Abstract

The present chapter comprises an overview on catalytic pathways to synthesize a highly desired variety of common compounds/chemicals starting from carbon dioxide as C1 building block and simple alkenes. After a summary of the corresponding pioneering work of the past, the authors focus on state-of-the-art protocols. New transformations based on simple and non-activated starting materials containing a C–C double bond functionality leading to a broad product portfolio are covered. Overall, this chapter embraces sustainable routes, reagents, and apparatus to produce value-added products starting from CO2 and alkenes as cheap and readily available building blocks.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Alcohols

- Aldehydes

- Alkenes

- Amines

- Carbon dioxide

- Carbonates

- Carbon–carbon bond formation

- Carboxylic acids

- Esters

- Homogeneous catalysis

- Lactones

- Reverse water-gas shift reaction

1 General Introduction

Fossil fuels are currently the world’s main source of carbon, with 93% used for energy and transportation purposes and the remaining 7% being used for chemical production [1]. Challenges associate with the use of fossil fuels are their finite nature and their release of greenhouse gases into the atmosphere by combustion. To address these problems, researchers have turned to CO2 as an alternative, abundant, and green carbon source. While enormous amounts of CO2 are released annually from anthropogenic sources, only about 0.3% is being utilized today [2]. Pursuing new routes to utilize CO2 would allow further exploitation of the vast and ubiquitous carbon source.

Researchers have successfully incorporated CO2 into simple compounds like urea and formic acid and into complex compounds like polyurethanes [3, 4]. In addition, CO2 has reacted effectively with numerous substrates, including alcohols, epoxides, aromatics, and alkynes, to produce molecules of industrial importance. In detail, this embeds the synthesis of fuels, bulk chemicals, commodities, and even fine chemicals and pharmaceuticals [5, 6]. The use of CO2 in their synthesis can significantly reduce the carbon footprint of chemical production, when coupled with renewable energy input [3, 7,8,9,10].

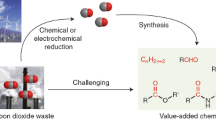

Among many conceivable target products, carbonates, lactones, carboxylic acids, esters, aldehydes, alcohols, and amines appear highly attractive. Their general structure implies a close relationship to the CO2 molecule. At the same time, their synthesis is particularly challenging as they mostly require formation of new carbon–carbon bonds. While CO2 reacts readily with O- and N-nucleophiles to give carbonic and carbamic acids, reactions to form C–C bonds require typically stoichiometric use of carbanions such as Grignard reagents or other metal alkyl and aryl species. Alternative pathways involving catalytic combinations of alkenes with CO2 are of great interest to synthesize the mentioned target molecules (Scheme 1), especially when the transformed alkene can be provided from biomass, e.g., by selective dehydration of the corresponding alcohol [11, 12]. According to the principles of Green Chemistry and Engineering, the synthesis of the target molecules will involve essentially a (molecular metal) catalyst and a highly intensified process scheme. Different classes of highly important chemical products are outlined in the next sections.

2 Reaction Products from CO2 and Alkenes

2.1 Cyclic Carbonates

Cyclic carbonates are generally stable compounds which can guarantee a long-term fixation of CO2 [13]. Carbonates are employed in a wide variety of industrial applications. Fluorinated carbonates are used in batteries production (as electrolytes additives) [14, 15]. Other carbonates, i.e., dimethyl carbonate, are used as solvents, considered greener compared to traditional VOCs [13, 16]. They are employed for the synthesis of compounds such as diols (i.e., ethylene glycol), carbamates, methanol, heterocyclic compounds, and ionic liquids [13]. In addition, carbonates are useful precursors for the synthesis of different polymers for various applications [17, 18]. Polycarbonates are thermoplastic polymers of high importance, finding application in the electrical sector, building, and automotive fields as well as data storing (i.e., CDs) and optical equipment (i.e., laboratory goggles) [19].

Traditionally, the production of carbonates requires the use of the highly toxic phosgene [16]. Recently, many protocols coupling epoxides and CO2 have been reported leading to a greener synthesis of carbonates [16, 18, 20, 21]. Nevertheless, some of the used epoxides (i.e., propylene oxide) are considered toxic, and they usually require to be synthesized from alkenes [16, 22]. Starting directly from alkenes, a safe oxidant, and CO2 can lead to a greener synthesis of these useful compounds, eliminating the need of toxic reagents such as phosgene and corresponding epoxides.

The synthesis of carbonates from alkenes is considered as oxidative carboxylation since it involves an oxidation step (to epoxides) followed by the carboxylation of the intermediate (Fig. 1). Different oxidants and different catalysts (homogeneous, heterogeneous, and nonmetallic) have been reported in the literature. The present literature deals mainly with the production of cyclic carbonates starting from alkenes, while other types of carbonates synthesis are not well represented by the current research. Linear carbonates can also be obtained by coupling CO2 with alcohols; however, this approach is reviewed elsewhere [23, 24]. Herein, the authors report a list of significant examples dealing with the production of cyclic carbonates starting from alkenes, CO2, and different types of oxidants.

The group of Aresta reported about a rhodium complex able to perform the transformation of olefins to carbonates in the presence of O2 and CO2 [25]. The homogenous system suffered from very low activity (TON = 3); therefore they decided to implement the system using a heterogeneous catalyst. Different heterogeneous catalysts known to perform a first epoxidation step and a following carboxylation were tested. Nb2O5 showed good catalytic activity but resulted in only low yields of the desired product (4.5%) [26]. Titanosilicate molecular sieves coupled with H2O2 or tert-butyl hydroperoxide (TBHB) oxidants were able to catalyze the oxidative carboxylation of alkenes in organic solvents with yields up to 52% [27]. The system was further implemented using ionic liquids as solvents, abolishing the need of organic volatile solvents [28]. More elaborated heterogeneous catalytic systems were developed more recently based on the gained mechanistic knowledge. In 2015, Jain et al. reported the immobilization of a cobalt complex and triphenylphosphonium bromide on chitosan [22]. The catalyst was able to convert alkenes, CO2, and O2 into carbonates, providing yields up to 85%. In addition, the catalyst was recyclable up to four times by simple magnetic separation. The same year the group of Han developed a polyoxometalate-based homochiral metal-organic framework (MOF) able to produce even enantiomerically pure carbonates [29]. The catalyst consists of a pyrrolidine moiety as chiral organocatalyst and Keggin-type anions (Zn(II)-based polyoxometalate) as oxidation catalyst. This moiety can convert the alkene into a chiral epoxide, using TBHB as oxidant. The MOF contains an amine-bridged ligand to adsorb and activate CO2 and therefore be able to perform the following transformation of the epoxide into the carbonate. Yields up to 92% for enantiomerically pure carbonates were achieved using this multifunctional catalytic system [29].

In addition to metal-based catalyst, other systems were reported. In 2007, Li et al. reported the transformation of alkenes to carbonates using CO2, H2O2 as oxidizing agent and bromides in catalytic amounts to activate the transformation [30]. The system is highly active and can lead to yields of carbonates of 89%. Recently, other examples of nonmetallic catalysts performing similar transformations were reported. For example, homoallylic alcohols and CO2 can lead to the enantioselective synthesis of cyclic carbonates with the aid of a dual Brønsted acid/base organocatalyst [31].

The reported examples represent an interesting step forward toward the development of technologies able to fix CO2 in valuable chemicals such as cyclic carbonates. In addition, the use of alkenes and CO2 for these processes would lead to substitute processes using highly toxic reagents (phosgene) and allow to elude the additional transformation step of alkenes via epoxides.

2.2 Lactones

Due to the formal relation in their synthetic pathway from CO2 and an alkene functionality or diene moiety, respectively, lactones and co-oligomerization products like 3-ethylidene-6-vinyltetrahydro-2H-pyran-2-one are discussed together within this section. Both products embody a 1-oxacycloalkan-2-one unit which is known to be abundant within comonomers for plastics, in flavors and fragrances, or for sesquiterpenoids in plants and in drugs. Apart from α- and β-lactones, these compounds are mostly made by an internal esterification of an alcohol and a carboxylic acid functionality under the release of one equivalent of water. Another typical method of producing lactones is the Baeyer-Villiger oxidation. Cyclic ketones are oxidized with peroxycarboxylic acids under ring expansion. The Baeyer-Villiger oxidation of cyclohexanone provides ε-caprolactone, which is industrially produced in considerable quantities as starting material for the preparation of polyesters and polyethers. However, the formation of lactones starting from simple alkenes in combination with renewable CO2 is so far rare in literature. Yet, the formation of β-lactones has never been observed experimentally.

Early catalytic reactions with CO2 in the formation of γ-lactones were carried out by Inoue et al. in 1979 [32]. For methylenecyclopropanes, 2.4 mol% of, e.g., [Pd(dpa)2] (dba = dibenzylideneacetone), in the presence of a phosphine ligand (2.0–4.0 eq.) catalyzed the reaction with CO2 (40 atm) and provided successfully a mixture of five-membered lactones in good yields (Fig. 2, up to 77%, 2 and 3). They were able to influence the selectivity between 2 and 3 by changing from PPh3 to a chelating dppe ligand. They suggest that the transformation with CO2 proceeds via a trimethylenemethane species 4 (Fig. 2) which has been suggested for the Pd-catalyzed cycloadditions of methylenecyclopropanes to alkenes before [33]. However, a methyl-substitution in positions 3 and 3′ instead of position 1 was not tolerated since no conversion was observed. Further details on the mechanism and on catalyst reusability remain unknown.

Reaction of methylenecyclopropanes with CO2 catalyzed by palladium(0) complexes [32]

Subsequently, Binger and Weintz described the dependence on the reaction conditions like temperature, pressure, ligand concentration, and substrate amount on the desired formation of products 2 and 3. During their investigations, even co-oligomerization products from 3 and 1 were observed which were already known for Pd0-catalyzed alkylations of CH-acidic compounds [34, 35]. Based on their experiments and optimizations (precursor, cyclopentadienyl allyl palladium, DMF, 165°C, PPh3), they were even able to yield compound 3 (R, R = H) with 80% yield from methylenecyclopropane and proposed a plausible reaction pathway involving the insertion of CO2 into a Pd–C bond forming a palladalactone with the mentioned consecutive reactions. The few protocols herein reported are still unique examples to produce simple five-membered γ-lactones 2 and 3 from monoenes and CO2 under catalytic conditions.

Compared to monoenes, reactions of dienes with CO2 have been studied more deeply. Regarding the coupling of dienes with CO2, lactones can be synthesized in the so-called co-oligomerization or telomerization (“linear dimerization”) reactions. In particular with conjugated dienes, transition metal compounds can readily form complexes via coupling reactions with CO2. Early publications from the 1970s reported about the first telomerization of dienes with CO2. In general, telomerizations can be considered as dimerization of two dienes in the presence of a suitable nucleophile, for example, alcohols, resulting in the case of 1,3-butadiene in substituted octadienes (1-substituted-2,7-octadienes, 3-substituted 1,7-octadiene). These products are useful intermediates, for example, in the total synthesis of natural products, precursors for plasticizer alcohols, solvents, corrosion inhibitors, and herbicides. From an industrial point of view, 1,3-butadiene and methanol are the most attractive starting materials due to their availability and low price. However, carbon dioxide can be used as suitable coupling partner as well for this reaction. Thus, Inoue et al. and Musco et al. found in the 1970s that highly functionalized organic compounds, γ- and δ-lactones, can be prepared by homogeneously Pd-catalyzed telomerization of 1,3-butadiene with CO2 [36,37,38]. In 1980, Döhring and Jolly introduced 1,2-butadienes (methylallene) as substrates [39]. However, theses transformations suffered from low selectivity for the lactone products, since open esters, carboxylic acids, and higher alkenes can be formed, too [40]. With immobilized palladium catalysts, prepared from [Pd(η5-Cp)(η3-C3H5)] and polymer-bound phosphines, the group around Dinjus was able to produce up to 72% selectivity of δ-lactone 2-ethylidene-6-heptene-5-olid, albeit at low conversion (7%) [41]. The resulting δ-lactone is a highly functionalized compound and may be used for producing various products and as intermediate for consecutive reactions, e.g., like hydrogenations, hydroformylations, hydroaminations, or polymerizations [42, 43].

Recently, Behr et al. discussed in detail the mechanistic pathways for the synthesis of γ- and δ-lactones with palladium-phosphine catalysts [42, 44] (Fig. 3). After coupling of two butadiene molecules, the equilibrium between bis-η3allyl- and mono-allyl-species complex allows insertion of carbon dioxide to the allylic carbonate species. Reductive elimination leads to the lactone isomers depending on the C–O formation. During an intensive investigation of this reaction [41], the same group published about their improvements toward a mini-plant with up to 95% selectivity of the δ-lactone at a conversion rate of 45% butadiene (Fig. 4) [42].

Pd-catalyzed transformation of 1,3-butadienes into lactones [42]

The group developed a stable and robust process enabling recycling of the by-products and closing all solvent and catalyst loops. In a continuously stirred tank reactor, butadiene and carbon dioxide are mixed together with acetonitrile and the catalyst system Pd(acac)2/PPh3. The product mixture is continuously fed into a thermal separation and a connected distillation unit to remove the gaseous phase and recycle the feeds. Thus, in their mini-plant, δ-lactone was obtained maintaining the catalyst activity over 70 h of continuous operation and with a constant product stream of 8 g h−1 with an overall yield of 30% and a selectivity of 85% [45].

In the rhodium-catalyzed reaction of butadiene and carbon dioxide, a C13 γ-lactone-2-ethyl-2,4,9-undecatrien-4-olide is formed by a combination of three molecules of butadiene with one CO2, besides the C9-lactones generated as in the case of palladium catalyst system [46]. Inspired by the given literature basis and results of the group of Nozaki in 2014 (Pd-catalyzed one-pot/two-step co-/terpolymerization of carbon dioxide and 1,3-dienes) [47], the group of Beller improved the yield of the δ-lactone up to 67% [48]. They reported a system comprised of Pd2dba3/TOMPP (tris-(o-methoxyphenyl)-phosphine) as catalyst showing high productivity at low loadings and under mild conditions (0.06 mol% [Pd], 0.18 mol% ligand, 80°C, TONs up to 1,500). Most recently, Bayón and Dupont developed a similar catalyst system, in the presence of an ionic liquid additive giving an increased TON of 4,540 of lactone with 96% selectivity after 5 h at 70°C [49].

2.3 Carboxylic Acids and Derivatives

Carboxylic acids and their derivatives are highly important for the synthetic utilization in the production of, e.g., polymers, pharmaceuticals, solvents, and food additives (commodities) [50]. Presently, the global market for carboxylic acids is predicted to grow each year ca. 5% [51]. Carboxylic acids are especially produced for applications in polymer industry as both monomers and additives, e.g., as polyvinyl acetate (glue) from acetic acid [52, 53], PET (polyethylene terephthalate) [54], nylon fibers (polyamides) [55] based on adipic acid, and amines or acrylic/methacrylic polymers [56]. For modifying the properties of synthetic polymers, long-chain carboxylic acids (>C9) are used as additives for alkyd resin films [57]. Apart from the polymer sector, carboxylic acids are widely used as solvents [58], for the textile and leather industry [59, 60]; in agrochemical industry to provide herbicides, fungicides, and rodenticides [58]; in pharmaceutical industry [51, 61, 62]; and for the food and feed industry [58, 63]. Moreover, Shell reported the use of valeric acid derivatives as biofuels [64], while formic acid is discussed as hydrogen carrier/storage [7, 65, 66]. Today, the majority of aliphatic (C4–C13), aromatic carboxylic, and dicarboxylic acids are produced via oxidation of the corresponding aldehydes usually obtained by the oxo synthesis (alkene hydroformylation). Oxidation catalysts are usually Co or Mn salts, and O2 (or HNO3, KMnO4) is used as oxidant [58, 67]. Small-chain acids like formic acid or acetic acid [53, 68, 69] are mainly produced by carbonylation, using, e.g., alcohols [70] or alkenes [71, 72], as substrates. Pivalic acid and other tertiary carboxylic acids can be obtained from alkenes by the Koch synthesis [58, 73]. Industrially, carboxylic acid esters can be synthesized by alkoxycarbonylations of alkenes, since it produces esters in a single step without coupling agents [74], or more generally via esterification reactions [75]. Stereoselective hydroesterification processes, mostly palladium- or rhodium-catalyzed, also enable the access to a variety of compounds which are widely used not only in the pharmaceutical field [76, 77]. For production of biodiesel, large quantities of fatty acid methyl esters are produced by transesterification of vegetable oils (mostly soybean, rapeseed or palm oil) with methanol [78].

The use of CO2 as C1 building block for industrial production of carboxylic acids is implemented for decades in the synthesis of salicylic acid according to Kolbe [79] and Schmitt [80], converting phenol with CO2 in the presence of a base (NaOH). However, this reaction has limited synthetic scope being applicable to phenolic type substrates and is based on a stoichiometric approach.

The examples discussed in this section focus on catalytic reactions where free acids are isolated as the products (if appropriate, after acidic hydrolysis) using mainly simple and non-activated alkenes as substrates.

According to Fig. 5, two basic routes (1) and (2) toward carboxylic acids based on an alkene moiety in combination with CO2 can be envisaged.

Following pathway (1), acrylic acid as important platform chemical is one of the major target molecules provided by this transformation [81]. Preliminary work in this field was carried out in particular by the group of Hoberg. They studied the oxidative coupling of different alkenes like ethene [82], 1,3-butadiene [83], or styrene [84] with CO2-forming metalla-latone intermediates in the presence of [Ni(cod)2] and a stabilizing base additive (DBU, 1,8-diazabicyclo[5.4.0]undec-7-ene). Starting from the isolated and stabile Ni-lactone, further saturated (e.g., propionic acid) and unsaturated carboxylic acids were accessible after hydrolysis. However, β-H elimination toward acrylic acid was not feasible at that time. These kinetic and thermodynamic constraints were computationally investigated by DFT calculations in 2007 [85]. A breakthrough for the catalytically Ni-promoted synthesis of acrylates was shown by Lejkowski et al. in 2012 [86, 87]. They developed a robust nickel catalyst for the direct carboxylation of simple alkenes, like ethene, styrene, and 1,3-dienes with CO2 to their corresponding linear α,β-unsaturated carboxylic acid salts (TONs up to 116 for butadiene carboxylation) by the usage of an electron-rich bisphosphine ligand (BenzP*) and a suitable base (sodium 2-fluorophenoxide).

Vogt and coworkers were also able to develop a catalytic procedure for the synthesis of acrylate with diphosphine nickelalactones in the presence of Et3N as base (with TONs up to 21) [88].

In addition to transition metal catalysts, such as Ni, Mo, and W, especially Pd offers new promising strategies to generate acrylic acid [88,89,90]. Most recently, the group of Schaub enhanced the TON to sodium acrylate to 514 using a Palladium system in an amide solvent (CHP: N-cyclohexylpyrrolidone) with a basic additive (alcoholates) [91, 92]. Additionally, the system was found suitable for other alkenes like propene and cyclopentene (TONs up to 92). In a semicontinuous reaction setup, they could show good results for the ethene conversion to acrylate with a total TON from 2 cycles of 235 in combination with an integrated catalyst recycling stream (Fig. 6).

Semicontinuous process scheme for Pd-catalyzed synthesis of sodium acrylate from ethene and CO2 [91]

The second pathway (2) to combine alkenes with CO2 to yield carboxylic acids involves an overall reductive process, whereby saturated aliphatic acids are obtained as the final products (Fig. 5). One of the first examples in literature for the homogeneous catalytic conversion of ethene with CO2 to the free propionic acid dates back to 1978. Lapidus et al. carried out the transformation in 38% yield in the presence of Wilkinson’s catalyst under harsh reaction conditions (180°C, 700 bar) [93]. An exact mechanism of this transformation has so far remained unclear as no reduction equivalents required for product formation are specified in the described protocol.

Based on the approach from pioneering work by Hoberg [82,83,84] as well as Walther and Dinjus [94] to regenerate reactive metal species for alkene/CO2 coupling, Rovis and coworkers reported about the first nickel-catalyzed reductive carboxylation of styrenes using CO2 under ambient conditions (23°C, 1 bar CO2) [95]. The transformation led regioselectively to saturated α-substituted carboxylic acids (phenylacetic acid derivatives). However, transmetallation of nickel by Et2Zn was required to regenerate the active species in this hydrocarboxylation. Under comparable reaction conditions (r.t., 1 bar CO2, THF), an iron-catalyzed system with similar regioselectivities of the formed α-aryl carboxylic acids has been reported in 2012 using an excess of a Grignard reagent (EtMgBr) as reductant [96, 97]. For aryl carboxylation reactions, light-driven transformations [98] or generally photo-redox catalytic systems [99, 100] have also attracted interest recently.

In 2013 the group of Leitner reported the rhodium-catalyzed formal hydrocarboxylation of alkenes. The reaction of olefins with CO2 and H2 leads to the corresponding one-carbon-atom elongated carboxylic acids (Fig. 7) [101]. Saturation of the C–C double bond provides an important energetic driving force, but competing hydrogenation poses also mechanistic challenges on the transformation [102].

Overall hydrocarboxylation of alkenes involving the rWGSR followed by the consecutive hydroxycarbonylation [101]

With a [RhCl(CO)2]2/PPh3 system and a promoting iodide reagent, very high to excellent yields (up to 92%) for the free acids were obtained for a range of cyclic and linear alkenes. For internal olefins, the ratio of regioisomeric acids is largely independent of the original position of the double bond. Mechanistic studies including isotopic labeling studies with 13CO2, D2, and H218O demonstrated that the formal hydrocarboxylation results from the effective interconnection of two catalytic cycles. In the first step, catalytic reverse water-gas shift reaction (rWGSR) generates carbon monoxide and water, which consecutively get converted in a subsequent Reppe-type hydroxycarbonylation cycle to yield the free carboxylic acid (Fig. 7).

In 2016 the group of Mikami published ambient synthesis of α-aryl carboxylic acids from CO2 and styrene derivatives via rhodium-catalyzed hydrocarboxylation (precursor, [RhCl(cod)2]) [103]. Depending on the substrate, yields up to 95% were obtained. As reduction equivalents, 1.2 eq. of ZnEt2 per mol substrate was most suitable. Remarkably, they were able to perform the catalytic asymmetric hydrocarboxylation of α,β-unsaturated esters synthesize with ee values up to 66% employing a cationic rhodium complex with (S)-(−)-4,4′-bi-1,3-benzodioxole-5,5′-diylbis(diphenylphosphine) [(S)-SEGPHOS] as a chiral diphosphine ligand (Fig. 8).

Rh-catalyzed hydrocarboxylation of alkenes with CO2 and ZnEt2 [103]

The group of R. Martin has reported a variety of carboxylation reactions of divers starting materials like allylic alcohols [104], styrenes [105], 1,3-dienes [106], halogenated aliphatic hydrocarbons [107, 108], unsaturated hydrocarbons [109,110,111], and others [112, 113]. They were able to control regioselective hydrocarboxylation of aryl- and alkyl-substituted C–C bonds with a catalytic system based on a nickel precursor, a bipyridine-based ligand, and a reducing reagent (metallic manganese) (Fig. 9) [109]. Even more recently, the same group published about the 1,4-dicarboxylation of 1,3-dienes (e.g., butadiene) using the Ni-based reaction system in Fig. 9 [106]. This multiple CO2 incorporation into abundant 1,3-dienes gives access to adipic acids from simple and available precursors. The salient features of this method are its excellent regio- and chemo-selectivity, mild conditions, and ease of execution. The (over-)stoichiometric use of a metal-based reducing agent is, however, a major limitation for large-scale application.

Site-selective incorporation of CO2 to a wide range of unsaturated hydrocarbons utilizing water as formal hydride source [109]

Clearly, the principle outlined in Fig. 7 utilizing a combination of CO2 and H2 as source for in situ formed CO (and H2O, respectively) offers the most attractive strategy for alkene transformations. Meanwhile, protocols were published about carboxylation-, alkoxycarbonylation- or hydroformylation-related reactions and may open new strategies in CO2 utilization [89, 114, 115]. Notably, the required hydrogen may also come from organic substrates, in particular alcohols, as most catalysts active in these reactions are generally active for dehydrogenation or reforming processes.

In 2012 the group of García reported the first example of catalytic reductive hydroesterification reaction of styrenes using CO2 as a C1 source and methanol as a reductant catalyzed by nickel complexes [116]. Yields up to 71% for the linear isomer were obtained using complex [(dippe)Ni(μ-H)]2 for styrenes bearing σ-electron-withdrawing groups. The corresponding TON was limited, however, as high catalyst loadings (20 mol%) were required.

In 2014, the group of Beller published a Ru-based conversion of alkenes, CO2, and alcohols into carboxylic acid esters (Fig. 10) [117]. Essential for their transformation is the activity of the catalytic system [Ru3(CO)12]/[BMIM]Cl in the rWGSR (reverse water-gas shift reaction), coupled with alkoxycarbonylation. A variety of linear and cyclic alkenes afforded the corresponding carboxylic acid esters with a yield range of 41–95% in the presence of different alcohols. No external hydrogen is required since the reduction of CO2 is proceeded by hydrogen transfer from the alcohol used in excess as solvent [118]. Investigations including isotopic labeling experiments provided experimental evidence for this catalytic pathway, similar to the previous reports on Rh-catalyzed hydrocarboxylation [101]. In case of the use of an internal alkene, isomeric mixtures of the ester products were obtained, whereby the distribution of product isomers seemed independent of the original substitution pattern, albeit with a slight preference toward the linear product.

Ru-catalyzed alkoxycarbonylation of alkenes with carbon dioxide and methanol [117]

In 2015, Fleischer et al. described the indirect utilization of CO2 as a C1 source under ambient reaction conditions by using N-formylsaccharin as a CO transfer reagent with an integrated recycling approach of the CO-surrogate (Fig. 11) [119]. The carbonylation proceeds in a highly region-selective manner yielding the desired branched ester from styrene derivatives in yields up to 97%. In contrast, linear esters were obtained in yields up to 91% with exclusive formation of the n-product from alkyl-substituted alkenes. The catalyst system is based on a Pd0 precursor, a bidentate phosphine ligand, and a Brønsted acid.

Indirect utilization of CO2 as a C1 source under ambient reaction conditions using N-formylsaccharin as a CO transfer reagent [119]

2.4 Further Reduced Target Molecules

The following section summarizes the state of the art for the use of CO2 as a C1 building block in combination with alkenes for the generation of more strongly reduced functional groups such as aldehydes, alcohols, and amines. It covers synthetic protocols comprising, e.g., hydroformylation, hydrohydroxymethylation, and hydroaminomethylation, using CO2/H2 as synthon to generate useful compounds. The target molecules are highly important for a lot of different applications like pharma, agriculture, or health care as well as for further chemical transformations by addressing compounds like APIs, solvents, lubricants, dyeing reagents, or plastics. Considering their usual synthetic routes, a change from common C1 building blocks to CO2 opens new fields and opportunities for upcoming synthetic pathways and transformations.

2.4.1 Aldehydes

While CO2 is long known as a possible C1 source in technical hydroformylation, its application has found more widespread attention in organic synthesis only most recently. In 2017, the research groups of Xia and Ding used the readily available and inexpensive poly(methylhydrosiloxane) (PMHS, MW = 1900) as alternative reductant to high pressure H2 for hydroformylation of alkenes and CO2 [120]. The desired aldehydes from alkyl- and aryl-based substrates were isolated in moderate to good yields (up to 70%) and with good selectivity to the linear product (l:b = up to 89:11). From their mechanistic studies, they found that CO2 was inserted preferentially into the Si–H bond to form the corresponding silyl formate [Si]OC(O)H which either decomposes into CO and silanols [Si]OH or is hydrolyzed to formic acid subsequently releasing CO and H2O. With the production of CO, aldehydes could then be formed by established Rh-catalyzed hydroformylation chemistry [121]. Interestingly, an excess of CO2 hindered the further reduction of the formed aldehyde toward the alcohol moiety (Fig. 12) [120].

Hydroformylation of alkenes with CO2, silane, and H2 [120]

2.4.2 Alcohols

Pioneering work in this area has been reported in 2000 by Tominaga and Sasaki, who used CO2 as building block with various ruthenium cluster complexes to obtain C1-elongated alcohols from different alkenes (Fig. 13) [122]. The highest yield of 88% alcohol was achieved using [H4Ru4(CO)12], a well-known rWGSR catalyst. The nature and performance of the required alkali salt additive were intensively studied together with investigations about the active species [123,124,125,126]. An immobilized system was also reported [127]. Although the inferred primary product of this reaction is the aldehyde obtained by hydroformylation of the alkene, these intermediates were not observed in high yield due to rapid further reduction. This system proved effective for several substrates. When CO was used instead of CO2, the yield of the alcohol was either significantly decreased or comparable to the system with CO2, showing that this catalyst was rather negatively affected by a large presence of CO in the system.

Ru-catalyzed hydroformylation/reduction of cyclohexene using CO2 [122]

More recently, the Beller group used a ruthenium catalyst comprising a (bulky)phosphite for this reaction, allowing the use of CO2 to afford alcohols from terminal and internal alkenes (Fig. 14) [128, 129]. The optimization of the catalyst and ligand allowed slightly lower temperatures to be used while suppressing the undesired hydrogenated product formed from the alkene. In the same year, the group of Dupont developed a catalytic system in which the ionic liquids [BMI·Cl] or [BMMI·Cl] reacted in the presence of H3PO4 with [Ru3(CO)12] to generate Ru-hydride-carbonyl-carbene species as further efficient catalysts for this transformation [130]. Thus, even lower temperatures (120°C) and shorter reaction times (12 h) were feasible.

Ru-catalyzed hydroformylation/reduction of alkenes with carbon dioxide (hydrohydroxymethylation) [128]

In 2017, Yu and coworkers realized a highly regio- and enantioselective copper-catalyzed hydrohydroxymethylation of alkenes with CO2 as the C1 source and (EtO)3Si-H as reductant (Fig. 15) [131]. A series of chiral homobenzylic/allylic alcohols from styrenes and 1,3-dienes were obtained under mild conditions. In this transformation, many functional groups, including halides, amine, ether, and ester, were tolerated. The isolated products were directly applied for the further synthesis of bioactive compounds like (R)-(−)-curcumene and (S)-(+)-ibuprofen. Mechanistic studies suggested that the key step was the formation of the active L*CuH catalyst which gave an alkyl copper species after subsequent insertion of the alkene into the Cu–H bond. Carboxylation of this complex with CO2 formed the copper carboxylate. Further reduction of the carboxylate by two equivalents of hydrosilane produced first the silyl ether which released the alcohol product after treating with NH4F. Thus, these studies suggest that pathways without involving the rWGS equilibrium may also be possible to exploit the CO2/H2 synthon.

Enantioselective hydrohydroxymethylation with CO2 to give chiral alcohols [131]

2.4.3 Amines

Amines are large-scale industrial products or intermediates that are often produced by multistep processes [70]. To provide amines in a single-unit operation, the hydroaminomethylation reaction approach can lead to the formation of C1-elongated amines from alkenes [132]. An initial hydroformylation of the alkene forms the aldehyde that gets further converted in a second step with an amine toward an enamine/imine from which the final amine is formed through subsequent reduction. The group of Eilbracht demonstrated already in 2009 the possibility to use CO2 as a CO surrogate for the conversion of alkenes with secondary amines and aniline [133]. The use of the rWGSR catalyst system [Ru3(CO)12]/LiCl/BTAC (BTAC = benzyltrimethylammonium chloride) proved to be an efficient system for the in situ formation of CO from CO2 and H2. Optimization of the four-step tandem reaction was successfully demonstrated using cyclopentene and morpholine as substrates (Fig. 16). The combination of promoting salts revealed a synergetic effect on the yield and selectivity, with the phase-transfer catalyst enhancing the solubility of LiCl in toluene. Isomeric mixtures (l:b up to 64:36) of secondary and tertiary amines were formed effectively from a variety of alkenes with yields in the range of 35–98%.

Hydroaminomethylation of cyclopentene with morpholine applying carbon dioxide as C1 building block [133]

In 2016, Dupont and coworkers reported about further development of this system that was able to perform more efficient under milder reaction conditions (120°C, 24–36 h). Similar to the alcohol synthesis mentioned above, the imidazolium salt-based ionic liquid [BMMI]Cl in the presence of H3PO4 was used to generate the active Ru catalyst for the CO2-based hydroaminomethylation [134].

3 Conclusion

The development of new processes to address a broad spectrum of chemicals starting from simple non-activated alkenes and CO2 has been an active field of research that has seen a high dynamic progress in the past decades. Many new synthetic pathways have been reported by groups all around the world. The reported protocols show a basis for processes reducing the dependence on fossil by incorporating CO2 into useful chemicals. Although many systems are still in an early stage of development, they set the stage for opening new perspectives in the development of processes that follow the “Green Chemistry” principles. At present, however, the need of organometallic (reducing) reagents in stoichiometric quantities is still a limiting factor. In this context, protocols relying on the use of CO2 and H2 as CO surrogate via the rWGSR appear very attractive, as they can capitalize on the established knowledge in organometallic carbonylation catalysis. These strategies offer alternatives to replace fossil-based CO by CO2, without changing drastically the chemistry of the following transformation. With the rapidly growing implementation of renewable electricity, the required H2 may be generated by electrolysis exploiting and buffering fluctuating energy sources. To develop these protocols toward practical procedures, deeper knowledge about the molecular transformations has to go hand in hand with the development of advanced reaction engineering solutions right from the beginning. Assessment tools beyond established life cycle assessment (LCA) methods are necessary to critically analyze the potential of using CO2 in combination with catalysis to lower the carbon footprint for industrial synthesis and, by that, provide more sustainable alternatives to conventional petrochemical productions.

References

Centi G, Quadrelli EA, Perathoner S (2013) Energy Environ Sci 6:1711

News (2014). Carbon Manage 5:13

Peters M, Kohler B, Kuckshinrichs W, Leitner W, Markewitz P, Muller TE (2011) ChemSusChem 4:1216

Langanke J, Wolf A, Hofmann J, Böhm K, Subhani M, Müller T, Leitner W, Gürtler C (2014) Green Chem 16:1865

Aresta M, Dibenedetto A, Angelini A (2014) Chem Rev 114:1709

Leitner W, Klankermayer J (2015) Science 350:629

Klankermayer J, Wesselbaum S, Beydoun K, Leitner W (2016) Angew Chem Int Ed 55:7296

Alper E, Yuksel Orhan O (2017) Petroleum 3:109

Artz J, Muller TE, Thenert K, Kleinekorte J, Meys R, Sternberg A, Bardow A, Leitner W (2018) Chem Rev 118:434

Cokoja M, Bruckmeier C, Rieger B, Herrmann WA, Kühn FE (2011) Angew Chem Int Ed 50:8510

Byun J, Han J (2017) Green Chem 19:5214

Bond JQ, Alonso DM, Wang D, West RM, Dumesic JA (2010) Science 327:1110

Shaikh RR, Pornpraprom S, D’Elia V (2017) ACS Catal 8:419

McMillan R, Slegr H, Shu Z, Wang W (1999) J Power Sources 81:20

Komaba S, Ishikawa T, Yabuuchi N, Murata W, Ito A, Ohsawa Y (2011) ACS Appl Mater Interfaces 3:4165

Schaffner B, Schaffner F, Verevkin SP, Borner A (2010) Chem Rev 110:4554

Gregory GL, Lopez-Vidal EM, Buchard A (2017) Chem Commun (Camb) 53:2198

Besse V, Camara F, Voirin C, Auvergne R, Caillol S, Boutevin B (2013) Polym Chem 4:4545

Abts G, Eckel T, Wehrmann R (2014) Polycarbonates. Ullmann’s encyclopedia of industrial chemistry. Wiley-VCH, Weinheim, p 1

Vaitla J, Guttormsen Y, Mannisto JK, Nova A, Repo T, Bayer A, Hopmann KH (2017) ACS Catal 7:7231

Scharfenberg M, Hilf J, Frey H (2018) Adv Funct Mater 28:1704302

Kumar S, Singhal N, Singh RK, Gupta P, Singh R, Jain SL (2015) Dalton Trans 44:11860

Shukla K, Srivastava VC (2016) RSC Adv 6:32624

Kindermann N, Jose T, Kleij AW (2017) Top Curr Chem 375:15

Aresta M, Dibenedetto A (2002) J Mol Catal A Chem 182:399

Aresta M, Dibenedetto A, Tommasi I (2000) Appl Organomet Chem 14:799

Srivastava R, Srinivas D, Ratnasamy P (2003) Catal Lett 91:133

Sun JM, Fujita S, Arai M (2005) J Organomet Chem 690:3490

Han Q, Qi B, Ren W, He C, Niu J, Duan C (2015) Nat Commun 6:10007

Eghbali N, Li C-J (2007) Green Chem 9:213

Vara BA, Struble TJ, Wang W, Dobish MC, Johnston JN (2015) J Am Chem Soc 137:7302

Inoue Y, Hibi T, Satake M, Hashimoto H (1979) J Chem Soc Chem Commun 982

Binger P, Schuchardt U (1977) Angew Chem Int Ed 16:249

Binger P, Weintz HJ (1984) Chem Ber 117:654

Trost BM (1980) Acc Chem Res 13:385

Inoue Y, Sasaki Y, Hashimoto H (1978) Bull Chem Soc Jpn 51:2375

Musco A, Perego C, Tartiari V (1978) Inorg Chim Acta 28:L147

Sasaki Y, Inoue Y, Hashimoto H (1976) J Chem Soc Chem Commun 605

Döhring A, Jolly P (1980) Tetrahedron Lett 21:3021

Musco A (1980) J Chem Soc Perkin Trans 1:693

Holzhey N, Pitter S, Dinjus E (1997) J Organomet Chem 541:243

Behr A, Henze G (2011) Green Chem 13:25

Omae I (2012) Coord Chem Rev 256:1384

Behr A, Bahke P, Becker M (2004) Chem Ing Tech 76:1828

Behr A, Becker M (2006) Dalton Trans 2006:4607

Behr A, He R (1984) J Organomet Chem 276:c69

Nakano R, Ito S, Nozaki K (2014) Nat Chem 6:325

Sharif M, Jackstell R, Dastgir S, Al-Shihi B, Beller M (2017) ChemCatChem 9:542

Balbino JM, Dupont J, Bayón JC (2018) ChemCatChem 10:206

Wu X-F, Zheng F (2017) Top Curr Chem 375:4

Juliá-Hernández F, Moragas T, Cornella J, Martin R (2017) Nature 545:84

Cordeiro CF, Petrocelli FP (2002) Vinyl acetate polymers. Encyclopedia of polymer science and technology, vol 12. Wiley, Hoboken, p 416

Budiman AW, Nam JS, Park JH, Mukti RI, Chang TS, Bae JW, Choi MJ (2016) Catal Surv Jpn 20:173

Reese G (2001) Polyesters, fibers. Encyclopedia of polymer science and technology, vol 3. Wiley, Hoboken, p 652

Anton A, Baird BR (2002) Polyamides, fibers. Encyclopedia of polymer science and technology, vol 3. Wiley, Hoboken, p 584

Swift G (2002) Acrylic (and Methacrylic) acid polymers. Encyclopedia of polymer science and technology, vol 1. Wiley, Hoboken, p 79

Wicks ZW (2007) Alkyd resins. Encyclopedia of polymer science and technology, vol 1. Wiley, Hoboken, p 1

Kubitschke J, Lange H, Strutz H (2014) Carboxylic acids, aliphatic. Ullmann’s encyclopedia of industrial chemistry. Wiley, Hoboken, p 1

Moret S, Dyson PJ, Laurenczy G (2014) Nat Commun 5:4017

Riemenschneider W, Tanifuji M (2011) Oxalic acid. In: Chemistry UsEoI (ed) Ullmann’s encyclopedia of industrial chemistry, vol 25. Wiley, Hoboken, p 529

Boullard O, Leblanc H, Besson B (2000) Salicylic acid. Ullmann’s encyclopedia of industrial chemistry, vol 32. Wiley, Hoboken, p 127

Kantor TG (1986) Pharmacotherapy 6:93

Szilagyi M (2012) Aliphatic carboxylic acids: saturated. Patty’s toxicology. Wiley, Hoboken, p 471

Lange JP, Price R, Ayoub PM, Louis J, Petrus L, Clarke L, Gosselink H (2010) Angew Chem Int Ed Engl 49:4479

Álvarez A, Bansode A, Urakawa A, Bavykina AV, Wezendonk TA, Makkee M, Gascon J, Kapteijn F (2017) Chem Rev 117:9804

Supronowicz W, Ignatyev IA, Lolli G, Wolf A, Zhao L, Mleczko L (2015) Green Chem 17:2904

Röhrscheid F (2000) Carboxylic acids, aromatic. Ullmann’s encyclopedia of industrial chemistry, vol 7. Wiley, Hoboken, p 113

Haynes A (2010) Adv Catal 53:1

Noriyuki Y, Takeshi M, Joe W, Ben S (1999) The chiyoda/uop acetica™ process: a novel acetic acid technology. In: Hideshi H, Kiyoshi O (eds) Studies in surface science and catalysis, vol 121. Elsevier, Amsterdam, p 93

Weissermel K, Arpe HJ (2008) Industrial organic chemistry, vol 3. Wiley, Weinheim

Reppe W, Kröper H (1953) Justus Liebigs Ann Chem 582:38

Samel U-R, Kohler W, Gamer AO, Keuser U, Yang S-T, Jin Y, Lin M, Wang Z (2014) Propionic acid and derivatives. Ullmann’s encyclopedia of industrial chemistry. Wiley, Weinheim, p 1

Koch H, Haaf W (1958) Justus Liebigs Ann Chem 618:251

Kiss G (2001) Chem Rev 101:3435

Batoux N (2004) Synthesis 2004:2766

Konrad TM, Durrani JT, Cobley CJ, Clarke ML (2013) Chem Commun (Camb) 49:3306

Kollár L (2008) Modern carbonylation methods. Wiley-VCH, Weinheim

Meher L, Sagar DV, Naik S (2006) Renew Sust Energ Rev 10:248

Kolbe H (1874) Adv Synth Catal 10:89

Schmitt R (1885) J Prakt Chem 31:397

Limbach M (2015) Acrylates from alkenes and CO2, the stuff that dreams are made of. In: Pérez PJ (ed) Advances in organometallic chemistry, vol 63. Elsevier, Amsterdam, p 175

Hoberg H, Peres Y, Krüger C, Tsay YH (1987) Angew Chem Int Ed 26:771

Hoberg H, Gross S, Milchereit A (1987) Angew Chem Int Ed 26:571

Hoberg H, Peres Y, Milchereit A (1986) J Organomet Chem 307:C38

Graham DC, Mitchell C, Bruce MI, Metha GF, Bowie JH, Buntine MA (2007) Organometallics 26:6784

Lejkowski ML, Lindner R, Kageyama T, Bódizs GÉ, Plessow PN, Müller IB, Schäfer A, Rominger F, Hofmann P, Futter C, Schunk SA, Limbach M (2012) Chem Eur J 18:14017

Huguet N, Jevtovikj I, Gordillo A, Lejkowski ML, Lindner R, Bru M, Khalimon AY, Rominger F, Schunk SA, Hofmann P, Limbach M (2014) Chemistry 20:16858

Hendriksen C, Pidko EA, Yang G, Schaffner B, Vogt D (2014) Chemistry 20:12037

Kirillov E, Carpentier JF, Bunel E (2015) Dalton Trans 44:16212

Aresta M, Pastore C, Giannoccaro P, Kovács G, Dibenedetto A, Pápai I (2007) Chem Eur J 13:9028

Manzini S, Cadu A, Schmidt AC, Huguet N, Trapp O, Paciello R, Schaub T (2017) ChemCatChem 9:2269

Manzini S, Huguet N, Trapp O, Paciello RA, Schaub T (2017) Catal Today 281:379

Lapidus A, Pirozhkov S, Koryakin A (1978) Bull Acad Sci USSR 27:2513

Dinjus E, Walther D, Schuetz H, Schade W (1983) Z Chem 23:303

Williams CM, Johnson JB, Rovis T (2008) J Am Chem Soc 130:14936

Greenhalgh MD, Thomas SP (2012) J Am Chem Soc 134:11900

Greenhalgh MD, Kolodziej A, Sinclair F, Thomas SP (2014) Organometallics 33:5811

Murata K, Numasawa N, Shimomaki K, Takaya J, Iwasawa N (2017) Chem Commun 53:3098

Seo H, Liu A, Jamison TF (2017) J Am Chem Soc 139:13969

Seo H, Katcher MH, Jamison TF (2017) Nat Chem 9:453

Ostapowicz TG, Schmitz M, Krystof M, Klankermayer J, Leitner W (2013) Angew Chem Int Ed 52:12119

Ostapowicz TG, Hölscher M, Leitner W (2012) Eur J Inorg Chem 2012:5632

Kawashima S, Aikawa K, Mikami K (2016) Eur J Org Chem 2016:3166

van Gemmeren M, Borjesson M, Tortajada A, Sun SZ, Okura K, Martin R (2017) Angew Chem Int Ed 56:6558

Yatham VR, Shen Y, Martin R (2017) Angew Chem Int Ed Engl 56:10915

Tortajada A, Ninokata R, Martin R (2018) J Am Chem Soc 140:2050

Julia-Hernandez F, Moragas T, Cornella J, Martin R (2017) Nature 545:84

Liu Y, Cornella J, Martin R (2014) J Am Chem Soc 136:11212

Gaydou M, Moragas T, Julia-Hernandez F, Martin R (2017) J Am Chem Soc 139:12161

Wang X, Nakajima M, Martin R (2015) J Am Chem Soc 137:8924

Correa A, León T, Martin R (2014) J Am Chem Soc 136:1062

Martin R, Tortajada A, Julia-Hernandez F, Borjesson M, Moragas T (2018) Angew Chem Int Ed. https://doi.org/10.1002/anie.201803186

Juliá-Hernández F, Gaydou M, Serrano E, van Gemmeren M, Martin R (2016) Top Curr Chem 374:1

Wu L, Liu Q, Jackstell R, Beller M (2014) Angew Chem Int Ed 53:6310

Porosoff MD, Yan B, Chen JG (2016) Energy Environ Sci 9:62

González-Sebastián L, Flores-Alamo M, García JJ (2012) Organometallics 31:8200

Wu L, Liu Q, Fleischer I, Jackstell R, Beller M (2014) Nat Commun 5:3091

Dibenedetto A, Stufano P, Nocito F, Aresta M (2011) ChemSusChem 4:1311

Gehrtz PH, Hirschbeck V, Fleischer I (2015) Chem Commun 51:12574

Ren X, Zheng Z, Zhang L, Wang Z, Xia C, Ding K (2017) Angew Chem Int Ed 56:310

Dong K, Wu XF (2017) Angew Chem Int Ed 56:5399

Tominaga K-I, Sasaki Y (2000) Catal Commun 1:1

Kontkanen M-L, Oresmaa L, Moreno MA, Jänis J, Laurila E, Haukka M (2009) Appl Catal A Gen 365:130

Jaaskelainen S, Haukka M (2003) Appl Catal A 247:95

Tominaga K-I, Sasaki Y (2004) J Mol Catal A Chem 220:159

Tsuchiya K, Huang J-D, Tominaga K-I (2013) ACS Catal 3:2865

Tominaga K-I (2006) Catal Today 115:70

Liu Q, Wu L, Fleischer I, Selent D, Franke R, Jackstell R, Beller M (2014) Chem Eur J 20:6888

Fritschi S, Korth W, Julis J, Kruse D, Hahn H, Franke R, Fleischer I, Chowdhury AD, Weding N, Jackstell R, Beller M, Jess A (2015) Chem Ing Tech 87:1313

Ali M, Gual A, Ebeling G, Dupont J (2014) ChemCatChem 6:2224

Gui Y-Y, Hu N, Chen X-W, Liao LL, Ju T, Ye J-H, Zhang Z, Li J, Yu D-G (2017) J Am Chem Soc 139:17011

Boerner A, Beller M, Wünsch B (2009) Sci Synth 40:111

Srivastava VK, Eilbracht P (2009) Catal Commun 10:1791

Ali M, Gual A, Ebeling G, Dupont J (2016) ChemSusChem 9:2129

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Schmitz, M., Solmi, M.V., Leitner, W. (2018). Catalytic Processes Combining CO2 and Alkenes into Value-Added Chemicals. In: Dixneuf, P., Soulé, JF. (eds) Organometallics for Green Catalysis. Topics in Organometallic Chemistry, vol 63. Springer, Cham. https://doi.org/10.1007/3418_2018_24

Download citation

DOI: https://doi.org/10.1007/3418_2018_24

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-10954-7

Online ISBN: 978-3-030-10955-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)