Abstract

In bone tissue engineering, the design of scaffolds with ECM is still challenging now-a-days. The objective of the study to develop an electrospun scaffold based on polyurethane (PU) blended with corn oil and neem oil. The electrospun nanocomposites were characterized through scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), contact angle measurement, atomic force microscopy (AFM) and tensile strength. The assays activated prothrombin time (APTT), partial thromboplastin time (PT) and hemolysis assay were performed to determine the blood compatibility parameters of the electrospun PU and their blends of corn oil and neem oil. Further, the cytocompatibility studies were performed using HDF cells to evaluate their proliferation rates in the electrospun PU and their blends. The morphology of the electrospun PU blends showed that the addition of corn oil and corn/neem oil resulted in reduced fiber diameter of about 845 ± 117.86 nm and 735 ± 126.49 nm compared to control (890 ± 116.911 nm). The FTIR confirmed the presence of corn oil and neem oil in PU matrix through hydrogen bond formation. The PU blended with corn oil showed hydrophobic (112° ± 1) while the PU together with corn/neem oil was observed to hydrophilic (64° ± 1.732) as indicated in the measurements of contact angle. The thermal behavior of prepared PU/corn oil and PU/corn/neem oil nanocomposites were enhanced and their surface roughness were decreased compared to control as revealed in the AFM analysis. The mechanical analysis indicated the enhanced tensile strength of the developed nanocomposites (PU/corn oil - 11.88 MPa and PU/corn/neem oil - 12. 96 MPa) than the pristine PU (7.12 MPa). Further, the blood compatibility assessments revealed that the developed nanocomposites possess enhanced anticoagulant nature compared to the polyurethane. Moreover, the developed nanocomposites was non-toxic to red blood cells (RBC) and human fibroblast cells (HDF) cells as shown in the hemolytic assay and cytocompatibility studies. Finally, this study concluded that the newly developed nanocomposites with better physio-chemical characteristics and biological properties enabled them as potential candidate for bone tissue engineering.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The various defects occurred in the bone were tumor ablation, bone cysts, osteolysis and neurosurgical defects. In general these defects were produced by the diseases or trauma [1]. The remodelling of the damaged bone is still challenging in the clinical applications. Recently, tissue engineering is emerging as a new approach for the reconstruction of the damaged bone tissue. The reason is that the tissue engineered scaffolds eliminates limitations possessed by the traditional autograft and allograft. The limitations were scarcity of donor, infections and immune rejection [2]. Further, they also help in the cells proliferation and supports the new tissue growth [3, 4]. The necessary characteristics should be posed by the scaffold for bone tissue engineering were biodegradable, biocompatible, good mechanical properties and also non-toxic [5, 6]. Till now, all materials such as metals, ceramics and polymers were utilized in remodelling of the damaged bone tissue [7]. But the polymers were found to better than the metals and ceramics in terms of degradability and flexibility which finds its wide spread applications in the tissue engineering [8, 9]. In bone tissue engineering, synthetic polymers like poly (caprolactone), poly (lactic-co-glycolic acid), poly (lactic acid), poly (glycolic acid) and natural polymers namely chitosan, collagen, gelatin and silk were utilized [10]. General, the fabricated scaffold must remodel the function of the host tissue and also minimic the structure of the ECM [11, 12]. The natural ECM is a 3D structure which has mainly proteoglycans and fibrous proteins with diameter in nanometric range [13].

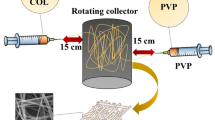

In fabricating the nanoscale matrices, the variety of techniques were utilized and they are electrospinning, solvent casting, freeze drying, batch foaming and injection foaming [14]. The scaffolds produced by the electrospinning technique have fibres in a nanometre range which look like the native structure of the ECM [11]. Electrospinning is a versatile and cost effective technique which utilizes the high electric field to produce the fibres in a nanometre range. In the electrospinning setup, the polymer solution in a syringe needle is placed on the syringe pump which was subjected to the high electric field. When the applied voltage overcomes the threshold voltage, the nanofibers were drawn from the needle and deposited on the collector drum [15]. The electrospinning process was influenced by various parameters like i) polymer solution properties, ii) processing parameters and iii) ambient conditions [16]. In this work, polymer used in fabricating the scaffold was Tecoflex EG-80A which is a medical grade polyurethane. It finds wide spread application in tissue engineering because of its desirable characteristics like biodegradability and good oxidative stability. Further, it was reported that the manufacturing of nanofibers from the PU polymer was very easy owing to its better flexibility [17, 18].

In this study, the PU was blended with corn and neem oil to improve their functionality. Corn oil is also called as maize oil which is obtained from the germ of corn. It is mainly used as cooking oil and also as feedstock for biodiesel. The other applications of corn oil were rustproofing for metal surfaces, inks, paints, textiles, nitroglycerin, and insecticides. Further, it also uses as carrier for drug molecules in pharmaceutical applications [19]. Neem or the Margosa trees (Azadirachta indica) are grown in tropical countries of the world and they possess better antimicrobial and medical properties owing to various biological constituents such as nimbin, nimbidin, nimbolide, and limonoids present in it [20, 21]. Further, it was very useful in curing the various human disease owing to its various pharmacological attributes [22]. In this work, a novel bone scaffold will be electrospun based on PU blended with corn and neem oil and their combination effect have been studied for the first time. The aim of this work will be investigation of physio-chemical characterization, blood compatibility assays and cytocompatibility studies of the newly developed nanocomposites to assess their effectiveness for bone tissue engineering.

Materials and methodology

Materials

Tecoflex EG-80A was obtained from Sigma-Aldrich. The solvent used DMF was purchased from Merck. The neem oil and corn oil were obtained locally. The chemical phosphate buffered saline (PBS) and sodium chloride physiological saline (0.9% w/v) were purchased from Sigma-Aldrich, Kuala Lumpur, Malaysia. The reagents such as rabbit brain activated cephaloplastin, calcium chloride (0.025 M), and thromboplastin (Factor III) used in the blood compatibility studies were purchased from Diagnostic Enterprises, Solan, India.

Preparation of spinning solution

PU solution with 9 wt% was prepared by mixing 0.405 g of PU in 4.5 ml DMF and stirred for 12 h to attain clear homogeneous solution. In the similar way, the 9 wt% of neem oil and corn oil was prepared by mixing 405 μl of oil in 4.5 ml of DMF and stirred for 1 h maximum. Then, PU solution was added to the prepared corn and neem oil and stirred for 2 h for even dissolution. The solution of PU/corn oil and PU/corn/neem oil were prepared at a ratio of 7:2 (v/v%) and 7:1:1 (v/v%) respectively.

Electrospinning process

For electrospinning of nanofibers, 5 mL of prepared homogeneous solution was loaded into a 10 mL glass syringe fitted with 18-G stainless steel needle and placed in the syringe pump holder. The prepared homogeneous solutions were electrospun at a flow rate of 0.5 mLh−1 with electric field of 10.5 kV. The nanofibers were deposited on the aluminum foil which was placed 20 cm away from the needle. The collected nanofibers were retrieved carefully and dried under vacuum to remove any residual content of DMF.

Physio-chemical characterizations

SEM analysis

SEM (Hitachi Tabletop TM3000) was used to investigate the morphologies and diameters of the electrospun nanofibers. Prior to SEM analysis, the samples were gold sputtered and the fiber diameter of the fabricated nanofibers was measured using Image J software.

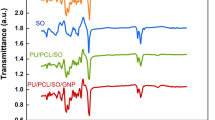

FTIR analysis

The spectrum of the electrospun PU and composite nanofibers were inspected using ATR-FTIR instrument. A small piece was cut from the fabricated membrane and placed on the surface of sensor. The spectrum was inspected through absorption mode between wavelengths of 600–4000 cm−1 at a resolution of 4 cm−1 with 32 scans per minute.

Contact angle measurements

The wetting ability of the electrospun membrane was determined through the contact angle measurement (VCA Optima contact angle measurement unit). The water droplets with size of 0.5 μL were placed on the testing membrane and visualized through high-resolution video camera. The static image of the droplet was captured and the angle of the droplet was measured using computer integrated software.

Mechanical testing

The electrospun membranes were tested using uniaxial tensile load machine to determine its mechanical properties. To begin the test, the samples were cut in the dimension of 40 mm * 15 mm and gripped at the ends of the tensile machine. Next, the elongation rate of 5 mm/min with load of 500 N was applied to the samples to determine the deformation rate of the electrospun membranes. Finally, from the generated stress strain curve, the tensile strength and the modulus were calculated.

TGA analysis

Thermogravimetric analyses (TGA) were performed using Perkin-Elmer TGA unit. Samples with 3 mg weight was placed on the aluminum pan and were heated at a temperature ranging from 30 to 1000 °C at a rate of 10 °C/min under nitrogen atmosphere.

AFM analysis

The roughness measurement were performed utilizing AFM unit (Nanowizard, JPK Instruments). A small piece of electrospun membrane were placed on the measuring surface and the scanning was done. The digital images in 3D with 20 * 20 μm size and 256 * 256 pixels were captured using JPKSPM data processing software.

Blood compatibility studies

APTT and PT assay

The in vitro activated partial thromboplastin time (APTT) and prothrombin time (PT) were determined to investigate the blood compatibility of the electrospun membranes. To begin the assay, the samples with size of 0.5 × 0.5 cm2 was incubated in 50 μL platelet-poor plasma (PPP) for 1 min at 37 °C. For APTT assay, 50 μL of APTT reagent (rabbit brain cephaloplastin) incubated with the PPP for 3 min followed by adding 50 μL of CaCl2 (0.025 M) which initiates the blood clot. Similarly, for PT assay, the samples were incubated with 50 μL of PPP and 50 μL of PT reactive reagent (thromboplastin (Factor III)). The time required for clotting was measured as PT [23].

Hemolysis assay

To start the assay, the samples were cut from the electrospun membrane and soaked in saline for 30 min at 37 °C. The mixture of citrated blood and diluted saline was prepared at a ratio of 4:5 (v/v%). After, the soaked samples was added to the prepared mixture for 1 h at 37 °C. The samples were removed and the blood was centrifuged at 3000 rpm for 15 min. The absorbance was recorded by pipetting the supernatant at 542 nm using spectrophotometer which measures release of hemoglobin. The hemolytic percentage was calculated using as described earlier [23].

Cytocompatibility studies

The cell viability of the electrospun membrane was tested using HDF cells. The cell were cultured using DMEM medium supplied with 10% fetal serum and maintained at 37 °C and 5% CO2. During cell culturing, the medium was changed for every 3 days. To begin the MTS assay, the samples were cut into small pieces and placed in the 96 well plates. Prior to cell seeding, the samples were sterilized with 75% alcohol solution for 3 h and washed with PBS. Then, the cells were seeded on each scaffold with the density of 10 * 103 cells/cm2 and incubated in CO2 incubator. After 3 days culturing, the samples with grown cells were added with 20% of ((3-(4,5-dimethylthiazol-2-yl)-5-(3-carboxymethoxyphenyl)-2-(4-sulfophenyl)-2Htetrazolium, inner salt) and incubated for 4 h. Finally, the samples were taken and the absorbance was measured at 490 nm using spectrophotometric plate reader to determine the viability of HDF cell on the electrospun membranes.

Statistical analysis

All experiments were performed three times independently and one-way ANNOVA was carried out to measure the statistical significance. The obtained results are indicated as mean ± SD and for qualitative experiments, a representative of three images is displayed.

Result and discussions

In tissue engineering applications, the performance of the scaffolds is influenced by their certain properties like microstructure and response to cells and tissues. Even though, the materials possess desirable characteristics but their usage in the clinical applications was limited owing to lack in blood compatibility and bioactivity. For the first time in this work, electrospun PU nanofibers was blended with corn oil and neem oil to enhance the bioactivity and cell response.

The SEM images of electrospun membranes prepared from PU blended with corn oil and neem oil were indicated in Fig. 1a, b and c. The SEM figure showed that the prepared PU fibers and PU nanocomposites exhibited uniform smooth fibers without any beads. Further, there was reduction in fiber diameter of the electrospun nanocomposites compared to the control. The fiber diameters for the electrospun PU, PU/corn oil and PU/corn oil/neem oil scaffolds were found to be 890 ± 116.911 nm, 845 ± 117.86 nm and 735 ± 126.49 nm. The graphical representation of the fiber distribution curves for the electrospun PU, PU/corn oil and PU/corn oil/neem oil scaffolds were shown in Fig. 2a, b and c. The obtained results suggested the synergistic reduction of fiber diameter when neem oil was incorporated with PU/corn oil matrix. Ngiam et al. electrospun PLGA scaffold incorporated with collagen nanofibers for bone tissue engineering. It was reported that the incorporation of collagen into the PLGA matrix resulted in the reduction of the fiber diameter and favored enhanced osteoblast adhesion and proliferation [24]. Hence, the blending of neem and corn oil into PU matrix might help in enhanced osteoblast adhesion and proliferation for new tissue growth.

The IR spectra of electrospun membranes prepared from PU blended with corn and neem oil were shown in Fig. 3. The spectra of PU exhibited peaks at 3323 cm−1, 1730 cm−1, 1703 cm−1, 1597 cm−1, 1531 cm−1, and 1413 cm−1. The peak at 3323 cm−1 corresponds to NH stretch and it vibrations were seen at 1597 cm−1 and 1531 cm−1. The absorption band of CH2 stretch was shown at 2939 cm−1, 2853 cm−1 and its vibration was observed at 1413 cm−1. Further, the twin peak seen at 1730 cm−1 and 1703 cm−1 represents the CO stretching [23]. In spectra of PU/corn oil and PU/corn oil/neem oil scaffold, no new peak formation but the intensity of the peak was decreased in PU/corn oil and PU/corn oil/neem oil scaffold owing to the hydrogen bond formation [25]. Further, there was slight shift of the CH band was observed from 2939 cm−1 in PU to 2930 cm−1 and 2929 cm−1 in PU/corn oil and PU/corn oil/neem oil nanocomposites which confirms binding of the PU matrix with corn and neem oil [26].

The surface wettability of the electrospun PU and PU blended with corn and neem oil determined via water contact angles measurements were discussed. From the results obtained, the contact angle of the pristine PU nanofibrous scaffolds was around 100° ± 0.5774 and the mean contact angle of the PU/corn oil and PU/corn oil/neem oil scaffolds were 112° ± 1 and 64° ± 1.732 respectively. Hence, the addition of corn oil decreased the wettability of PU whereas the neem oil incorporation enhance the wettability. The electrospun scaffolds blended with corn oil favored hydrophobic nature which was indicated by the contact angle measurement. The optimal contact angle for the adhesion of osteoblast cells were suggested to be 0 ° to 106° [27]. Hence, it would be better to modify the wettability of the electrospun PU/corn oil. This was done by incorporation of neem oil in to the scaffold which resulted the contact angle of the nanocomposite scaffold to shift below 90°. Generally, the hydrophilic scaffolds may be appropriate for bone tissue engineering applications as reported in a recent research. Shanmugavel et al. electrospun polycaprolactone scaffold blended with Aloe vera and silk fibroin for bone tissue engineering. It was observed that the incorporation of Aloe vera and silk fibroin improve the wettability of the PCL and exhibited enhanced osteoblast adhesion and proliferation [28]. Hence, the hydrophilic behavior of the developed nanocomposites might be suitable for bone tissue engineering.

TGA analysis for the corn and neem oil was indicated in Fig. 4a, b. The corn oil showed the onset degradation temperature of 372 °C, while the neem oil showed onset degradation of 219 °C. The onset degradation of the neem oil was observed to be low which might be due to the evaporation of water molecules. TGA analysis of corn and neem oil incorporated electrospun PU scaffolds were shown in Fig. 5a, b and c. TGA results clearly indicates the improvement in thermal stability of the electrospun PU/corn oil and PU/corn oil/neem oil scaffold compared to PU nanofiber. The PU nanofibers exhibited initial degradation temperature begins at 277 °C, while for the electrospun PU/corn oil and PU/corn oil/neem oil scaffolds showed initial degradation temperature at 285 °C and 306 °C respectively. Hence, incorporation of corn oil and neem oil increased the thermal stability of the pristine PU. Kakroodi et al. fabricated nanocomposites utilizing PVA blended with the cellulose nanofibers. It was observed that the incorporation of cellulose nanofibers into the PVA matrix enhanced the thermal stability of the pure PVA which correlates with our findings [29]. Further, the PU nanofibers exhibited low residual weight percentage compared to the electrospun PU/corn oil and PU/corn oil/neem oil scaffolds. At 1000 °C, the residual weight percentage of PU nanofibers was 0.47%, while for the electrospun PU/corn oil and PU/corn/neem oil scaffolds exhibited residual weight percentage of 1.22 and 2.19%. Further, DTG curve of corn and neem oil was shown in Fig. 4c, d. The corn oil showed single weight loss which starts from 274 °C to 577 °C. In the case of neem oil, it showed two weight loss in which first loss begins at 147 °C to 307 °C and the second loss from 307 °C to 505 °C. However, with the addition of corn and neem oil resulted in the reduced weight loss of PU as shown in Fig. 6a, b and c. This may be due to the combined effect of the constituents present in them. The pristine polyurethane showed three weight loss in which first weight loss starts from 223 °C to 348 °C, the second loss from 348 °C to 446 °C and final loss from 557 °C to 684 °C. In the case of the prepared nanocomposites, the first weight loss for PU/corn oil scaffolds occurs at 223 °C to 365 °C, the second loss at 365 °C to 524 °C and the third loss at 524 °C to 731 °C. In the electrospun PU/corn/neem oil scaffolds, it shows three weight loss peaks namely first peak begins at 245 °C to 366 °C, the second loss starts at 366 °C to 532 °C and the third loss at 532 °C to 680 °C respectively. In the both electrospun nanocomposites, it was observed that the first weight loss peak was decreased compared to the PU which revealed the reduced weight loss in the developed nanocomposites.

The AFM analysis of electrospun membranes prepared from PU and PU blended with neem and corn oil were shown in Fig. 7a, b and c. The measured Ra from the AFM images for electrospun PU and PU/corn oil and PU/corn oil/neem oil scaffolds were 576 nm, 445 nm and 431 nm respectively. Hence, the surface roughness was decreased by incorporating corn oil and neem oil into the PU matrix. Rosa et al. reported that the bone marrow cells preferred low roughness surface to attach and proliferate more when compared to the higher roughness surfaces [30]. The fabricated nanocomposites with lower surface roughness compared to the PU might serve as a plausible scaffolds to improve the adhesion and proliferation of the bone cells.

The mechanical testing results of electrospun membranes prepared from PU and PU blended with neem oil and corn oil were shown in Fig. 8a, b and c. It was observed that the addition of corn and neem oil resulted in the improvement of the tensile strength of the pristine PU. The tensile strength the electrospun PU nanofibers was observed to be 7.12 MPa, while for the electrospun PU/corn oil and PU/corn oil/neem oil scaffolds, it was observed to be 11.88 MPa and 12.96 MPa respectively. Shanmugavel et al. prepared electrospun scaffold based on polycaprolactone/Aloe vera/silk fibroin for bone tissue engineering. It was observed that the addition of Aloe vera and silk fibroin improved the tensile strength of the PCL and their tensile strength was reported to be 4 MPa [28]. The tensile strength of the developed nanocomposites were found to be fall within these reported values indicating its suitability for the bone tissue engineering.

The blood compatibility properties of electrospun membranes prepared from PU blended with corn and neem oil were indicated in Figs. 9 and 10. It was observed that the incorporation of corn and neem oil increased the blood clotting time of the pristine PU. The blood clotting time measured through APTT assay for the electrospun PU/corn oil and PU/corn/neem oil scaffolds were found to be 176.3 ± 5.508 s and 158 ± 3 s and for pristine PU nanofibers, the clotting time was found to be 152.7 ± 3.055 s. Similarly, the blood clotting time measured through PT assay for the electrospun PU/corn oil and PU/corn oil/neem oil scaffolds were found to be 95.33 ± 2.082 s and 92 ± 2.646 s and for the pristine PU nanofibers, the clotting time was found to be 88.67 ± 2.517 s. Further, to analyze the safety of RBC on the fabricated nanocomposites, the hemolysis assay was performed. From the results of hemolysis, it was reported that the developed nanocomposites shows non-toxic behaviour to the RBC. The hemolytic index of the pristine PU nanofibers was found to 2.48%, while the developed electrospun PU/corn oil and PU/corn oil/neem oil scaffolds showed less hemolytic index of around 1.13 and 0.90% respectively as shown in Fig. 11. The reported hemolytic index of developed nanocomposites was found to below 2% and it was considered to be a non-hemolytic material [23]. The ability of the scaffold to slow down the thrombus formation is very important for all tissue engineering applications. Initially, when corn oil is added in the scaffold, the membrane become hydrophobic resulting in the strong adhesion of plasma protein which causes the prolonging of the blood coagulation times. In the PU/corn oil/neem oil nanocomposites with the incorporation of neem oil, it favors the hydrophilic behavior which resulted in the reduction of blood clotting time compared to the PU/corn oil scaffold. The reason for the reduction might be due to the polar and apolar regions trade off occurred in the PU/corn oil/neem oil nanocomposites [31]. Further, it was observed that blood clotting time of PU/corn oil/neem oil scaffold is still higher than the pure polyurethane suggesting its suitability for bone tissue engineering application. In addition to this, the reduced fiber diameter of the composites may also have a putative role in influencing the blood compatibility. In one of the work, Milleret et al. fabricated scaffolds based on Degarapol and PLGA and investigated the blood compatibility with various fiber diameters. It was reported that the smaller fiber diameter resulted in enhanced blood compatibility which correlates with our findings [32].

The proliferation rates of HDF cells in the electrospun membranes prepared from PU blended with corn and neem oil were shown in Fig. 12. After 3 days cell culture, the HDF cells were viable on the electrospun PU nanofibers and PU blended with neem and corn oil. Further, the cell viability of the HDF cells on the electrospun PU/corn oil and PU/corn oil/neem oil scaffolds were observed to be increased compared to the control. The HDF cell viability in PU membrane was reported to be 179.7 ± 15.04%, while the electrospun PU/corn oil and PU/corn oil/neem oil scaffolds showed cell viability of 246.7 ± 2.082% and 244.7 ± 7.095% respectively. Further, in the electrospun PU/corn oil/neem oil membranes, a slight increase in the adhesion and proliferation of the fibroblast cells was observed. This might be due to the hydrophilicity of PU/corn oil/neem oil nanocomposites which was reported to in the optimal range of contact angle (40° - 70°) where the adhesion and proliferation of the fibroblast cells were reported to be maximum [33].

Conclusions

In this study, the PU incorporated with corn oil and neem oil were successfully electrospun using electrospinning technique. The morphology of the electrospun PU blends showed that the addition of corn oil and corn/neem oil resulted in reduced fiber diameter compared to control. The FTIR confirmed the presence of corn oil and neem oil in PU matrix through hydrogen bond formation. The PU blended with corn oil showed hydrophobic while the PU with corn/neem oil was observed to hydrophilic as indicated in the contact angle measurements. The thermal behavior of prepared PU/corn oil and PU/corn/neem oil scaffolds were enhanced and their surface roughness were decreased compared to control as revealed in the AFM analysis. The mechanical analysis indicated the enhanced tensile strength of the developed nanocomposites than the pristine PU. Further, the blood compatibility assessments revealed that the developed nanocomposites possess enhanced anticoagulant nature compared to the polyurethane. Moreover, the developed nanocomposites was non-toxic to RBC and HDF cells as shown in the hemolytic assay and cytocompatibility studies. Finally, this study concluded that the newly developed nanocomposites with better physio-chemical characteristics and biological properties enabled them as potential candidate for bone tissue engineering.

References

Ong KL (2015) New biomaterials for orthopedic implants. Int J Nanomedicine 7:107–130

Zhao L, Zhao J-L, Wan L, Wang S-K (2008) The study of the feasibility of segmental bone defect repair with tissue- engineered bone membrane: a qualitative observation. Strat Trauma Limb Reconstr 3(2):57–64

Amini AR, Laurencin CT, Nukavarapu SP (2012) Bone tissue engineering: recent advances and challenges. Biomed Eng 40(5)

Polo-Corrales L, Latorre-Esteves M, Ramirez-Vick JE (2014) Scaffold design for bone regeneration. J Nanosci Nanotechnol 14(1):15–56

O'brien FJ (2011) Biomaterials & scaffolds for tissue engineering. Mater. Today 14(3):88–95

Dhandayuthapani B, Yoshida Y, Maekawa T, Kumar DS (2011) Polymeric scaffolds in tissue engineering application: a review. Int J Polym Sci 2011:1–19

Sheikh Z, Najeeb S, Khurshid Z, Verma V, Rashid H, Glogauer M (2015) Biodegradable materials for bone repair and tissue engineering applications. Mater 8(9):5744–5794

Zohora FT, Azim AYMA (2014) Biomaterials as a porous scaffold for tissue engineering applications: a review. Europ Sci J 10:186–209

Kar KK, Rana S, Pandey J (2015) Handbook of polymer nanocomposites processing; performance and application. Verlag berlin. Springer, Heidelberg

Wang J, Wang L, Zhou Z, Lai H, Xu P, Liao L, Wei J (2016) Biodegradable polymer membranes applied in guided bone/tissue regeneration: a review. Polym 29 8(4):115

Wang X, Ding B, Li B (2013) Biomimetic electrospun nanofibrous structures for tissue engineering. Mater Today 16(6):229–241

Cheung HY, Lau KT, Lu TP, Hui D (2007) A critical review on polymer-based bio-engineered materials for scaffold development. Comp Part B: Eng 38(3):291–300

Heydarkhan-Hagvall S, Schenke-Layland K, Dhanasopon AP, Rofail F, Smith H, Wu BM, Shemin R, Beygui RE, MacLellan WR (2008) Three-dimensional electrospun ECM-based hybrid scaffolds for cardiovascular tissue engineering. Biomaterials 29(19):2907–2914

Mi HY, Palumbo S, Jing X, Turng LS, Li WJ, Peng XF (2014) Thermoplastic polyurethane/hydroxyapatite electrospun scaffolds for bone tissue engineering: effects of polymer properties and particle size. J Biomed, Mater Res Part B: Appl Biomater 102(7):1434–1444

Subbiah T, Bhat GS, Tock RW, Parameswaran S, Ramkumar SS (2005) Electrospinning of nanofibers. J Appl Polym Sci 96(2):557–569

Kharisov BI, Kharissova OV, Dias HR (2014) Nanomaterials for environmental protection. John Wiley & Sons

Lamba NMK, Woodhouse KA, Cooper SL (1998) Polyurethanes in biomedical applications. CRC Press, Florida

Ma ZW, Hong Y, Nelson DM, Pichamuthu JE, Leeson CE, Wagner WR (2011) Biodegradable polyurethane ureas with variable polyester or polycarbonate soft segments: effects of crystallinity, molecular weight, and composition on mechanical properties. Biomacromolecules 12:3265–3274

Gupta S, Kumar S (2015) Experimental investigation of bio-diesel with corn oil. Int J Mech Product Eng 3(2):73–78

Alzohairy MA (2016) Therapeutics role of Azadirachta indica (neem) and their active constituents in diseases prevention and treatment. Evi Base Comp Alter Med:1–11

Asif M (2012) Antimicrobial potential of Azadirachta Indica against pathogenic Bacteria and fungi. J Pharm Phytochemistry 1(4)

Kumar VS, Navaratnam V (2013) Neem (Azadirachta indica): prehistory to contemporary medicinal uses to humankind. Asian Pacif J Trop Biomed 3(7):505–514

Manikandan A, Mani MP, Jaganathan SK, Rajasekar R, Jagannath M (2017) Formation of functional nanofibrous electrospun polyurethane and murivenna oil with improved haemocompatibility for wound healing. Polym Test 61:106–113

Ngiam M, Liao S, Patil AJ, Cheng Z, Chan CK, Ramakrishna S (2009) The fabrication of nano-hydroxyapatite on PLGA and PLGA/collagen nanofibrous composite scaffolds and their effects in osteoblastic behavior for bone tissue engineering. Bone 45(1):4–16

Unnithan AR, Tirupathi PB, Gnanasekaran G, Seenivasan K, Barakat Nasser AM, Jung Y-S, Shanmugam A, Kim HY (2012) Emu oil-based electrospun nanofibrous scaffolds for wound skin tissue engineering. Colloids Surf A Physicochem Eng Asp 415:454–460

Tijing LD, Ruelo MTG, Amarjargal A, Pant HR, Park C-H, Kim DW, Kim CS (2012) Antibacterial and superhydrophilic electrospun polyurethane nanocomposite fibers containing tourmaline nanoparticles. Chem Eng J 197:41–48

Wei J, Igarashi T, Okumori N, Igarashi T, Maetani T, Liu B, Yoshinari M (2009) Influence of surface wettability on competitive protein adsorption and initial attachment of osteoblasts. Biomed Mater 4(4):045002

Shanmugavel S, Reddy VJ, Ramakrishna S, Lakshmi BS, Dev VG (2014) Precipitation of hydroxyapatite on electrospun polycaprolactone/aloe vera/silk fibroin nanofibrous scaffolds for bone tissue engineering. J Biomater Appl 29(1):46–58

Kakroodi AR, Cheng S, Sain M, Asiri A (2014) Mechanical, thermal, and morphological properties of nanocomposites based on polyvinyl alcohol and cellulose nanofiber from Aloe vera rind. J Nanomater 2014:139

Rosa AL, Beloti MM (2003) Effect of cpTi surface roughness on human bone marrow cell attachment, proliferation, and differentiation. Braz Dent Journal 14(1):16–21

Szycher M (1991) High performance biomaterials: a complete guide to medical and Pharmceutical applications. CRC Press

Vincent M, Thomas H, Heike H, Viola V, Daniel E (2012) Influence of fiber diameter and surface roughness of electrospun vasculargrafts on blood activation. Acta Biomater 8(12):4349–4356

Miguel SP, Ribeiro MP, Coutinho P, Correia IJ (2017) Electrospun Polycaprolactone/aloe Vera_Chitosan Nanofibrous asymmetric membranes aimed for wound healing applications. Polym 9(5):183

Acknowledgements

This work was supported by the Ministry of Higher Education Malaysia with the Grant no. Q.J130000.2545.17H00 and Q.J130000.2545.20H00.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Jaganathan, S.K., Mani, M.P., Palaniappan, S.K. et al. Fabrication and characterisation of nanofibrous polyurethane scaffold incorporated with corn and neem oil using single stage electrospinning technique for bone tissue engineering applications. J Polym Res 25, 146 (2018). https://doi.org/10.1007/s10965-018-1543-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-018-1543-1