Abstract

Fabrication of covalently bonded molecular structures on the surface of metal single crystals is attracting increased attention because of the special synthetic strategies and potential applications (e.g., in molecular electronics). In contrast to traditional organic synthesis, surface-assisted reactions have the advantages of structural control of the produced polymers/oligomers, understanding of detailed reaction processes, and, most importantly, production of new materials that cannot be synthesized by traditional methods. The types of reactants, choice of metal surface, and initial conditions are critical parameters for control of surface-assisted reactions. Covalent bonds formed in the reaction ensure higher mechanical and thermodynamic stability of the produced structures compared with self-assembled monolayers (SAMs). Some conjugated polymers are ideal candidate organic semiconductors for next-generation carbon-based electronics. In this review, we summarize the surface-assisted reactions reported in recent years, analyzing their mechanisms and comparing them with the corresponding reactions in solution systems. We also discuss the important role that the substrate surface plays in the reaction process.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Molecular self-assembly has been widely used in recent decades in the patterning of organic molecules and functionalization of surfaces [1, 2]. In the assembly process, molecules are collected together spontaneously through noncovalent interactions such as van der Waals’ forces, [3, 4], hydrogen bonds [5,6,7], halogen bonds [8, 9], and coordination bonds [10, 11]. Self-assembled monolayers (SAMs) on surfaces have the advantage of forming compact molecular structures over a large area as a result of their spontaneous and reversible growth [12]. Although weak interactions between molecules are the key requirement for reaction reversibility, they reduce the stability of these structures and thus restrict their application in molecular electronics, sensors, catalysis, and molecular templates, which all require high stability. Combination of organic molecules through on-surface reaction to produce molecular networks or polymers is a new synthetic method in chemistry, and also an effective way to fabricate stable two-dimensional (2D) structures on surfaces. In contrast to reactions taking place in solution, on-surface synthesis implements a different propagating path because of involvement of the metal surface and the totally different reaction conditions. This kind of reaction has been named “on-surface chemistry” or “surface-assisted reaction.” Investigation of different kinds of surface-assisted reactions helps in obtaining deeper understanding of the process and mechanisms. At the same time, organization of molecules using surface-assisted reactions can be used to fabricate covalently bonded 2D structures with higher stability. Several low dimensional molecular structures have been fabricated through this strategy and the advantages are as follows:

-

1.

The strength of the covalent bond (several electronvolts) is much stronger than the weak interactions mentioned above. This kind of strong interaction in SAMs greatly enhances the stability of the fabricated film, reflected both in higher mechanical strength and higher thermodynamic stability [13,14,15].

-

2.

Surface-assisted reactions provide new strategies for synthesis of some new functional materials that cannot be produced by other methods.

-

3.

Products fabricated on metal surfaces can easily be characterized using surface characterization techniques such as scanning tunneling microscopy (STM), X-ray photoelectron spectroscopy (XPS), infrared spectroscopy (IR), ultraviolet photoelectron spectroscopy (UPS), and near edge X-ray absorption fine structure (NEXAFS).

-

4.

Conjugated polymers/macromolecules can work as a channel for transfer of electrons. In this case, some special electrical materials such as graphene nanoribbons (GNRs) and molecular wires can be fabricated directly on surfaces.

Similar to traditional fabrication techniques for SAMs, surface-assisted reactions are executed through bottom-up strategies. In most cases, precursor molecules containing the required functional groups can be deposited on a substrate surface under ultrahigh vacuum (UHV) conditions. The molecules diffuse over the surface and form self-assembled structures driven by weak interactions between molecules. Enough energy needs to be supplied through heating [16, 17], injection of electrons [18,19,20], exposure to ultraviolet light [21,22,23], or other methods to activate the cleavage of bonds in functional groups with the assistance of metal substrate. The formed molecular radicals connect with each other to generate macromolecules or polymers. As a result of great effort in the past decade, researchers have reported a series of surface-assisted reactions, including some classic reactions in solution, such as the Ullmann coupling reaction [24, 25], Glaser coupling reaction [26], condensation of boronic acids [27], “Click” reaction [28], cyclodehydrogenation [29], and Sonogashira coupling reaction [30], as well as some new reactions that only take place on surfaces, such as dehydrogenation of alkanes under mild conditions [31]. Here, we summarize some typical surface-assisted reactions that have been reported in the last few years and analyze the important role of the substrate surface in the reaction process. Finally, we give a vision of the future ability to fabricate functional structures based on these reactions.

2 Advantages and Challenges of Surface-Assisted Reactions Under UHV Conditions

Until recently, most reported surface-assisted reactions took place in a UHV chamber. Compared with the traditional liquid environment, the advantages of using a vacuum are very attractive, as listed below [14, 32]:

-

1.

UHV conditions afford a perfect environment for reactions to occur, where the ultraclean environment enables metal surfaces to remain clean at the atomic scale. The metal substrate not only acts as a plane to support molecules, but also as a kind of template to locate the adsorption molecules and as a catalyst in the reaction. Thus, the reaction ingredients can be simplified such that the precursor molecules are the primary elements, and solvents or other catalysts are not necessary. Furthermore, the negative influence of gases such as O2 and CO2 in air can be avoided. These advantages afford an optimized path for study of reaction mechanisms.

-

2.

Absence of solvent allows a much larger range of reaction temperatures than for reactions in solution. Furthermore, without the requirement for solvent as intermediary in the reaction process, insoluble substances no longer restrict the reactions. This allows a larger species of materials to be chosen.

-

3.

The structure and morphology of products on surfaces can be detected by SPM and other surface characterization instruments in situ. Importantly, the STM tip can operate on the substrate surface and measure the electronic properties of products. Additionally, a template can be used on the surface to adjust the reaction procedure.

-

4.

The controllable active process of reactions on surfaces allows step-by-step study, which means that the reaction can be focused at some intermediate state for detailed study of the reaction procedure on surfaces.

Additionally, electronic chemistry (EC) takes place in a strictly controlled environment that also allows clean conditions and the operation of STM on single-crystal metal surfaces in situ. Moreover, EC-STM can supply an additional electric field on surfaces, which provides another important platform for study of surface-assisted reactions. In fact, some reactions studied under EC conditions have been previously reported [33,34,35]. In contrast to EC conditions, UHV conditions permit activation of reactions easily by the supply of energy through different techniques. More importantly, radicals are the basic elements in most reactions on surfaces and are stable in UHV conditions but might be trapped by an electrolyte.

Of course, there are some drawbacks to surface-assisted reactions under vacuum conditions. The desorption of some byproducts (e.g. H2, H2O) from the substrate surface under low vapor conditions and the difficulty in separation of products from each other because of the strong interaction between molecules and substrate lead to the nonreversible nature of these reactions. This hinders the fabrication of flexible, self-healing, or multimorphology structures on surfaces. Furthermore, the strong interaction between molecules and metal substrate restricts the diffusion distance of molecules on surfaces, which increases the difficulty of fabricating ordered covalent networks over a large scale. Additionally, applications based on the electronic properties of the produced materials need to be carried out on insulated surfaces, whereas surface-assisted reactions normally take place on metal single-crystal surfaces, which remains a big challenge for potential applications.

3 Different Kinds of Surface-Assisted Reactions

3.1 Ullmann Coupling Reaction

Ullmann coupling is a classical reaction widely used in organic synthesis. The reaction between aryl halides is catalyzed by copper to synthesize polymeric phenyl. The first study was reported in 1901 by Ullmann and Bielecki, who heated a mixture of Cu powder and iodobenzene to synthesize biphenyl [36]. Xi et al. [37] reported the reaction of iodobenzene on a Cu(111) surface to produce biphenyl through annealing, which was the first time realize the initiation of Ullmann coupling was realized on a metal surface. The reaction proceeds as follows: iodobenzene dissociates iodine atoms on a Cu(111) surface to form phenyl radicals by heating; those phenyl radicals diffuse over the surface and combine into biphenyl when annealed to a higher temperature [38]. In 2000, Hla et al. [18] succeeded in synthesizing biphenyl from iodobenzene by manipulation of the STM tip step by step on a Cu(111) surface. As shown in Fig. 1, iodobenzene molecules deposited on a Cu(111) surface were kept at low temperature in the vacuum chamber. The STM tip was moved above one iodobenzene molecule and supplied a positive voltage to cleave off the iodine atom. Two phenyl radicals were brought together, followed by a positive voltage to combine them together. The STM tip acted to manipulate the molecules in the reaction process and, more importantly, as a versatile tool at the submolecule scale to detect the structure of components at every step and reveal the detailed procedure of reaction on the Cu(111) surface. However, the limitation is that the STM tip operation is slow and multifarious, which make it unsuitable for large-scale fabrication.

STM-tip-induced synthesis of biphenyl [18]: (a, b) STM-induced abstraction of iodine from iodobenzene; (c) removal of iodine atom; (d) bringing two phenyl radicals together; (e) electron-induced association of two phenyls to form a biphenyl molecule; (f) moving one side of the biphenyl molecule to confirm the association

In 2007, Grill et al. [25] reported production of poly-phenylporphyrin on an Au(111) surface from brominated porphyrin-derived molecules through the Ullmann reaction. In the experimental strategy, poly-phenylporphyrin was fabricated in two different ways. First, the brominated porphyrin derivates were evaporated from the crucible onto an Au(111) surface kept at low temperature and were subsequently activated by heating the sample to dissociate the substituted Br atoms. The formed radicals diffused over the surface and connected into polymers. The second method was to evaporate molecules at a high temperature (more than 590 K) in a Knudsen cell, where cleavage of C–Br bonds was completed; subsequent deposition of the radicals on an Au(111) surface induced combination of those radicals. Interestingly, the obtained polymerized structures could be controlled by adjusting the number and position of the substituted Br atoms in the monomers. Figure 2a–c shows the molecular structures of different precursor molecules with one, two and four Br atoms substituted in tetraphenylporphyrin (TPP). The resulting products were dimers, molecular wires, and molecular networks, respectively. Compared with the tip-induced reaction, thermo-induced Ullmann reaction benefits from simplified operation and has set a precedent for disseminating surface-assisted reactions. Grill’s group later exchanged two of the bromine atoms for iodine atoms in the precursor molecule Br4TPP, in which the halogen atoms can be cleaved off at different temperature to explore the sequential reaction process. In this experiment, they first deposited precursor molecules on an Au(111) surface kept at 80 K to obtain the self-assembled structure, subsequently annealed the sample to 393 K to produce covalently bonded molecular linear structures through cleavage of iodine atoms, and then annealed the sample to 523 K to obtain the final product with dissociation of Br and subsequent combination of the linear polymer chains into 2D networks [16]. This kind of step-by-step procedure affords a new bottom-up strategy for production of nanomolecular frameworks.

Structural formulae (a–c) and corresponding STM images (d–i) of different kinds of brominated porphyrin-derived molecules [25]: (d, g) dimer; (e, h) molecular line; and (f, i) molecular network

The general view of the mechanism of this surface Ullmann coupling is that there exits an important intermediate between the dissociation of the halogen atoms and the formation of C–C bonds. At first, researchers considered the intermediates to be coordination structures attached by dehalogenated molecules to metal atoms on the surface [38,39,40]. Later works provided more unambiguous evidence to prove that the intermediates are stable metal–organic coordination structures linked by molecular radicals to free metal atoms on the substrate surface. Wang et al. [41] observed this kind of structure when they studied the Ullmann reaction of 4.4′-dibromo-p-terphenyl [Br-(ph)3)-Br] on a Cu(111) surface. Figure 3a shows the reaction procedure of the experiment, where a set of molecular wires were detected by STM when the sample was annealed to 300 K. As shown in Fig. 3b, a series of bright dots can be clearly identified in every linear structure, uniformly distributed between every two molecules. Furthermore, these molecular linear structures possessed high stability, which even grew across the atomic steps on the surface, and behaved similarly to the coordination structures reported previously [42]. The authors attributed the bright dots to free Cu atoms on surface, linked by molecular radicals. The simulated coordination structure calculated by density functional theory (DFT) agreed well with the STM result (see Fig. 3c). At the same time, the DFT-calculated intermediate on the Cu(111) surface in Fig. 3d shows that both the molecules and the Cu atoms were located in the same plane, far from the substrate surface. Additionally, in the inset of Fig. 3b, lots of bright dots can be observed between the linear structures and were attributed to Br atoms dissociated from the precursor molecules and adsorbed on the Cu(111) surface. The authors confirmed this stable metal–organic coordination structure to be the intermediate in surface Ullmann reactions, with a Cu–C bond length of 0.211 nm. Further annealing of the intermediates to 473 K produced covalently bonded linear polymers. Other works have also been presented that give further evidence for the existence of metal-linked intermediates [43,44,45,46,47].

(a) Ullmann coupling reaction of 4,4″-dibromo-p-pterphenyl (Br-(ph)3-Br) on a Cu(111) surface. (b) STM topography and high-resolution image (inset) of the sample after annealing to 300 K. (c) Simulated STM image covered on the STM topography of the intermediate. (d) Top and side views of the intermediate structure on a Cu(111) surface, obtained through DFT calculation [41]

One important reason for study of Ullmann coupling is the fabrication of covalently bonded conjugated structures, such as molecular wires and organic semiconductors. Grill et al. [48] succeeded in fabrication of a set of molecular wires of different lengths on an Au(111) surface by annealing the deposited dibromoterfluorene (DBTF) to 520 K, with the longest wire being over 100 nm. Furthermore, the STM tip can be used to drag up one side of the wire to determine the conductance. The conjugated products can be used as organic semiconductors in the fabrication of various organic devices by adjusting the precursor molecules to have different configurations and symmetries [16, 49].

3.2 Schiff Base Reaction

Schiff base reactions refer to those reactions in which an amine reacts with an oxo-compound (aldehyde and ketone) through nucleophilic addition to form the hemiaminal intermediate, followed by dehydration to generate imine (the reaction procedure is shown in Fig. 4a) [51]. Weigelt et al. [50] reported the first Schiff base reaction between dialdehyde and octylamine on an Au(111) surface. Dialdehyde molecules were first deposited on Au(111) and then exposed to a vapor of octylamine (p ≈ 1–5 × 10−8 mbar). The reaction took place at room temperature and resulted in self-assembly of the produced imines. Compared with the self-assembled structure of imines synthesized in solution, the morphology and inner structure of the SAMs were exactly the same, giving strong evidence for initiation of the Schiff base reaction on the Au(111) surface. The mechanism of a surface-assisted Schiff base reaction is different from that in solution. Normally, the solvent plays a very important role in catalysis of the transformation from intermediate to final product in solution, but this is impossible in a vacuum chamber. Learning from DFT calculations, the authors estimated that the hydroxyl group in phenol acted as acceptor/donor and, at the same time, played as the factor of solvent in the reaction in solution. Furthermore, the DFT-calculated activation energy of this reaction is 1.17 eV, and the reaction initiated at room temperature, which is much lower than estimated. This is a result of the catalytic effect of the Au(111) surface in reducing the activation energy of the reaction.

(a) Schiff base reaction in solvent. (b) Schiff base reaction from dialdehyde and octylamine to diimine on an Au(111) surface. (c) STM topography of the self-assembled structure of diamine, overlaid with the structural model [50]

More importantly, Schiff base reactions involve two reactants, which enhances the controllability of the product structures through adjusting the precursor molecules or reaction parameters. Weigelt et al. [52] tried using trialdehyde to react with 1,6-diaminohexane to fabricate covalently bonded networks. They found that the parameters of the network (e.g., pore size and shape) can be easily adjusted by using different amines. Furthermore, the reaction also depended on the reaction conditions. For example, reactants handled using two different paths gave different connected networks. In method A, after the deposition of trialdehyde, the sample was exposed to 1,6-diaminohexane (p = 1–5 × 10−7 mbar) and subsequently annealed to 400–450 K to initiate the reaction. The products were small oligomers. In method B, after the deposition of trialdehyde, the sample was heated to 400 K and exposed to 1,6-diaminohexane (5 × 10−9 mbar). In this case, the products were extended polymers. Comparing the two products synthesized using different procedures, the trialdehyde connected with more 1,6-diaminohexane molecules in method B, inducing a more compact network structure. In addition to fabrication of oligomers and anomalous polymers, a honeycomb network can also be produced through optimizing the reaction [53].

3.3 Condensation Reaction of Boronic Acids

Condensation of boronic acids is often applied for fabrication of covalent organic frameworks (COFs) in solution [54, 55]. More recently, this reaction has also been used in the synthesis of surface covalent organic frameworks (SCOFs). Zwaneveld et al. [27] first reported the fabrication of large scale 2D frameworks from condensation of boronic acids on a metal surface. The reaction was initiated when the precursor molecules 1,4-benzenediboronic acid (BDBA) reached the Ag(111) surface at room temperature. The formed framework was detected by STM, as shown in Fig. 5a. The pore size was 1.52 nm, agreeing with the calculated structure. Learning from the fabrication of 3D COF structures, 2D SCOFs structure can also be produced from multireactants. As an example, BDBA and 2,3,6,7,10,11-hexahydroxytriphenylene (HHTP) were simultaneously deposited on an Ag(111) surface, producing a framework with pore size of 2.98 nm. In addition to the flexibility of controllable pore size, other advantages of the reaction using double reactants are that the produced SCOF structure has higher stability (even annealed to 750 K) and less defects. With the assistant of HHTP, dioxaborole formation is a bimolecular reaction, in contrast to the trimolecular boroxine reaction, and thus follows a more favorable kinetic path. As shown in Fig. 5b, in addition to the majority existence of hexagons, other structures such as five-, seven-, and eight-membered rings are also present. That is probably due to the fact that, although the hexagon is the optimal structure in the reaction, in the experimental process some molecules might not have enough time or space to reach the right position when the reaction is initiated, thus inducing the formation of other structures. Meanwhile, the produced water molecules are desorbed from the surface during the reaction process, which causes the irreversible nature of this reaction. Consequently, all defects created in the process are kept on the metal surface. Defects can be reduced by optimizing the reaction conditions, such as increasing the deposition flux rate or raising the substrate temperature to enhance transformation of molecules on the surface [56]. It is worth mentioning that the condensation reaction of boronic acids can be excited not only by heating, but also by an STM tip or electronic beam. This confers the ability to control the reaction area as well as the activation sequence [57].

STM images of surface covalent organic framework (SCOF) structures synthesized from different precursors on an Au(111) surface [27]: (a) 1,4-benzenediboronic acid (BDBA); (b) co-adsorption of BDBA and 2,3,6,7,10,11-hexahydroxytriphenylene (HHTP)

3.4 Dehydrogenation

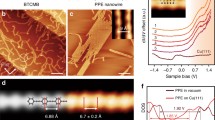

Dehydrogenation, as a convenient strategy for generating C–C coupling structures through cleaving the C–H bond directly with the assistance of catalytic metals, is widely used in standard organic synthesis. To break a C–H bond, an activation energy of more than 4.5 eV is needed [58]. However, on a single-crystal metal surface, especially one with high reactivity, the cleavage energy can be significantly reduced. For example, on a Cu(110) surface, tetra(mesityl)porphyrin (TAP) molecules dehydrogenated in the methyl group form a combinatorial mixture of covalent nanostructures when annealed to 423 K [59]. Furthermore, Zhong et al. [31] succeeded in combining alkane molecules into linear polymers on the more ‘inert’ Au surface. Dotriacontane (C32H66) was deposited on reconstructed Au(110)-(1 × 3) surface and subsequently annealed to 440 K. One of the H atoms in every methyl was dissociated from the alkyl chains, combined into H2, and released into the vacuum chamber. The alkyl radicals moved along the grooves and connected with each other to generate linear alkane polymers. The self-assembled structure as well as the polymerized alkyl chains are shown in Fig. 6. In comparison, this reaction did not occur on an Au(111) surface. DFT calculation shows that the selected polymerization is a result of the special structure of reconstructed Au(110)-(1 × 3) surfaces. The grooves of the Au(110)-(1 × 3) surface enhanced the interaction between molecules and substrate, which reduced the energy barrier for dehydrogenation. More importantly, the grooves restricted the movement of molecules on the surface, limiting molecules to a “head-to-tail” connection mode. The benefit of producing polymers through dehydrogenation is the clean synthetic process, because only H2 is produced as byproduct in this reaction and is released from the surface immediately after combination of H atoms, affecting neither the formation of product nor the substrate surface activity. More recently, the polymerization of porphyrin molecules through cleavage of C–H bonds on an Ag(111) surface was reported [60].

STM images of self-assembled and polymerized structures formed by dotriacontane (C32H66) [31]: (a) self-assembled structure on an Au(110)-(1 × 2) surface at 300 K; (b) parallel polyethylene chains on a reconstructed Au(110)-(1 × 3) surface at 440 K

3.5 Cyclodehydrogenation

Cyclodehydrogenation is a common method for fabricating planar aromatic structures in solution [61]. AlCl3 or FeCl3 is normally used as catalyst for cleaving neighboring C–H bonds. Analogously, C–C coupling through cyclodehydrogenation can also be carried out to synthesize monolayer GNRs or graphene nanoplates on metal substrate surfaces. For example, Cai et al. [62] fabricated GNRs from 10,10′-dibromo-9,9′-bianthryl (DBBA) precursor monomers. The experimental procedures are shown in Fig. 7a. The authors deposited DBBA on an Au(111) surface and subsequently annealed to 473 K to generate the tortuous connected linear polymers via Ullmann reaction. A consecutive second annealing step at 673 K was executed to transfer the linear polymers into GNRs via cyclodehydrogenation. The produced GNRs were imaged by STM and are shown in Fig. 7b. The type of nanoribbon obtained is related to the choice of precursor monomers. As an example, a chevron-type GNR fabricated from tetraphenyl-triphenylene monomers is shown in Fig. 7c. More recently, the fabrication of other GNRs with much more complicated structures has been reported [63, 64]. Björk et al. [65] analyzed the cyclization mechanism through DFT calculation and explained the detailed procedure for cyclodehydregenation of anthracene polymer. Hydrogen atoms are first adsorbed on the metal surface, subsequently cleaved off by the catalytic substrate, combined into H2 with other hydrogen atoms, and desorbed from the surface. On the other hand, the molecular radicals connect with each other spontaneously to generate GNRs. Interestingly, only one energy barrier exists in the cyclodehydregenation process in a single chain. The formation of GNR proceeds from one end of the linear chain. After activation of the first molecule, subsequent energy barriers are reduced, which induces the cyclodehydregenation to propagate unit-by-unit through the entire polymer in a domino-like fashion. Treier et al. [66] studied the cyclodehydrogenation process of cyclohexa-o-p-o-p-o-p-phenylene on a Cu(111) surface by STM and DFT calculation and found that the reaction contained six steps, in which two intermediates were stable enough to be detected by STM.

Strategy for synthesis of graphene nanoribbon (GNR) and STM images of two kinds of GNR [62]: (a, b) GNRs synthesized from 10,10′-dibromo-9,9′-bianthryl (BDDA) on an Au(111) surface; (c) GNRs fabricated from 6,11-dibromo-1,2,3,4-tetraphenyltriphenylene monolayer

Fullerenes, as special carbon materials, have been extensively used for various biomedical applications and are mostly obtained through vaporization of graphite. Researchers are continuously searching for routes to avoid uncontrolled procedures [67]. A promising path is to catalyze the cyclization of planar precursors. This strategy has the advantages of mild conditions and predesigned products. Furthermore, various fullerenes and their derivatives that cannot be produced in other ways can be synthesized by this method. There are also obvious disadvantages of this method, such as low efficiency and complicated operation [68, 69]. However, the synthesis is simplified when taking place on noble metal substrate surfaces, where the precursor molecules can be reproduced into fullerenes or fullerene derivatives through spontaneous cyclodehydrogenation. For example, open-cage C57H33N3 precursor molecules were deposited on a Pt(111) surface and annealed to 750 K to generate ball-shaped C57N3 molecules. The benefits are not only the simplified experimental procedure, but also enhanced yield, from less than 1% in solution to about 100% on a surface [29]. Figure 8a, b shows STM images of the precursor molecules C57H33N3 adsorbed on a Pt(111) surface. Because of the strong interaction between molecules and Pt surface, the molecules rotate into a special state to reduce the distance between the hydrogen atoms and Pt surface. Subsequently, the C–H bond was cleaved by the substrate in the annealing process, inducing cyclization of the molecules into C57N3. Figure 8c, d shows STM images of the produced C57N3. It is noteworthy that the strong interaction between molecule and substrate acts as a crucial factor in the reaction. For comparison, annealing the same precursor molecules on an Au(111) surface, which has a low adsorption interaction with C57H33N3, resulted in very low yield (less than 1%). Consequently, the strong interaction induced deformation of the C57N3 cages. STM measurement showed the diameter of the formed C57N3 to be 1.5 nm and the height 0.38 nm. Amsharov et al. [70] pointed out that the transformation from precursor to fullerene is not a random combination of inner functional groups, but an ordered process in which hydrogen atoms dissociate and the radicals formed are connected step by step, without any rearrangement of C–C bonds. This means that the type and structure of the produced fullerene or derivative is only dependent on the structure of the precursor.

STM images of C57H33N3 and C57H33N3 on a Pt(111) surface [29]: (a) high resolution and (b) large area STM images of C57H33N3 deposited on a Pt(111) surface; (c) high resolution and (d) large area STM images of the produced C57N3 after annealing at 750 K

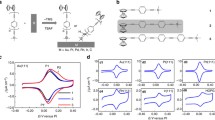

3.6 Glaser Coupling Reaction

Glaser coupling was first reported in the 1860s and is catalyzed by cuprous salts in alkaline solution [71]. This kind of reaction can also take place on single-crystal surfaces. Zhang et al. [26] first reported the Glaser reaction on Ag(111) surfaces in 2012. The scheme of the reaction process is shown in Fig. 9a. By depositing 1,3,5-triethynyl-benzene (TEB) on an Ag(111) surface kept at 170 K, the self-assembled structures shown in Fig. 9c were obtained. Because the molecules might desorb from the surface before the initiation of reaction in the annealing process, the TEB was directly deposited on an Au(111) surface held at 330 K. A new self-assembled structure composed of dumbbell-like molecules was obtained, as shown in Fig. 9d. Analysis of these structures by STM and DFT calculation, enabled the dumbbell like structures to be attributed to coupled TEB molecules. In contrast to the Ullmann reaction, XPS characterization and DFT calculation both showed that there is no analogous intermediate such as C–Ag–C in the reaction procedure. During on-surface Glaser coupling, two neighboring alkynyl groups combine together first, followed by the cleavage of H atoms to form a dimer. Another precursor molecule of larger size, 1,3,5-tris-(4-ethynylphenyl)benzene (Ext-TEB), was also investigated. The self-assembly structure shown in Fig. 9e was obtained when Ext-TEB was deposited on an Ag(111) surface at 152 K. Subsequent annealing to 300 K produced dimer structures. When the sample was further annealed to a higher temperature (400 K), another new covalent bonded network was obtained (shown in Fig. 9f). Moreover, Eichhorn et al. [72] observed several different underlying reaction schemes when they studied the coupling of 1,4-diethynylbenzene on a Cu(111) surface. In this case, it was difficult to control the polymerization path by adjusting experimental parameters such as annealing temperature or time. Gao et al. [73] introduced hexyl groups into the aromatic ring to enhance steric hindrance between molecules to prevent creation of other polymers, and succeeded in generating linear polymerized chains on an Ag(111) surface, which was thought to be impossible using conventional organic synthesis. However, the substrate material also affects the selectivity of this reaction. It was found that Glaser coupling is more efficient on Ag(111) surfaces than on Au(111) and Cu(111) [23].

(a) Scheme of Glaser coupling reaction on a metal surface. (b) Molecular structures of 1,3,5-triethynylbenzene (TEB) and 1,3,5-tris-(4-ethynylphenyl)benzene (Ext-TEB). (c, d) STM images of TEB deposited on an Ag(111) surface kept at 170 K (c) and 330 K (d). (e, f) STM images of Ext-TEB deposited on Ag(111) kept at 152 K (e) and annealed to 400 K (f). The inset shows the high-resolution image with a structural model [26]

3.7 Sonogashira Coupling Reaction

The Sonogashira reaction is a crosscoupling reaction used in organic synthesis to form C–C bonds and has also been implemented on metal surfaces by Kanuru et al. [30]. Phenylacetylene and iodobenzene were co-deposited on a 90 K Au(111) surface and subsequently annealed to 200 K to generate the polymerized diphenylacetylene. XPS and NEXAFS characterization were applied to find the mechanism of this reaction. After the deposition of two precursor molecules, they both adsorbed on the surface in planer state, forming separated self-assembled structures because of their different adsorption behaviors on the Au(111) surface. The annealing process induced cleavage of the I atom on iodobenzene, while the produced phenyl radicals reacted with phenylacetylene located at the boundary of neighboring phenylacetylene islands (reaction scheme is shown in Fig. 10). Compared with the reaction in solution, the absence of Pt and base promoted the Au atoms to act as base, inducing a different reaction procedure. In this case, only the reactants located at the boundary possessed the ability to initiate Sonogashira coupling, whereas the inner iodobenzene/phenylacetylene islands initiated the Ullmann reaction/Glaser coupling. On-surface Sonogashira coupling had a low yield of about 10%, but it should be possible to increase this by expanding the boundary area of the two kinds of islands.

(a) Reaction equation and (b) step-by-step process of the Sonogashira coupling reaction on an Au(111) surface [30]

Furthermore, Sonogashira coupling reactions are very sensitive to the properties of the substrate surface. On Au(111), the coupling process prefers to occur on a flat surface, because the low coordinated Au sites on a rough surface can cause decomposition of the adsorbed phenylacetylene molecules. In contrast, Sánchez-Sánchez et al. [74] reported that rough Au(100) surfaces have advantages for Sonogashira coupling. The difference is a result of the different distribution of nucleation centers on the two kinds of surfaces. Au(100) is not suitable for nucleation of either phenylacetylene or iodobenzene molecules to form separate islands; thus, roughening treatment affords new nucleation centers for those molecules to grow more islands. However, on an Au(111) surface, the main nucleation centers are herringbone reconstruction structures [75], which disappear if the surface is roughened. In this case, the rough Au(111) surface is no longer suitable for growth of small molecular islands.

3.8 Azide–Alkyne Cycloaddition (“Click” Reaction)

Azide–alkyne cycloaddition catalyzed by cuprous salts has attracted wide attention because of the advantages of no byproducts and low activation energy (0.65 eV). This reaction was implemented on metal surfaces by Bebensee et al. in 2013 [28]. 9-Ethynylphenanthrene (alkyne) and 4-azidobiphenyl (azide) were simultaneously deposited on Cu(111) at room temperature, and spontaneously generated 1,4-triazole by 1,3-cycloaddition (the reaction scheme is shown in Fig. 11a). Figure 11b shows the STM image of the products, where the molecules marked by quadrangles are the formed 1,4-triazole molecules. To confirm the initiation of this reaction, the authors compared the self-assembly structure of 1,4-triazole produced in solution with that synthesized on a surface and found no difference in the STM measurements. In contrast to the high yield obtained for reaction in solution, the surface-assisted reaction gave a very low yield. XPS detection showed that the alkyne molecules were not stable on the surface and degraded rapidly after reaching the surface. Most of the alkyne molecules were not integral when the reaction was initiated. The loss of alkyne molecules induced the low reaction yield. In the reaction taking place in solution, Cu ions act as catalyst in the cycloaddition process. By contrast, Arado et al. [76] found that Cu atoms were not an essential agent for cycloaddition of N-(4-azidophenyl)-4-ethynyl-benzamide (AEB) on an Au(111) surface. Both STM detection and DFT calculation proved that the surface only acted as a support to locate the molecules.

Scheme of azide–alkyne cycloaddition reaction and STM image of the products after cycloaddition [28]: (a) comparison of azide–alkyne cycloaddition reaction in solution (A) and on Cu(111) surface (B); (b) co-deposition of 9-ethynylphenanthrene and 4-azidobiphenyl on a Cu(111) surface kept at room temperature. The 1,4-triazole reaction products are marked in quadrangles

3.9 Other Reactions

Some other surface-assisted reactions have also been reported recently, with some exciting examples. The formation of imide from anhydride and amine through condensation in a 2D plane was previously considered to be impossible because initiation of the reaction requires the amine to attack the anhydride in a nonplanar manner. However, with the assistance of metal substrate to locate the two reactants under high vacuum conditions, the reaction took place on a metal substrate surface [77]. 4,4′-Diamino-p-terphenyl (DATP) and 3,4,9,10-perylenetetracarboxylic-dianhydride (PTCDA) molecules (the chemical structures are shown in Fig. 12a) were deposited on an Au(111) surface and subsequently annealed to 570 K for 15 min to achieve the polyimide structures shown in Fig. 12b. The authors estimated that it is the high transfer ability of the amine molecules that allow them to attack the anhydride. When the substrate was heated to the critical temperature for desorbing DATP, the diffusion of DATP on surfaces was greatly enhanced, which increased the amount of nucleophilic attack in the reaction procedure. In this case, 2D covalent networks were fabricated by this reaction to combine 2,4,6-tris(4-aminophenyl)-1,3,5-triazine (TAPT) and PTCDA.

Chemical structures of the precursors and STM image of the products formed in imidization condensation reaction [77]: (a) 3,4,9,10-perylenetetracarboxylic-dianhydride (PTCDA), 4,4′-diamino-p-terphenyl (DATP), and 2,4,6-tris(4-aminophenyl)-1,3,5-triazine (TAPT); (b) parallel polyimide formed from annealing at 570 K of DATP and PTCDA molecules co-deposited on Au(111)

Marele et al. [78] reported the condensation between 1,3,5-tri(4-hydroxyphenyl)benzene (TPB) and benzene-1,3,5-tricarbonyl trichloride (TMC) to generate polyester-based SCOF structures. In this work, TPB was deposited on an Au(111) surface and heated to 575 K; exposure to TMC vapor provided honeycomb networks through the condensation reaction.

Bergman cyclization is an important cycloaromatization reaction, which was first reported for on-surface synthesis in 2013 [79]. Sun et al. [80] studied the Bergman cyclization of 1,6-di-2-naphthylhex-3-ene-1,5-diyne (DNHD) on a Cu(110) surface and obtained linear polyphenylene chains. It was thought that the cyclization of DNHD induced formation of diradicals on the surface, which subsequently combined to form polyphenylene chains. Furthermore, the movement of precursor molecules was restricted to one direction by the Cu(110) surface, which led to a tendency to generate long polymer chains.

Cyclotrimerization is another important method for solution fabrication of COF crystals [81, 82]. Yang et al. [83] first introduced the method into the family of surface-assisted reactions for production of 2D conjugated SCOF structures. Precursor molecules of 1,3,5-tris(4-acetylphenyl)benzene (TAPB) were deposited on an Ag(111) surface kept at 590 K to generate conjugated SCOF structures through cyclotrimerization. The products were imaged by STM, as shown in Fig. 13a. The reaction mechanism was studied by DFT calculation and XPS characterization, and the proposed procedure is shown in Fig. 13b. To activate the reaction, one C–H bond in a methyl group is cleaved. Then, the formed radical attacks the nearby molecule, with subsequent dissociation of a hydroxyl to obtain a dimer. The dimer reacts with a third molecule to produce the final trimerization product. It is worth noting that this reaction is universal on other surfaces such as Au(111) and Cu(111), whereas Ag(111) was the best choice because of the high mobility of the precursor molecules on Ag surfaces.

(a) STM image of SCOF structure formed from 1,3,5-tris(4-acetylphenyl) benzene (TAPB) on an Ag(111) surface and (b) schematic representation of the reaction [83]

4 Choice of Substrate Surface

Many surface-assisted reactions have been successfully implemented on metal surfaces. Compared with the corresponding reactions in solution, the same products can be synthesized from the same reactants; the difference is that they may proceed through different reaction paths. In surface-assisted reactions, without the presence of solvent or other catalyst, the metal surfaces play a crucial role. In fact, the basic effect of the substrate surface is to afford a 2D plane to support adsorption and promote the movement of precursor molecules. Additionally, the periodic electronic structures on metal surfaces can reduce the activation energy barriers of on-surface reactions, which allows the metal surface to serve as catalyst in the reaction process. Thus, the material and the surface orientation of the substrate both need to be carefully chosen when designing a surface-assisted reaction.

Taking the Ullmann reaction as an example, Bieri et al. [84] investigated the influence of different surfaces on Ullmann coupling. The hexaiodo-substituted macrocycle cyclohexa-m-phenylene (CHP) was employed as precursor, deposited on Cu(111), Ag(111), and Au(111) and subsequently annealed to different temperatures to activate the reactions. On Cu(111), the reaction initiated at 475 K and generated dendritic network structures with single-molecule-wide branches; on Ag(111), an activation temperature of 575 K was used, and the products were extended and well-ordered 2D networks; on Au(111), the activation temperature was 525 K and 2D networks in small domains were obtained (shown in Fig. 14). These differences were the result of variations in the reactivity and mobility of the three surfaces. Cu surfaces show higher reactivity than Ag surfaces, but have a higher diffusion barrier (2.2 eV) than Ag(111) surfaces (0.8 eV) [85]. In this case, CHP polymerization on Cu(111) surfaces can be activated at low temperature, but the movement of molecules is hindered by the large diffusion barrier on the surface; thus, formation of loose polymerized structures is induced. By contrast, coupling of CHP on Ag(111) surfaces requires a higher activation temperature because of the low reactivity of the substrate, whereas the low diffusion barrier promotes the formation of large-scale 2D networks. Au(111) surfaces exhibit properties between those of Cu(111) and Ag(111) surfaces, with an activation temperature between the two, and the formed products being a mixture of branched polymers and 2D networks.

STM images of hexaiodo-substituted macrocycle cyclohexa-m-phenylene (CHP) deposited on different surfaces [84]:. (a, b) Cu(111); (c, d) Au(111); (e, f) Ag(111); inset chemical structure of CHP

It is worth noting that not only the excitation conditions of reaction, but also the proceeding paths, are related to the properties of the substrate surface. The Ullmann reactions on Cu(111) [41, 86] and Ag(111) [87] contain metal–organic coordination structures as intermediates. On Au(111), only direct transformation of reactants to the final covalently bonded structures was detected. It was thought that the C–Au–C structure is not stable enough to be detected [24]. However, Zhang et al. [88] successfully fabricated stable C–Au–C structures when they studied the coupling of chlorosubstituted perylene-3,4,9,10-tetracarboxylic acid bisimides (PBIs) on Au(111) surfaces. Additionally, study of the coupling of 1,4,5,8-tetrabromonaphthalene (TBN) proved that the C–Au–C coordination structure is the intermediate of the Ullmann reaction on an Au(111) surface. The authors deposited TBN molecules on an Au(111) surface at 273 K and obtained the self-assembled structure shown in Fig. 15a. However, the molecules desorbed before reaching the activation temperature for Ullmann coupling on the surface. TBN deposited on an Au(111) surface held at 370 K produced a stable coordination structure intermediate (STM image and molecular model are shown in Fig. 15b). Subsequent annealing of the coordination structures at higher temperatures (400–470 K) gave GNRs with the width of only five carbon atoms [89]. Therefore, this work proved the stability of the coordinated intermediate in the Ullmann reaction on an Au surface, and also indicated another way to synthesize GNRs under gentle conditions without involving the cyclodehydregenation process.

STM images of 1,4,5,8-tetrabromonaphthalene (TBN) molecules deposited on Au(111) surfaces held at different temperatures [89]: (a) 273 K; (b) 370 K; (c) 470 K

Walch et al. [90] studied the Ullmann coupling of 1,3,5-tris(4-bromophenyl)benzene (TBB) on Ag(111) and Ag(110) surfaces to identify the effect of substrate surface orientation. They found that the reaction only occurred on Ag(110) surfaces and not Ag(111) surfaces at room temperature. They attributed the difference to the higher catalytic ability of an Ag(110) surface than that of an Ag(111) surface, as well as the unique anisotropy structure on Ag(110) surfaces that enhanced the directional combination. Another example is the linear polymerization of alkane molecules through dehydrogenation on Au(110) because of the special properties of the surface, but not on Au(111) under the same conditions [31].

One important application of surface-assisted reactions is the fabrication of conjugated 1D or 2D organic materials, which can be further used as organic semiconductors or molecular wires in organic devices. However, until now, most of the reactions took place on metal [23, 91] or semiconductor [92] surfaces under vacuum conditions. This hindered the application of such organic materials because device fabrication requires them to be transferred from these conductive surfaces onto insulator substrates. Stripping the organic polymers from metal surfaces proved to be difficult, whereas directly producing the conjugated polymers on an insulator surface seems to be difficult because of the low catalytic properties of insulating surfaces [93]. Bombis et al. [94] tried to fabricate organic wires from dibromoterfluorene (DBTF) on NaCl crystal surfaces and found that it is impossible to fabricate poly(9,9-dimethylfluorene) on an NaCl surface because of the low surface reactivity. They found a circuitous path for solving this problem, that is, initial synthesis of poly(9,9-dimethylfluorene) on an Au(111) surface by the Ullmann reaction followed by deposition of NaCl molecules on the sample kept at 270 K. The NaCl crystal thin film grew under the polymer chains to give a set of molecular wires with the middle part laid on insulating NaCl crystal films and two ends connected with gold substrate. Later, Abel et al. [95] succeeded in fabrication of polymeric Fe-phthalocyanine single sheet on an Ag(100) surface covered by single layer of NaCl film through co-evaporating Fe and 1,2,4,5-tetracyanobenzene (TCNB). More recently, researchers have explored the polymerization of molecules on bulk insulated CaCO3 (104) surface and obtained polymers of linear, zig-zag, and dimer structure [96, 97]. A speculated explanation of the initiation of these reactions is that the strong anchoring of the molecules on the substrate surface reduces the activation barrier, although exploration of detailed mechanisms is still in progress.

5 Outlook

In summary, we have reviewed a series of surface-assisted reactions on single-crystal metal surfaces for preparation of various macromolecules and polymers. Various activation methods, such as heat, exposure to light, or electron injection, can be used to trigger reactions on metal surfaces under vacuum conditions. In these on-surface reactions, the metal substrate plays an important role in determining the activation barrier of the reaction and the final structure of products. In each specific reaction, the structure of precursor molecules, substrate temperature, type of metal substrate, and the orientation of single-crystal planes are important factors that deserve particular concern. Compared with physisorbed SAMs, SCOF structures are much more stable as a result of the covalently bonded connections between molecular moieties. Such a stable and structurally controllable monolayer can be used as a chemically protective layer for metal surfaces, and as molecular template to selectively host guest molecules (e.g., C60) [98]. Specifically, conjugated structures (e.g., molecular chains and GNRs) prepared by on-surface reactions are potential candidates for next-generation carbon-based semiconductors. Surface-assisted reactions are still in their infancy and there are many challenges and open questions that need to be addressed.

First, surface-supported polymers (e.g., GNRs on metal substrate) cannot be efficiently transferred onto insulating surfaces, which significantly impedes their application in electronics. In contrast to the direct etching of metal substrate [99], other possible methods can be taken into consideration, such as synthesis of the polymer on an insulating surface. Because a bulk insulating substrate is not suitable for STM measurements, an alternative substrate could be a metal substrate with a thin insulating film (about 1–4 atomic thickness) on top. The insulating film can decouple the hybridization of electrons from metal substrate and, at the same time provide sufficient tunneling current for STM investigations. Furthermore, the insulating film can remarkably reduce the charge transfer between organic materials and metal surfaces, enabling investigation of the intrinsic properties of the molecules (polymers) (e.g., electronic structure and molecular vibration).

Second, there is no effective method for controlling the reaction in terms of the pathway and the structure of products. Surface-assisted reactions frequently take place on metal surfaces with high catalytic activity, mostly leading to the formation of other byproducts. Byproducts are adsorbed steadily on the metal substrate and thus limit subsequent investigation of the physical and chemical properties of the products. Although there are several examples where high yields of the pure product have been achieved in terms of molecule–surface interactions [16, 31, 73, 100], the methods are still not general enough to avoid byproducts in different reactions.

Finally, the strong covalently bonded connections between molecules are a double-edged sword. On the one hand, they provides a stable connection between molecular moieties, but, on the other hand, they also prevent the reversibility of the reaction. The lack of reversibility leads to the formation of random defects in produced structures. Reduction of defects in produced polymers and exploration of controllable synthesis of functional materials are both urgent tasks in the study of surface-assisted reactions. Under UHV conditions, because of the irreversibility of the reaction, defects are preserved and present in the final product on surfaces. However, it seems possible to solve this problem using a solution system established in air. Recently, researchers have succeeded in fabricating large-scale, ordered and defect-free SCOF structures in the condensation reaction of boronic acids [101] and the Schiff base reaction [102, 103] on HOPG in ambient conditions. Those reactions proceed reversibly by controlling the surrounding environment, which makes it possible to decrease defects in the final products. In conclusion, the exploration of surface-assisted reactions is still in progress. Many traditional solution chemistry reactions will be reevaluated under UHV conditions. More importantly, practical application of the synthesized materials is still highly challenging and requires further study.

References

Barth JV, Costantini G, Kern K (2005) Engineering atomic and molecular nanostructures at surfaces. Nature 437:671–679

Ciesielski A, Palma C-A, Bonini M, Samorì P (2010) Towards supramolecular engineering of functional nanomaterials: pre-programming multi-component 2D self-assembly at solid-liquid interfaces. Adv Mater 22:3506–3520

Xie Z-X, Huang Z-F, Xu X (2002) Influence of reconstruction on the structure of self-assembled normal-alkane monolayers on Au(111) surfaces. Phys Chem Chem Phys 4:1486–1489

Tahara K, Furukawa S, Uji-i H, Uchino T, Ichikawa T, Zhang J, Mamdouh W, Sonoda M, De Schryver FC, De Feyter S, Tobe Y (2006) Two-dimensional porous molecular networks of dehydrobenzo[12]annulene derivatives via alkyl chain interdigitation. JACS 128:16613–16625

Griessl SJH, Lackinger M, Jamitzky F, Markert T, Hietschold M, Heckl WM (2004) Incorporation and manipulation of coronene in an organic template structure. Langmuir 20:9403–9407

Madueno R, Raisanen MT, Silien C, Buck M (2008) Functionalizing hydrogen-bonded surface networks with self-assembled monolayers. Nature 454:618–621

Wasio NA, Quardokus RC, Forrest RP, Lent CS, Corcelli SA, Christie JA, Henderson KW, Kandel SA (2014) Self-assembly of hydrogen-bonded two-dimensional quasicrystals. Nature 507:86–89

Silly F (2013) selecting two-dimensional halogen–halogen bonded self-assembled 1,3,5-tris(4-iodophenyl)benzene porous nanoarchitectures at the solid–liquid interface. J Phys Chem C 117:20244–20249

Gutzler R, Ivasenko O, Fu C, Brusso JL, Rosei F, Perepichka DF (2011) Halogen bonds as stabilizing interactions in a chiral self-assembled molecular monolayer. Chem Commun 47:9453–9455

Schlickum U, Decker R, Klappenberger F, Zoppellaro G, Klyatskaya S, Ruben M, Silanes I, Arnau A, Kern K, Brune H, Barth JV (2007) Metal−organic honeycomb nanomeshes with tunable cavity size. Nano Lett 7:3813–3817

Shi Z, Lin N (2009) Porphyrin-based two-dimensional coordination kagome lattice self-assembled on a Au(111) surface. JACS 131:5376–5377

Bonifazi D, Mohnani S, Llanes-Pallas A (2009) Supramolecular chemistry at interfaces: molecular recognition on nanopatterned porous surfaces. Chem – A Eur J 15:7004–7025

El Garah M, MacLeod JM, Rosei F (2013) Covalently bonded networks through surface-confined polymerization. Surf Sci 613:6–14

Franc G, Gourdon A (2011) Covalent networks through on-surface chemistry in ultra-high vacuum: state-of-the-art and recent developments. Phys Chem Chem Phys 13:14283–14292

Lackinger M, Heckl WM (2011) A STM perspective on covalent intermolecular coupling reactions on surfaces. J Phys D: Appl Phys 44:464011

Lafferentz L, Eberhardt V, Dri C, Africh C, Comelli G, Esch F, Hecht S, Grill L (2012) Controlling on-surface polymerization by hierarchical and substrate-directed growth. Nat Chem 4:215–220

Bieri M, Blankenburg S, Kivala M, Pignedoli CA, Ruffieux P, Mullen K, Fasel R (2011) Surface-supported 2D heterotriangulene polymers. Chem Commun 47:10239–10241

Hla S-W, Bartels L, Meyer G, Rieder K-H (2000) Inducing all steps of a chemical reaction with the scanning tunneling microscope tip: towards single molecule engineering. Phys Rev Lett 85:2777–2780

Dinca LE, MacLeod JM, Lipton-Duffin J, Fu C, Ma D, Perepichka DF, Rosei F (2014) Tip-induced C-H activation and oligomerization of thienoanthracenes. Chem Commun 50:8791–8793

Jiang Y, Huan Q, Fabris L, Bazan GC, Ho W (2013) Submolecular control, spectroscopy and imaging of bond-selective chemistry in single functionalized molecules. Nat Chem 5:36–41

Basagni A, Colazzo L, Sedona F, DiMarino M, Carofiglio T, Lubian E, Forrer D, Vittadini A, Casarin M, Verdini A, Cossaro A, Floreano L, Sambi M (2014) Stereoselective photopolymerization of tetraphenylporphyrin derivatives on Ag(110) at the sub-monolayer level. Chem – A Eur J 20:14296–14304

Basagni A, Ferrighi L, Cattelan M, Nicolas L, Handrup K, Vaghi L, Papagni A, Sedona F, Valentin CD, Agnoli S, Sambi M (2015) On-surface photo-dissociation of C-Br bonds: towards room temperature Ullmann coupling. Chem Commun 51:12593–12596

Gao H-Y, Franke J-H, Wagner H, Zhong D, Held P-A, Studer A, Fuchs H (2013) Effect of metal surfaces in on-surface Glaser coupling. J Phys Chem C 117:18595–18602

Dong L, Liu PN, Lin N (2015) Surface-activated coupling reactions confined on a surface. Acc Chem Res 48:2765–2774

Grill L, Dyer M, Lafferentz L, Persson M, Peters MV, Hecht S (2007) Nano-architectures by covalent assembly of molecular building blocks. Nat Nano 2:687–691

Zhang Y-Q, Kepčija N, Kleinschrodt M, Diller K, Fischer S, Papageorgiou AC, Allegretti F, Björk J, Klyatskaya S, Klappenberger F, Ruben M, Barth JV (2012) Homo-coupling of terminal alkynes on a noble metal surface. Nat Commun 3:1286

Zwaneveld NAA, Pawlak RM, Abel M, Catalin D, Gigmes D, Bertin D, Porte L (2008) Organized formation of 2D extended covalent organic frameworks at surfaces. JACS 130:6678–6679

Bebensee F, Bombis C, Vadapoo S-R, Cramer JR, Besenbacher F, Gothelf KV, Linderoth TR (2013) On-surface azide–alkyne cycloaddition on Cu(111): does it “click” in ultrahigh vacuum? JACS 135:2136–2139

Otero G, Biddau G, Sanchez-Sanchez C, Caillard R, Lopez MF, Rogero C, Palomares FJ, Cabello N, Basanta MA, Ortega J, Mendez J, Echavarren AM, Perez R, Gomez-Lor B, Martin-Gago JA (2008) Fullerenes from aromatic precursors by surface-catalysed cyclodehydrogenation. Nature 454:865–868

Kanuru VK, Kyriakou G, Beaumont SK, Papageorgiou AC, Watson DJ, Lambert RM (2010) Sonogashira coupling on an extended gold surface in vacuo: reaction of phenylacetylene with iodobenzene on Au(111). JACS 132:8081–8086

Zhong D, Franke J-H, Podiyanachari SK, Blömker T, Zhang H, Kehr G, Erker G, Fuchs H, Chi L (2011) Linear alkane polymerization on a gold surface. Science 334:213–216

Gourdon A (2008) On-surface covalent coupling in ultrahigh vacuum. Angew Chem Int Ed 47:6950–6953

Sakaguchi H, Matsumura H, Gong H, Abouelwafa AM (2005) Direct visualization of the formation of single-molecule conjugated copolymers. Science 310:1002–1006

Lapitan Jr LDS, Tongol BJV, Yau S-L (2012) In situ scanning tunneling microscopy imaging of electropolymerized poly(3,4-ethylenedioxythiophene) on an iodine-modified Au(111) single crystal electrode. Electrochim Acta 62:433–440

Lapitan LDS, Tongol BJV, Yau S-L (2010) Molecular assembly and electropolymerization of 3,4-ethylenedioxythiophene on Au(111) single crystal electrode as probed by in situ electrochemical STM in 0.10 M HClO4. Langmuir 26:10771–10777

Ullmann F, Bielecki J (1901) Ueber synthesen in der biphenylreihe. Ber Dtsch Chem Ges 34:2174–2185

Xi M, Bent BE (1992) Iodobenzene on Cu(111): formation and coupling of adsorbed phenyl groups. Surf Sci 278:19–32

Xi M, Bent BE (1993) Mechanisms of the Ullmann coupling reaction in adsorbed monolayers. JACS 115:7426–7433

Blake MM, Nanayakkara SU, Claridge SA, Fernández-Torres LC, Sykes ECH, Weiss PS (2009) Identifying reactive intermediates in the Ullmann coupling reaction by scanning tunneling microscopy and spectroscopy. J Phys Chem A 113:13167–13172

Lipton-Duffin JA, Ivasenko O, Perepichka DF, Rosei F (2009) Synthesis of polyphenylene molecular wires by surface-confined polymerization. Small 5:592–597

Wang W, Shi X, Wang S, Van Hove MA, Lin N (2011) Single-molecule resolution of an organometallic intermediate in a surface-supported Ullmann coupling reaction. JACS 133:13264–13267

Heim D, Écija D, Seufert K, Auwärter W, Aurisicchio C, Fabbro C, Bonifazi D, Barth JV (2010) Self-assembly of flexible one-dimensional coordination polymers on metal surfaces. JACS 132:6783–6790

Koch M, Gille M, Viertel A, Hecht S, Grill L (2014) Substrate-controlled linking of molecular building blocks: Au(111) vs. Cu(111). Surf Sci 627:70–74

Cardenas L, Gutzler R, Lipton-Duffin J, Fu C, Brusso JL, Dinca LE, Vondracek M, Fagot-Revurat Y, Malterre D, Rosei F, Perepichka DF (2013) Synthesis and electronic structure of a two dimensional [small pi]-conjugated polythiophene. Chem Sci 4:3263–3268

Fan Q, Wang T, Liu L, Zhao J, Zhu J, Gottfried JM (2015) Tribromobenzene on Cu(111): temperature-dependent formation of halogen-bonded, organometallic, and covalent nanostructures. J Chem Phys 142:101906

Fan Q, Wang C, Liu L, Han Y, Zhao J, Zhu J, Kuttner J, Hilt G, Gottfried JM (2014) Covalent, organometallic, and halogen-bonded nanomeshes from tetrabromo-terphenyl by surface-assisted synthesis on Cu(111). J Phys Chem C 118:13018–13025

Eichhorn J, Strunskus T, Rastgoo-Lahrood A, Samanta D, Schmittel M, Lackinger M (2014) On-surface Ullmann polymerization via intermediate organometallic networks on Ag(111). Chem Commun 50:7680–7682

Lafferentz L, Ample F, Yu H, Hecht S, Joachim C, Grill L (2009) Conductance of a single conjugated polymer as a continuous function of its length. Science 323:1193–1197

Bieri M, Treier M, Cai J, Ait-Mansour K, Ruffieux P, Groning O, Groning P, Kastler M, Rieger R, Feng X, Mullen K, Fasel R (2009) Porous graphenes: two-dimensional polymer synthesis with atomic precision. Chem Commun 2009:6919–6921

Weigelt S, Busse C, Bombis C, Knudsen MM, Gothelf KV, Strunskus T, Wöll C, Dahlbom M, Hammer B, Lægsgaard E, Besenbacher F, Linderoth TR (2007) Covalent interlinking of an aldehyde and an amine on a Au(111) surface in ultrahigh vacuum. Angew Chem Int Ed 46:9227–9230

Cordes EH, Jencks WP (1962) On the mechanism of Schiff base formation and hydrolysis. JACS 84:832–837

Weigelt S, Busse C, Bombis C, Knudsen MM, Gothelf KV, Lægsgaard E, Besenbacher F, Linderoth TR (2008) Surface synthesis of 2D branched polymer nanostructures. Angew Chem 120:4478–4482

Weigelt S, Bombis C, Busse C, Knudsen MM, Gothelf KV, Lægsgaard E, Besenbacher F, Linderoth TR (2008) Molecular self-assembly from building blocks synthesized on a surface in ultrahigh vacuum: kinetic control and topo-chemical reactions. ACS Nano 2:651–660

El-Kaderi HM, Hunt JR, Mendoza-Cortés JL, Côté AP, Taylor RE, O'Keeffe M, Yaghi OM (2007) Designed synthesis of 3D covalent organic frameworks. Science 316:268–272

Côté AP, El-Kaderi HM, Furukawa H, Hunt JR, Yaghi OM (2007) Reticular synthesis of microporous and mesoporous 2D covalent organic frameworks. JACS 129:12914–12915

Ourdjini O, Pawlak R, Abel M, Clair S, Chen L, Bergeon N, Sassi M, Oison V, Debierre J-M, Coratger R, Porte L (2011) Substrate-mediated ordering and defect analysis of a surface covalent organic framework. Phys Rev B 84:125421

Clair S, Ourdjini O, Abel M, Porte L (2011) Tip- or electron beam-induced surface polymerization. Chem Commun 47:8028–8030

Streitwieser A, Heathcock CH (1985) Introduction to organic chemistry. Macmillan, New York

In’t Veld M, Iavicoli P, Haq S, Amabilino DB, Raval R (2008) Unique intermolecular reaction of simple porphyrins at a metal surface gives covalent nanostructures. Chem Commun 2008:1536–1538

Wiengarten A, Seufert K, Auwärter W, Ecija D, Diller K, Allegretti F, Bischoff F, Fischer S, Duncan DA, Papageorgiou AC, Klappenberger F, Acres RG, Ngo TH, Barth JV (2014) Surface-assisted dehydrogenative homocoupling of porphine molecules. JACS 136:9346–9354

Simpson CD, Mattersteig G, Martin K, Gherghel L, Bauer RE, Räder HJ, Müllen K (2004) Nanosized molecular propellers by cyclodehydrogenation of polyphenylene dendrimers. JACS 126:3139–3147

Cai J, Ruffieux P, Jaafar R, Bieri M, Braun T, Blankenburg S, Muoth M, Seitsonen AP, Saleh M, Feng X, Mullen K, Fasel R (2010) Atomically precise bottom-up fabrication of graphene nanoribbons. Nature 466:470–473

Chen Y-C, Cao T, Chen C, Pedramrazi Z, Haberer D, de OteyzaDimas G, Fischer FR, Louie SG, Crommie MF (2015) Molecular bandgap engineering of bottom-up synthesized graphene nanoribbon heterojunctions. Nat Nano 10:156–160

Rogers C, Chen C, Pedramrazi Z, Omrani AA, Tsai H-Z, Jung HS, Lin S, Crommie MF, Fischer FR (2015) Closing the nanographene gap: surface-assisted synthesis of peripentacene from 6,6′-bipentacene precursors. Angew Chem Int Ed 54:15143–15146

Björk J, Stafström S, Hanke F (2011) Zipping up: cooperativity drives the synthesis of graphene nanoribbons. JACS 133:14884–14887

Treier M, Pignedoli CA, Laino T, Rieger R, Müllen K, Passerone D, Fasel R (2011) Surface-assisted cyclodehydrogenation provides a synthetic route towards easily processable and chemically tailored nanographenes. Nat Chem 3:61–67

Mendez J, Lopez MF, Martin-Gago JA (2011) On-surface synthesis of cyclic organic molecules. Chem Soc Rev 40:4578–4590

Scott LT, Boorum MM, McMahon BJ, Hagen S, Mack J, Blank J, Wegner H, de Meijere A (2002) A rational chemical synthesis of C60. Science 295:1500–1503

Gómez-Lor B, Echavarren AM (2004) Synthesis of a triaza analogue of crushed-fullerene by intramolecular palladium-catalyzed arylation. Org Lett 6:2993–2996

Amsharov K, Abdurakhmanova N, Stepanow S, Rauschenbach S, Jansen M, Kern K (2010) Towards the isomer-specific synthesis of higher fullerenes and buckybowls by the surface-catalyzed cyclodehydrogenation of aromatic precursors. Angew Chem Int Ed 49:9392–9396

Hay AS (1962) Oxidative coupling of acetylenes. II1. J Org Chem 27:3320–3321

Eichhorn J, Heckl WM, Lackinger M (2013) On-surface polymerization of 1,4-diethynylbenzene on Cu(111). Chem Commun 49:2900–2902

Gao H-Y, Wagner H, Zhong D, Franke J-H, Studer A, Fuchs H (2013) Glaser coupling at metal surfaces. Angew Chem Int Ed 52:4024–4028

Sánchez-Sánchez C, Yubero F, González-Elipe AR, Feria L, Sanz JF, Lambert RM (2014) The Flexible surface revisited: adsorbate-induced reconstruction, homocoupling, and Sonogashira cross-coupling on the Au(100) surface. J Phys Chem C 118:11677–11684

Yokoyama T, Yokoyama S, Kamikado T, Okuno Y, Mashiko S (2001) Selective assembly on a surface of supramolecular aggregates with controlled size and shape. Nature 413:619–621

Díaz Arado O, Mönig H, Wagner H, Franke J-H, Langewisch G, Held PA, Studer A, Fuchs H (2013) On-surface azide–alkyne cycloaddition on Au(111). ACS Nano 7:8509–8515

Treier M, Richardson NV, Fasel R (2008) Fabrication of surface-supported low-dimensional polyimide networks. JACS 130:14054–14055

Marele AC, Mas-Balleste R, Terracciano L, Rodriguez-Fernandez J, Berlanga I, Alexandre SS, Otero R, Gallego JM, Zamora F, Gomez-Rodriguez JM (2012) Formation of a surface covalent organic framework based on polyester condensation. Chem Commun 48:6779–6781

de Oteyza DG, Gorman P, Chen Y-C, Wickenburg S, Riss A, Mowbray DJ, Etkin G, Pedramrazi Z, Tsai H-Z, Rubio A, Crommie MF, Fischer FR (2013) Direct imaging of covalent bond structure in single-molecule chemical reactions. Science 340:1434–1437

Sun Q, Zhang C, Li Z, Kong H, Tan Q, Hu A, Xu W (2013) On-surface formation of one-dimensional polyphenylene through Bergman cyclization. JACS 135:8448–8451

Liu J, Lam JWY, Tang BZ (2009) Acetylenic polymers: syntheses, structures, and functions. Chem Rev 109:5799–5867

Dong H, Zheng R, Lam JWY, Häussler M, Qin A, Tang BZ (2005) A New Route to hyperbranched macromolecules: syntheses of photosensitive poly(aroylarylene)s via 1,3,5-regioselective polycyclotrimerization of bis(aroylacetylene)s. Macromolecules 38:6382–6391

Yang B, Björk J, Lin H, Zhang X, Zhang H, Li Y, Fan J, Li Q, Chi L (2015) Synthesis of surface covalent organic frameworks via dimerization and cyclotrimerization of acetyls. JACS 137:4904–4907

Bieri M, Nguyen M-T, Gröning O, Cai J, Treier M, Aït-Mansour K, Ruffieux P, Pignedoli CA, Passerone D, Kastler M, Müllen K, Fasel R (2010) Two-dimensional polymer formation on surfaces: insight into the roles of precursor mobility and reactivity. JACS 132:16669–16676

Hammer BN, Norskov JK (2000) Theoretical surface science and catalysis—calculations and concepts. In: Gates B, Knoezinger H (eds) Advances in catalysis, vol 45. Academic, San Diego 2000, pp 71–129

Chen M, Xiao J, Steinrück H-P, Wang S, Wang W, Lin N, Hieringer W, Gottfried JM (2014) Combined photoemission and scanning tunneling microscopy study of the surface-assisted Ullmann coupling reaction. J Phys Chem C 118:6820–6830

Chung K-H, Koo B-G, Kim H, Yoon JK, Kim J-H, Kwon Y-K, Kahng S-J (2012) Electronic structures of one-dimensional metal-molecule hybrid chains studied using scanning tunneling microscopy and density functional theory. Phys Chem Chem Phys 14:7304–7308

Zhang H, Franke J-H, Zhong D, Li Y, Timmer A, Arado OD, Mönig H, Wang H, Chi L, Wang Z, Müllen K, Fuchs H (2013) Surface supported gold–organic hybrids: on-surface synthesis and surface directed orientation. Small 10:1361–1368

Zhang H, Lin H, Sun K, Chen L, Zagranyarski Y, Aghdassi N, Duhm S, Li Q, Zhong D, Li Y, Müllen K, Fuchs H, Chi L (2015) On-surface synthesis of rylene-type graphene nanoribbons. JACS 137:4022–4025

Walch H, Gutzler R, Sirtl T, Eder G, Lackinger M (2010) Material- and orientation-dependent reactivity for heterogeneously catalyzed carbon−bromine bond homolysis. J Phys Chem C 114:12604–12609

Matena M, Riehm T, Stöhr M, Jung TA, Gade LH (2008) Transforming surface coordination polymers into covalent surface polymers: linked polycondensed aromatics through oligomerization of N-heterocyclic carbene intermediates. Angew Chem Int Ed 47:2414–2417

Kolmer M, Ahmad Zebari AA, Prauzner-Bechcicki JS, Piskorz W, Zasada F, Godlewski S, Such B, Sojka Z, Szymonski M (2013) Polymerization of polyanthrylene on a titanium dioxide (011)-(2×1) surface. Angew Chem 125:10490–10493

Gutzler R, Walch H, Eder G, Kloft S, Heckl WM, Lackinger M (2009) Surface mediated synthesis of 2D covalent organic frameworks: 1,3,5-tris(4-bromophenyl)benzene on graphite(001), Cu(111), and Ag(110). Chem Commun 2009:4456

Bombis C, Ample F, Lafferentz L, Yu H, Hecht S, Joachim C, Grill L (2009) Single molecular wires connecting metallic and insulating surface areas. Angew Chem Int Ed 48:9966–9970

Abel M, Clair S, Ourdjini O, Mossoyan M, Porte L (2010) Single layer of polymeric Fe-phthalocyanine: an organometallic sheet on metal and thin insulating film. JACS 133:1203–1205

Kittelmann M, Nimmrich M, Lindner R, Gourdon A, Kühnle A (2013) Sequential and site-specific on-surface synthesis on a bulk insulator. ACS Nano 7:5614–5620

Kittelmann M, Rahe P, Nimmrich M, Hauke CM, Gourdon A, Kühnle A (2011) On-surface covalent linking of organic building blocks on a bulk insulator. ACS Nano 5:8420–8425

Blunt MO, Russell JC, Champness NR, Beton PH (2010) Templating molecular adsorption using a covalent organic framework. Chem Commun 46:7157–7159

Bennett PB, Pedramrazi Z, Madani A, Chen Y-C, de Oteyza DG, Chen C, Fischer FR, Crommie MF, Bokor J (2013) Bottom-up graphene nanoribbon field-effect transistors. Appl Phys Lett 103:253114

Faury T, Clair S, Abel M, Dumur F, Gigmes D, Porte L (2012) Sequential linking to control growth of a surface covalent organic framework. J Phys Chem C 116:4819–4823

Guan C-Z, Wang D, Wan L-J (2012) Construction and repair of highly ordered 2D covalent networks by chemical equilibrium regulation. Chem Commun 48:2943–2945

Liu X-H, Guan C-Z, Ding S-Y, Wang W, Yan H-J, Wang D, Wan L-J (2013) On-surface synthesis of single-layered two-dimensional covalent organic frameworks via solid–vapor interface reactions. JACS 135:10470–10474

Xu L, Zhou X, Yu Y, Tian WQ, Ma J, Lei S (2013) Surface-confined crystalline two-dimensional covalent organic frameworks via on-surface schiff-base coupling. ACS Nano 7:8066–8073

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Wang, H., Zhang, H., Chi, L. (2017). Surface-Assisted Reaction Under Ultrahigh Vacuum Conditions. In: Müllen, K., Feng, X. (eds) From Polyphenylenes to Nanographenes and Graphene Nanoribbons. Advances in Polymer Science, vol 278. Springer, Cham. https://doi.org/10.1007/12_2017_3

Download citation

DOI: https://doi.org/10.1007/12_2017_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-64169-0

Online ISBN: 978-3-319-64170-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)