B Biointerfaces 148. https://doi.org/10.1016/j.colsurfb.2016.08.036

Anderson TH, Min Y, Weirich KL, Zeng H, Fygenson D, Israelachvili JN (2009) Formation of supported bilayers on silica substrates. Langmuir 25. https://doi.org/10.1021/la900181c

Kushiro K, Lee CH, Takai M (2016) Simultaneous characterization of protein-material and cell-protein interactions using dynamic QCM-D analysis on SAM surfaces. Biomater Sci 4. https://doi.org/10.1039/c5bm00613a

Kao WL, Chang HY, Lin KY, Lee YW, Shyue JJ (2017) Effect of surface potential on the adhesion behavior of NIH3T3 cells revealed by quartz crystal microbalance with dissipation monitoring (QCM-D). J Phys Chem C 121. https://doi.org/10.1021/acs.jpcc.6b11217

Saitakis M, Gizeli E (2012) Acoustic sensors as a biophysical tool for probing cell attachment and cell/surface interactions. Cell Mol Life Sci 69

Tymchenko N, Nileba E, Voinova MV, Gold J, Kasemo B, Svedhem S (2012) Reversible changes in cell morphology due to cytoskeletal rearrangements measured in real-time by QCM-D. Biointerphases 7. https://doi.org/10.1007/s13758-012-0043-9

Shoaib S, Tabrizian M (2019) A QCM-D sensing strategy for investigating the real-time effects of oxidative stress on the viscoelastic properties of pre-osteoblast cells. Sens Actuators B Chem 293. https://doi.org/10.1016/j.snb.2019.04.154

Leavy O (2010) Therapeutic antibodies: past, present and future. Nat Rev Immunol:10

Al Ojaimi Y, Blin T, Lamamy J, Gracia M, Pitiot A, Denevault-Sabourin C, Joubert N, Pouget JP, Gouilleux-Gruart V, Heuzé-Vourc’h, N. et al (2022) Therapeutic antibodies – natural and pathological barriers and strategies to overcome them. Pharmacol Ther:233

Garidel P, Kuhn AB, Schäfer LV, Karow-Zwick AR, Blech M (2017) High-concentration protein formulations: how high is high? Eur J Pharm Biopharm 119. https://doi.org/10.1016/j.ejpb.2017.06.029

Muschol M, Rosenberger F (1995) Interactions in undersaturated and supersaturated lysozyme solutions: static and dynamic light scattering results. J Chem Phys 103. https://doi.org/10.1063/1.469891

Hartl J, Peschel A, Johannsmann D, Garidel P (2017) Characterizing protein-protein-interaction in high-concentration monoclonal antibody systems with the quartz crystal microbalance. Phys Chem Chem Phys 19. https://doi.org/10.1039/c7cp05711c

Stein SW (1999) Size distribution measurements of metered dose inhalers using Andersen mark II Cascade impactors. Int J Pharm 186. https://doi.org/10.1016/S0378-5173(99)00136-2

Bonam M, Christopher D, Cipolla D, Donovan B, Goodwin D, Holmes S, Lyapustina S, Mitchell J, Nichols S, Pettersson G et al (2008) Minimizing variability of Cascade impaction measurements in inhalers and nebulizers. AAPS PharmSciTech 9

Holzner PM, Müller BW (1995) Particle size determination of metered dose inhalers with inertial separation methods: apparatus A and B (BP), four stage Impinger and Andersen mark II Cascade impactor. Int J Pharm 116. https://doi.org/10.1016/0378-5173(94)00263-5

Tzou TZ (1999) Aerodynamic particle size of metered-dose inhalers determined by the quartz crystal microbalance and the Andersen Cascade impactor. Int J Pharm 186. https://doi.org/10.1016/S0378-5173(99)00139-8

Jones SA, Martin GP, Brown MB (2005) High-pressure aerosol suspensions – a novel laser diffraction particle sizing system for hydrofluoroalkane pressurised metered dose inhalers. Int J Pharm 302. https://doi.org/10.1016/j.ijpharm.2005.07.001

Murtomaa M, Strengell S, Laine E, Bailey A (2003) Measurement of electrostatic charge of an aerosol using a grid-probe. J Electrostat 58. https://doi.org/10.1016/S0304-3886(03)00048-2

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Chianella, I. (2023). QCM Strategies for Fundamental and Applied Measurements on Particles and Formulations. In: Lieberzeit, P. (eds) Piezoelectric Sensors. Springer Series on Chemical Sensors and Biosensors, vol 18. Springer, Cham. https://doi.org/10.1007/5346_2023_35

Download citation

DOI: https://doi.org/10.1007/5346_2023_35

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-53784-4

Online ISBN: 978-3-031-53785-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)