Abstract

The emerging technique of microfluidics offers new approaches for precisely controlling fluidic conditions on a small scale, while simultaneously facilitating data collection in both high-throughput and quantitative manners. As such, the so-called lab-on-a-chip (LOC) systems have the potential to revolutionize the field of biotechnology. But what needs to happen in order to truly integrate them into routine biotechnological applications? In this chapter, some of the most promising applications of microfluidic technology within the field of biotechnology are surveyed, and a few strategies for overcoming current challenges posed by microfluidic LOC systems are examined. In addition, we also discuss the intensifying trend (across all biotechnology fields) of using point-of-use applications which is being facilitated by new technological achievements.

Graphical Abstract

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Biochemical engineering

- Industrial biotechnology

- Lab-on-a-chip

- Medical biotechnology

- Microfluidic screening

- Microfluidics

- Nanofluidics

- Organ-on-a-chip

- Point-of-care

- Point-of-use

1 Introduction

The application of microfluidic systems in biotechnology has recently become a subject of intense research interest [1, 2]. Emerging research and industrial applications include point-of-care medical diagnostics [3], organ-on-a-chip [4], and multiresistant bacteria testing [5] via microbioreactors [6] in red biotechnology. In white biotechnology, current approaches include catalysis, single-cell culture [7, 8], and droplet-based screening [9] through integrated biosensors and other analytics in miniaturized devices. Nevertheless, many microfluidic applications still depend on proof-of-concept systems, which have not yet realized their full potential. Accordingly, one of the most pressing challenges that will need to be addressed over the next few years is how to efficiently and effectively transform these systems into routine applications that can actually be advanced into the market and, ideally, exceed the “gold standards” that currently exist in the field.

But how does this process look like? What, exactly, does it entail? In this review, the current state of the art of microfluidic systems is surveyed, with the aim of highlighting some of the most promising applications that have been developed to date. Furthermore, we identify and consider a number of pressing challenges that must be addressed before the full potential of this emerging technology can be realized within the field of biotechnology – and a few emerging applications and technologies are also highlighted to illustrate how (taken together) they might be leveraged to create superior microfluidic devices in the near future. Finally, we offer a few cautious predictions regarding how microfluidic systems might shape biotechnology in the future.

2 Main Fields of Microfluidics in Biotechnology and Their Realized Potential

There is an enormous variety of microfluidic systems currently being deployed in the field of biotechnology research – although lab-on-a-chip (LOC) is frequently employed as an umbrella term to broadly describe all of these microfluidic-based biotechnologies. By way of example, some of these systems include PCR-, genomics-, proteomics-, diagnosis-, catalysis-, transfection-, organ-, human-, tumor-, electrophoresis-, differentiation-, microscopy-, and bioreactors-on-a-chip. While most LOCs remain locked in the proof-of-concept phase, over the last decade a few have made advancements into the broader market. The commercial potential of LOCs has thus already been partially realized, in the form of aspiring start-ups and commercially available devices – although the present state of affairs only hits at the tremendous future potential for deploying LOCs within routine biotechnological applications. In this review, we have identified 350 companies that have begun to explore incorporating microfluidics into biotechnological applications (Fig. 1), with the particular focus on microfluidic devices in the following application areas in biotechnology: clinical applications, including point-of-care (POC) devices and other devices for clinical diagnosis; screening techniques; cell manipulation and analysis, such as single-cell sorting; genetics and genomics, with established technologies like PCR-on-a-chip; bioanalytics and biosensors; and organ-on-a-chip (OOC), among others.

Overview of the development of companies offering microfluidics for application in biotechnology over the past 20 years. This figure is based on an extensive market research, which the authors have carried out consistently (based on the references [10,11,12]) in 2020 and reflects only a trend in company development. The authors provide no guarantee for the exact number of existing companies focusing on microfluidics for biotechnological applications

The number of companies developing microfluidic systems for biotechnological application is now growing significantly. The first companies in this field primarily focused on diagnostic devices and gene analysis systems (see Fig. 1, “Clinical Applications (POC/Diagnosis)” and “Genetics and Genomics”). This is not surprising, taking into account that the first microfluidic breakthroughs in the world of biotechnology were achieved in these fields. Driven by the human genome project, capillary electrophoresis technology (a predecessor to the electrophoresis-on-a-chip) was invented to increase DNA sequencing speed and throughput [13]. Not only the sequencing, but also the powerful technology of PCR has been successfully miniaturized [14]. PCR-on-a-chip technology has developed rapidly in recent years, and these days more advanced technologies that build on this foundation – such as the digital PCR (dPCR) (Fig. 2) [16, 17] – are actually beginning to replace longstanding non-microfluidic “gold standards” such as quantitative PCR (qPCR).

The principle of digital PCR. In the first step, droplet microfluidics is used to distribute the DNA molecules in independent droplets. After the PCR, only droplets containing DNA are detected by fluorescence measurements. The distribution of DNA in the droplets follows a Poisson’s distribution that is finally used to calculate the DNA quantity. Translated with permission from J. Bahnemann and A. Grünberger [15], Copyright (2021), Zukunftsforum Biotechnologie (Hrsg.), DECHEMA e.V. Frankfurt/M. (2021)

Companies have also increasingly started to deploy these technologies in more commercially profitable endeavors, that is the development of POC diagnostics (Fig. 3). The potent combination of advanced liquid handling features – such as pumping, mixing, and separation – with gene analysis techniques, and the potential for usage in highly rentable clinical studies, has led to a veritable explosion of microfluidic POC start-up companies. Indeed, POC devices (see chapter: “Lab-on-a-Chip Devices for Point-of-Care Medical Diagnostics” [3]) currently constitute the single largest market for LOCs in biotechnologies.

Example of a microfluidic point-of-care device. A patient sample, such as blood, saliva, or urine, is processed and analyzed using a microfluidic chip. The chip contains a biosensor for detection of biologic markers and is read out and analyzed by a connected smartphone. Reprinted from Samandari et al. [18] (Copyright (2018), with permission from Elsevier)

The discovery of droplet microfluidics has facilitated the emerging field of single-cell analytics (Fig. 4). In the last years, droplet microfluidics has been applied to cell sorting [19], mammalian cell analysis [20, 21], microorganism analysis [22], and single-cell drug screening [23]. In addition, developments in the field of droplet microfluidics have also led to advancements in microfluidic ultra-high-throughput screening [24]. One major push on this front is to replace the current well-plate drug screening process commonly used in the pharmaceutical industry by droplet microfluidics.

Principle of single-cell analysis using droplet microfluidics. Herein, droplet microfluidics is used to singularize different types or strains of bacteria of a library in droplets followed by single-cell analysis and identification of potent cells for optimization of a specific bioprocess. Translated with permission from J. Bahnemann and A. Grünberger [15], Copyright (2021), Zukunftsforum Biotechnologie (Hrsg.), DECHEMA e.V. Frankfurt/M. (2021)

As illustrated in the chart shown in Fig. 1, there are also companies working in the field of bioanalytics and biosensors. These companies offer an ever-increasing set of diverse analytical tools – from biosensors for environmental or animal applications to novel microfluidic modulation spectrometers [25], microfluidic resistive pulse sensing [26], sub-terahertz (THz) vibrational spectroscopy [27], optical microcavity technologies [28], to name but a few.

OOC applications represent perhaps the latest – and certainly the most advanced – application of this technology. OOCs combine tissue engineering with microfluidics to achieve complex 2D or 3D cellular systems [4]. Due to their exciting potential to revolutionize drug testing protocols and minimize costs associated with drug failure in the clinical stages (which is unfortunately extremely common), multiple start-ups have charged into the market in this area [29]. Furthermore, these systems can also be further refined into disease-on-a-chip (DOC) systems, which may be able to provide researchers entirely new insights into pathological processes. Even human-on-a-chip systems are now being developed. In principle, these systems combine several OOCs containing different human cells in a single chip to simulate even the most complex human physiological processes (Fig. 5).

Principle of the human-on-a-chip. The human-on-a-chip mimics human physiological processes by connecting and maintaining several different organ-on-a-chip systems in a single microfluidic chip. With permission from Springer International Publishing: Bahnemann et al. [30], Copyright (2021)

As the illustrated examples demonstrate, microfluidics is currently experiencing a significant breakthrough period within the field of biotechnology. The sheer scope and diversity of the adoption of this technology in this field is perhaps most starkly underlined by the fact that the fraction of “unassignable” companies (see Fig. 1, “Others”) is increasing rapidly. At the same time, however, microfluidics unquestionably still remains in its infancy – indeed, many LOCs exist only in the form of proof-of-concept systems [31]. With inconvenient handling requirements, comparatively low robustness, complex standards, and bulky hardware, LOCs are often derided as complicated “chip-in-a-lab” systems [32]. Accordingly, beyond the few commercially available systems, most published microfluidic devices still suffer from a low technological readiness level (TRL) of just 3–4 points out of a 12-point scale [32]. Even comparatively established technologies in this area – such as POC testing – have a long way to go before their full potential will be realized. Critical challenges continue to plague researchers and developers, and must be adequately addressed before microfluidic routine applications can truly replace the current “gold standards” in biotechnology.

3 Challenges and Solutions for Microfluidic Proof-of-Concept Systems in Biotechnology

In the last 20–30 years, the applications of microfluidic technologies have been pioneered in research areas such as microsystems engineering, physics, chemistry, and biology. This has led to the development of a wide array of promising proof-of-concept systems, which primarily seek to miniaturize and automatize existing lab procedures in a LOC format. But the central question now faced by this maturing industry is whether these systems actually confer any true advantage over the “gold standards” that are currently being used in these areas. Three major challenges – summarized in Fig. 6 – that continue to plague microfluidic proof-of-concept systems and early commercialized devices are identified and discussed below.

3.1 Design and Fabrication

The first key obstacle for the development and deployment of microfluidic devices for biotechnological applications has been the relatively limited access that researchers actually have to microfluidic fabrication facilities [33,34,35]. As reported by Kotz et al. [36], a number of fabrication techniques have been developed for manufacturing microfluidic devices. Perhaps the most widely used are molding techniques – including, for example, hot embossing, injection molding, and soft lithography – and laminates. While these techniques represent a solid foundation for the production of three-dimensional microfluidic structures, they are also extremely laborious and costly [31]. As a result, only engineers and microsystems technicians who are already experts in the field of microfluidics tend to be comfortable deploying them, whereas experts in the fields of their intended substantive application – such as biologists and biochemists – can generally contribute little to their development. In addition, the complicated and time-consuming developmental process of these fabrication techniques creates an understandable reluctance to implement many small, but often useful, improvements. One potential solution is showcased in the latest advances in additive manufacturing [31, 37,38,39,40].

Design and fabrication through these methods are comparatively much simpler, and 3D printers are far more affordable than classic clean room facilities. Furthermore, one early concern with respect to this method – that the printing resolution would be too low – has effectively been mitigated through recent advancements in multijet printing [41], stereolithography, and two-photon laser techniques (which are now reaching the micrometer and even nanometer scale). As the number of 3D printers is increasing, so are the number of different 3D printing materials that can be used.

Especially for biological applications, materials (such as acrylates or silicones) that are biocompatible are increasingly being brought onto the market [42,43,44]. Although many high-resolution 3D printers remain limited for fabrications employing just a single material, in the last few years, tremendous efforts have been made to achieve multimaterial 3D printing [45] or multiprocess 3D printing (as well as print-pause-print (PPP) 3D printing) [46]. The successful integration of sealing connections (e.g., elastic silicones), movable functional units (e.g., microvalves or micropumps [47]), porous barriers (e.g., porous membranes [48]), electronic components (e.g., electrochemical sensors [49, 50], heating/cooling elements [51], magnetic elements [52], and cupper fibers for dielectrophoresis [53]) – and even the implementation of chemical reagents [54, 55] solely by 3D printing – has already been well demonstrated in the literature. Because multimaterial 3D printing is of significant interest for many other industries, we will likely see further advances within this field in the years to come.

3.2 Handling

As one might expect, realizing the vision of miniaturizing very complex multi-step lab procedures into a simple LOC has also turned out to be a very challenging endeavor. At the micro- or nano-scale, even the smallest disturbances – such as dust particles, air bubbles, vibrations, leaking interconnections, leachables, etc. – can lead to dysfunction of the whole chip, necessitating time-consuming and expensive repair (or even replacement) efforts. The robustness of any LOC is thus a crucial component of consideration [56], and this is only all the more true when the system in question will be used not by a trained scientist, but rather by untrained people (such as students or even patients) as in the so-called easy-to-use POC devices.

Improving the robustness of future LOC devices can be best achieved by replacing actively controlled units, such as pumps and valves, with passively controlled elements that are incorporated directly into the design of the chip itself (Fig. 7). Paper-based POC devices have already illustrated how this can be realized by using microcapillary forces that induce a passively controlled flow [58]. These flow speeds depend on the kind of adsorption material used, which can be determined during the design process. Similarly, centrifugal POC devices use predefined channel sizes to convert centrifugal forces into well-defined liquid flow. The so-called passive check and burst valves allow a more complex design of the fluid circuit. And complex processes can also be completely controlled by either the chip design or by a few external actuators. The concept of passive control can be transferred into any application where easy handling and automatization is needed – and since many protocols for preparative or analytical applications in biotechnology follow predictable steps that are always the same, this is a logical fit.

Different approaches employed in passively driven microfluidics and LOC devices. All techniques are actuated by a single driving force that is controlled by specific structural elements for precise control of flow, mixing events, and other LOC operations. Reproduced from Ref. [57] with permission from The Royal Society of Chemistry

Adoption of this principle is currently a prime focus of the so-called microfluidic circuits or microfluidic networks [59]. These networks seek to transfer Ohm’s law (U = I·R) of electric resistance into the field of microfluidics, where the resistance R corresponds to the microfluidic channel resistance, the intensity I to the flow-rate, and the potential U to the pressure [60]. In theory, this means that the flow can be controlled by the channel resistance, the channel resistance in turn by the channel geometry, and the channel geometry by the chip design and fabrication. Using these built-in control features, a manufacturer can theoretically exert maximum control of the process – to the point where, at least ideally, an unexperienced end user may only need to push a start-button. This principle can also be further extended to achieve time-dependent LOC control (e.g., where a specific valve only opens when an increasing pressure gradient reaches a critical value, etc.). Duncan et al. have already used a constant and single vacuum source in combination with microvalves and resistors to achieve oscillating microvalves, which, in principle, could function as a membrane-based micropump [61]. Furthermore, slower or faster oscillations could certainly be achieved by adaptation of the resistors, leading to different pump speeds. Just like in electronic chips, these oscillators could theoretically be further used to induce rhythms that activate several LOC procedures after a specific time or after a single externally controlled event (such as a simple valve opening).

None of the above-mentioned methods can currently control complete LOC procedures. However, although they are still in their infancy, these methods already demonstrate the high potential of passively controlled microfluidics for easy-to-use but fully automated LOCs – as illustrated by the possibility that a sophisticated design of a microfluidic chip could (for example) be harnessed to upgrade a microvalve to a micropump without losing robustness. In contrast, classic pneumatic micropumps are controlled by at least two pressure or vacuum sources [62], which are in turn controlled by external valves constituting a serious additional risk for device dysfunctionalities.

3.3 Standardization

In principle, the primary purpose of LOC technologies is to transfer research in the fields of biology and chemistry into our modern world of machines, computers, and data. This requires tremendous interdisciplinary input from scientists across a wide range of fields, all leveraging and combining their specific areas of substantive knowledge to design, manufacture, functionalize, automize, and deploy sophisticated LOCs. On the one hand, this interdisciplinarity push has led to a huge variety in LOC devices while, on the other hand, it has also led to veritable confusion in the form of a seemingly endless number of different fabrication techniques, design concepts, ways of flow control, integration techniques, etc. Successful mass-market incorporation of microfluidics technology into biotechnological applications will ultimately require the adoption of standardization concepts (e.g., ISO standards, protocols and guidelines to organize the pioneered knowledge into a common microfluidic language, etc.) in order to allow researchers from all fields to meaningfully understand and contribute to future LOC development by adopting high level good manufacturing practice (GMP) standards in most fields of biotechnology. This standardization will also allow biologists to consider fabrication and design rules (such as material properties and microchannel characteristics), and engineers to consider biological demands (such as maximal shear flow, biocompatibility and more), and to allow both groups to effectively communicate their own needs using a common language of sorts [63].

For very basic operations (such as pumping, mixing, and separation), microfluidic solutions have already been developed that can be further characterized and classified to develop a database of microfluidic operators. This modularity is crucial to facilitate faster design and configuration via plug-and-play processes [31]. Once again, drawing on analogies to the field of mechanics, these modules could be saved as 3D computer-aided design (CAD) files – although, of course, new software must still be developed to enable the proper and efficient use of these files. 3D printing of microfluidic devices, in particular, could further push the standardization of LOC modules. Additionally, there is a need for standardization efforts regarding the chip-to-world interface [64]. Currently, many proof-of-concept systems use diverse kinds of tube connections, pumps, control units, and more. For industrial applications (such as drug screening), however, LOCs must be easily implementable into existing processes and standards.

4 Emerging LOCs: From the Lab to the Chip

One focus of current microfluidics development aims to miniaturize biotechnological workflows “to the chip,” in order to take advantage of greatly improved workflows that are realizable via miniaturization and/or automatization. In principle, this holds true not just for classical LOCs procedures (such as the PCR), but also for newer biotechnological methods (see following subchapters). The huge variety of possible LOCs cannot be summed up in a single book chapter; therefore, in this section, we focus only on a subset of novel LOCs that show a high potential for further revolutionizing biotechnologies.

4.1 Directed Evolution and Adapted Laboratory Evolution

In 2018, the Nobel Prize in Chemistry was awarded to Frances H. Arnold for her pioneering achievements in directed evolution. The techniques that she spearheaded have helped to optimize reactions by developing faster, more specific, more stable, and/or more sensitive enzymes [65]. These advances are of particular interest for large industries focused on improving or streamlining the performance of bioprocesses. Using the phenomenon of mutagenesis, enzymes can be either specifically or randomly modified to create mutant libraries, which can then be subsequently screened to identify improved enzyme abilities. The last step remains a challenging task – and LOC platforms that make use of droplet screening, in combination with advanced droplet sorting systems, are ideal tools for efficiently screening mutant libraries to identify enzymes with enantio-selectivity or high catalytic activity in ultrahigh-throughput [66]. Organisms (such as Escherichia coli) that express the mutant enzymes may also be singularized in droplets, lysed, analyzed, and sorted. Such systems could even be further extended by LOC-based transformation or transfection, to re-cultivate promising mutants. It also bears noting that the high-throughput and automatization properties of directed evolution on-chip would contribute to a greater understanding of enzyme mechanisms and evolution processes in general.

4.2 “CRISPR-on-a-Chip” (COC)

Emmanuelle Charpentier and Jennifer A. Doudna were honored with the Nobel Prize for Chemistry in 2020 for their outstanding scientific achievement in developing the CRISPR-Cas (Clustered Regularly Interspaced Short Palindromic Repeats) method for gene editing. The discovery of the so-called gene scissor represents a fundamental breakthrough in the field of molecular biology, and is expected to tremendously change life sciences in the years to come [67, 68] – just like DNA sequencing and PCR have done in previous decades. Indeed, researchers have already started to use this technique in microfluidic platforms [69], predominantly for on-chip point-of-care gene detection with CRISPR-based gene biosensors or automated gene editing in LOCs.

One recently developed chip uses a graphene field-effect transistor, in combination with a deactivated CRISPR-Cas9 protein complexed with a specific single-guide RNA, to achieve the unmediated detection of a specific gene on-chip (Fig. 8a) [70]. In contrast to PCR, this system can abstain from gene amplification and leverage CRISPR technology to create gene biosensors. By implementing biosensors into future COCs, this technique could potentially be used to screen large numbers of mutations for detecting diseases in a microarray – and the quantification of gene expression could also be applied to clusters of genes for a completely new molecular understanding of gene regulation and other basic mechanisms (such as cell differentiation), which in turn might be used for the development of novel drugs.

CRISPR-on-a-chip. (a) CRISPR-Cas9 for unamplified gene detection in biosensors. The Cas9 complexed with a target-specific guide RNA is immobilized on the surface of the graphene within a graphene field-effect transistor. The complex identifies and binds to the target gene, resulting in an electrical signal output. Adapted by permission from Springer Nature: Nature Biomedical Engineering, Hajian et al. [70], copyright, 2020. (b) An automated CRISPR-based gene editing platform. Designed plasmids (1) are used for gene editing of cell cultures inside a microfluidic chip (2, 3) and results are analyzed by microscopy (4). The computer-controlled chip is based on digital microfluidics for dispersion, merging, mixing, and splitting of droplets. Reproduced from Ref. [71] with permission from The Royal Society of Chemistry

In combination with microfluidics, the CRISPR-Cas9 system may also be used to automatize gene editing. A recent approach combines digital microfluidics with the CRISPR-Cas9 technique for on-chip gene editing of cell cultures (Fig. 8b) [71]. Similar platforms could enable multiplexing and high-throughput gene editing in future, opening up theoretically endless application possibilities across many diverse subfields in the biotechnology sphere.

4.3 Organisms-on-a-Chip

After single-cell analysis and organs-on-a-chip, the “next level of life” is represented in the emerging “organisms-on-a-chip” technology. Similar to organs-on-a-chip, organisms-on-a-chip can be used for drug testing, diagnosis, or simply to understand biochemical and physiological processes. Prominent examples thereof are the nematode Caenorhabditis elegans [72], the malaria parasite Plasmodium falciparum [73], and the zebrafish [74]. Plants-on-a-chip [75] and roots-on-a-chip [76] have also been developed in the field of green biotechnology, while for blue biotechnology corals-on-a-chip are being developed [77]. It can simply be stated that the opportunities for future organisms-on-a-chip systems are essentially endless – although to date, few avenues have truly been explored in this emerging field. One challenge is the difficulty of adequately emulating natural as well as defined artificial environments [78, 79] to enable detailed fundamental insights regarding an organism’s overall behavioral pattern.

5 Future LOC Technologies: From Lab Applications to Point-of-Use Solutions

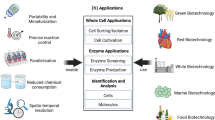

The dawning of the twenty-first century has ushered in the so-called information age, and the immediate access to comprehensive information enabled by this incredible technological revolution in computing will only become increasingly important in the years to come. Industrial applications are already promoting on-demand and easy-to-use technologies. Smartphones, for example, have demonstrated the enormous benefit of immediate information exchange. POC devices remain perhaps the best examples, to date, of similar efforts to leverage microfluidic biotechnologies for rapid extraction of information via implemented analytics – however, in the future, this trend will not be limited to POC and other red biotechnological analytic devices, but will instead almost certainly expand to all biotechnology fields in the form of point-of-use applications (Fig. 9). Accordingly, in the following we will discuss three central LOC technologies representing advancements of current microfluidic lab applications to point-of-use analytics in all aspects of biotechnology.

Microfluidic devices in biotechnology: From microfluidic lab applications to microfluidic point-of-use. Advances in microfluidics, analytics, and digitalization will accelerate the trend to advanced microfluidic devices – available at the point-of-use. These point-of-use systems will rapidly expand to large biotechnological application fields, such as research, healthcare, food safety, environment protection, and agriculture

5.1 Advanced Microfluidic Technologies

Point-of-use applications require robust LOCs based on easy-to-use working principles. As described above, passively actuated LOCs (such as paper, centrifugal, and capillary microfluidics) further these goals by increasing the level of automatization within the system. Another emerging technology that also exhibits great potential to automate actively controlled LOCs is digital microfluidics based on the concept of electrowetting. Electrowetting – originally developed for displays and lenses – uses electrodes that, when activated, increase hydrophilicity. Consequently, droplets of liquids can be freely controlled in two dimensions and mixed, incubated, or divided using digital commands [80]. These very basic operations in turn facilitate greater automatization of lab procedures. In addition, the electronic (i.e., digital) control of droplets also makes it easier to connect and control electrowetting-based LOCs with smartphones. Because LOCs always benefit from advances in liquid handling within the system, this technique is increasingly being leveraged within new microfluidic applications [80].

LOCs must also offer as many functionalities as possible to meet the complex demands of endless possible point-of-use applications – and the nascent field of nanofluidics offers even greater promise for further expansion of microfluidic functions [81, 82]. Due to substantial recent improvements in device fabrication, LOCs have now reached the nanometer and even sub-nanometer scale. This does not simply result in advantages such as the further increase in throughput; it also introduces both molecular and quantum effects, as well as special fluid phenomena not seen in macroscale systems [82]. These effects include (for example) faster flow of water in nanotubes and faster ion transport, both of which can be used for biological or biotechnological purposes. For example, nanochannels have already been designed to mimic the high water permeability and selectivity of aquaporins [83], and artificial carbon nanotube molecular transport systems have been designed that mimic the process seen in proteins transported across cell membranes [84].

5.2 Advanced Miniaturized Analytics

Aside from microfluidic technologies, implementable analytics are also essential for advancing to omnifarious point-of-use systems. Biosensors are currently the analytical tools of choice in this regard [44, 85]. They typically contain biological catalytic recognition elements (such as enzymes, antibodies, aptamers [86], peptides, cells, or molecularly imprinted polymers) and a transducer (which is typically electrochemical, optical, acoustic, or gravimetric in nature) [87, 88]. Transducer technology in particular has been rapidly advancing, to the point where nanoresonators, localized surface plasmon resonance (LSPR) [89], surface acoustic waves (SAW) [90], optical fibers [91], photonic crystals [92], and quartz crystal microbalances (QCM) [93] are now all being miniaturized into an on-chip format. But biosensors may not be the tool of choice in the future – emerging analytics such as microscopy-on-a-chip [94, 95], terahertz spectroscopy [96], and field asymmetric ion mobility spectrometry (FAIMS) all show tremendous promise on this front [97]. As soon as it comes to identification and quantification of analytes in complex samples, however, state-of-the-art analytics such as mass spectrometry, Raman-, NMR-, or IR-spectroscopy remain indispensable. Although attempts have been made to miniaturize mass spectrometers [98], NMR- [99], IR- [100], and Raman spectrometers [99], miniaturized building components are often not commercially available yet. Nevertheless, the current trend to point-of-use applications may well create a market for such parts, which would thereby facilitate the future miniaturization of high-end analytics.

5.3 Digitalization: Machine Learning, Neuronal Networks, and Artificial Intelligence

The capacity for high-throughput analysis within microfluidic devices, in combination with advanced analytics, can quickly generate a veritable mass of data which can itself become very difficult to evaluate and visualize. This is particularly true when the raw data is tough to quantify as, for example, is the case for microscopic images of cells or complex sequence analysis. Machine learning, neuronal networks, and artificial intelligence have all been suggested as tools for efficiently combing through such data [101]. Possible microfluidic applications include cell classification [102], signal processing [103], DNA base calling for DNA sequencing [104], flow sculpting for microchannel design [105], and cell segmentation [106]. Moving forward, it will only become increasingly important to set up systems that facilitate the global sharing and evaluation of large data sets in real-time. For example, environmental pollution of the air might 1 day be tracked by smartphone compatible LOCs – which would then feed the data generated into cloud saving and deep learning tools that can be used to immediately identify possible causes, direct further measurements, and make useful predictions.

6 Integrated Point-of-Use Devices for Monitoring, Understanding, and Controlling Bioprocesses

Currently, the primary benefit of point-of-use devices is mostly seen in their portability, time efficiency, cost efficiency, and easy-to-use handling [107, 108]. But all of these abilities are really just basic requirements that will ultimately help to enable integrated point-of-use devices that facilitate unprecedented opportunities to constantly monitor important parameters and immediately react to alterations. Wherever there are processes which will benefit from creating such a real-time monitoring and feedback control loop, integrated point-of-use devices point the way towards an even more efficient and integrated future.

One prominent example of this phenomenon from the field of biotechnology is the bioreactor. Monitoring bioprocess parameters like pH, biomass, oxygen, glucose, and product concentration – and, in turn, controlling these parameters via a live feed – is the key to maximize product yields and purities [109]. While some basic parameters such as pH, temperature, and dissolved oxygen concentration are already being monitored on-line, various parameters still remain dependent on sampling for off-line detection. There is thus a clear need for novel on-line or at-line microfluidic, analytical, and data processing techniques that can be implemented within a single or multiple LOCs for multi-parameter monitoring. As illustrated in Fig. 10a, at-line LOCs could allow for the delivery and processing of samples and feedback-controlled feeding in a quasi on-line process with minimal dead volumes, dead time, and without unwanted influence on the process. Future advances in analytics will undoubtedly offer a wide variety of on-chip biosensors, spectrometers, microscopes, and other elements all aimed at measuring and calibrating an endless array of parameters with minimal time or sample requirements. In addition, LOCs could also exceed current feeding methods due to their ability to facilitate the precise mixing and distribution of a variety of independently controlled substances, enabling even the most complex feeding strategies for any kind of bioreactor. Finally, digitalization (including machine learning and neuronal networks) could foreseeably be used to interpret complex changes in bioprocess parameters and correlate them with a feedback control – effectively creating a full-automated bioreactor.

The use of integrated point-of-use microfluidic devices for optimizing bioprocesses. The concept is illustrated using the example of a bioreactor (a) and a human being (b). These two bioprocesses can be monitored, analyzed, and controlled to improve either an industrial production or the state of health. Therefore, each LOC contains a sensor system, a connection to modern data analysis with computers or smartphones and an integrated feed. This results in a fully automatable control loop for permanent optimization, which in principle could be transferred to any bioprocess in all areas of life

Similar to bioreactors, the objective of current POC devices is to understand, optimize, and control the human physiological (and in particular, pathological) processes. At present, most microfluidic POC devices obtain body fluids used for off-line analysis and subsequent therapy via drugs or other therapeutic strategies. But with miniaturized biosensors and micropumps, online monitoring and instantaneous feedback-controlled drug therapy may foreseeably become available in the future. Exciting current examples of this young technology are implantable or on-skin glucose sensors in combination with insulin pumps [110, 111], dopamine monitoring [112], and online supplementation by infusion pumps [113]. Completely integrated point-of-use LOC devices for monitoring and feedback control could, in principle, be applied for nearly every biomarker in body fluids (Fig. 10b). This would create an invaluable tool in the fight against public health scourges like diabetes and hypertension – and it would also help physicians to recognize serious conditions (like lactate acidosis) as they are in the process of actively developing. To go even one step further, in the distant future, LOCs may 1 day become key tools in enhancing human physiology; for example, extracorporeal membrane oxygenation (ECMO) has already been intensively used to increase oxygenation in the blood of premature neonates [114] and COVID-19 patients [115]. And recently developed ECMO-on-a-chip systems [116, 117] may not only replace current ECMO devices – they could even be applied to increase athletic performance. Novel cancer treatment approaches are already exploring LOCs for on-chip immunotherapy [118]. Immunotherapy-on-a-chip could theoretically extract, sort, genetically modify, and return immune cells to the blood in a faster, less toxic, and more reproducible manner. Genetic modifications may also increase the effectiveness of immune cells against tumor cells [119] – and, in principle, other cells and other cell properties could also be modified, as well. In short, within our lifetimes LOCs may well become a valuable tool not only to develop a whole host of novel disease treatments, but also to optimize what even a healthy human being is capable of doing.

7 Concluding Remarks

Spearheaded by LOCs, microfluidics technology is an increasingly important tool across the field of biotechnology. Many successful proof-of-concept studies have already demonstrated the high potential for its application, and enterprising companies have already started to further realize this potential by introducing commercially available LOCs for routine applications (with a predominant focus, to date, on POC, screening, single-cell analytics, and novel organ-on-a-chip devices). Like with any emerging technology, significant challenges still block the path to full realization – including laborious and costly fabrication, inconvenient handling, and unsatisfactory standardization. Fast and easy fabrication by novel multimaterial 3D-printing, higher robustness via passively actuated chips as well as modularity, and the adoption of a unified and common biomicrofluidic language represent promising – but, as yet, not-fully-realized – solutions to these challenges. When these problems have been addressed and this technology is further buttressed via advanced microfluidic handling, advanced analytics, and digitalization, the practical applications promised by fully-mature microfluidic systems are nearly limitless: for example, the overwhelming number of analytical instruments currently used for monitoring and controlling processes could be simplified into a single, fully integrated point-of-use LOC. These new opportunities will undoubtedly raise a whole host of thorny ethical considerations, up to and including the question of whether these new advances actually make our lives easier and better or instead threaten to fundamentally alter our very physical existence. In closing, such is the promise of this exciting field that it may not ultimately be a question of what we can do with microfluidics – but rather, what we want to do with it.

References

Scheler O, Postek W, Garstecki P (2019) Recent developments of microfluidics as a tool for biotechnology and microbiology. Curr Opin Biotechnol 55:60–67. https://doi.org/10.1016/j.copbio.2018.08.004

Bai Y, Gao M, Wen L et al (2018) Applications of microfluidics in quantitative biology. Biotechnol J 13:e1700170. https://doi.org/10.1002/biot.201700170

Arshavsky-Graham S, Segal E (2020) Lab-on-a-chip devices for point-of-care medical diagnostics. Adv Biochem Eng Biotechnol. https://doi.org/10.1007/10_2020_127

Maschmeyer I, Kakava S (2020) Organ-on-a-chip. Springer, Berlin, pp 1–32

Khan ZA, Siddiqui MF, Park S (2019) Progress in antibiotic susceptibility tests: a comparative review with special emphasis on microfluidic methods. Biotechnol Lett 41:221–230. https://doi.org/10.1007/s10529-018-02638-2

Frey LJ, Krull R (2020) Microbioreactors for process development and cell-based screening studies. Springer, Berlin

Dusny C, Grünberger A (2020) Microfluidic single-cell analysis in biotechnology: from monitoring towards understanding. Curr Opin Biotechnol 63:26–33. https://doi.org/10.1016/j.copbio.2019.11.001

Matuła K, Rivello F, Huck WTS (2020) Single-cell analysis using droplet microfluidics. Adv Biosyst 4:1900188. https://doi.org/10.1002/adbi.201900188

Payne EM, Holland-Moritz DA, Sun S et al (2020) High-throughput screening by droplet microfluidics: perspective into key challenges and future prospects. Lab Chip 20:2247–2262. https://doi.org/10.1039/D0LC00347F

Fluidicmems (2020) Microfluidic companies | fluidicmems. https://www.fluidicmems.org/microfluidic-companies. Accessed 5 Dec 2020

Google My Maps (2020) FluidicMEMS.com’s list of microfluidics/lab-on-a-chip companies – Google My Maps. https://www.google.com/maps/d/u/0/viewer?ie=UTF8&hl=en&msa=0&z=2&mid=1e7udQl9Wyzaq4RVk48vWv8P59GM&ll=16.911338356870246%2C-6.3215279999999865. Accessed 5 Dec 2020

The MicroFluidic Circle (2020) Emerging microfluidic companies – the microfluidic circle. https://www.ufluidix.com/circle/microfluidic-companies/. Accessed 6 Dec 2020

Swerdlow H, Gesteland R (1990) Capillary gel electrophoresis for rapid, high resolution DNA sequencing. Nucleic Acids Res 18:1415–1419. https://doi.org/10.1093/nar/18.6.1415

Northrup MA, Gonzalez C, Hadley D et al (1995) A mems-based miniature DNA analysis system. In: Proceedings of the international solid-state sensors and actuators conference – TRANSDUCERS’95. IEEE, pp 764–767

Bahnemann J, Grünberger A (2021) Biotechnologie ganz klein. Zukunftsforum Biotechnologie (Hrsg.), DECHEMA e.V., Frankfurt. [ISBN] 978-3-89746-232-8

Quan P-L, Sauzade M, Brouzes E (2018) dPCR: a technology review. Sensors 18:1271. https://doi.org/10.3390/s18041271

Samiei E, Tabrizian M, Hoorfar M (2016) A review of digital microfluidics as portable platforms for lab-on a-chip applications. Lab Chip 16:2376–2396. https://doi.org/10.1039/c6lc00387g

Samandari M, Julia MG, Rice A et al (2018) Liquid biopsies for management of pancreatic cancer. Transl Res 201:98–127. https://doi.org/10.1016/j.trsl.2018.07.008

Cheng Z, Wu X, Cheng J et al (2017) Microfluidic fluorescence-activated cell sorting (μFACS) chip with integrated piezoelectric actuators for low-cost mammalian cell enrichment. Microfluid Nanofluid 21:9. https://doi.org/10.1007/s10404-017-1847-1

Manak MS, Varsanik JS, Hogan BJ et al (2018) Live-cell phenotypic-biomarker microfluidic assay for the risk stratification of cancer patients via machine learning. Nat Biomed Eng 2:761–772. https://doi.org/10.1038/s41551-018-0285-z

Nimir M, Ma Y, Jeffreys SA et al (2019) Detection of AR-V7 in liquid biopsies of castrate resistant prostate cancer patients: a comparison of AR-V7 analysis in circulating tumor cells, circulating tumor RNA and exosomes. Cell 8:688. https://doi.org/10.3390/cells8070688

Mahler L, Du G, Dajkovic A et al (2020) Rethinking culture-based microbiology – deep insights into any microbiota. Biomillenia, Romainville

Josephides D, Davoli S, Whitley W et al (2020) Cyto-mine: an integrated, picodroplet system for high-throughput single-cell analysis, sorting, dispensing, and monoclonality assurance. SLAS Technol 25:177–189. https://doi.org/10.1177/2472630319892571

Hengoju S, Tovar M, Man DKW et al (2020) Droplet microfluidics for microbial biotechnology. Adv Biochem Eng Biotechnol. https://doi.org/10.1007/10_2020_140

Mirasol F (2020) Shaping IR spectroscopy into a powerful tool for biopharma characterizations. BioPharm Int 33:42–47

Vaclavek T, Prikryl J, Foret F (2019) Resistive pulse sensing as particle counting and sizing method in microfluidic systems: designs and applications review. J Sep Sci 42:445–457. https://doi.org/10.1002/jssc.201800978

Globus T, Ferrance J, Moskaluk C et al (2018) Sub-terahertz spectroscopic signatures from micro-rna molecules in fluid samples for ovarian cancer analysis. Case Rep Liter Rev 2(2):1–3

Tsai A (2019) Ultra-sensitive chemical and nanoparticle sensing with optical microcavities. Periodic 7:16. http://www.chem.ox.ac.uk/periodic2019/

Zhang B, Radisic M (2017) Organ-on-a-chip devices advance to market. Lab Chip 17:2395–2420. https://doi.org/10.1039/c6lc01554a

Bahnemann J, Enders A, Winkler S (2021) Microfluidic systems and organ (human) on a chip. In: Basic concepts on 3D cell culture. Springer, Heidelberg. ISBN: 978-3-030-611 66749-8. https://doi.org/10.1007/978-3-030-66749-8

Chiu DT, deMello AJ, Di Carlo D et al (2017) Small but perfectly formed? Successes, challenges, and opportunities for microfluidics in the chemical and biological sciences. Chem 2:201–223. https://doi.org/10.1016/j.chempr.2017.01.009

Dekker S, Isgor PK, Feijten T et al (2018) From chip-in-a-lab to lab-on-a-chip: a portable Coulter counter using a modular platform. Microsyst Nanoeng 4:34. https://doi.org/10.1038/s41378-018-0034-1

Andersson H, van den Berg A (2006) Where are the biologists? Lab Chip 6:467–470. https://doi.org/10.1039/b602048h

Kandelousi MS (2018) Microfluidics and nanofluidics. InTech, London

Nguyen H-T, Thach H, Roy E et al (2018) Low-cost, accessible fabrication methods for microfluidics research in low-resource settings. Micromachines 9:461. https://doi.org/10.3390/mi9090461

Kotz F, Helmer D, Rapp BE (2020) Emerging technologies and materials for high-resolution 3D printing of microfluidic chips. Adv Biochem Eng Biotechnol. https://doi.org/10.1007/10_2020_141

Rupal BS, Garcia EA, Ayranci C et al (2019) 3D printed 3D-microfluidics: recent developments and design challenges. JID 22:5–20. https://doi.org/10.3233/jid-2018-0001

Preuss J-A, Nguyen GN, Berk V et al (2020) Miniaturized free-flow electrophoresis – production, optimization and application using 3D printing technology. Electrophoresis. https://doi.org/10.1002/elps.202000149

Enders A, Siller IG, Urmann K et al (2019) 3D printed microfluidic mixers-a comparative study on mixing unit performances. Small 15:e1804326. https://doi.org/10.1002/smll.201804326

Siller IG, Preuss J-A, Urmann K et al (2020) 3D-printed flow cells for aptamer-based impedimetric detection of E. coli crooks strain. Sensors 20:4421. https://doi.org/10.3390/s20164421

Lavrentieva A, Fleischhammer T, Enders A et al (2020) Fabrication of stiffness gradients of GelMA hydrogels using a 3D printed micromixer. Macromol Biosci 20:e2000107. https://doi.org/10.1002/mabi.202000107

Siller IG, Enders A, Gellermann P et al (2020) Characterization of a customized 3D-printed cell culture system using clear, translucent acrylate that enables optical online monitoring. Biomed Mater 15:55007. https://doi.org/10.1088/1748-605X/ab8e97

Siller IG, Epping N-M, Lavrentieva A et al (2020) Customizable 3D-printed (co-)cultivation systems for in vitro study of angiogenesis. Materials 13:4290. https://doi.org/10.3390/ma13194290

Siller IG, Enders A, Steinwedel T et al (2019) Real-time live-cell imaging technology enables high-throughput screening to verify in vitro biocompatibility of 3D printed materials. Materials 12:2125. https://doi.org/10.3390/ma12132125

Li F, Macdonald NP, Guijt RM et al (2018) Increasing the functionalities of 3D printed microchemical devices by single material, multimaterial, and print-pause-print 3D printing. Lab Chip 19:35–49. https://doi.org/10.1039/c8lc00826d

MacDonald E, Wicker R (2016) Multiprocess 3D printing for increasing component functionality. Science 353:aaf2093. https://doi.org/10.1126/science.aaf2093

Begolo S, Zhukov DV, Selck DA et al (2014) The pumping lid: investigating multi-material 3D printing for equipment-free, programmable generation of positive and negative pressures for microfluidic applications. Lab Chip 14:4616–4628. https://doi.org/10.1039/c4lc00910j

Li F, Smejkal P, Macdonald NP et al (2017) One-step fabrication of a microfluidic device with an integrated membrane and embedded reagents by multimaterial 3D printing. Anal Chem 89:4701–4707. https://doi.org/10.1021/acs.analchem.7b00409

O’Neil GD, Ahmed S, Halloran K et al (2019) Single-step fabrication of electrochemical flow cells utilizing multi-material 3D printing. Electrochem Commun 99:56–60. https://doi.org/10.1016/j.elecom.2018.12.006

Duarte LC, Chagas CLS, Ribeiro LEB et al (2017) 3D printing of microfluidic devices with embedded sensing electrodes for generating and measuring the size of microdroplets based on contactless conductivity detection. Sensors Actuators B Chem 251:427–432. https://doi.org/10.1016/j.snb.2017.05.011

Fornells E, Murray E, Waheed S et al (2020) Integrated 3D printed heaters for microfluidic applications: ammonium analysis within environmental water. Anal Chim Acta 1098:94–101. https://doi.org/10.1016/j.aca.2019.11.025

Scotti G, Nilsson SME, Haapala M et al (2017) A miniaturised 3D printed polypropylene reactor for online reaction analysis by mass spectrometry. React Chem Eng 2:299–303. https://doi.org/10.1039/C7RE00015D

Yuan R, Lee J, Su H-W et al (2018) Microfluidics in structured multimaterial fibers. Proc Natl Acad Sci U S A 115:E10830–E10838. https://doi.org/10.1073/pnas.1809459115

Sanchez D, Nordin G, Munro T (2020) Microfluidic temperature behavior in a multi-material 3D printed chip. American Society of Mechanical Engineers Digital Collection, New York

Kitson PJ, Rosnes MH, Sans V et al (2012) Configurable 3D-printed millifluidic and microfluidic ‘lab on a chip’ reactionware devices. Lab Chip 12:3267–3271. https://doi.org/10.1039/c2lc40761b

Kaminski TS, Scheler O, Garstecki P (2016) Droplet microfluidics for microbiology: techniques, applications and challenges. Lab Chip 16:2168–2187. https://doi.org/10.1039/c6lc00367b

Narayanamurthy V, Jeroish ZE, Bhuvaneshwari KS et al (2020) Advances in passively driven microfluidics and lab-on-chip devices: a comprehensive literature review and patent analysis. RSC Adv 10:11652–11680. https://doi.org/10.1039/D0RA00263A

Carrell C, Kava A, Nguyen M et al (2019) Beyond the lateral flow assay: a review of paper-based microfluidics. Microelectron Eng 206:45–54. https://doi.org/10.1016/j.mee.2018.12.002

Case DJ, Liu Y, Kiss IZ et al (2019) Braess’s paradox and programmable behaviour in microfluidic networks. Nature 574:647–652. https://doi.org/10.1038/s41586-019-1701-6

Zaidon N, Nordin AN, Ismail AF (2015) Modelling of microfluidics network using electric circuits. In: 2015 IEEE regional symposium on micro and nanoelectronics (RSM). IEEE, pp 1–4

Duncan PN, Nguyen TV, Hui EE (2013) Pneumatic oscillator circuits for timing and control of integrated microfluidics. Proc Natl Acad Sci U S A 110:18104–18109. https://doi.org/10.1073/pnas.1310254110

Lee Y-S, Bhattacharjee N, Folch A (2018) 3D-printed quake-style microvalves and micropumps. Lab Chip 18:1207–1214. https://doi.org/10.1039/C8LC00001H

Ortseifen V, Viefhues M, Wobbe L et al (2020) Microfluidics for biotechnology: bridging gaps to foster microfluidic applications. Front Bioeng Biotechnol 8:1324. https://doi.org/10.3389/fbioe.2020.589074

Mohammed MI, Haswell S, Gibson I (2015) Lab-on-a-chip or chip-in-a-lab: challenges of commercialization lost in translation. Proc Technol 20:54–59. https://doi.org/10.1016/j.protcy.2015.07.010

Arnold FH (2018) Directed evolution: bringing new chemistry to life. Angew Chem Int Ed Engl 57:4143–4148. https://doi.org/10.1002/anie.201708408

Ma F, Chung MT, Yao Y et al (2018) Efficient molecular evolution to generate enantioselective enzymes using a dual-channel microfluidic droplet screening platform. Nat Commun 9:1030. https://doi.org/10.1038/s41467-018-03492-6

Waddington SN, Privolizzi R, Karda R et al (2016) A broad overview and review of CRISPR-cas technology and stem cells. Curr Stem Cell Rep 2:9–20. https://doi.org/10.1007/s40778-016-0037-5

McNutt M (2015) Breakthrough to genome editing. Science 350:1445. https://doi.org/10.1126/science.aae0479

Ahmadi F, Quach ABV, Shih SCC (2020) Is microfluidics the “assembly line” for CRISPR-Cas9 gene-editing? Biomicrofluidics 14:61301. https://doi.org/10.1063/5.0029846

Hajian R, Balderston S, Tran T et al (2019) Detection of unamplified target genes via CRISPR-Cas9 immobilized on a graphene field-effect transistor. Nat Biomed Eng 3:427–437. https://doi.org/10.1038/s41551-019-0371-x

Sinha H, Quach ABV, Vo PQN et al (2018) An automated microfluidic gene-editing platform for deciphering cancer genes. Lab Chip 18:2300–2312. https://doi.org/10.1039/c8lc00470f

Mondal S, Ben-Yakar A (2020) Caenorhabditis elegans-on-a-chip: microfluidic platforms for high-resolution imaging and phenotyping. In: Organ-on-a-chip. Elsevier, Amsterdam, pp 363–390

Kolluri N, Klapperich CM, Cabodi M (2017) Towards lab-on-a-chip diagnostics for malaria elimination. Lab Chip 18:75–94. https://doi.org/10.1039/c7lc00758b

Yang F, Gao C, Wang P et al (2016) Fish-on-a-chip: microfluidics for zebrafish research. Lab Chip 16:1106–1125. https://doi.org/10.1039/c6lc00044d

Jiang H, Xu Z, Aluru MR et al (2014) Plant chip for high-throughput phenotyping of Arabidopsis. Lab Chip 14:1281–1293. https://doi.org/10.1039/c3lc51326b

Grossmann G, Guo W-J, Ehrhardt DW et al (2011) The RootChip: an integrated microfluidic chip for plant science. Plant Cell 23:4234–4240. https://doi.org/10.1105/tpc.111.092577

Shapiro OH, Kramarsky-Winter E, Gavish AR et al (2016) A coral-on-a-chip microfluidic platform enabling live-imaging microscopy of reef-building corals. Nat Commun 7:10860. https://doi.org/10.1038/ncomms10860

Stanley CE, Grossmann G, i Solvas XC et al (2016) Soil-on-a-Chip: microfluidic platforms for environmental organismal studies. Lab Chip 16:228–241. https://doi.org/10.1039/c5lc01285f

Täuber S, Golze C, Ho P et al (2020) dMSCC: a microfluidic platform for microbial single-cell cultivation of Corynebacterium glutamicum under dynamic environmental medium conditions. Lab Chip 20:4442–4455. https://doi.org/10.1039/d0lc00711k

Wang H, Chen L, Sun L (2017) Digital microfluidics: a promising technique for biochemical applications. Front Mech Eng 12:510–525. https://doi.org/10.1007/s11465-017-0460-z

Edel JB, Ivanov A, Kim M (eds) (2017) Nanofluidics: nanoscience and nanotechnology. In: RSC nanoscience & nanotechnology, vol 41, 2nd edn. Royal Society of Chemistry, Cambridge

Bocquet L (2020) Nanofluidics coming of age. Nat Mater 19:254–256. https://doi.org/10.1038/s41563-020-0625-8

Barboiu M (2016) Artificial water channels--incipient innovative developments. Chem Commun 52:5657–5665. https://doi.org/10.1039/c6cc01724j

Ghasemi A, Amiri H, Zare H et al (2017) Carbon nanotubes in microfluidic lab-on-a-chip technology: current trends and future perspectives. Microfluid Nanofluidics 21:151. https://doi.org/10.1007/s10404-017-1989-1

Serra PA (2011) New perspectives in biosensors technology and applications. InTech, London

Prante M, Segal E, Scheper T et al (2020) Aptasensors for point-of-care detection of small molecules. Biosensors 10:108. https://doi.org/10.3390/bios10090108

Bhalla N, Jolly P, Formisano N et al (2016) Introduction to biosensors. Essays Biochem 60:1–8. https://doi.org/10.1042/EBC20150001

Preuß J-A, Reich P, Bahner N et al (2020) Impedimetric aptamer-based biosensors: applications. Adv Biochem Eng Biotechnol 174:43–91. https://doi.org/10.1007/10_2020_125

Aćimović SS, Šípová H, Emilsson G et al (2017) Superior LSPR substrates based on electromagnetic decoupling for on-a-chip high-throughput label-free biosensing. Light Sci Appl 6:e17042. https://doi.org/10.1038/lsa.2017.42

Liu B, Chen X, Cai H et al (2016) Surface acoustic wave devices for sensor applications. J Semicond 37:21001. https://doi.org/10.1088/1674-4926/37/2/021001

Zhao Y, Tong R-J, Xia F et al (2019) Current status of optical fiber biosensor based on surface plasmon resonance. Biosens Bioelectron 142:111505. https://doi.org/10.1016/j.bios.2019.111505

Inan H, Poyraz M, Inci F et al (2017) Photonic crystals: emerging biosensors and their promise for point-of-care applications. Chem Soc Rev 46:366–388. https://doi.org/10.1039/c6cs00206d

Montagut Y, Garcia J, Jimenez Y et al (2011) QCM technology in biosensors. In: Serra PA (ed) Biosensors – emerging materials and applications. InTech, London

Paiè P, Bragheri F, Bassi A et al (2016) Selective plane illumination microscopy on a chip. Lab Chip 16:1556–1560. https://doi.org/10.1039/c6lc00084c

Pirnstill CW, Coté GL (2015) Malaria diagnosis using a mobile phone polarized microscope. Sci Rep 5:13368. https://doi.org/10.1038/srep13368

Tang Q, Liang M, Lu Y et al (2016) Microfluidic devices for terahertz spectroscopy of live cells toward lab-on-a-chip applications. Sensors 16:476. https://doi.org/10.3390/s16040476

Costanzo MT, Boock JJ, Kemperman RHJ et al (2017) Portable FAIMS: applications and future perspectives. Int J Mass Spectrom 422:188–196. https://doi.org/10.1016/j.ijms.2016.12.007

Zhai Y, Feng Y, Wei Y et al (2015) Development of a miniature mass spectrometer with continuous atmospheric pressure interface. Analyst 140:3406–3414. https://doi.org/10.1039/c5an00462d

Zalesskiy SS, Danieli E, Blümich B et al (2014) Miniaturization of NMR systems: desktop spectrometers, microcoil spectroscopy, and “NMR on a chip” for chemistry, biochemistry, and industry. Chem Rev 114:5641–5694. https://doi.org/10.1021/cr400063g

Bomers M, Charlot B, Barho F et al (2020) Microfluidic surface-enhanced infrared spectroscopy with semiconductor plasmonics for the fingerprint region. React Chem Eng 5:124–135. https://doi.org/10.1039/C9RE00350A

Riordon J, Sovilj D, Sanner S et al (2019) Deep learning with microfluidics for biotechnology. Trends Biotechnol 37:310–324. https://doi.org/10.1016/j.tibtech.2018.08.005

Heo YJ, Lee D, Kang J et al (2017) Real-time image processing for microscopy-based label-free imaging flow cytometry in a microfluidic chip. Sci Rep 7:11651. https://doi.org/10.1038/s41598-017-11534-0

Han S, Kim T, Kim D et al (2018) Use of deep learning for characterization of microfluidic soft sensors. IEEE Robot Autom Lett 3:873–880. https://doi.org/10.1109/LRA.2018.2792684

Boža V, Brejová B, Vinař T (2017) DeepNano: deep recurrent neural networks for base calling in MinION nanopore reads. PLoS One 12:e0178751. https://doi.org/10.1371/journal.pone.0178751

Stoecklein D, Lore KG, Davies M et al (2017) Deep learning for flow sculpting: insights into efficient learning using scientific simulation data. Sci Rep 7:46368. https://doi.org/10.1038/srep46368

Zaimi A, Wabartha M, Herman V et al (2018) AxonDeepSeg: automatic axon and myelin segmentation from microscopy data using convolutional neural networks. Sci Rep 8:3816. https://doi.org/10.1038/s41598-018-22181-4

Vashist SK, Luong JHT (2019) An overview of point-of-care technologies enabling next-generation healthcare monitoring and management. In: Vashist SK, Luong JHT (eds) Point-of-care technologies enabling next-generation healthcare monitoring and management. Springer, Cham, pp 1–25

Vashist SK, Luong JHT (eds) (2019) Point-of-care technologies enabling next-generation healthcare monitoring and management. Springer, Cham

Stanke M, Hitzmann B (2013) Automatic control of bioprocesses. Adv Biochem Eng Biotechnol 132:35–63. https://doi.org/10.1007/10_2012_167

Vettoretti M, Facchinetti A (2019) Combining continuous glucose monitoring and insulin pumps to automatically tune the basal insulin infusion in diabetes therapy: a review. Biomed Eng Online 18:1–17. https://doi.org/10.1186/s12938-019-0658-x

Kim J, Campbell AS, Wang J (2018) Wearable non-invasive epidermal glucose sensors: a review. Talanta 177:163–170. https://doi.org/10.1016/j.talanta.2017.08.077

Godinho C, Domingos J, Cunha G et al (2016) A systematic review of the characteristics and validity of monitoring technologies to assess Parkinson’s disease. J Neuroeng Rehabil 13:24. https://doi.org/10.1186/s12984-016-0136-7

Kim HJ, Jeon BS, Jenner P (2017) Hallmarks of treatment aspects: Parkinson’s disease throughout centuries including l-dopa. Int Rev Neurobiol 132:295–343. https://doi.org/10.1016/bs.irn.2017.01.006

Fletcher K, Chapman R, Keene S (2018) An overview of medical ECMO for neonates. Semin Perinatol 42:68–79. https://doi.org/10.1053/j.semperi.2017.12.002

Bartlett RH, Ogino MT, Brodie D et al (2020) Initial ELSO guidance document: ECMO for COVID-19 patients with severe cardiopulmonary failure. ASAIO J 66:472–474. https://doi.org/10.1097/MAT.0000000000001173

Dabaghi M, Saraei N, Fusch G et al (2018) An ultra-thin highly flexible microfluidic device for blood oxygenation. Lab Chip 18:3780–3789. https://doi.org/10.1039/c8lc01083h

Gimbel AA, Flores E, Koo A et al (2016) Development of a biomimetic microfluidic oxygen transfer device. Lab Chip 16:3227–3234. https://doi.org/10.1039/c6lc00641h

Lagae L (2018) Boosting cell therapy production. Genet Eng Biotechnol News 38:20. https://doi.org/10.1089/gen.38.09.08

Li D, Li X, Zhou W-L et al (2019) Genetically engineered T cells for cancer immunotherapy. Signal Transduct Target Ther 4:35. https://doi.org/10.1038/s41392-019-0070-9

Acknowledgements

The authors would like to thank Niklas M. Epping (Institute of Technical Chemistry, Leibniz University Hannover, Germany) and Dr. Natalie Rotermund (Institute of Zoology, University of Hamburg, Germany) for their contribution in creating the illustrations.

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Winkler, S., Grünberger, A., Bahnemann, J. (2021). Microfluidics in Biotechnology: Quo Vadis. In: Bahnemann, J., Grünberger, A. (eds) Microfluidics in Biotechnology. Advances in Biochemical Engineering/Biotechnology, vol 179. Springer, Cham. https://doi.org/10.1007/10_2020_162

Download citation

DOI: https://doi.org/10.1007/10_2020_162

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-04187-7

Online ISBN: 978-3-031-04188-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)